Sulfoalkyl starch, preparation method and application thereof

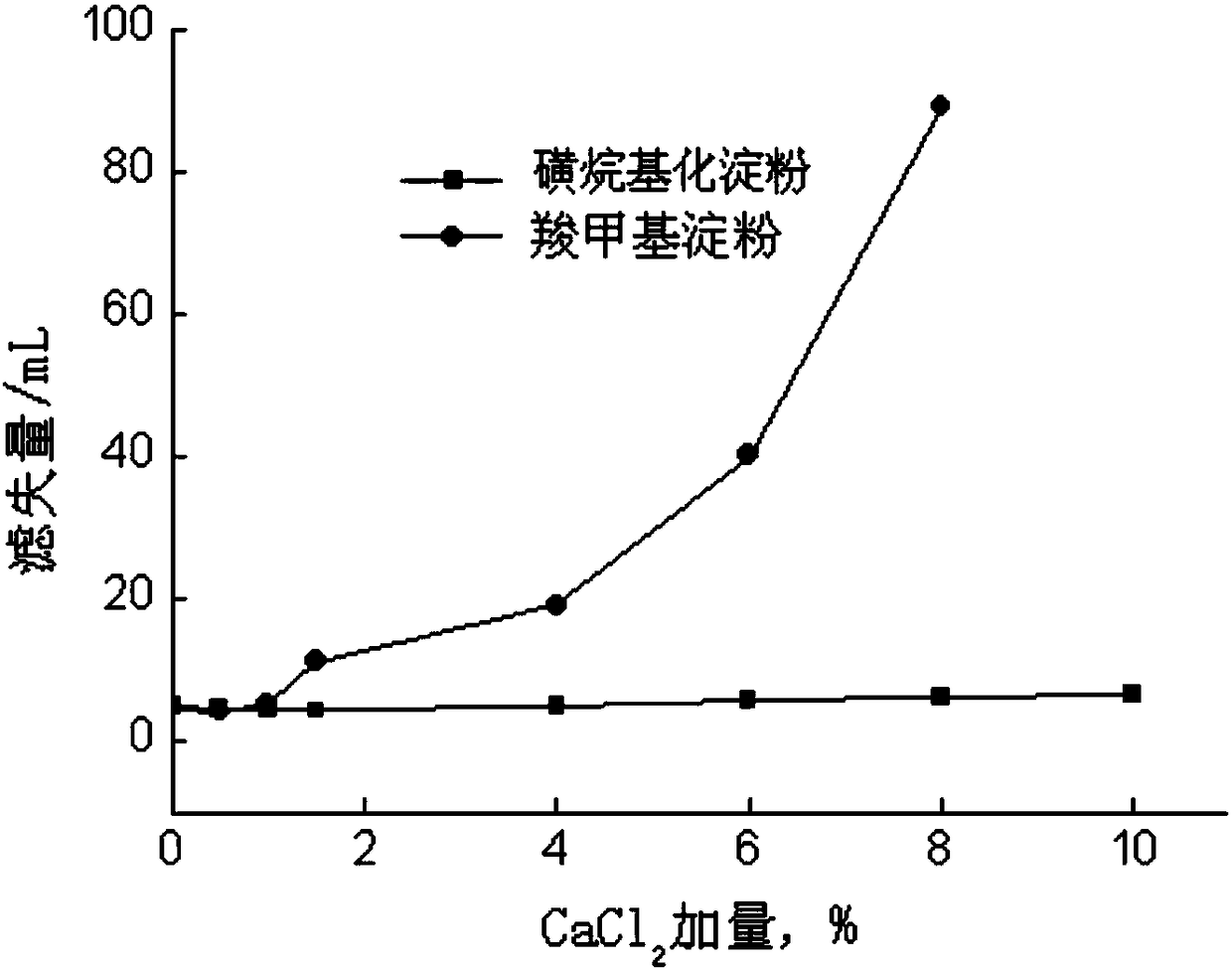

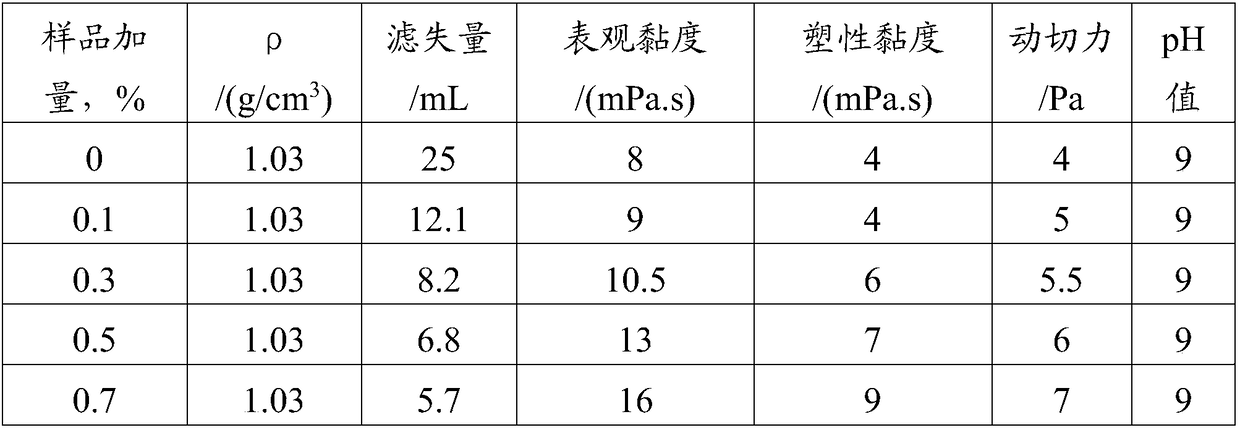

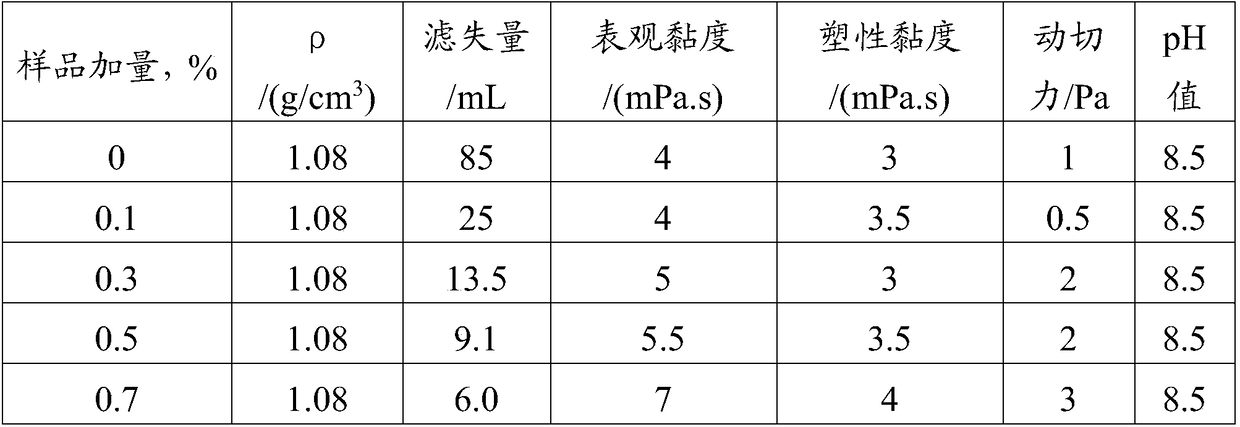

A technology of sulfoalkylated starch, which is applied in the field of sulfoalkylated starch, and its preparation can solve the problems of drilling fluid foaming, insufficient anti-calcium ability, and limited application range, etc., and achieve improved thermal stability and stable product quality , Improve the effect of anti-salt pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing sulfoalkylated starch, comprising the following steps:

[0027] Under alkaline conditions, starch and water-soluble haloethanesulfonate are reacted in an aqueous solvent to obtain sulfoalkylated starch.

[0028] The present invention synthesizes starch derivatives with sulfonic acid groups that are insensitive to high-valent metal ions, that is, prepares sulfoalkylated starch, which has strong temperature resistance and calcium resistance, and can expand the application range of starch treatment agents .

[0029] In the embodiment of the present invention, starch, alkaline substances and water-soluble ethanesulfonate are added into the aqueous solvent system according to a certain ratio of substances to carry out the reaction. In the present invention, it is preferred to firstly add starch into the aqueous solvent, then add alkaline substances, and then add water-soluble ethanesulfonate for reaction after stirring.

[0030...

Embodiment 1

[0045] According to the ratio of starch: sodium hydroxide: sodium 2-bromoethanesulfonate: benzyltriethylammonium chloride = 1:0.905:0.505:0.025, 100g starch is added to the ethanol-water system (alcohol: water volume ratio=7:3), then adding mass fraction of 50% sodium hydroxide aqueous solution, stirred at room temperature for 0.5h; ammonium, heated to 35°C with stirring, and reacted at 35°C for 10 hours to obtain a reaction solution; neutralized with hydrochloric acid to a pH value of 7 to 8.5, then centrifuged the reactant, recovered the solvent by distillation, and used 1 ~3 times of washing with methanol, centrifugation, and recovery of methanol through distillation; the obtained product was dried and pulverized to obtain 106.5 g of product.

[0046] The product was detected according to the method described above, and the DS of the obtained product was 0.15; the viscosity of 1% aqueous solution was 70 mPa.s.

Embodiment 2

[0048] According to the ratio of starch: sodium hydroxide: sodium 2-bromoethanesulfonate: benzyltriethylammonium chloride = 1:1.2:1.05:0.05, 100g starch is added to the ethanol-water system (alcohol: water volume ratio=6:4), then adding mass fraction is 50% aqueous sodium hydroxide solution, stirred at room temperature for 4h; adding 2-sodium bromoethanesulfonate and benzyltriethylammonium chloride in formula quantity , heated to 70°C with stirring, and reacted at 70°C for 1 hour to obtain a reaction solution; neutralized with hydrochloric acid to a pH value of 7 to 8.5, then centrifuged the reactant, and recovered the solvent for reuse after distillation. Wash 3 times with methanol, centrifuge, and recycle the methanol through distillation; the product obtained is dried and pulverized to obtain 107.1 g of the product.

[0049] The product was detected according to the method described above, and the DS of the obtained product was 0.41; the viscosity of 1% aqueous solution was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density ρ | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com