Thermoplastic biodegradable plastic and preparation method thereof

A biodegradable plastic and thermoplastic technology, applied in the field of thermoplastic biodegradable plastic and its preparation, can solve the problems of difficult large-scale industrialization of PPC, low glass transition temperature, poor processing performance, etc. Good performance and enhanced thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

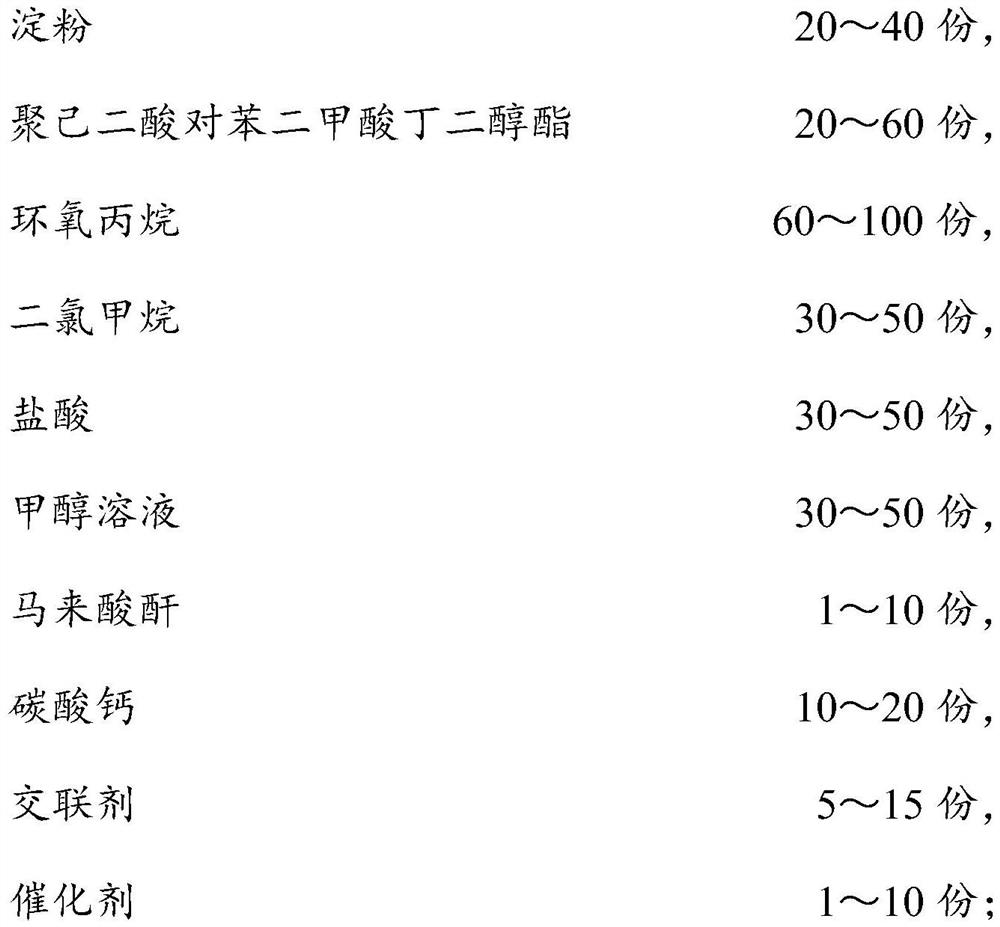

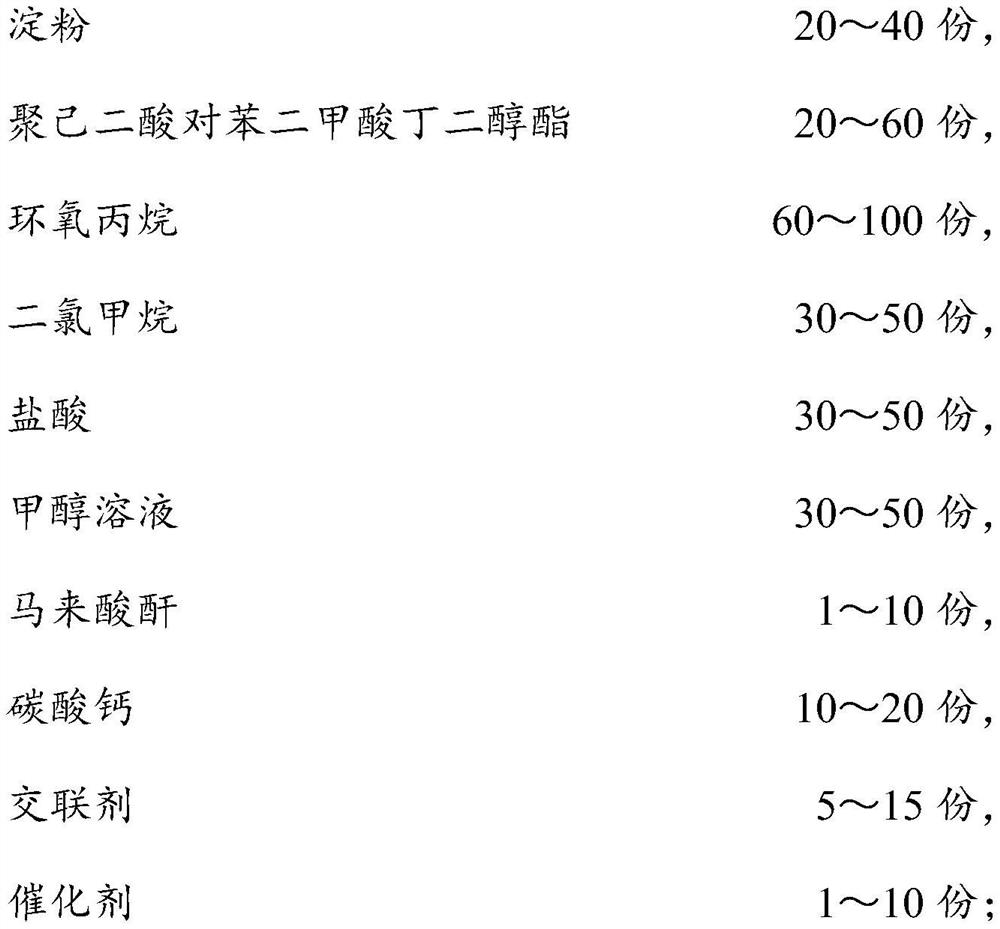

[0026] A thermoplastic biodegradable plastic, comprising the following raw materials in parts by mass: 20 parts of starch, 20 parts of polybutylene adipate terephthalate, 60 parts of propylene oxide, 30 parts of methylene chloride, 30 parts of hydrochloric acid, 30 parts of methanol solution, 1 part of maleic anhydride, 10 parts of calcium carbonate, 5 parts of crosslinking agent, and 1 part of catalyst;

[0027] The preparation method of described thermoplastic biodegradable plastics, comprises the following steps:

[0028] Step 1: Add mass parts of catalyst to stainless steel autoclave, dry at 80°C for 24 hours, add mass parts of propylene oxide and maleic anhydride, and introduce CO 2 Gas, make the pressure reach 4MPa, the stirring speed is 100r / min, the reaction temperature is 70°C, react for 24h, after the reaction stops, cool to room temperature to obtain a viscous substance;

[0029] Step 2: Rinse the viscous matter twice with dichloromethane, hydrochloric acid, and di...

Embodiment 2

[0032] A thermoplastic biodegradable plastic, comprising the following raw materials in parts by mass: 40 parts of starch, 60 parts of polybutylene adipate terephthalate, 100 parts of propylene oxide, 50 parts of methylene chloride, 50 parts of hydrochloric acid, 50 parts of methanol solution, 10 parts of maleic anhydride, 20 parts of calcium carbonate, 15 parts of crosslinking agent, 10 parts of catalyst;

[0033] The preparation method of described thermoplastic biodegradable plastics, comprises the following steps:

[0034] Step 1: Add mass parts of catalyst to stainless steel autoclave, dry at 90°C for 24 hours, add mass parts of propylene oxide and maleic anhydride, and introduce CO 2 Gas, so that the pressure reaches 6MPa, the stirring speed is 300r / min, the reaction temperature is 90°C, and the reaction is for 24h. After the reaction stops, cool to room temperature to obtain a viscous substance;

[0035] Step 2: Rinse the viscous matter three times with dichloromethane...

Embodiment 3

[0038] A thermoplastic biodegradable plastic, comprising the following raw materials in parts by mass: 30 parts of starch, 40 parts of polybutylene adipate terephthalate, 80 parts of propylene oxide, 40 parts of methylene chloride, 40 parts of hydrochloric acid, 40 parts of methanol solution, 5 parts of maleic anhydride, 15 parts of calcium carbonate, 10 parts of crosslinking agent, 5 parts of catalyst;

[0039]The preparation method of described thermoplastic biodegradable plastics, comprises the following steps:

[0040] Step 1: Add mass parts of catalyst to stainless steel autoclave, dry at 85°C for 24 hours, add mass parts of propylene oxide and maleic anhydride, and introduce CO 2 Gas, so that the pressure reaches 5MPa, the stirring speed is 200r / min, the reaction temperature is 80°C, react for 24h, after the reaction stops, cool to room temperature to obtain a viscous substance;

[0041] Step 2: Rinse the viscous matter three times with dichloromethane, hydrochloric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com