Fire-retardant silicon-based thermoplastic vulcanizate and method for synthesizing the same

A technology of thermoplastic vulcanizate and synthesis method, which is applied in the field of halogen-free flame-retardant silicon-based thermoplastic vulcanizate and its synthesis, and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Various embodiments of the invention are discussed in more detail below. However, this embodiment may be an application of various inventive concepts, and may be embodied in various specific ranges. The specific embodiments are for illustrative purposes only and do not limit the scope of the disclosure.

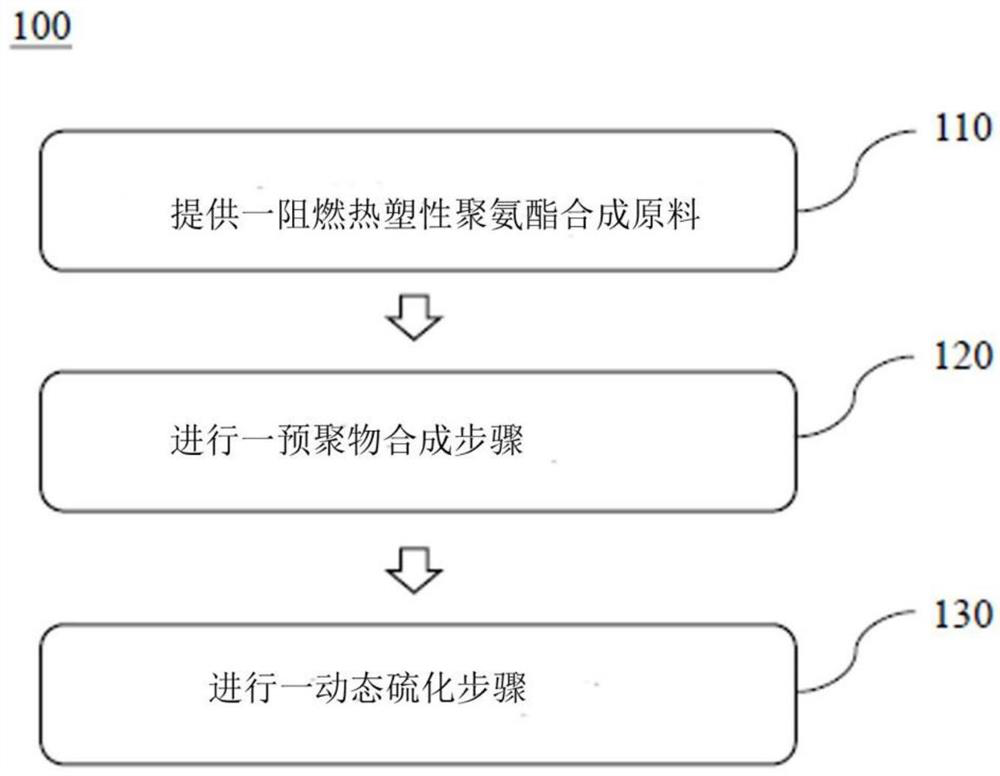

[0034] Please refer to figure 1 , figure 1 It is a flow chart showing the steps of the synthesis method 100 of the flame-retardant silicon-based thermoplastic vulcanizate according to an embodiment of the present invention. figure 1 Among them, the synthesis method 100 of the flame-retardant silicon-based thermoplastic vulcanizate includes step 110 , step 120 and step 130 .

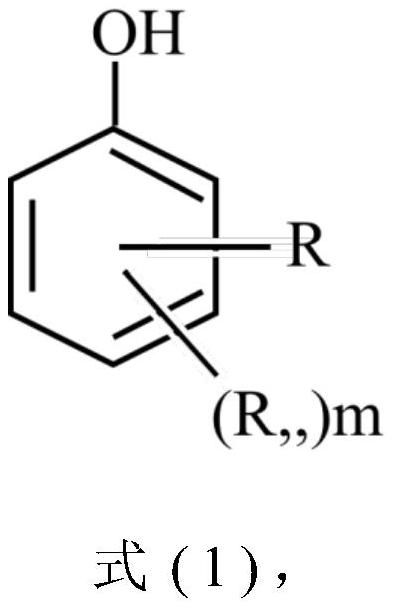

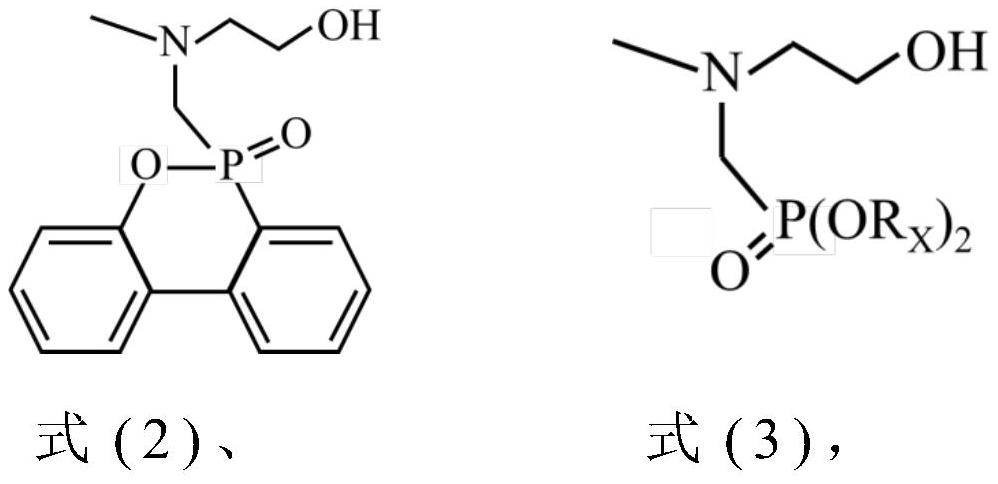

[0035] Step 110 is to provide a flame retardant thermoplastic polyurethane synthetic raw material, which includes polyisocyanate compound, macromolecular polyol compound and small molecular polyol. Specifically, the polyisocyanate may be one type of isocyanate, or may be formed by mixing two o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com