Hollow polyimide fiber solar micro cell and manufacturing method thereof

A polyimide fiber and solar micro-battery technology, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problems of large solar cells and inflexible development, and achieve skin adaptation Good performance, long service life, comfortable wearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

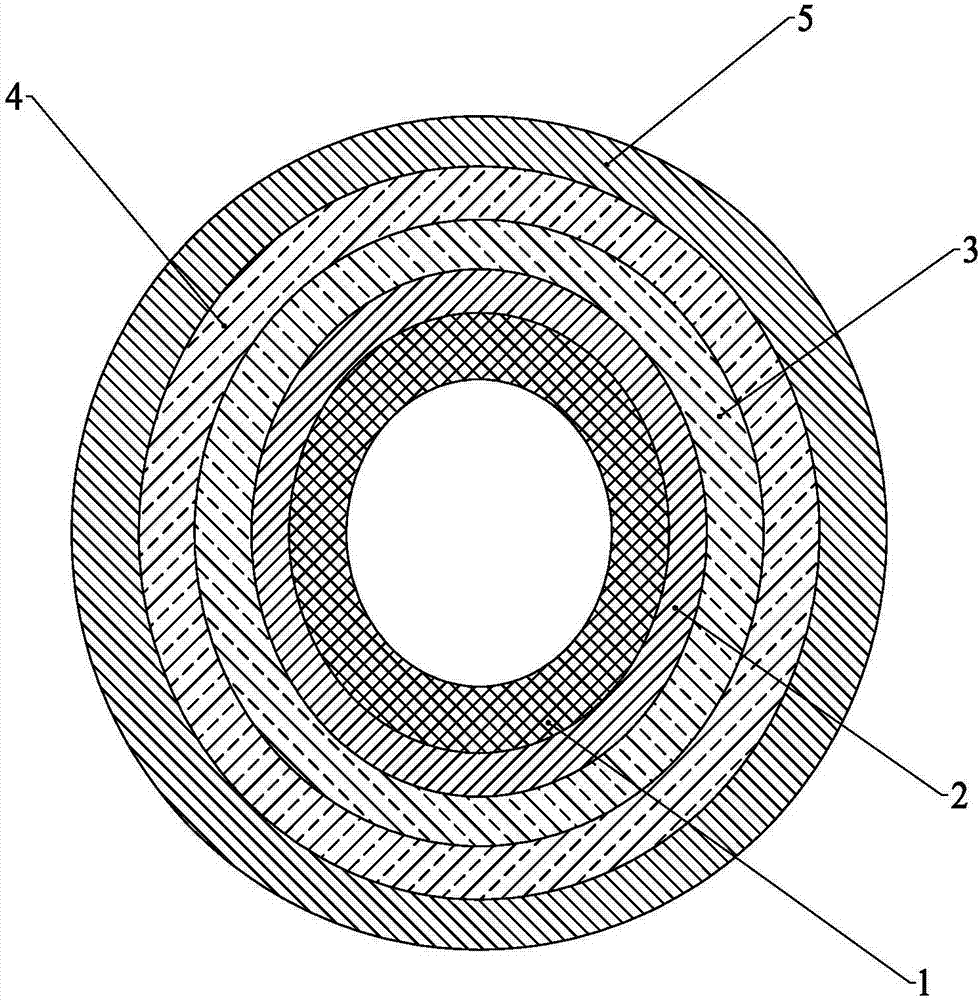

[0017] refer to figure 1 , a method for manufacturing a hollow polyimide fiber solar micro-battery, which is carried out according to the following process steps: hollow polyimide fiber cleaning → hollow polyimide fiber surface aluminized film layer → preparing the second aluminized film layer A PIN film layer → prepare a second PIN film layer on the first PIN film layer → prepare a TCO or ITO transparent conductive film layer on the second PIN film layer;

[0018] The hollow polyimide fiber is cleaned by ultrasonic cleaning and dried;

[0019] The aluminum coating layer on the surface of the hollow polyimide fiber adopts measurement and control sputtering technology, and an aluminum film layer 2 is coated on the outer surface of the hollow polyimide fiber 1 as a negative electrode, and the thickness of the aluminum film layer is 300~400nm , the coating temperature is 200~300℃;

[0020] The preparation of the first PIN film layer is to adopt six-chamber continuous VHF~PECVD ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com