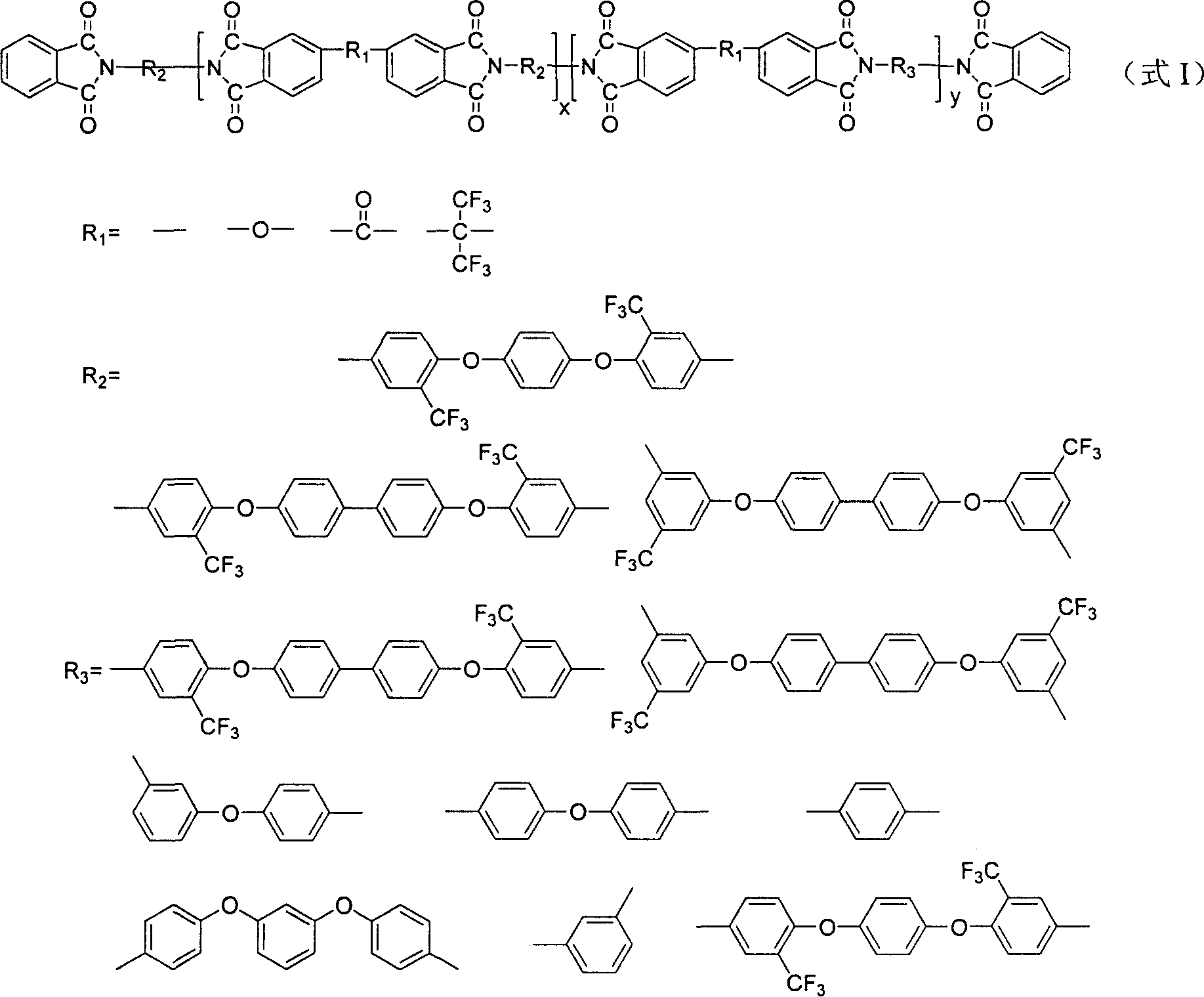

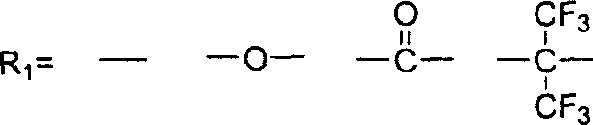

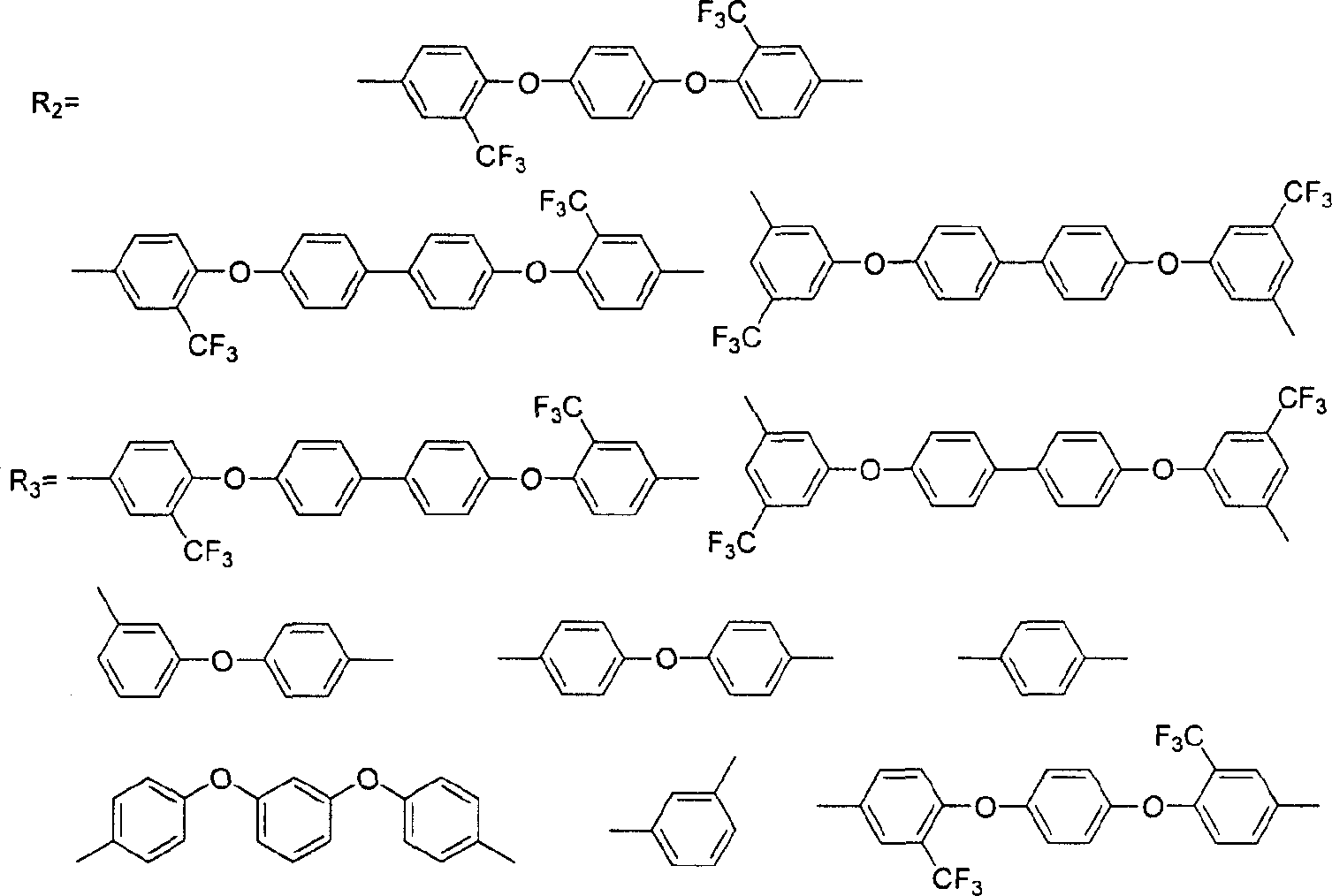

Fluorine-containing thermoplastic polyimide polymer and preparation method thereof

A polyimide and thermoplastic technology, which is applied in the field of fluorine-containing thermoplastic polyimide polymer and its preparation, can solve the problems of few types of polyimide, reduce water absorption, improve thermal oxidation stability, and good The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In a three-neck flask equipped with inert gas, mechanical stirring, water separator / water condenser, and thermometer, add 125 parts of 1,4-bis(4'-amino-2'-trifluoromethylphenoxy)benzene (BAPB) and 1000 parts of m-cresol, stir and dissolve completely, add 90 parts of 3,3',4,4'-diphenylmethyl ether tetra-acid dianhydride (ODPA) and 2.65 parts of phthalic anhydride, then add 40ml of toluene and 3- 5 drops of isoquinoline, heated to 180°C, reacted at this temperature for 15 hours, cooled the reaction solution below 120°C, washed repeatedly with a large amount of ethanol and water to remove the solvent, and dried to obtain a white powder. The powder can be thermally molded at high temperature to obtain resin molded parts.

Embodiment 2

[0022] Add 500ml of N-methylpyrrolidone (NMP) in a three-necked flask equipped with inert gas and mechanical stirring, and then gradually add 52 parts of 4,4'-bis(4-amino-2-trifluoromethylphenoxy) After the biphenyl (p-6FBAB) is completely dissolved, add 95 parts of 3,3',4,4'-biphenyltetraacid dianhydride and 1.12 parts of phthalic anhydride, and react under the protection of an inert gas for 24 hours to obtain a polyamic acid solution. The polyamic acid solution was coated on a smooth glass plate, and the polyimide film was obtained by temperature programming up to 300°C.

Embodiment 3

[0024] Add NMP600ml in a three-necked flask equipped with inert gas and mechanical stirring, then gradually add 60 parts of 4,4'-bis(4-amino-2-trifluoromethylphenoxy)biphenyl (p-6FBAB), After all the solution was dissolved, 127 parts of 4,4'-(hexafluoroisopropyl)diphthalic dianhydride and 1.25 parts of phthalic anhydride were added, and a polyamic acid solution was obtained after reacting for 10 hours under the protection of an inert gas. The short fiber is added to the above polyamic acid solution, and the composite material molding powder is obtained after the temperature program is raised in a vacuum oven, and the composite material molded part is obtained by hot molding at a high temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com