Kraft pulping process of camphorwood

A technology of kraft method and camphor wood, applied in the direction of pulping with inorganic alkali, chemical/chemical mechanical pulping, textile and papermaking, etc. The effect of improving cooking uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

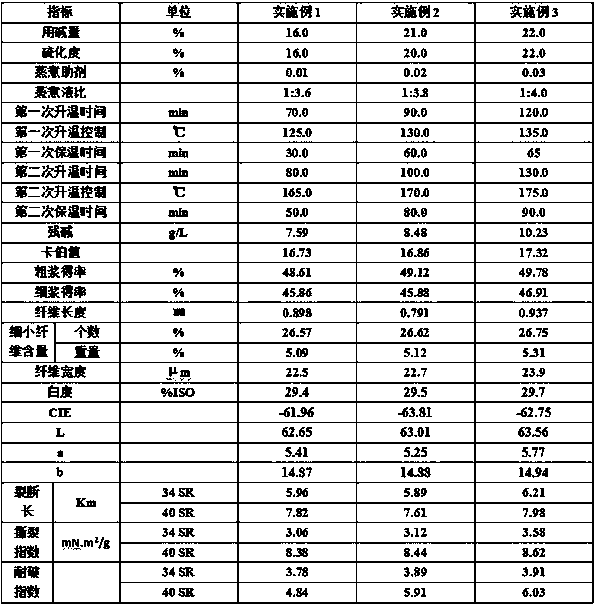

Examples

Embodiment 1

[0026] The kraft pulping process of camphor wood comprises the following preparation steps:

[0027] Step A, get 100% camphor wood chips and carry out peeling, chipping and screening operations. After screening, the length of Eucalyptus urophylla wood chips is controlled to be 10mm; Moisture content of camphor wood chips is 10%;

[0028] Step B. Put the camphor wood chips produced in step A into the cooking pot, control the cooking liquid ratio to 1:3.6, control the amount of alkali used to 16.0% (calculated as NaOH, for absolute dry wood chips), control the degree of sulfide to 16%, and cook The pressure inside the pot is controlled at 0.70Mpa. During the cooking process, the heating rate is controlled. The heating process is divided into 2 times. The first temperature rise is controlled at 125.0°C, and the non-condensable gas in the cooking pot is discharged 2-3 times. The heating time The control is 70.0 minutes. When the highest temperature is reached, the holding time is...

Embodiment 2

[0034] The kraft pulping process of camphor wood comprises the following preparation steps:

[0035] Step A, get 100% camphor wood chips and carry out peeling, chipping and screening operations. After screening, the length of Eucalyptus urophylla wood chips is controlled to be 30mm; Moisture content of camphor wood chips is 45%;

[0036] Step B. Put the camphor wood chips produced in step A into the cooking pot, control the cooking liquid ratio to 1:4.0, control the amount of alkali used to 21% (calculated as NaOH, for absolute dry wood chips), control the degree of sulfide to 20%, and cook The pressure inside the pot is controlled at 0.80Mpa. During the cooking process, the heating rate is controlled. The heating process is divided into 2 times. The first temperature rise is controlled at 130°C, and the non-condensable gas in the cooking pot is discharged 2-3 times. The heating time The control is 90 minutes. When the highest temperature is reached, the holding time is contr...

Embodiment 3

[0042] The kraft pulping process of camphor wood comprises the following preparation steps:

[0043] Step A, get 100% camphor wood chips and carry out peeling, chipping and screening operations. After screening, the length of Eucalyptus urophylla wood chips is controlled to be 35mm; Moisture content of camphor wood chips is 50%;

[0044] Step B, put the camphor wood chips produced in step A into the cooking pot, control the cooking liquid ratio to 1:4.0, control the amount of alkali used to 22% (calculated as NaOH, for absolute dry wood chips), control the degree of sulfide to 22%, and cook The pressure inside the pot is controlled at 0.90Mpa. During the cooking process, the heating rate is controlled. The heating process is divided into 2 times. The first temperature rise is controlled at 135°C, and the non-condensable gas in the cooking pot is discharged 2-3 times. The heating time The control is 120 minutes. When the highest temperature is reached, the holding time is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com