High-density polyethylene resin composition for floating photovoltaic barrel and preparation method of high-density polyethylene resin composition

A technology of high-density polyethylene and resin composition, which is applied in the field of high-density polyethylene resin composition for floating photovoltaic barrels and its preparation, and can solve problems such as insufficient strength, unsatisfactory processing performance of photovoltaic barrels, and poor product uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

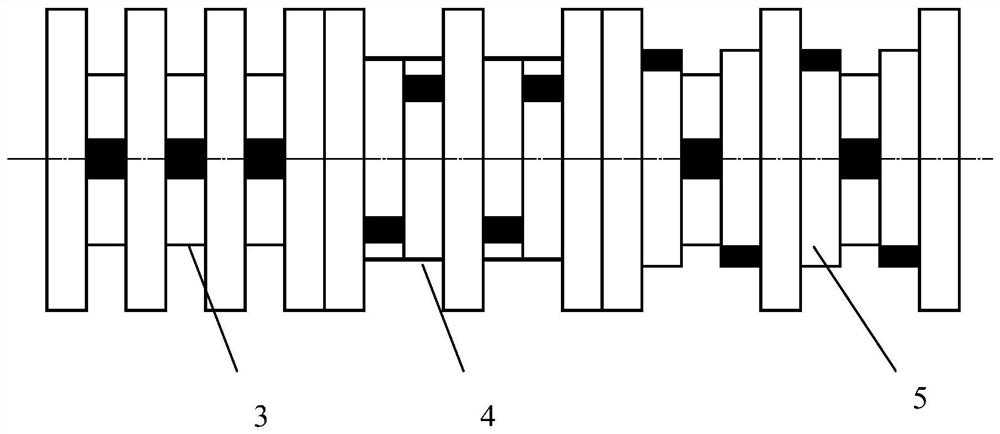

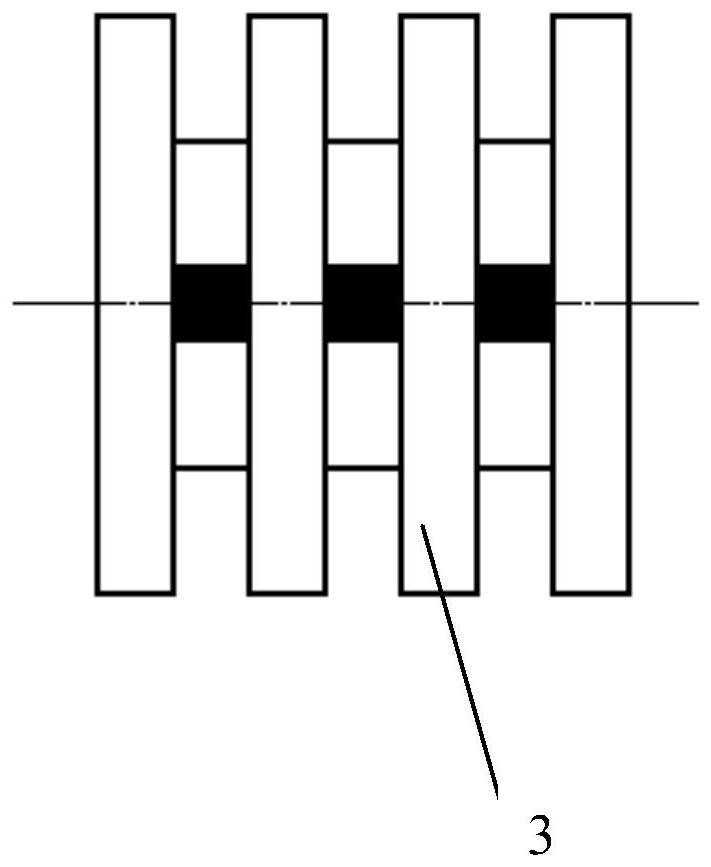

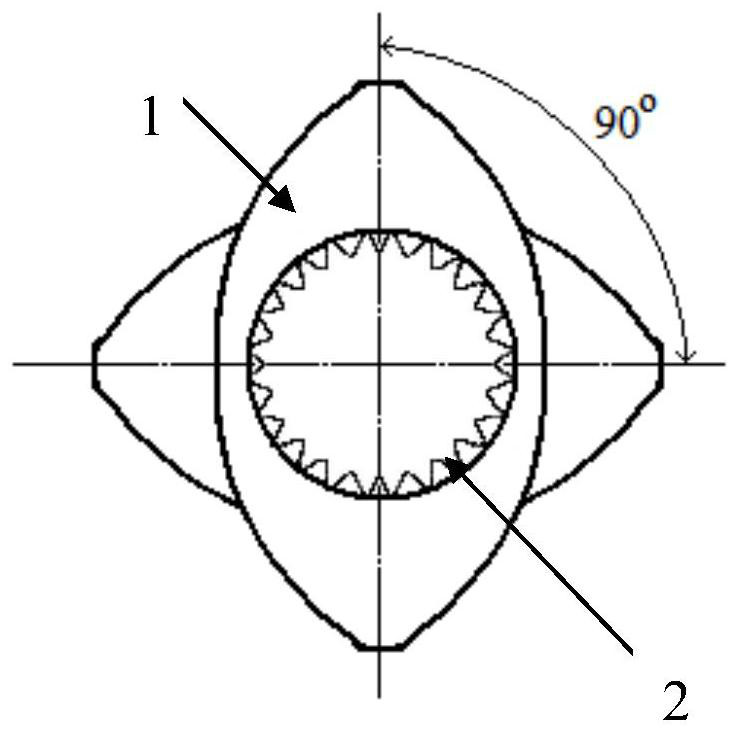

[0049] Refer to attached Figure 1-7 , the twin-screw extruder used in the present invention is equipped with three groups of kneading blocks in the metering section of the screw, and the three groups of kneading blocks are successively a group of 90° kneading blocks 3 and a group of 60° kneading blocks from the feed end to the discharge end Block 4 and a group of 45° kneading block 5; the included angle of the vertical line between adjacent kneading sheets 1 in 90° kneading block 3 is 90°, and the clip of the vertical line between adjacent kneading sheets 1 in 60° kneading block 4 The angle is 60°, and the included angle of the vertical line between adjacent kneading pieces 1 in the 45° kneading block 5 is 45°. The kneading blocks are arranged in sequence to form a kneading zone. During the extrusion process, the composition is easy to shear and disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com