Preparation method of high-density and high-physical-property suede superfine fiber artificial leathers

A technology of microfiber, artificial leather, applied in chemical instruments and methods, synthetic resin layered products, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

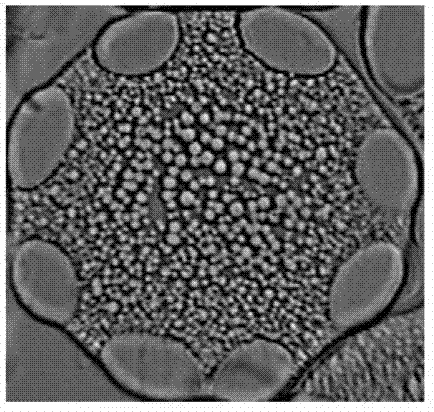

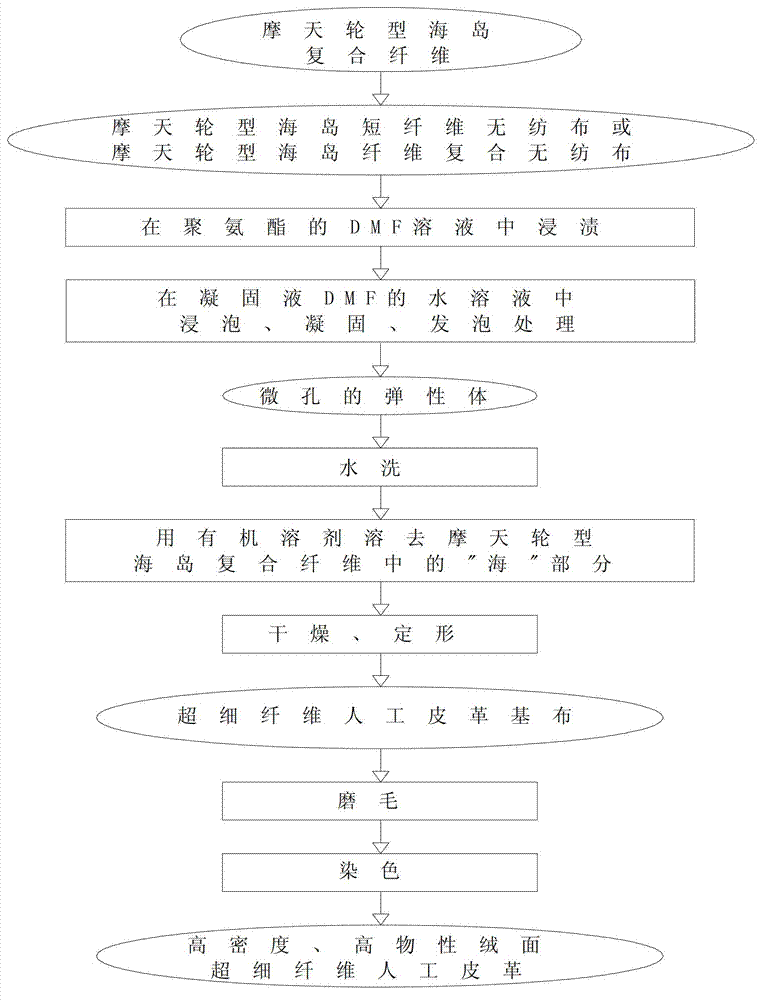

[0023] Such as image 3 Shown, the preparation method of this high-density, high physical suede microfiber artificial leather comprises the following steps:

[0024] (1) Ferris wheel-shaped sea-island composite fibers are made into ferris wheel-shaped superfine fiber non-woven fabrics;

[0025] (2) Immerse the ferris wheel-type ultrafine fiber non-woven fabric obtained in step (1) in DMF solution of polyurethane;

[0026] (3) Soak the semi-finished product obtained in step (2) in an aqueous solution of coagulation liquid DMF, perform coagulation and foaming treatment, and make polyurethane into an elastomer containing microcells;

[0027] (4) washing;

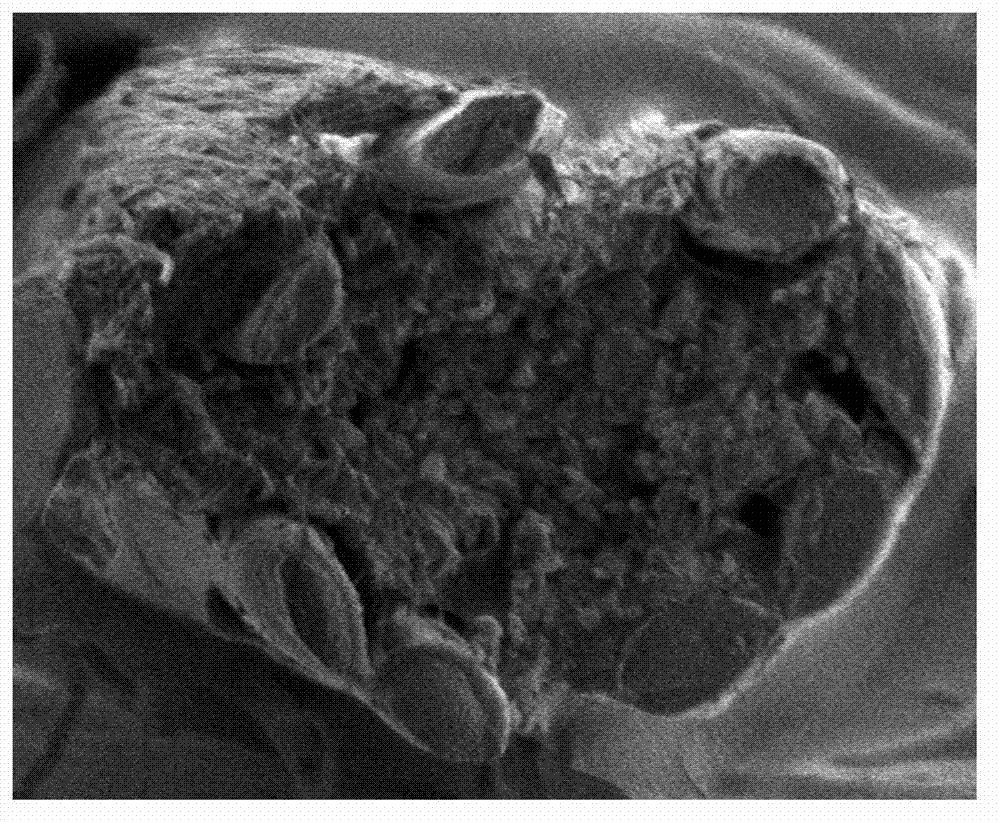

[0028] (5) Use an organic solvent to dissolve the LDPE part in the Ferris wheel-shaped sea-island composite fiber;

[0029] (6) Dry and set the shape to prepare the superfine fiber artificial leather base cloth.

[0030] (7) Sanding and dyeing to produce high-density, high-property suede microfiber artificial leather

[00...

Embodiment 1

[0043] High physical suede microfiber artificial leather for casual shoes

[0044] 1. Preparation of PA6 / (PA6+LDPE) ferris wheel type sea-island staple fiber:

[0045] (a) Raw material for spinning:

[0046] Dingdao component: PA6 chips, grade M32600, relative viscosity 2.6η; produced by Guangzhou Xinhui Meilunda Co., Ltd.

[0047] Blends of LDPE+PA6: LDPE, brand 1160A, melt index 60MFI, produced by Beijing Yanshan Petrochemical Branch; PA6 nylon chips, brand M32800, relative viscosity 2.8η, produced by Guangzhou Xinhui Meilunda Co., Ltd.

[0048] (b) Raw material ratio: weight ratio: PA6 / (PA6+LDPE)=30 / (35+35);

[0049] (c) Spinneret specifications: number of holes x ∩ shape x aperture is 1200x16x0.35mm;

[0050] (d) Screw extruder: specification 125, length-to-diameter ratio L / D=30:1;

[0051] (e) Metering pump specifications: wheel type component 10cc / rev, indeterminate island core layer component 20cc / rev;

[0052] (f) Cooling air temperature: 16°C, wind speed: 2.5m / s;...

Embodiment 2

[0074] Suede Microfiber Artificial Leather for Sofa Covered with Ferris Wheel Type Sea Island Filament Woven Mesh

[0075] 1: Spinning of PA6 / (PA6+LDPE) ferris wheel type sea-island filament:

[0076] (a) Raw material for spinning:

[0077] Dingdao component: PA6 chips, grade M32600, relative viscosity 2.6η; produced by Guangzhou Xinhui Meilunda Co., Ltd. Blends of LDPE+PA6: LDPE, brand 1I60A, melt index 60MFI, produced by Beijing Yanshan Petrochemical Branch; PA6, brand name M32800, relative viscosity 2.8η, produced by Guangzhou Xinhui Meilunda Co., Ltd.

[0078] (b) Raw material ratio: weight ratio: PA6 / (PA6+LDPE)=35 / (32+33);

[0079] (c) Spinneret specifications: number of holes × ∩ shape number × aperture is 36 × 12 × 0.30mm;

[0080] (d) Screw extruder: Dingdao components Adventitious island component

[0081] (e) Metering pump specifications: wheel type fixed island component 0.6cc / rev, variable island core layer component 1.2cc / rev;

[0082] (f) Cooling air tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com