Improved process for preparing 2-sodium naphthalenesulfonate in production of beta-naphthol

A technology of sodium naphthalenesulfonate and ethyl naphthol, which is applied in the preparation of sulfonate, organic chemistry, etc., can solve the problems of high production cost, high loss rate of sodium naphthalenesulfonate, high consumption quota of ethyl naphthol, etc., and achieve reduction The effect of processing fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

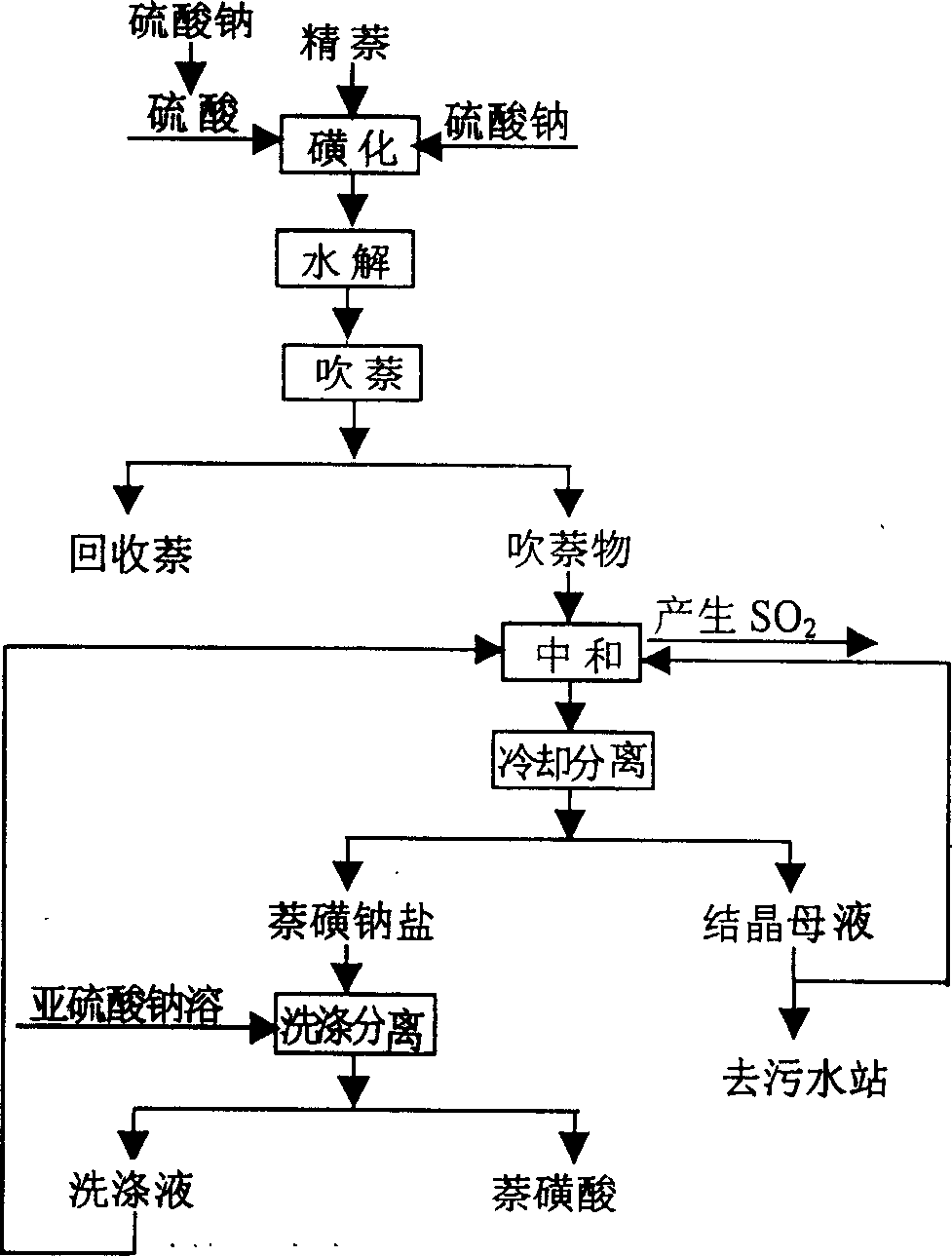

Method used

Image

Examples

Embodiment 1

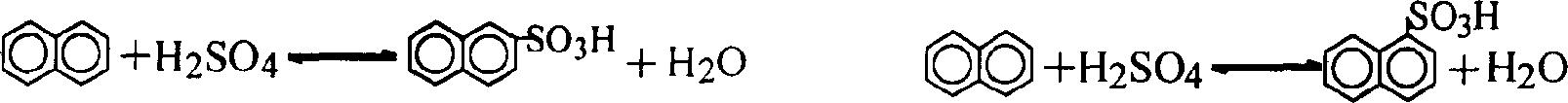

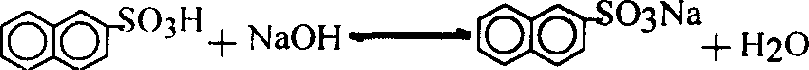

[0024] Embodiment 1, adopt 2m 3 The sulfonation pot, the pressure, temperature, stirring, and jacket heating during operation, are consistent with the existing equipment for the production of ethyl naphthol except for special conditions; 1211kg of 100% molten naphthalene at 120°C is added to the sulfonation pot , heated to 140°C, 878kg of 98% concentrated sulfuric acid was added within 45 minutes after the reaction started, and kept at 163°C for 2 hours, and 201kg of anhydrous sodium sulfate preheated to 165°C was added evenly within 1.5 hours In the sulfonation pot, under the condition of 163°C, keep the reaction for 45 minutes, and the total acidity of the sulfonated product is 18.39%, and the free sulfuric acid is 5.25%. The material is sent to the neutralization pot, neutralized for 1 hour with the washing solution of the naphthalenesulfonic acid sodium salt produced in the previous time, then added to the 800 kg of the neutralization mother liquor produced in the previous...

Embodiment 2

[0025] Embodiment 2, unless otherwise specified, equipment and operating conditions are the same as embodiment 1, add molten naphthalene 1211kg, constantly stir under 145 ℃ of conditions, add 926kg of 98% vitriol oil 926kg in the 40 minutes that reaction begins to carry out. Sulfonate at 160°C for 2.5 hours, add 134kg of anhydrous sodium sulfate heated to 140°C evenly into the pot within 1 hour, keep the reaction at 164°C for half an hour, and the total acidity of the sulfonated product is 20.7%. , free sulfuric acid 5.5%, get reclaiming 56kg of naphthalene through blowing naphthalene again, and the resultant is blown naphthalene thing and sent to neutralization pot, with the washing solution of the naphthalenesulfonic acid sodium salt that produced last time and neutralize 1 hour, then add the former Produce 300kg of neutralized mother liquor for dilution, and then send it to the cooling pot for cooling for 3.5 hours, control the temperature at 40°C, separate and obtain 4164kg...

Embodiment 3

[0026]Embodiment 3, except special designation, equipment and operating conditions are the same as embodiment 1, add molten naphthalene 1211kg, be warming up to 145 ℃ under constant stirring, add 831kg of 98% concentrated sulfuric acid in the 40 minutes that reaction begins to carry out, this sulfuric acid is in advance Dissolve 50kg of anhydrous sodium sulfate, sulfonate at 165°C for 2 hours, uniformly add 178kg of anhydrous sodium sulfate at 165°C within 1 hour, keep at the boiling point and react for half an hour, and the total acidity of the sulfonated product is 16.1%. Free sulfuric acid 5.0%, get reclaiming naphthalene 44kg through blowing naphthalene again, and blowing naphthalene thing is delivered to neutralization pot, neutralizes with the washing solution of the naphthalene sulfonic acid sodium salt of previous production, then add into the previous production neutralization pot. Dilute with 1100kg of mother liquor, then send it to cooling pot for cooling for 3.5 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com