High-temperature anticorrosion lubricating oil composition and preparation method thereof

A lubricating oil composition and anti-corrosion technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as easy wear and cannot meet the requirements of high-speed spinning production lines, and achieve excellent high temperature resistance and thermal oxidation stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a high-temperature anti-corrosion lubricating oil composition, comprising the following steps:

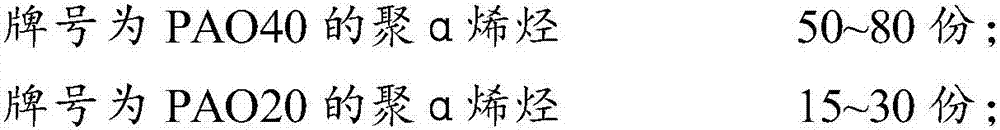

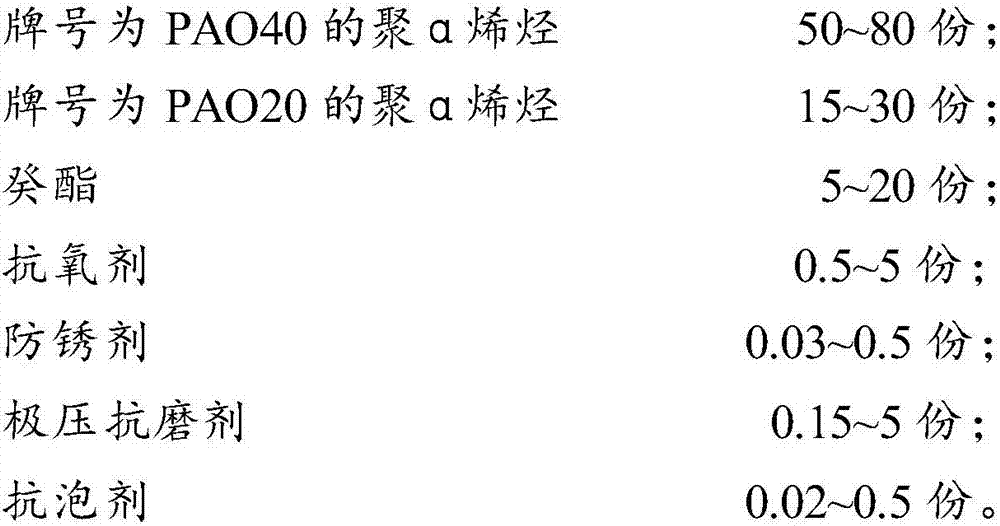

[0037] 50-80 parts by weight of PAO40 polyalphaolefin, 15-30 parts by weight of PAO20 polyalphaolefin, 5-20 parts by weight of decyl ester and 0.5-5 parts by weight of antioxidant are mixed to obtain a high-temperature anti-corrosion lubricating oil combination;

[0038] Described antioxidant is the steam turbine oil compound agent that BASF company provides, and the trade mark is IR2030D.

[0039]In the preparation method provided by the present invention, the high-temperature anti-corrosion lubricating oil provided by the present invention can be obtained by directly mixing the polyalphaolefin with the grade of PAO40, the polyalphaolefin with the grade of PAO20, decyl ester and antioxidant in proportion combination. Wherein, the raw materials for preparing the composition preferably further include one or more of antirust age...

Embodiment 1

[0044] 1) Recipe

[0045] components Content (parts by weight) PAO40 (FOX) 67 PAO20 (FOX) 21.9 Diisodecyl phthalate 10 IR2030D 0.9 L353 0.15 T746 0.03 Silicon type antifoaming agent 0.02

[0046] 2) Preparation

[0047] According to the formula, the above-mentioned components were uniformly mixed at 55° C. and a vacuum degree of 0.6 MPa to obtain a high-temperature anti-corrosion lubricating oil composition.

Embodiment 2

[0049] 1) Recipe

[0050] components Content (parts by weight) PAO40 (FOX) 67 PAO20 (FOX) 21.9 Diisodecyl phthalate 10 IR2030D 0.9 H543 0.15 T746 0.03 Silicon type antifoaming agent 0.02

[0051] 2) Preparation

[0052] According to the formula, the above-mentioned components were uniformly mixed at 55° C. and a vacuum degree of 0.6 MPa to obtain a high-temperature anti-corrosion lubricating oil composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com