Microbial deodorant and preparation method thereof

A deodorant and microbial technology, applied in the field of microbial deodorant and its preparation, can solve the problems of incomplete deodorization, temporary cure, pollution, etc., and achieve the effects of low treatment cost, wide range of action and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

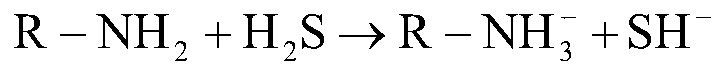

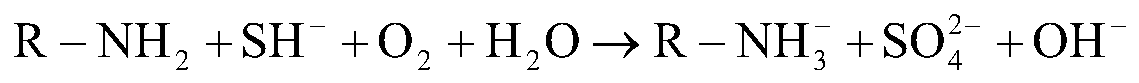

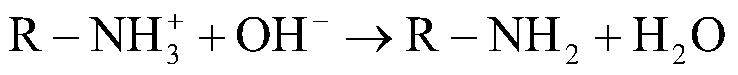

Method used

Image

Examples

preparation example Construction

[0035] A preparation method based on microbial deodorant, comprising the following steps:

[0036] S1, weighing

[0037] Weigh the raw materials according to the formula;

[0038] S2, dissolving essence

[0039] Add the camphor oil, eucalyptol, terpineol and terpinene weighed in step S1 to the water in turn, and stir until dissolved;

[0040] S3, add polyoxyethylene sorbitan fatty acid ester, fatty alcohol polyoxyethylene ether, amylase, lactic acid bacteria, saccharomyces, actinomycetes, bacillus to the solution obtained in step S2 successively , bacilli and micrococci, stirred until dissolved;

[0041] S4, dissolved pigment

[0042] Add the pigment to the solution obtained in step S3, and stir until dissolved;

[0043] S5, sealed fermentation.

[0044] After the above operations are completed, an acidic solution with a pH of 6 can be obtained. The acidic environment can destroy the basis for the survival of bacteria and viruses, thereby achieving the effects of deodori...

Embodiment

[0059]First, add 0.5 liters of camphor oil, 0.2 liters of eucalyptol, 1.5 liters of terpineol, and 0.1 liters of terpinene to 90 liters of water, and stir until dissolved; then add 2.5 liters to the dissolved solution 0.1 liter of polyoxyethylene sorbitan fatty acid ester, 0.1 liter of fatty alcohol polyoxyethylene ether, 0.1 liter of amylase, 0.1 liter of lactic acid bacteria, 0.1 liter of yeast, 0.1 liter of actinomycetes, 0.1 liter of spores Bacillus, 0.1 liter of bacillus and 0.1 liter of micrococcus, stir until dissolved; then add pigment and stir until dissolved; finally add water to 100 liters to form a microbial deodorant solution, seal and ferment for 24 hours.

[0060] In a domestic garbage dump in the city, dilute the microbial deodorant formed above with tap water 500 times (volume ratio), spray 1 liter evenly with a spray gun, and detect the concentration of odor, ammonia, hydrogen sulfide, and methyl mercaptan after 24 hours of action. Table 1 is the test result ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com