Making method of polyvinyl chloride plastic, and making method of charging pile connecting cable sheath material

A technology of polyvinyl chloride and production method, which is applied in the manufacture of electric vehicle charging pile connection cable sheath materials and the production of polyvinyl chloride plastics, achieving the effects of high insulation resistance, improved light aging resistance, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the objectives, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with implementation examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

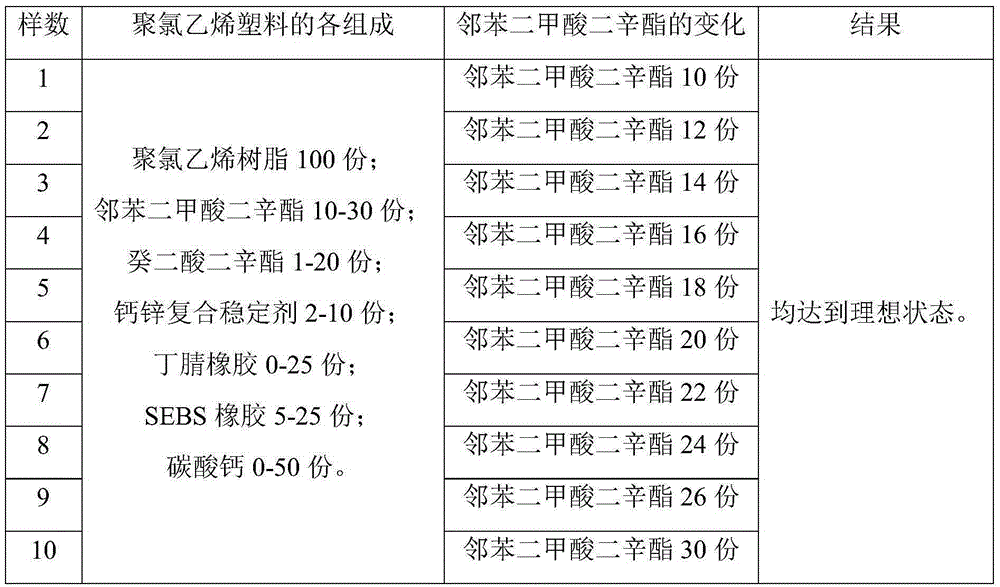

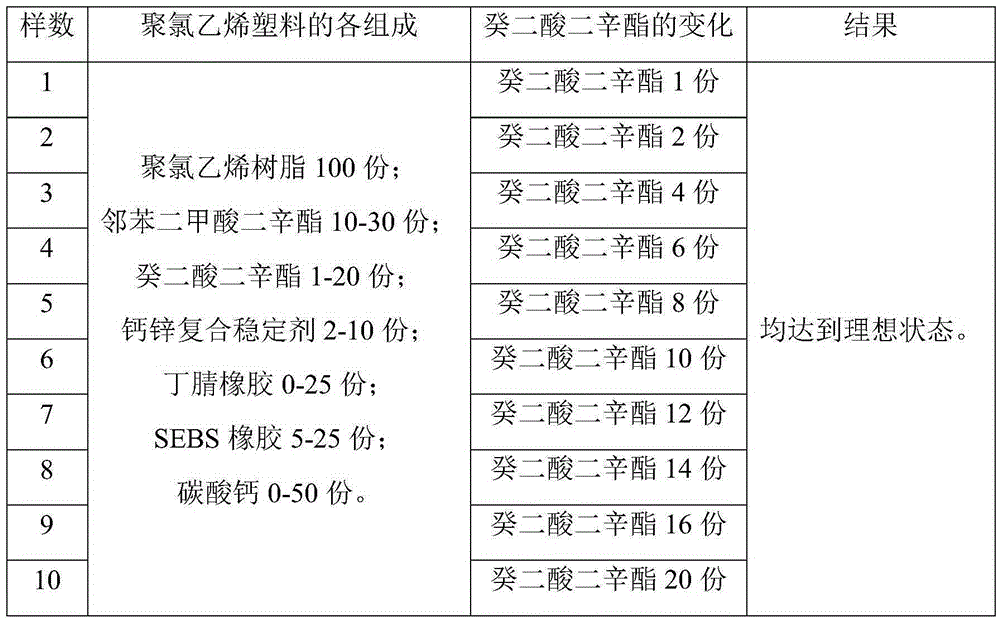

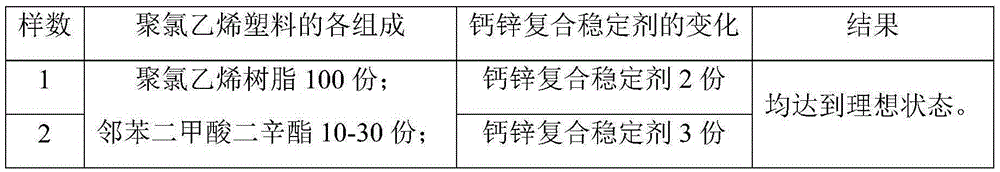

[0019] The polyvinyl chloride plastic of the present invention is mainly used in the production of sheath materials for connecting cables of charging piles, especially for the production of sheathing materials for connecting cables of electric vehicle charging piles. Polyvinyl chloride plastics include polyvinyl chloride resin, dioctyl phthalate, dioctyl sebacate, calcium zinc composite stabilizer, nitrile rubber, SEBS rubber, among them, SEBS rubber is made of styrene-ethylene-butylene The block copolymer produced by hydrogenation reaction of diene-styrene is a linear or star-shaped copolymer with styrene a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| rate of change of tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com