Oil shale residue aerated brick and preparation method thereof

A technology of oil shale slag and aerated bricks, which is applied in the field of building materials, can solve the problems of land occupation and environmental pollution, and achieve the effects of protecting the environment, reducing environmental pollution, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

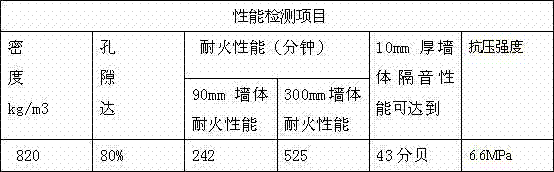

Image

Examples

Embodiment 1

[0025] Weigh the following raw materials in parts by weight: oil shale slag 20-30, fly ash 25-30, cement 5-10, modified nano-attapulgite 4-6, mica powder 5-10, ceramic factory waste 5-10 , light calcium powder 5-10, lime 10-15, triethanolamine lime weight 0.1-0.3%, gypsum 1-3, aluminum powder 0.02-0.08, sodium dibutyl naphthalene sulfonate added to the aluminum powder weight 3- 5%, calcium bicarbonate 0.01-0.02, volcanic rock 2-3, lignocellulose 1-2, soda ash 0.3-0.5, sodium diacetate 1-2, borax 0.03-0.05, hydroxypropyl methylcellulose sodium 1-2 , ultrafine polyvinyl alcohol 1-2,

[0026] Among them, the attapulgite is modified: first soak the attapulgite with 15-20% hydrochloric acid for 1-2 hours, let it stand, clarify, centrifuge, wash the solid with water until it is neutral, and after drying, add an amount equivalent to the weight of the solid 3-5% vinyltriethoxysilane is stirred evenly, dried and ground into nanopowder,

[0027] Process the above-mentioned substances ...

Embodiment 2

[0035] Weigh the following raw materials in parts by weight: oil shale slag 25, cement 56, modified nano-attapulgite 5, mica powder 8, ceramic factory waste 6, light calcium powder 12, lime 14, triethanolamine lime weight 0.1-0.3 %, gypsum 2, aluminum powder 0.05, sodium dibutylnaphthalene sulfonate 4% of the weight of aluminum powder, calcium bicarbonate 0.01, volcanic rock 3, lignocellulose 1.5, soda ash 0.4, sodium diacetate 1, borax 0.04, Hydroxypropyl methyl cellulose sodium 2, superfine polyvinyl alcohol 1, wherein, modified attapulgite is made by following method: first soak sepiolite 1-2 hour with 15% hydrochloric acid, leave standstill, clarification, centrifugation , the solid is washed with water until neutral, after drying, add vinyltriethoxysilane equivalent to 3-5% of the solid weight, stir evenly, dry, and pulverize into powder,

[0036] Process the above-mentioned substances that have been weighed into finished aerated bricks according to the following methods,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com