Anti-static, anti-alcohol and anti-plasma medical non-woven fabric

An anti-alcohol and anti-plasma technology, applied in textiles and papermaking, biochemical fiber processing, fiber types, etc., can solve the problems of non-persistent performance and easy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

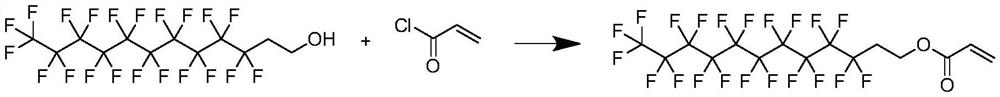

Method used

Image

Examples

Embodiment 1

[0039] In this example, a kind of three-antibody slurry is prepared, and the steps are as follows

[0040] Add 5g of modified graphene oxide, 0.6g of sodium dodecylsulfonate and 0.1g of sodium bicarbonate into a four-neck flask, add 100mL of ethanol solution with a mass fraction of 40%, stir in a water bath for 30min, and then add 1 / 10 of the total mass Potassium persulfate was passed into nitrogen protection, the temperature was raised to 75°C, 10g of fluorine-containing monomer, 2g of chitosan quaternary ammonium salt monomer, 2g of methyl acrylate, and the remaining potassium persulfate were added, the temperature was raised to 75°C, and the temperature was kept for reaction 4h, after the reaction is over, after the reaction is over, add the penetrating agent and mix, add acetone and dilute to 10 times of its original volume, to obtain the three-antibody slurry, the penetrating agent is the same as the fluorine-containing monomer, and the amount of potassium persulfate is ch...

Embodiment 2

[0051] In this example, a kind of three-antibody slurry is prepared, and the steps are as follows

[0052] Add 5g of modified graphene oxide, 0.6g of sodium dodecylsulfonate and 0.1g of sodium bicarbonate into a four-neck flask, add 100mL of ethanol solution with a mass fraction of 40%, stir in a water bath for 30min, and then add 1 / 10 of the total mass Potassium persulfate was passed into nitrogen protection, the temperature was raised to 75°C, 11g of fluorine-containing monomer, 2.5g of chitosan quaternary ammonium salt monomer, 3g of methyl acrylate, and the remaining potassium persulfate were added, the temperature was raised to 78°C, and the temperature was kept React for 5h, after the reaction is over, after the reaction is over, add the penetrating agent and mix, add acetone to dilute to 10 times of its original volume, to obtain the three-antibody slurry, the penetrating agent is the same as the fluorine-containing monomer, and the amount of potassium persulfate is 4% ...

Embodiment 3

[0063] In this example, a kind of three-antibody slurry is prepared, and the steps are as follows

[0064] Add 5g of modified graphene oxide, 0.6g of sodium dodecylsulfonate and 0.1g of sodium bicarbonate into a four-neck flask, add 100mL of ethanol solution with a mass fraction of 40%, stir in a water bath for 30min, and then add 1 / 10 of the total mass Potassium persulfate was passed into nitrogen protection, the temperature was raised to 75°C, 12g of fluorine-containing monomer, 3g of chitosan quaternary ammonium salt monomer, 4g of methyl acrylate, and the remaining potassium persulfate were added, the temperature was raised to 80°C, and the temperature was kept for reaction. 6h, after the reaction is over, after the reaction is over, add the penetrating agent and mix, add acetone and dilute to 10 times of its original volume, to obtain the three-antibody slurry, the amount of the penetrating agent is the same as that of the fluorine-containing monomer, and the amount of pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com