Novel heat-resistant high-toughness polylactic acid composite material and preparation method thereof

A composite material and polylactic acid technology, applied in the field of composite materials, can solve problems such as deteriorating the performance of composite materials, achieve excellent mechanical properties, and ensure the effect of biodegradation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

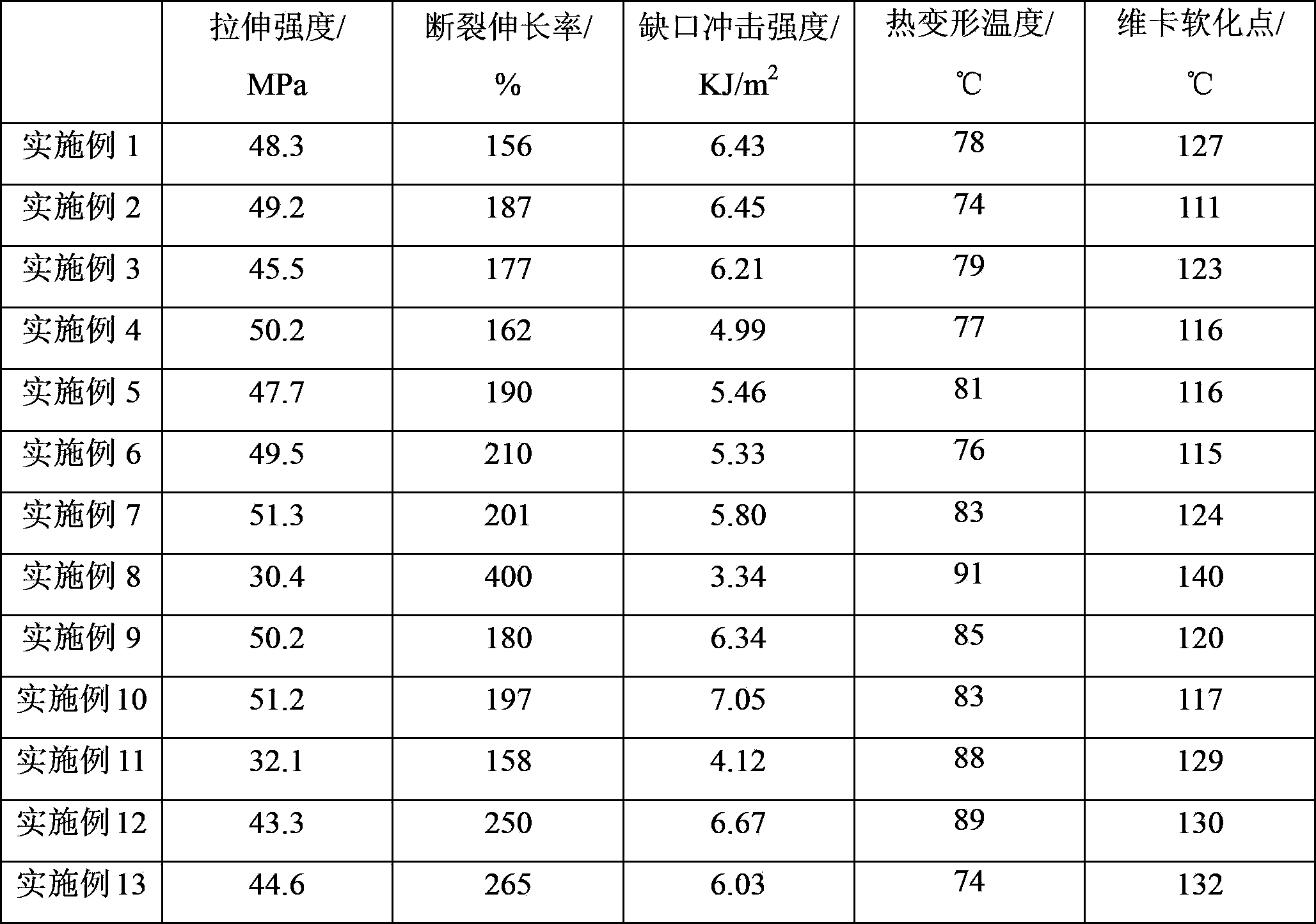

Embodiment 1

[0052] (1) Preparation of heat-resistant masterbatch:

[0053] Take 16Kg PBAT prepolymer (80wt%), 2Kg nanomaterials organically modified montmorillonite (10wt%), 2g catalyst butyl titanate (0.01wt%), 10g modifier isocyanate (0.05wt%), 2g anti- Oxygen agent butylated hydroxyanisole (0.01wt%) and 1.986Kg antistatic agent alkylimidazoline (9.93wt%) were added to the extruder for melt extrusion at a temperature of 140°C and a screw speed of 100rpm to obtain a heat-resistant Masterbatch 1;

[0054] (2) Preparation of PLA composite materials

[0055] Take 18Kg PLA (90wt%), 1Kg (5wt%) PBAT and 1Kg heat-resistant masterbatch 1 (5wt%) and put them into the extruder to melt and extrude. The extrusion temperature is 175°C and the screw speed is 100rpm to obtain high toughness For the heat-resistant PLA composite material, its related thermal and mechanical properties are shown in Table 1.

Embodiment 2

[0057] (1) Preparation of heat-resistant masterbatch:

[0058] Get 2Kg PBS prepolymer (10wt%), 16Kg nano material organically modified montmorillonite (80wt%), 1Kg catalyst stannous octoate (5wt%), 600g modifier isocyanate (3wt%), 380g thermal stabilizer triaryl Base phosphite (1.9wt%), 20g flame retardant magnesium hydroxide (0.1wt%) were added to the extruder and melted and extruded, the temperature was 140°C, and the screw speed was 100rpm to obtain heat-resistant masterbatch 2;

[0059] (2) Preparation of PLA composite materials

[0060] Take 9.4Kg PLA (47wt%), 3.8Kg biodegradable polyester PHA (19wt%) and 6.8Kg heat-resistant masterbatch 2 (34wt%) into the extruder for melt extrusion, the extrusion temperature is 175 ° C, the screw speed The heat-resistant PLA composite material with high toughness was obtained, and its related thermal and mechanical properties are shown in Table 1.

Embodiment 3

[0062] (1) Preparation of heat-resistant masterbatch:

[0063] Get 9.5Kg lactide (47.5wt%), 8Kg nano material carbon black (40wt%), 500g catalyst aluminum oxide (2.5wt%), 1Kg modifier maleic anhydride (5wt%), 500g thermal stabilizer Trialkyl phosphite (2.5wt%) and 500g antioxidant propyl gallate (2.5wt%) were added to the extruder for melt extrusion at a temperature of 140°C and a screw speed of 100rpm to obtain a heat-resistant masterbatch 3;

[0064] (2) Preparation of PLA composite materials

[0065] Take 10.4Kg PLA (52wt%), 3.8Kg PHA (19wt%) and 5.8Kg heat-resistant masterbatch 3 (29wt%) into the extruder to melt and extrude, the extrusion temperature is 180 ° C, the screw speed is 100rpm, and the obtained The thermal and mechanical properties of the high-toughness heat-resistant PLA composites are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com