Automatic tuning method of electron gun filament heating current based on constant grid bias voltage

A technology of grid bias voltage and heating current, which is applied in the field of automatic setting of electron gun filament heating current, can solve the problem that electron beam processing equipment cannot take into account the service life of electron beam filament cathode, and achieve the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

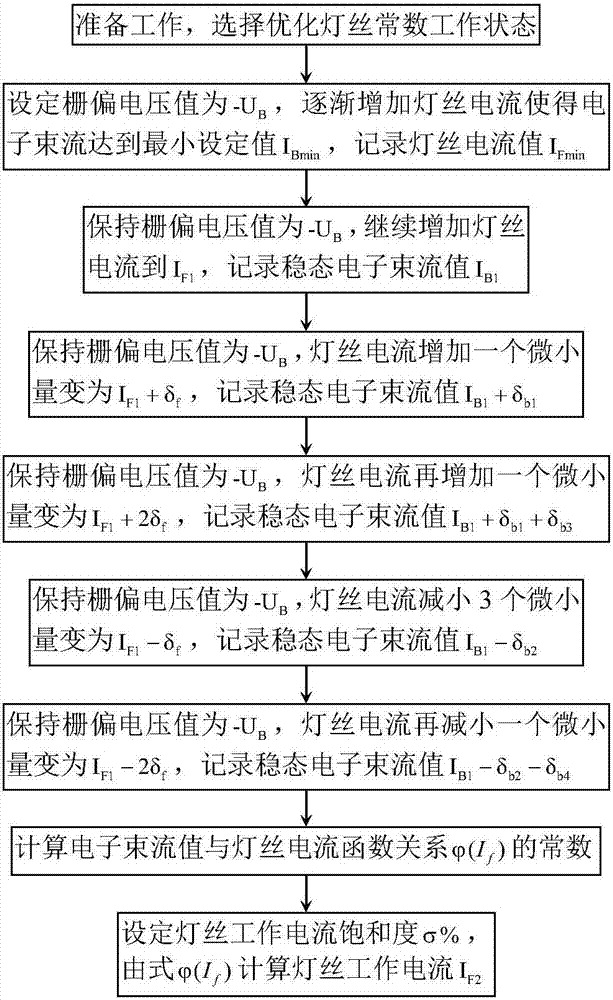

[0028] The principle of the present invention based on the electron gun filament heating current automatic tuning method with constant grid bias voltage is as follows:

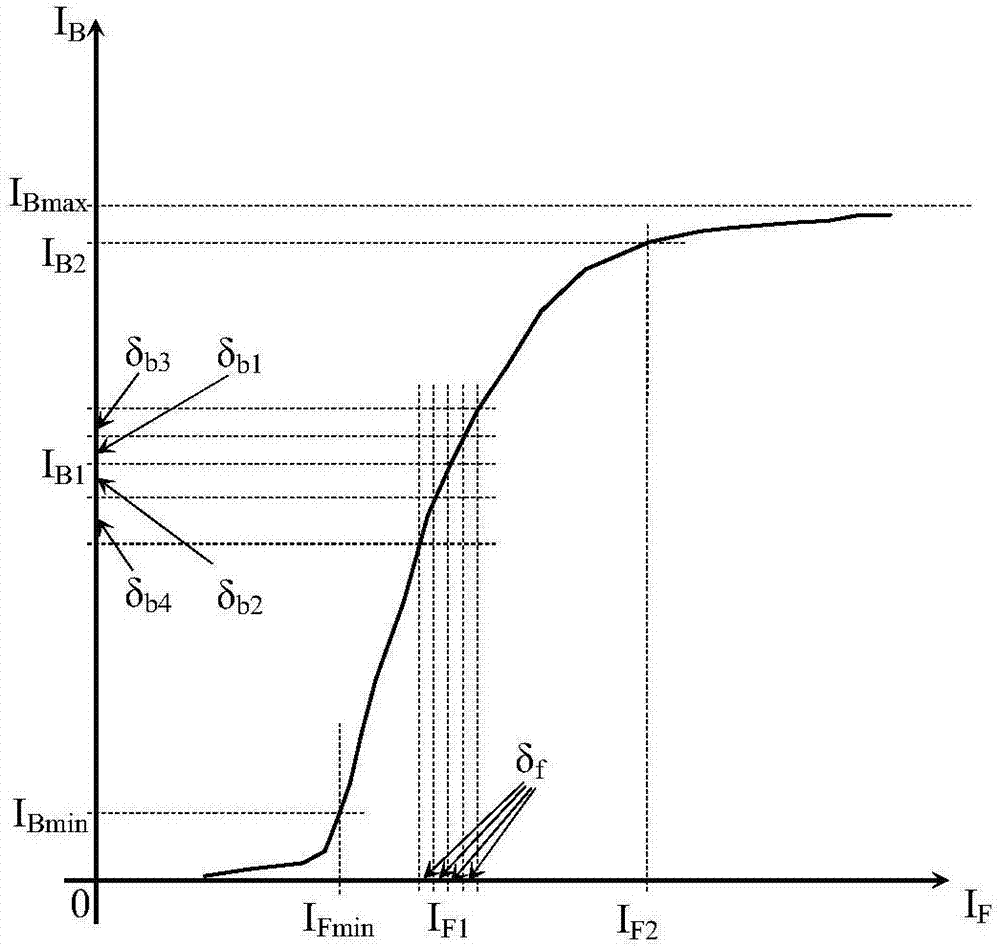

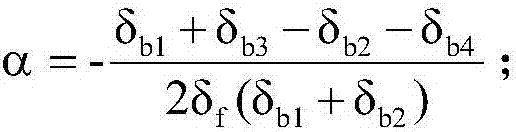

[0029] The acceleration voltage of the three-pole Pierce electron gun is stabilized at U A value, while the gate bias voltage is constant at -U B value, after the filament current reaches a certain value, the electron beam current I B vs. filament current I F It is an exponential function relationship with the natural number e as the base, such as figure 1 shown. Define the filament current I F with minimum filament current I Fmin The difference is the relative filament current I f =I F -I Fmin , defining the electron beam current I B with minimum electron beam current I Bmin The difference is the relative electron beam current Then after the filament current exceeds a certain value, the relative electron beam current I b with relative filament heating current I f The relation is

[0030]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com