A kind of production method of flame-retardant reflective cloth

A production method and technology of reflective cloth, applied in the direction of chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problems of cured film performance decline, large amount of flame retardant, slow curing system, etc., to achieve The effect of improving the bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

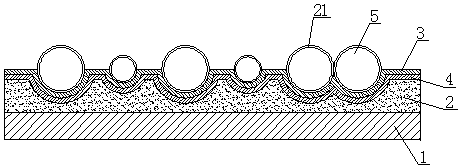

[0015] Such as figure 1 As shown, a method for making a flame-retardant reflective cloth, which includes a base cloth 1, a composite adhesive layer 2, a thin adhesive layer 3 and an aluminum-coated layer 4, the base cloth 1 is an aramid woven cloth, and the base cloth 1 The top surface is provided with a composite adhesive layer 2, the top of the composite adhesive layer 2 is provided with an aluminum-coated layer 4, the top of the aluminum-coated layer 4 is provided with a thin adhesive layer 3, and the top of the thin adhesive layer 3 is provided with a plurality of glass micro Beads 5, the lower half of each glass microsphere 5 is all arranged in the thin adhesive layer 3, and the upper part of each glass microsphere 5 is all arranged on the outside of the thin adhesive layer 3, each of the glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com