Comfortable anti-flaming fabric and manufacturing method thereof

A flame-retardant fabric and comfortable technology, applied in the field of textile fabrics, can solve the problems affecting the wearer's mobility and activity efficiency, and affect the wearer's comfort, and achieve good filament luster, enhanced appearance luster, and good slip resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

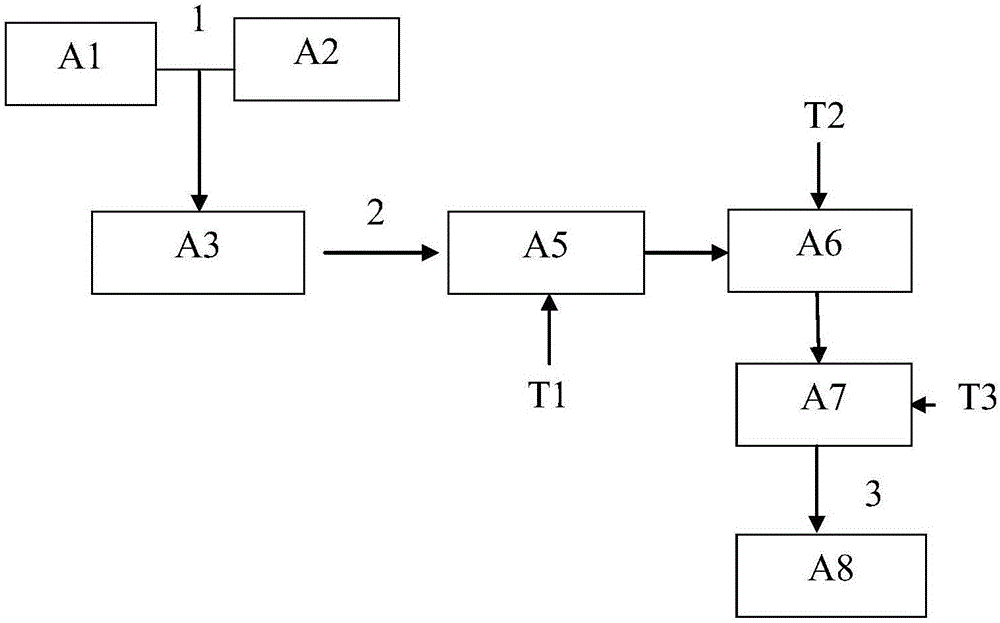

[0032] Such as figure 1 A flow chart of a method for making a comfortable flame-retardant fabric according to an embodiment of the present invention is shown, including:

[0033] The warp yarn A1 and the weft yarn A2 are interwoven vertically with each other to form the finished product A3, the warp yarn A1 is composed of a second yarn made of flame-retardant filament, and the weft yarn A2 is made of a first yarn made of a short fiber with flame-retardant properties line structure; the finished product A3 is transferred to the immersion tank, the finishing liquid (bath ratio 1:30) is added to the immersion tank 2, and the finished product A3 is soaked under the condition that the temperature T1 is 80°C Rolling (two dipping and two rolling) A5; transfer the finished product to the high temperature setting machine, and raise the temperature to T2, T2 is preferably 100°C, and dry A6; raise the temperature to T3, the temperature T3 is the best The temperature is 160°C, and the fi...

Embodiment 2

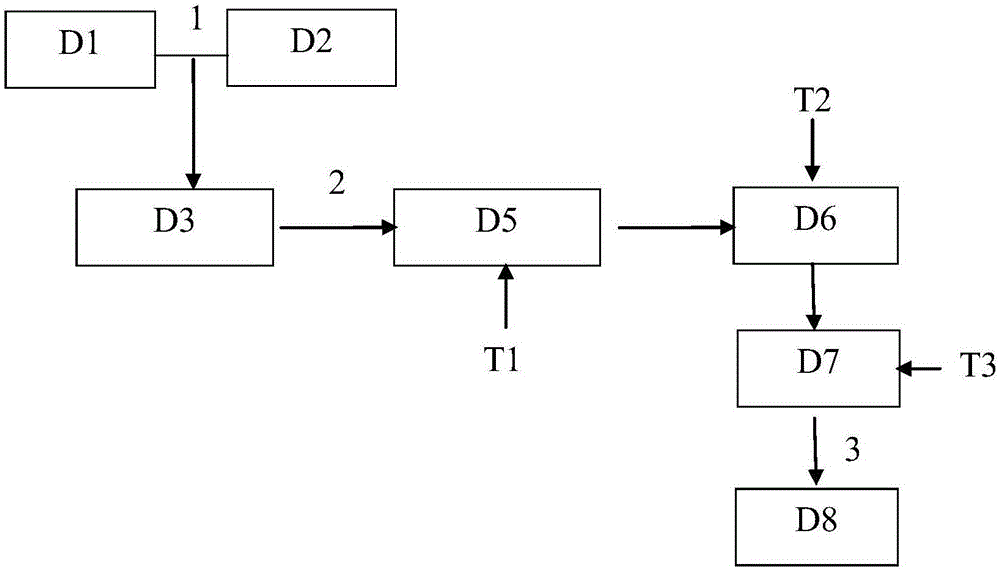

[0044] Such as image 3 A flow chart of a method for making a comfortable flame-retardant fabric according to an embodiment of the present invention is shown, including:

[0045] The warp yarn D1 and the weft yarn D2 are vertically interlaced 1 to form the finished product D3, wherein the warp yarn D1 and the weft yarn D2 are composed of a first yarn made of short fibers with flame-retardant properties and a second yarn made of flame-retardant filaments; The finished product D3 is transferred to the soaking tank, and the finishing solution (bath ratio 1:30) is added to the soaking tank. Under the condition of temperature T1 of 80°C, the finished product is padded (a Dipping and rolling) D5; transfer the finished product to a high-temperature appliance, and raise the temperature to T2, preferably 100°C, and dry the finished product D6; raise the temperature to T3, the temperature T3 is preferably 160°C, and the finished product is baked D7; the finished product is cooled to ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com