Heat resistance single-component silane modified polyurethane sealant and preparation method thereof

A polyurethane sealant and silane modification technology, applied in the field of sealants, can solve problems such as mechanical property attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A heat-resistant silane-modified polyurethane sealant was prepared, the composition of which is shown in Table 1. At the same time, a sealant with the same ratio was prepared without adding cerium oxide. The parts mentioned below are all parts by mass. Put it into the planetary stirring tank according to the stated ratio and dehydrate it under high temperature vacuum for 2 hours. After the temperature of the premix is lowered to below 50°C, add water remover, silane coupling agent, thixotropic agent and catalyst, and stir for 0.5h to obtain a sealant.

[0035]

[0036] After the silane-modified polyurethane sealant is cured, it is placed in an oven for heat-resistant aging test. Its test method is:

[0037] (1) GB / T 528 Determination of tensile properties of vulcanized rubber and thermoplastic rubber;

[0038] (2) GB / T 531 Shore A hardness test method for vulcanized rubber.

[0039] The test results are shown in Table 2 below:

[0040]

Embodiment 2

[0042] A heat-resistant silane-modified polyurethane sealant was prepared, the composition of which is shown in Table 3. At the same time, a sealant with the same proportion was prepared, in which no ferric oxide was added. The parts mentioned below are all parts by mass. Put it into the planetary stirring tank according to the stated ratio and dehydrate it under high temperature vacuum for 2 hours. After the temperature of the premix is lowered to below 50°C, add water remover, silane coupling agent, thixotropic agent and catalyst, and stir for 0.5h to obtain a sealant.

[0043]

[0044] After the prepared modified silane polyether sealant is cured, it is placed in an oven for heat aging test. Its test method is:

[0045] (1) GB / T 528 Determination of tensile properties of vulcanized rubber and thermoplastic rubber;

[0046] (2) GB / T 531 Shore A hardness test method for vulcanized rubber.

[0047] The test results are shown in Table 4:

[0048]

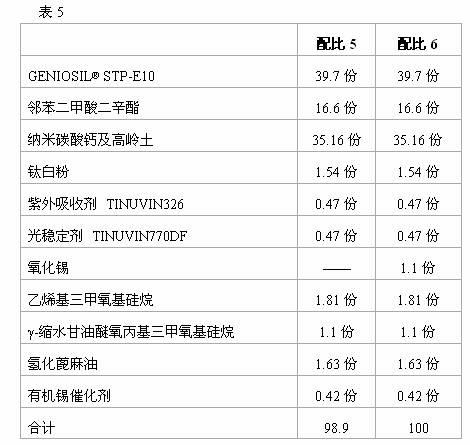

Embodiment 3

[0050] A heat-resistant silane-modified polyurethane sealant was prepared, the composition of which is shown in Table 5. At the same time, a sealant with the same ratio was prepared without adding tin oxide. The parts mentioned below are all parts by mass. Put it into the planetary stirring tank according to the stated ratio and dehydrate it under high temperature vacuum for 2 hours. After the temperature of the premix is lowered to below 50°C, add water remover, silane coupling agent, thixotropic agent and catalyst, and stir for 0.5h to obtain a sealant.

[0051]

[0052] After the prepared modified silane polyether sealant is cured, it is placed in an oven for heat aging test. Its test method is:

[0053] (1) GB / T 528 Determination of tensile properties of vulcanized rubber and thermoplastic rubber;

[0054] (2) GB / T 531 Shore A hardness test method for vulcanized rubber.

[0055] The test results are shown in Table 6:

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com