A kind of preparation method of low temperature high current density scandium oxide cathode

A scandium oxide, high current technology, applied in the field of electric vacuum, can solve the problems of low current density and poor uniformity of the emission coating, and achieve the effects of enhancing electrical conductivity, reducing cathode evaporation, and improving current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

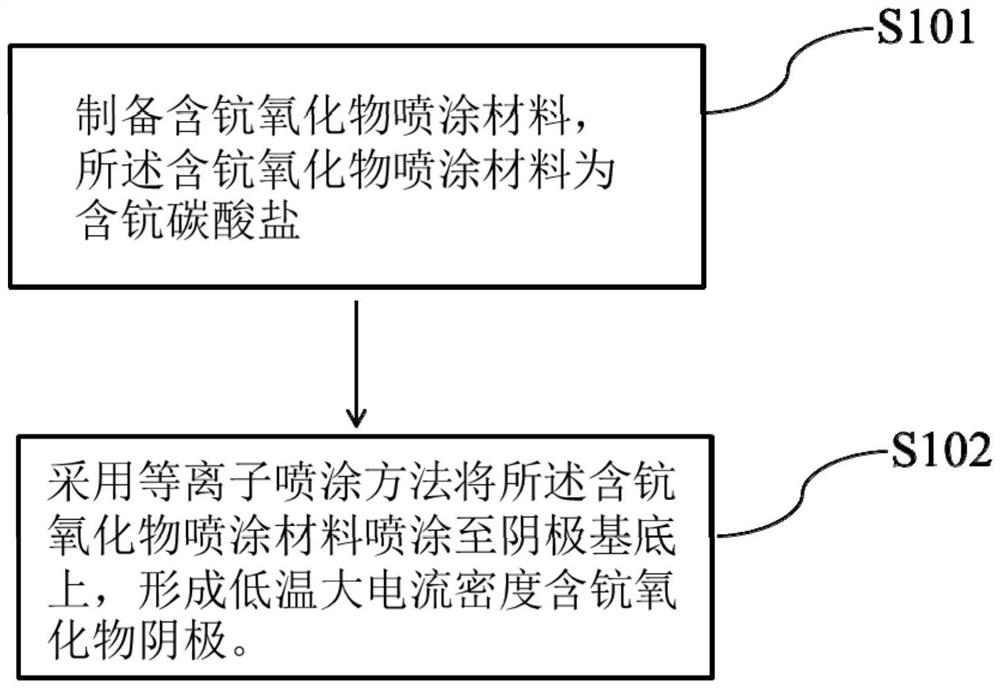

[0042] In a basic embodiment of the present invention, a method for preparing a scandium-containing oxide cathode with low temperature and high current density is disclosed. figure 1 It shows one of the flow charts for preparing a scandium-containing oxide cathode with low temperature and high current density according to the embodiment of the present invention. like figure 1 As shown, this embodiment includes:

[0043] Step S101, preparing scandium-containing oxide spraying material, the scandium-containing oxide spraying material is scandium-containing carbonate;

[0044] Step S102, using a plasma spraying method to spray the scandium-containing oxide spraying material onto the cathode substrate to form a low-temperature high-current-density scandium-containing oxide cathode.

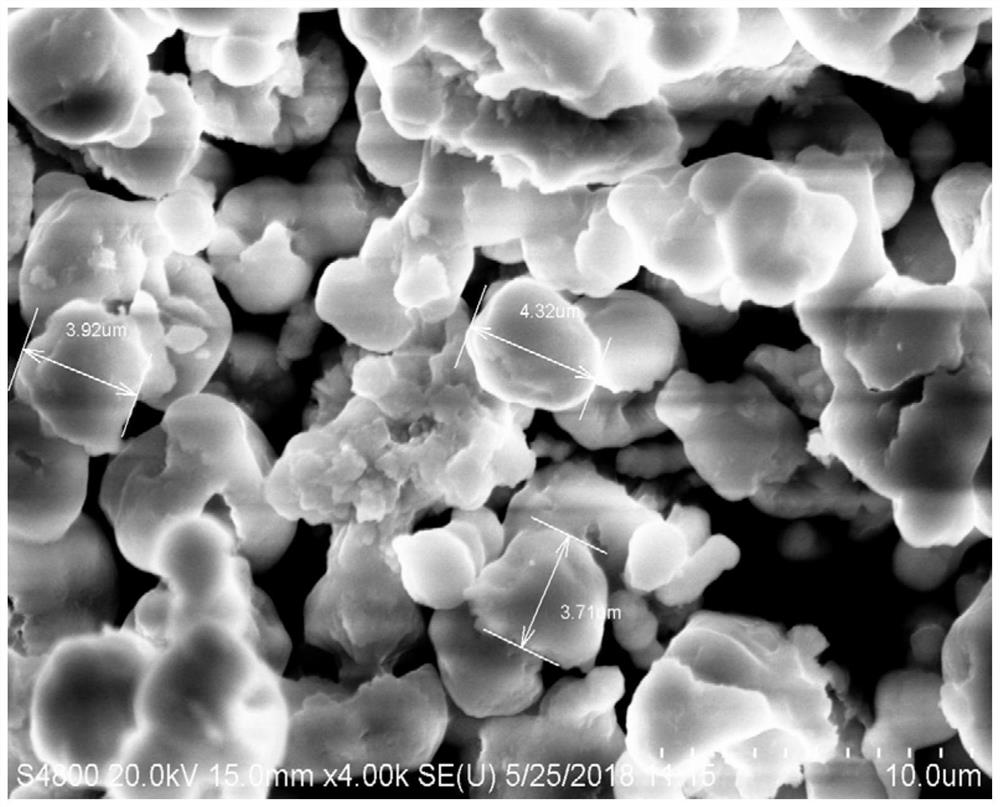

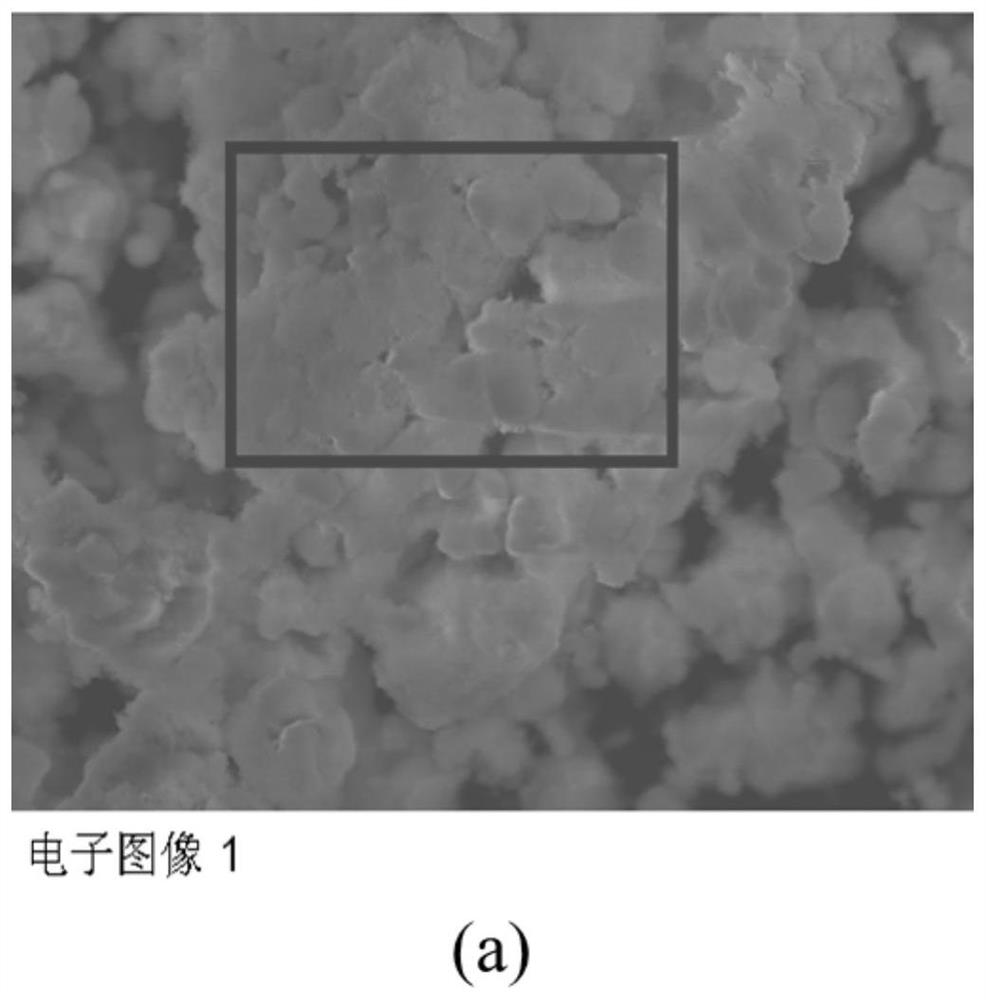

[0045] Compared with the oxide cathode prepared by the ordinary coating method, the oxide coating prepared by the plasma spraying technology in the present invention is dense, which can enhance the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com