Three-effect liquid laundry detergent composition and preparation method thereof

A laundry liquid and composition technology, which is applied in the directions of detergent compositions, surface-active detergent compositions, chemical instruments and methods, etc., can solve the problem of hard clothes, increased laundry costs, and cumbersome and time-consuming household chores, etc. problem, to achieve the effect of not easy to pilling, rapid and complete biodegradation, and good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Three-in-one laundry detergent composition, in parts by mass, comprises the following ingredients:

[0031] Cationic softener 0.02%~15%;

[0032] Modified silicone oil 0.01%~10%;

[0033] Non-ionic surfactant 2% to 50%;

[0034] Enzyme 0.02%~6%;

[0035] Enzyme stabilizer 0.01%~12%;

[0036] The balance is deionized water.

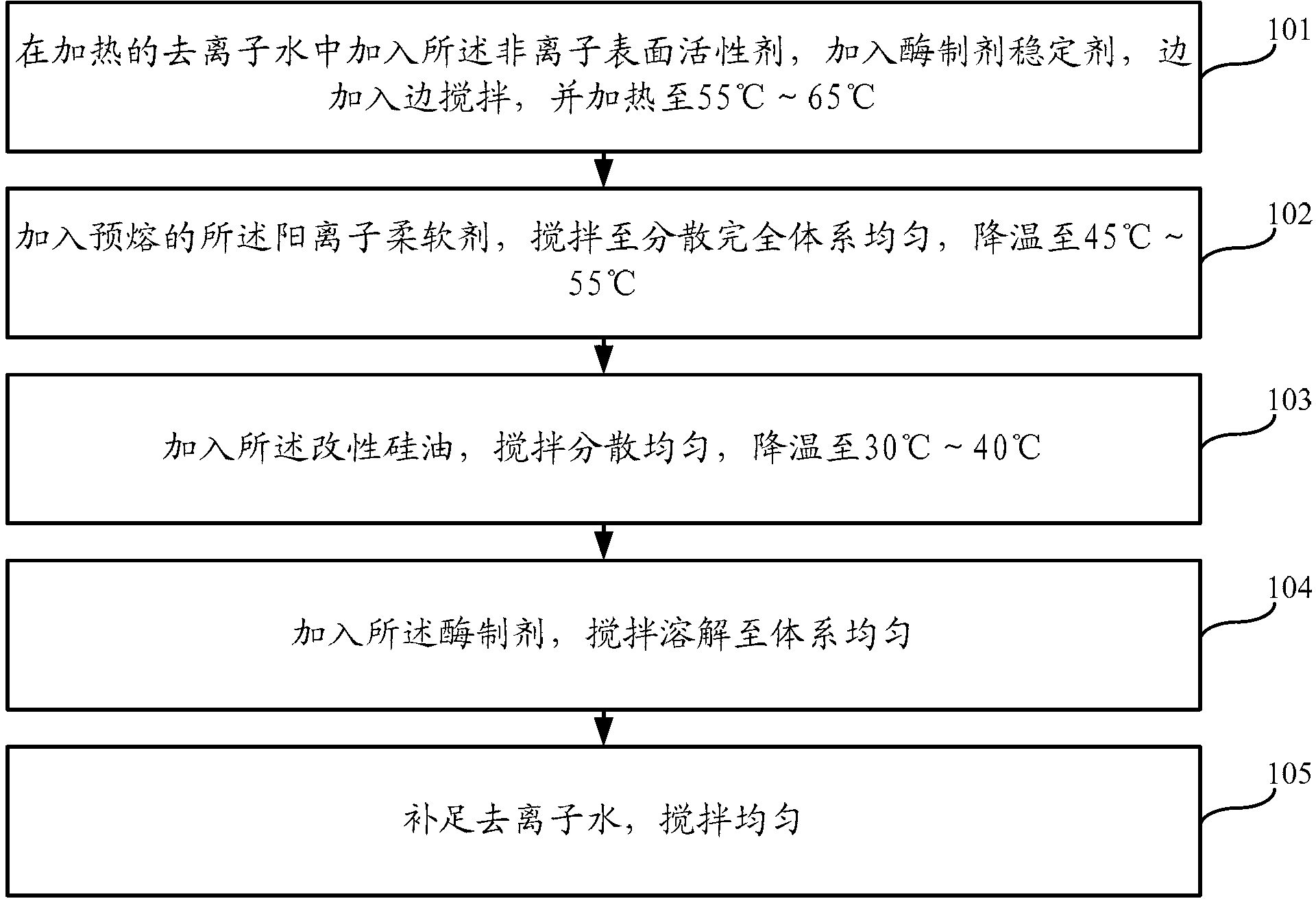

[0037] like figure 1 Shown: the preparation method of the three-in-one laundry detergent composition provided in this embodiment specifically comprises the following steps:

[0038] 101. Add the non-ionic surfactant in the heated deionized water, add the enzyme stabilizer, stir while adding, and heat to 55°C-65°C;

[0039] 102. Add the pre-melted cationic softener, stir until the dispersion is complete and the system is uniform, and cool down to 45°C-55°C;

[0040] 103. Add the modified silicone oil, stir and disperse evenly, and cool down to 30°C-40°C;

[0041] 104. Add the enzyme preparation, stir and dissolve until the syste...

Embodiment 2

[0048] Three-in-one laundry detergent composition, in parts by mass, comprises the following ingredients:

[0049] Cationic softener 0.8%;

[0050] Modified silicone oil 0.1%;

[0051] Cardanol ethoxylate surfactant 9.0%;

[0052] Fatty alcohol polyoxyethylene ether surfactant 8.0%;

[0053] Alkyl glycoside surfactant 5.0%;

[0054] Borax 3.0%

[0055] Protease 0.4%;

[0056] Cellulase 0.2%;

[0057] The balance is deionized water.

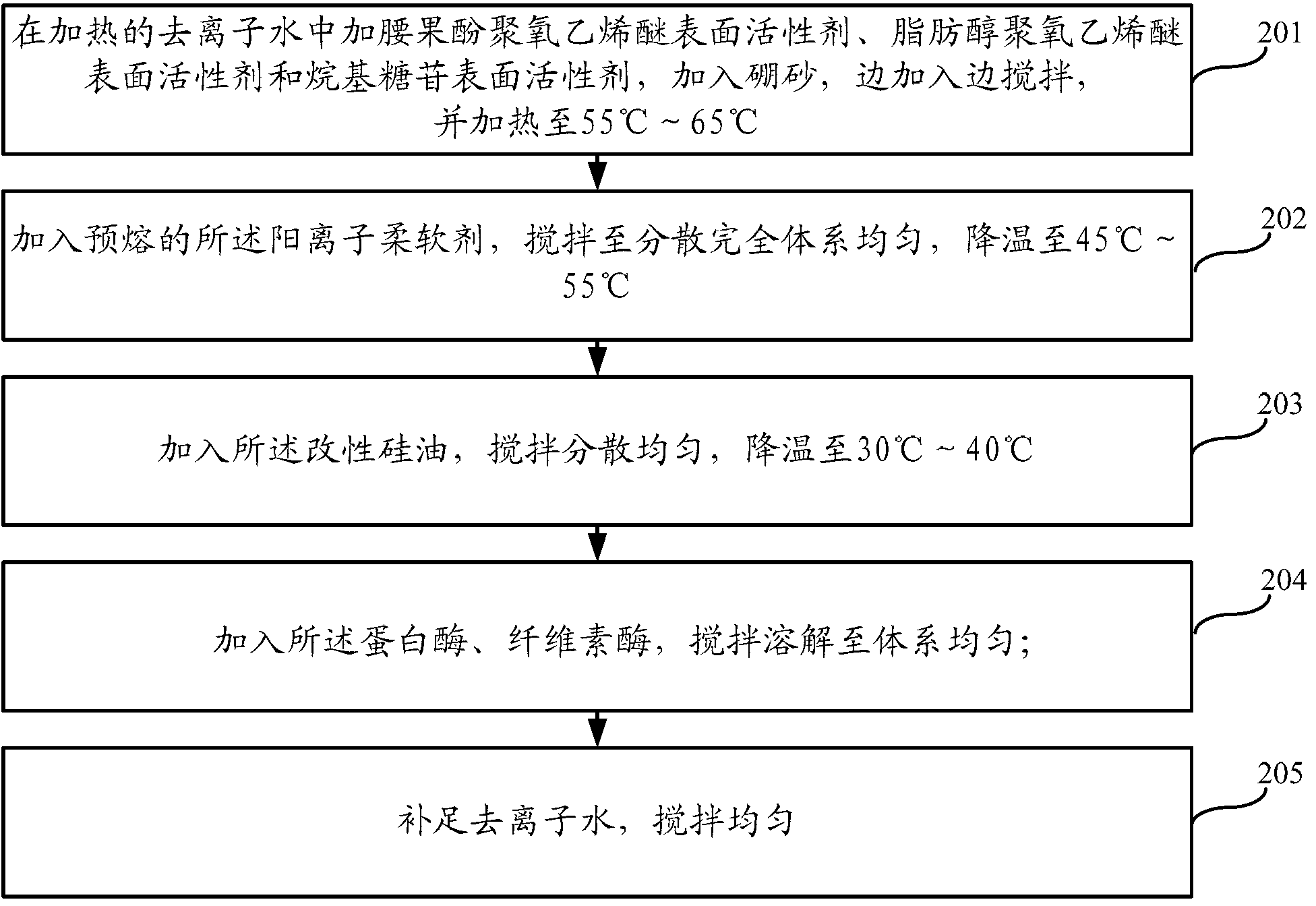

[0058] like figure 2 Shown: the preparation method of the three-in-one laundry detergent composition provided in this embodiment specifically comprises the following steps:

[0059] 201. Add cardanol polyoxyethylene ether surfactant, fatty alcohol polyoxyethylene ether surfactant and alkyl glycoside surfactant to heated deionized water, add borax, stir while adding, and heat to 55°C~ 65°C;

[0060] 202. Add the pre-melted cationic softener, stir until the dispersion is complete and the system is uniform, and cool down to 45°C-55°C;

[...

Embodiment 3

[0085] Three-in-one laundry detergent composition, in parts by mass, comprises the following ingredients:

[0086] Cationic softener 0.6%;

[0087] Modified silicone oil 0.3%;

[0088] Cardanol ethoxylate surfactant 9.0%;

[0089] Fatty alcohol polyoxyethylene ether surfactant 8.0%;

[0090] Alkyl glycoside surfactant 5.0%;

[0091] Protease 0.4%;

[0092] Cellulase 0.2%;

[0093] Borax 2.0%;

[0094] Sodium citrate dihydrate 1.0%;

[0095] Polyacrylic acid (OP301) 0.3%;

[0096] Appropriate amount of pigment;

[0097] Preservative (KF88) 0.1%;

[0098] Fragrance 0.2%;

[0099] The balance is deionized water.

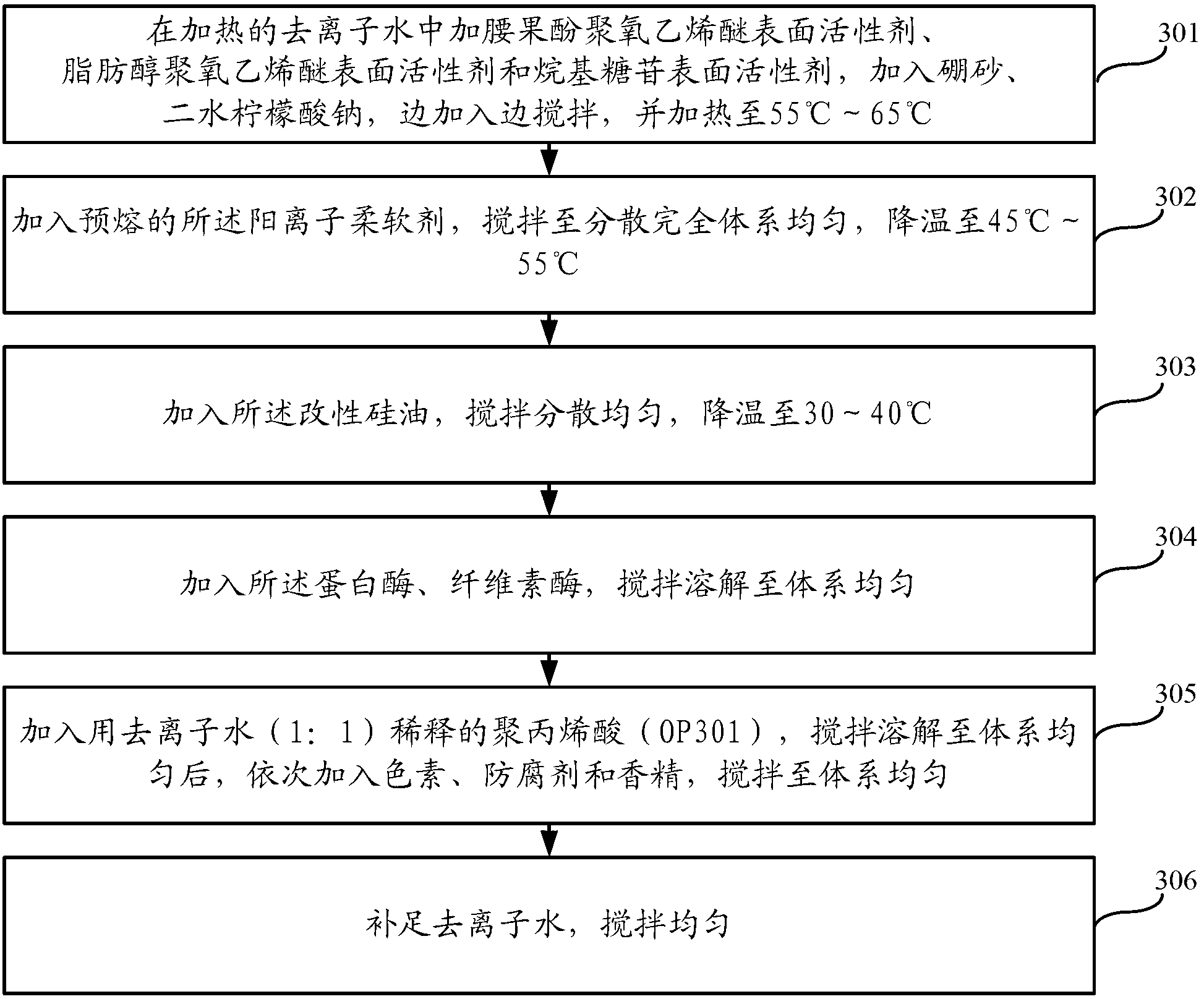

[0100] like image 3 Shown: the preparation method of the three-in-one laundry detergent composition provided in this embodiment specifically comprises the following steps:

[0101] 301. Add cardanol polyoxyethylene ether surfactant, fatty alcohol polyoxyethylene ether surfactant and alkyl glycoside surfactant in heated deionized water, add borax, sodium ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com