Antiaging water-resistant architectural paint and preparation method thereof

An architectural coating and anti-aging technology, which is applied in the field of coating technology materials, can solve the problems of poor adhesion resistance, insignificant performance improvement, and poor wear resistance of the paint film, and achieve good antibacterial performance and improve the effect of light aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

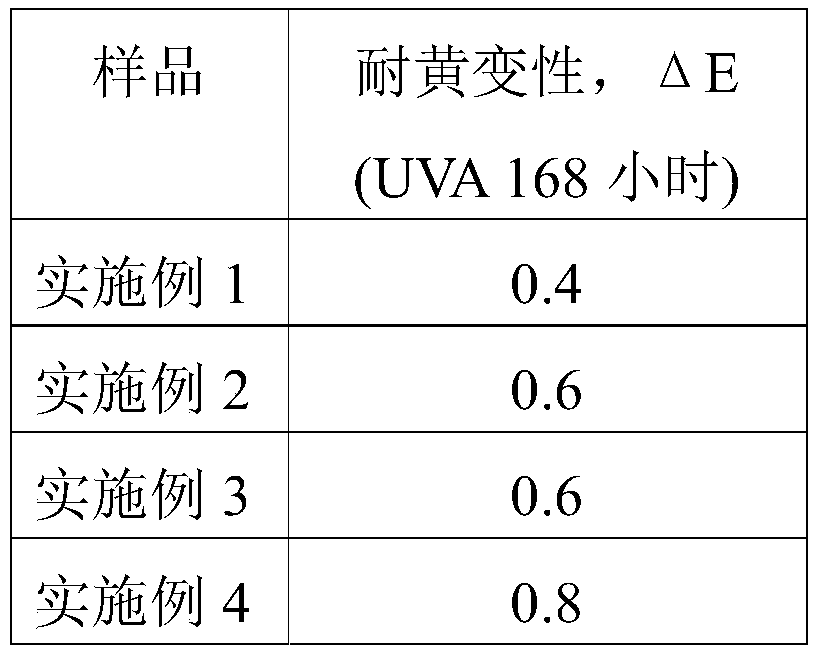

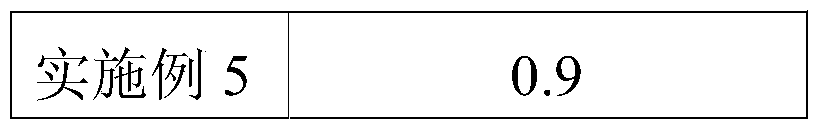

Examples

Embodiment 1

[0033] Weigh each raw material (parts by weight): 40 parts of acrylate emulsion, 8 parts of polyvinyl alcohol, 6 parts of 2-methoxy-4-methylphenol, 10 parts of ethylene glycol, 4 parts of ethylene-vinyl acetate copolymer emulsion , 6 parts of titanium dioxide, 2 parts of sodium lauryl sulfonate, 0.4 part of simethicone, 2 parts of propylene glycol methyl ether acetate, 0.5 part of antibacterial agent, and 0.5 part of ultraviolet light absorber.

[0034] The ultraviolet absorber consists of 0.25 parts of 2,2'-dihydroxy-4,4'-dimethoxybenzophenone-5,5'-disulfonic acid and 0.25 parts of 2,5-dihydroxy- 4-Methoxybenzophenone is obtained by mixing evenly.

[0035] The antibacterial agent is obtained by uniformly mixing 0.25 parts of 1,3-diiodo-5,5-dimethylhydantoin and 0.25 parts of 3-bromo-5,5-dimethylhydantoin.

[0036] Anti-aging waterproof architectural coating preparation:

[0037] Acrylate emulsion, polyvinyl alcohol, 2-methoxy-4-methylphenol, ethylene glycol, ethylene-vinyl ...

Embodiment 2

[0039] The anti-aging waterproof architectural coating was prepared according to the raw material ratio and method of Example 1, except that the antibacterial agent was 0.5 part of 1,3-diiodo-5,5-dimethylhydantoin. Obtain the anti-aging waterproof architectural coating of embodiment 2.

Embodiment 3

[0041] The anti-aging waterproof architectural coating was prepared according to the raw material ratio and method of Example 1, except that the antibacterial agent was 0.5 parts of 3-bromo-5,5-dimethylhydantoin. Obtain the anti-aging waterproof architectural coating of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com