Spinning process of polyester fleece knitted fabric

A knitted fabric and polyester technology, applied in the processing, knitting, weft knitting and other directions of textile materials, can solve the problems of easy generation of static electricity, low hygroscopicity, high crystallinity, and achieve non-fading, durable flame retardant effect, soft hand feel fluffy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

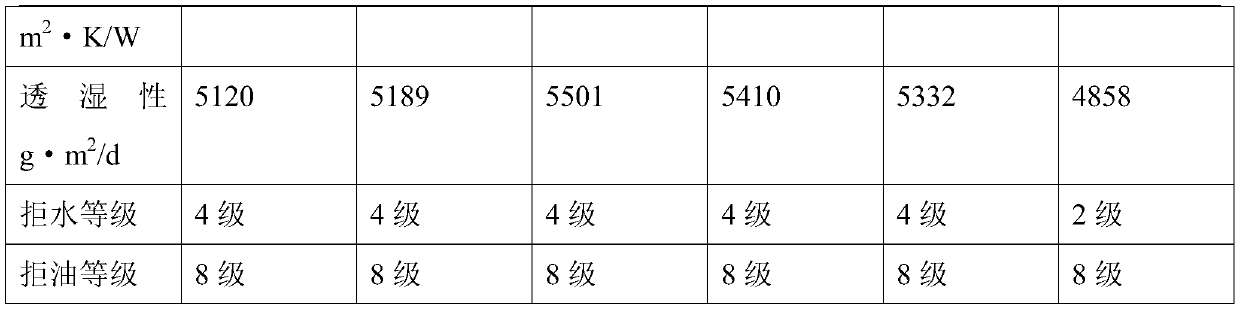

Embodiment 1

[0029] This embodiment provides a kind of weaving process of polyester velvet knitted fabric, and its weaving production steps are:

[0030] Step 1, pre-treatment of gray cloth: the gray cloth is produced by a weft knitting terry machine, the weaving density is 3.6cm with a stretch width of 20 stitches, the height of the pile sinker is 2.5mm, and the gray cloth is subjected to pre-scouring and bleaching treatment; polyester filament The weft-knitted fabric prepared with polyester staple yarn as raw material, the scouring and bleaching process formula is: caustic soda 4% (owf), whitening agent CPS-D 0.25% (owf), chelating dispersant DME-101 1.5% (owf) , degreasing agent 1% (owf), the process conditions are heating rate: 2°C / min, scouring temperature: 125°C, holding time: 40min, bath ratio 1:10;

[0031] Step 2, dyeing and printing: Dyeing with disperse dyes, the equipment is a high-temperature and high-pressure dyeing machine, the dyeing temperature is 125°C, and the liquor rat...

Embodiment 2

[0040] This embodiment provides a kind of weaving process of polyester velvet knitted fabric, and its weaving production steps are:

[0041] Step 1, pre-treatment of gray cloth: gray cloth is produced by weft-knitting terry machine, the weaving density is 3.8cm with a stretch width of 20 stitches, the height of the pile sinker is 2.5mm, and the gray cloth is subjected to pre-scouring and bleaching treatment; polyester filament The weft-knitted fabric prepared with polyester staple yarn as raw material, the scouring and bleaching process formula is: caustic soda 4.5% (owf), whitening agent CPS-D 0.25% (owf), chelating dispersant DME-101 1.5% (owf) , degreasing agent 1% (owf), the process conditions are heating rate: 2.5 ℃ / min, scouring temperature: 128 ℃, holding time: 38min, bath ratio 1:10;

[0042] Step 2, dyeing and printing: Dyeing with disperse dyes, the equipment is a high-temperature and high-pressure dyeing machine, the dyeing temperature is 128°C, and the liquor rat...

Embodiment 3

[0051] This embodiment provides a kind of weaving process of polyester velvet knitted fabric, and its weaving production steps are:

[0052] Step 1, pre-treatment of gray cloth: the gray cloth is produced by a weft-knitting terry machine, the weaving density is 4.1 cm with a stretch width of 20 stitches, the height of the pile sinker is 2.5 mm, and the gray cloth is subjected to pre-scouring and bleaching treatment; polyester filament The weft-knitted fabric prepared with polyester staple yarn as raw material, the scouring and bleaching process formula is: caustic soda 5% (owf), whitening agent CPS-D 0.25% (owf), chelating dispersant DME-101 1.5% (owf) , degreasing agent 1% (owf), process conditions are heating rate: 3°C / min, scouring temperature: 130°C, holding time: 35min, bath ratio 1:10;

[0053] Step 2, dyeing and printing: Dyeing with disperse dyes, the equipment is a high-temperature and high-pressure dyeing machine, the dyeing temperature is 130°C, and the liquor ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com