Preparation process of graphene nanocomposite material

A nanocomposite material and preparation process technology, applied in the field of graphene nanocomposite material preparation process, can solve the problems of unendowed graphene, environmental pollution, etc., and achieve the effect of promoting crosslinking density, enhancing mechanical properties, and preventing stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

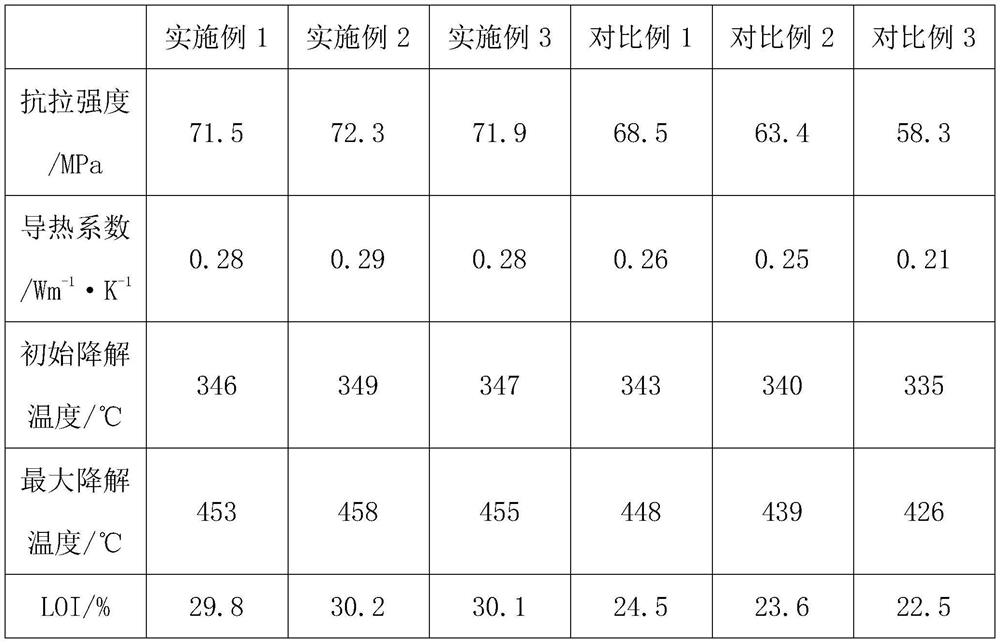

Examples

Embodiment 1

[0043] A kind of graphene nanocomposite preparation technology, comprises the steps:

[0044] In the first step, each raw material is weighed according to the following parts by weight: 50 parts of bisphenol A diglycidyl ether, 11 parts of diethyltoluenediamine, 2 parts of modified graphene oxide, and 100 parts of absolute ethanol;

[0045] In the second step, after mixing bisphenol A diglycidyl ether and diethyltoluenediamine, stir vigorously at 100° C. for 15 minutes to obtain a pale yellow liquid epoxy resin precomposition;

[0046] The third step is to add the epoxy resin premix to absolute ethanol, stir and mix at 300r / min for 26min at room temperature, and then place it in a vacuum oven at 110°C for 30-40min to degas the epoxy resin premix Mixture with ethanol;

[0047] The fourth step is to add the modified graphene oxide to the above-mentioned mixture of epoxy resin premixture and ethanol, ultrasonicate at room temperature for 40 minutes to form a suspension, and then...

Embodiment 2

[0050] A kind of graphene nanocomposite preparation technology, comprises the steps:

[0051] In the first step, each raw material is weighed according to the following parts by weight: 55 parts of bisphenol A diglycidyl ether, 12.5 parts of diethyltoluenediamine, 2.5 parts of modified graphene oxide, and 100 parts of absolute ethanol;

[0052] In the second step, after mixing bisphenol A diglycidyl ether and diethyltoluenediamine, stir vigorously at 100° C. for 16 minutes to obtain a pale yellow liquid epoxy resin precomposition;

[0053] The third step is to add the epoxy resin premix to absolute ethanol, stir and mix at 300r / min for 28min at room temperature, and then place it in a vacuum oven at 110°C for 35min to degas the epoxy resin premix and ethanol. the mixture;

[0054] The fourth step is to add the modified graphene oxide to the above-mentioned mixture of epoxy resin premixture and ethanol, ultrasonicate at room temperature for 45 minutes to form a suspension, and...

Embodiment 3

[0057] A kind of graphene nanocomposite preparation technology, comprises the steps:

[0058] In the first step, each raw material is weighed according to the following parts by weight: 60 parts of bisphenol A diglycidyl ether, 14 parts of diethyltoluenediamine, 3 parts of modified graphene oxide, and 100 parts of absolute ethanol;

[0059] In the second step, after mixing bisphenol A diglycidyl ether and diethyltoluenediamine, stir vigorously at 100° C. for 18 minutes to obtain a pale yellow liquid epoxy resin precomposition;

[0060] The third step is to add the epoxy resin premix to absolute ethanol, stir and mix at 300r / min for 30min at room temperature, and then place it in a vacuum oven at 110°C for 40min to degas the epoxy resin premix and ethanol. the mixture;

[0061] The fourth step is to add the modified graphene oxide to the mixture of the above epoxy resin premix and ethanol, and ultrasonicate at room temperature for 50 minutes to form a suspension, and then plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com