Biodegradable heat shrink film and processing technology thereof

A biodegradable, heat-shrinkable film technology, applied in the field of biodegradable heat-shrinkable film and its processing technology, can solve the problems of loss of reuse value, plastics do not have biodegradable properties, damage, etc., to achieve excellent comprehensive performance, guaranteed biodegradability, optimized strength and heat shrinkability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

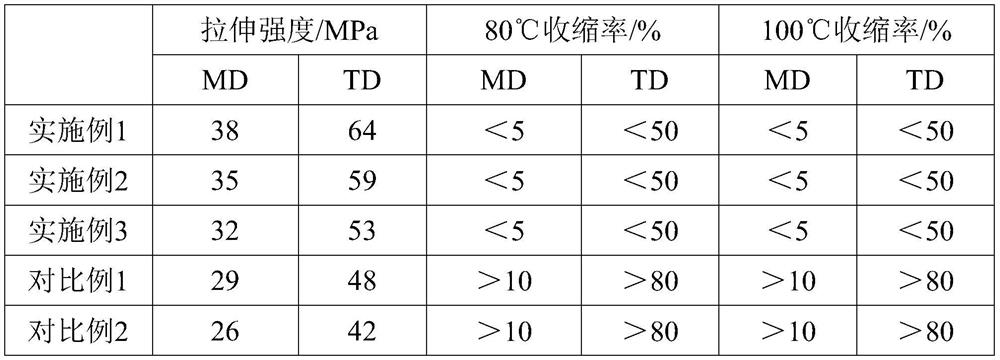

Examples

Embodiment 1

[0028] 1. Preparation of modified polylactic acid:

[0029] Mix 85 parts of polylactic acid, 15 parts of allyl (diisopropylamino) dimethylsilane and 1 part of azobisisobutyronitrile evenly, then transfer to a twin-screw extruder for reaction, and the screw speed is 150rpm , the reaction temperature is 180°C, and the product is cooled, pelletized and dried to obtain modified polylactic acid.

[0030] 2. Processing of heat shrinkable film:

[0031] (1) Mix 100 parts of modified polylactic acid, 1 part of fatty alcohol polyoxyethylene ether AEO-9, 2 parts of zinc stearate, 1 part of antioxidant 1010, and 0.5 part of light stabilizer 622, and dry to contain The amount of water is less than 100ppm.

[0032] (2) Transfer the mixed material obtained in step (1) to a twin-screw extruder, melt extrude, and the melt extrusion temperature is 180°C, the die is cast, the cast sheet is wound, biaxially stretched, and the biaxially stretched temperature is 100°C, cooling and setting, and ...

Embodiment 2

[0034] 1. Preparation of modified polylactic acid:

[0035] 90 parts of polylactic acid, 10 parts of allyl (diisopropylamino) dimethyl silane and 1 part of benzoyl peroxide are mixed homogeneously, then transferred to a twin-screw extruder for reaction, the screw speed is 100rpm, The reaction temperature is 170°C, and the product is cooled, pelletized and dried to obtain modified polylactic acid.

[0036] 2. Processing of heat shrinkable film:

[0037] (1) Mix 100 parts of modified polylactic acid, 1 part of fatty alcohol polyoxyethylene ether AEO-9, 1 part of ethylene bisstearamide, 1 part of antioxidant 1076, 0.5 part of light stabilizer 944, and dry To the water content below 100ppm.

[0038] (2) Transfer the mixed material obtained in step (1) to a twin-screw extruder, melt extrude, and the melt extrusion temperature is 190°C, the die is cast, the cast sheet is wound, biaxially stretched, and the biaxially stretched temperature is 110°C, cooling and setting, and winding...

Embodiment 3

[0040] 1. Preparation of modified polylactic acid:

[0041] 95 parts of polylactic acid, 5 parts of allyl (diisopropylamino) dimethylsilane and 0.5 part of azobisisoheptanonitrile are mixed uniformly, and then transferred to a twin-screw extruder for reaction, and the screw speed is 150rpm , the reaction temperature is 190°C, and the product is cooled, pelletized, and dried to obtain modified polylactic acid.

[0042] 2. Processing of heat shrinkable film:

[0043] (1) Mix 100 parts of modified polylactic acid, 1 part of fatty alcohol polyoxyethylene ether AEO-9, 2 parts of calcium stearate, 0.5 part of antioxidant 1010, and 0.5 part of light stabilizer 944, and dry to contain The amount of water is less than 100ppm.

[0044] (2) Transfer the mixed material obtained in step (1) to a twin-screw extruder, melt extrude, and the melt extrusion temperature is 180°C, the die is cast, the cast sheet is wound, biaxially stretched, and the biaxially stretched temperature is 100°C, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com