Method for producing phosphor boronation ashless dispersant

An ashless dispersant, phosphorus boron technology, used in additives, petroleum industry, lubricating compositions, etc., can solve the problems of producing boron slag, the quality of boronization is not good enough, etc., and achieve the effect of improving quality and improving anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

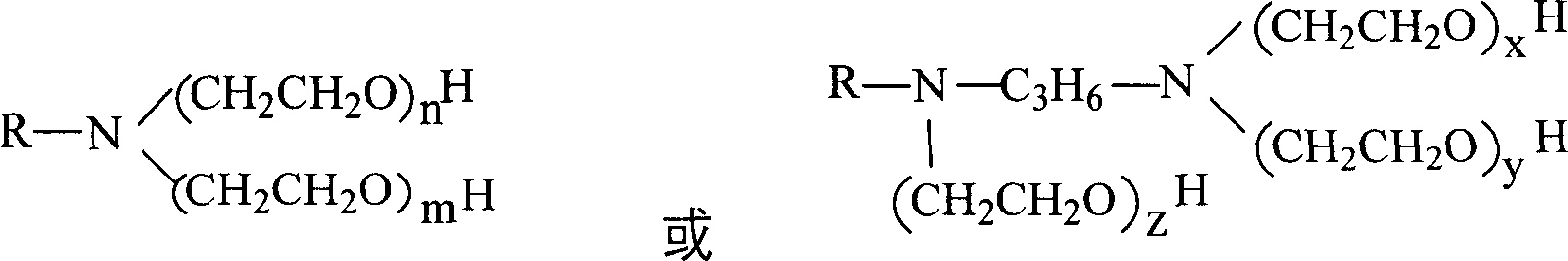

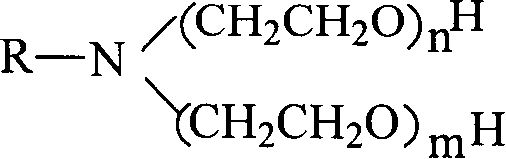

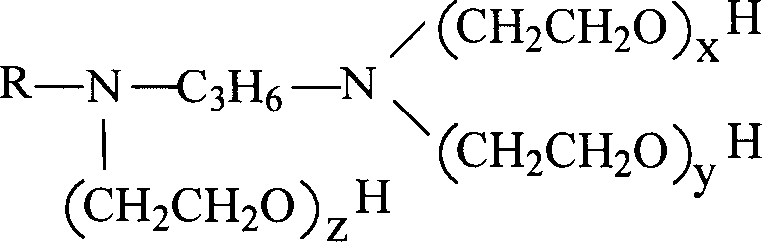

Method used

Image

Examples

example 1

[0032] In a three-neck flask equipped with a heating and stirring device, add 195g of monopolyisobutenyl succinimide T151, 21.5g of di-n-butyl phosphite T304, 7.8g of boric acid, 11g of ethoxylated tallow amine (Ethomeen T- 12), 1g n-butanol, 2.2g water, feed nitrogen, stir at 95±5°C for 3h, gradually heat up to 110°C, remove water and n-butanol under 40mmHg pressure, the obtained transparent liquid is the Phosphorus boride ashless dispersant, no boron slag was found after the product was filtered, and its thermal oxidation stability is shown in Table 1.

example 2

[0034] In a three-neck flask equipped with a heating and stirring device, add 195g of monopolyisobutenyl succinimide T151, 38.5g of phosphoric acid, 11.8g of boric acid, 19g of ethoxylated coconut oil alkylamine (EthomeenC-12), 4.7 g n-butanol, feed nitrogen, stir at 85±5°C for 6 hours, gradually raise the temperature to 110°C, remove water and n-butanol under a pressure of 30mmHg, and the obtained transparent liquid is the phosphorus boride ashless dispersant of the present invention, No boron slag was found after the product was filtered, and its thermo-oxidative stability is shown in Table 1.

example 3

[0036] In a three-neck flask equipped with a heating and stirring device, add 195g of bispolyisobutenyl succinimide T152, 32g of di-n-butyl phosphite T304, 4.9g of boric acid, 28g of ethoxylated tallow diamine (Ethoduomeen T- 13), 1.9g of isobutanol, 2.2g of water, nitrogen, stirred at 90±5°C for 4h, gradually warmed up to 110°C, pulled out water and butanol under 60mmHg pressure, the obtained transparent liquid is the present invention Phosphorus boride ashless dispersant, no boron slag was found after the product was filtered, and its thermo-oxidative stability is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com