Method for preparing special polyethylene resin composition for pipe by master batch method

A technology of polyethylene resin and composition, which is applied in the field of preparation of polyethylene resin composition for manufacturing pipes, can solve the problem that the light aging resistance of non-black PE pipes cannot reach the same level, and achieve obvious positive effects and improved light aging resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0025] Take the PE resin with a melt flow rate of 18-22g / 10min as the carrier, add the colorant permanent orange G and the components of the additive according to the required proportion, and mix well. The materials are put into the twin-screw extruder for melt mixing and granulation. The residence time of the material in the screw is 2-4 minutes, and the temperature of the screw is controlled at 160-200°C. The obtained masterbatch particles are finished products after being cooled and dried, and 500kg samples are prepared for each embodiment.

[0026] Above-mentioned additive comprises antioxidant, light stabilizer I and light stabilizer II, wherein:

[0027] Antioxidant is B225 antioxidant,

[0028] Light stabilizer I is 2'-(2'-hydroxyl-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole,

[0029] Light stabilizer II is N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)hexanediamine.

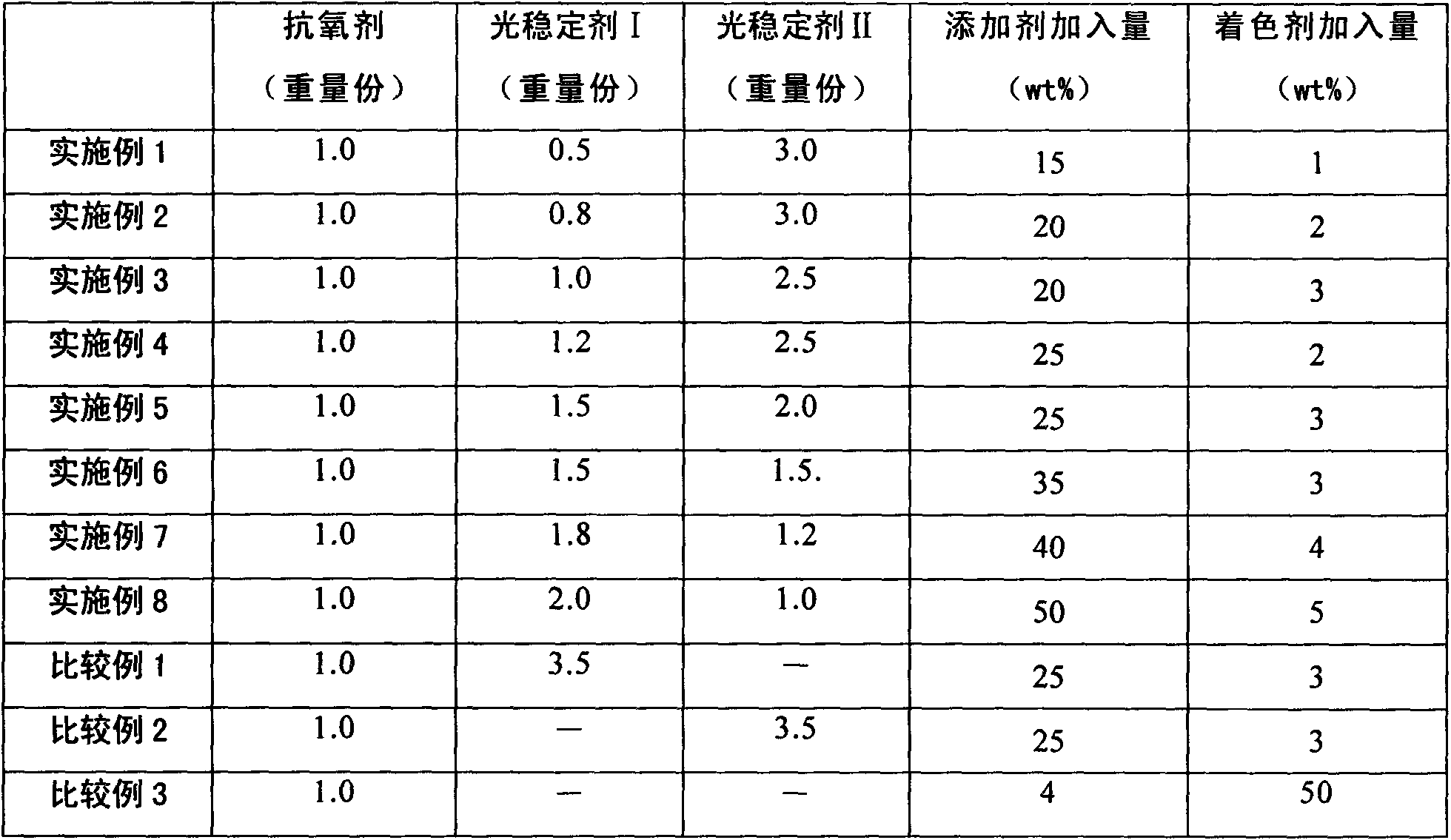

[0030] See Table 1 for the proportioning of each component of the additive and the addition ...

Embodiment 9~16、 comparative example 4~6

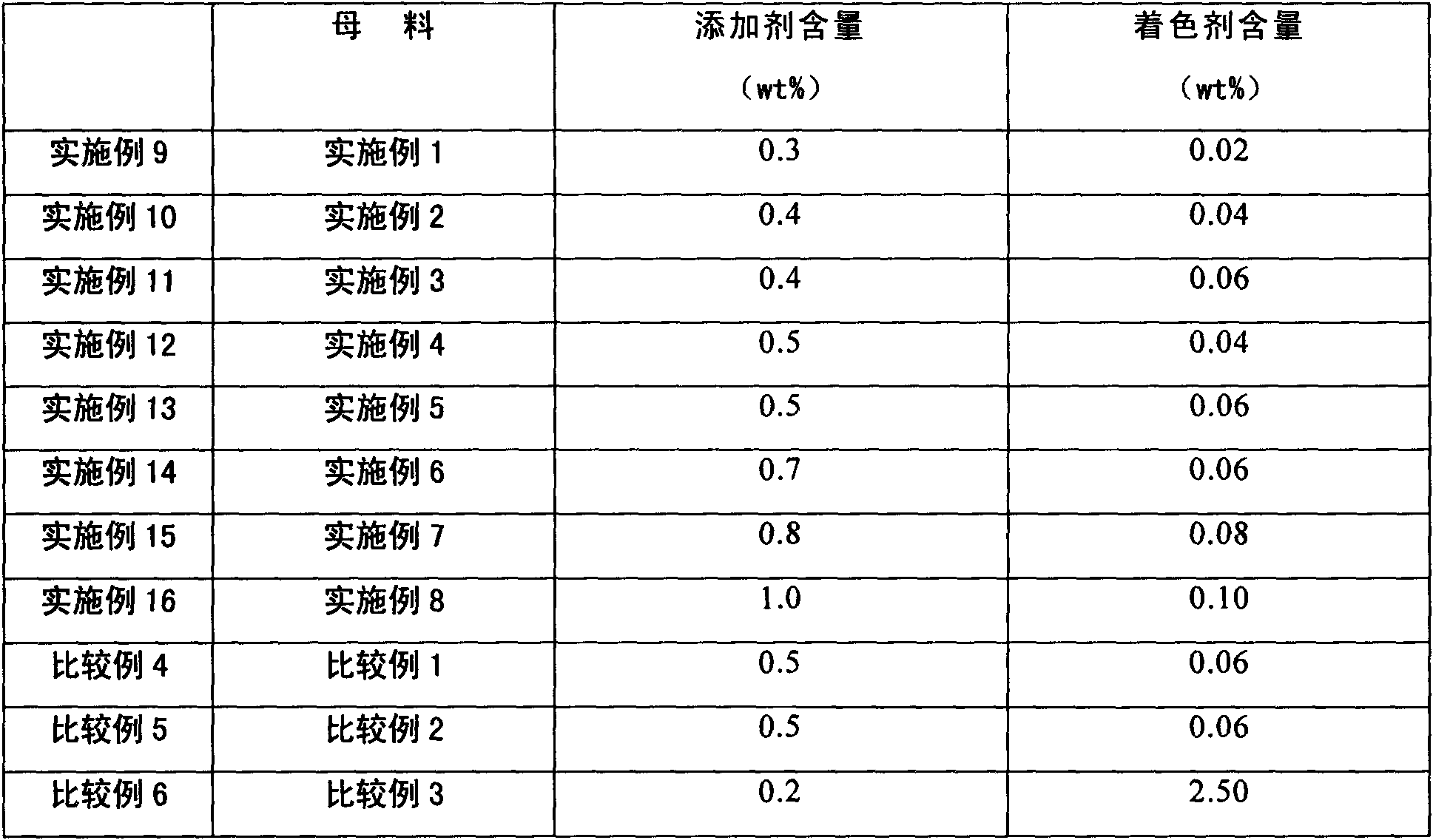

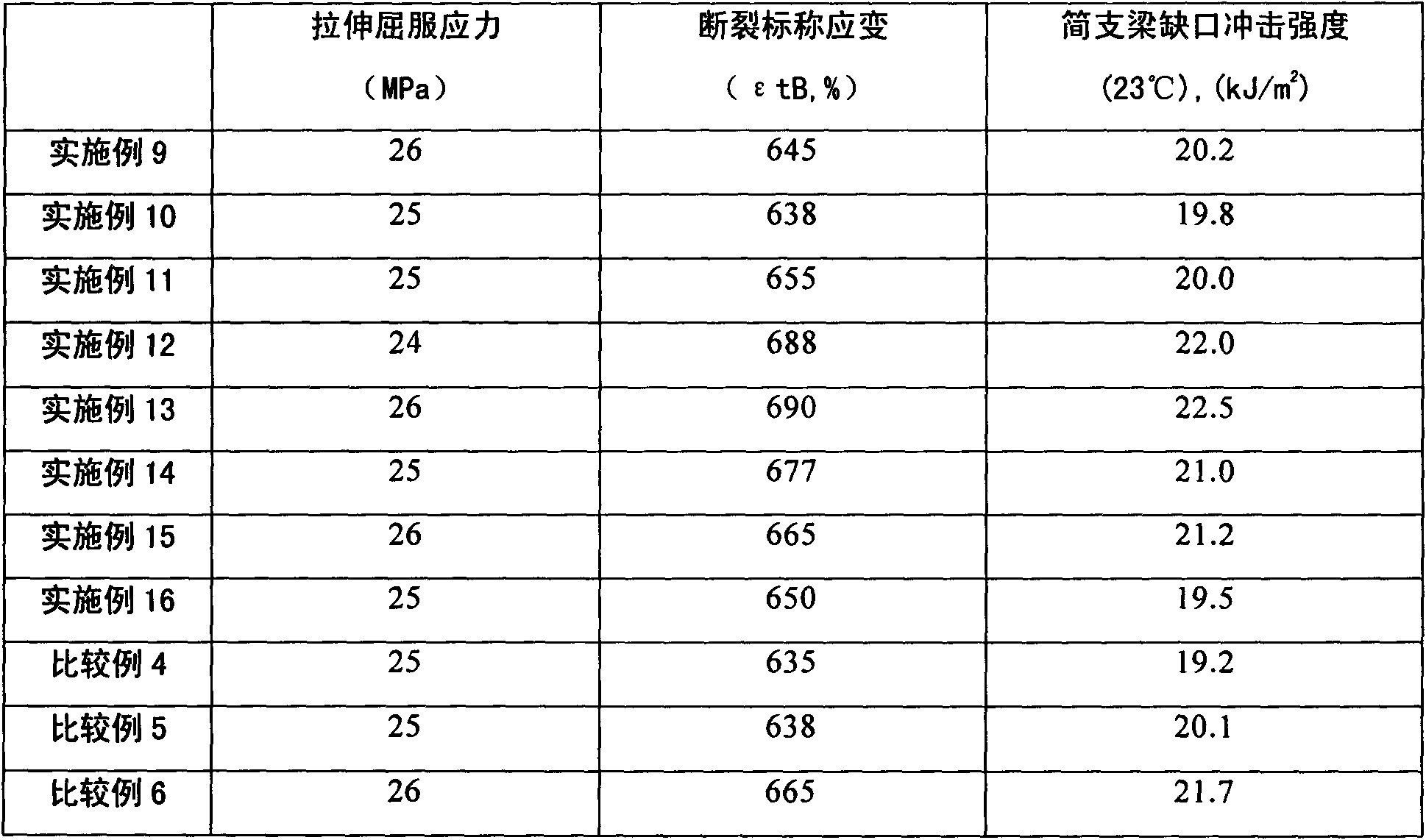

[0039] Take the masterbatches prepared in Examples 1-8 and Comparative Examples 1-3, and use the conventional masterbatch method to manufacture the special PE resin for pipes.

[0040] Take 500kg of PE resin base material, the PE resin base material is bimodal molecular weight distribution polyethylene, its density is 0.920-0.965g / mL, and the melt flow rate under the load 5kg test condition is 0.2-0.5g / 10min. The weight average molecular weight Mw of the low molecular weight part L 20000-22000, the weight average molecular weight Mw of the high molecular weight part H 250,000 to 280,000, the weight ratio W of the low molecular weight part to the high molecular weight part L :W H It is 1: (1.2~1.4).

[0041] Calculate the required amount of masterbatch according to the required content of the colorant permanent orange G and additives in the PE resin specially used for pipes, mix the required amount of masterbatch and PE base material, and put them into the twin-screw extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com