Matt textured paper with high layer-to-layer bonding strength and preparation method of paper

A technology of combining strength and textured paper, applied in the field of papermaking, can solve the problems of single textured paper product, poor bonding strength between layers, and poor diversity of artistic sense, achieve good physical strength indicators, improve the bonding strength between layers, Moderate beating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

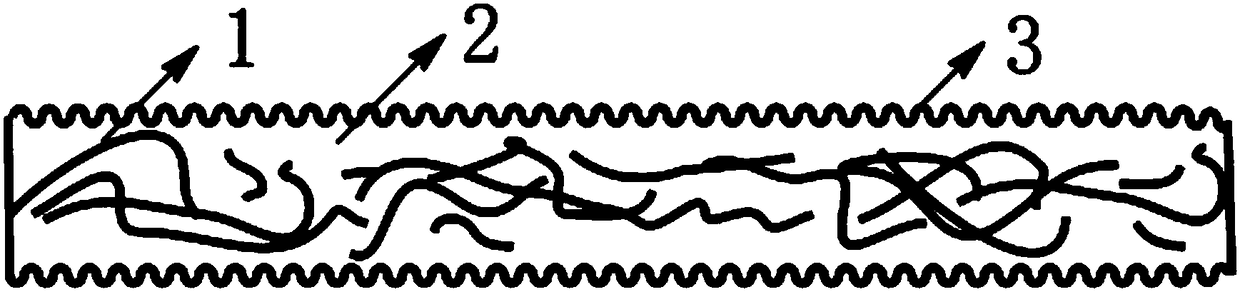

Image

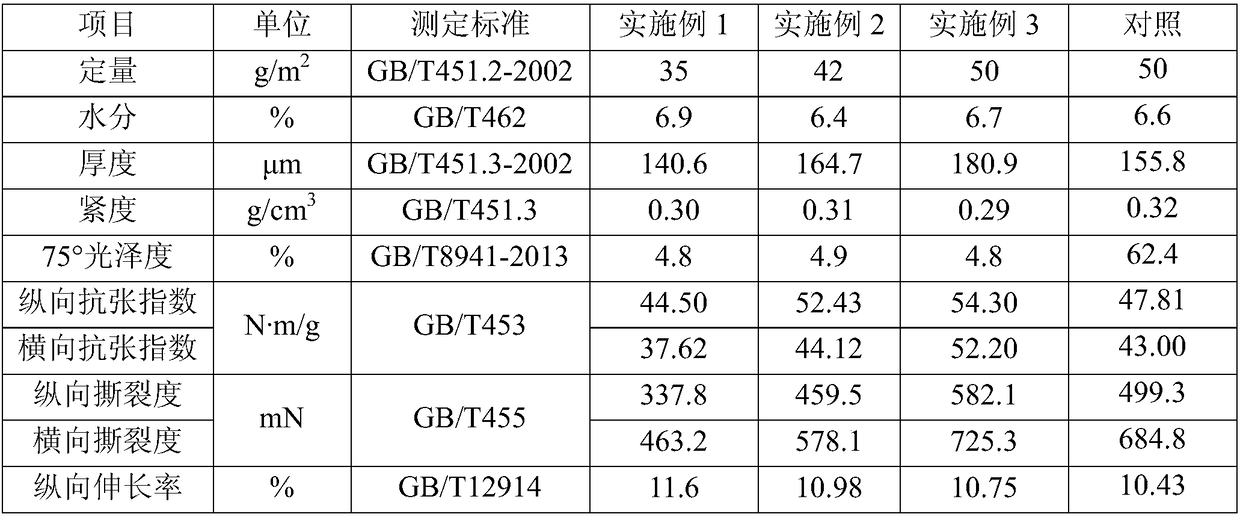

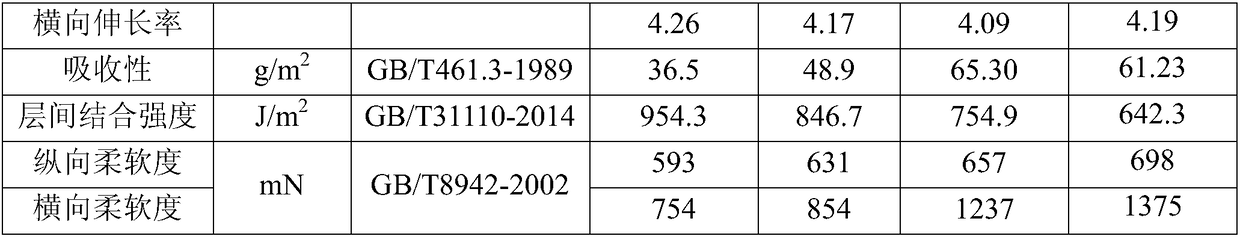

Examples

Embodiment 1

[0057] (1) preparation of online slurry;

[0058] ① stock preparation

[0059] Among them, the bleached coniferous wood pulp board is disintegrated by a hydraulic pulper, and after screening and slag removal, beating is carried out to a beating degree of 30°SR to obtain bleached softwood pulp for use; the bleached hardwood pulp board is disintegrated by a hydraulic pulper , beating after screening and deslagging, the degree of beating is 25 ° SR, to obtain bleached hardwood pulp, for subsequent use;

[0060] In the pulp pool, the ratio is bleached softwood pulp: the mass ratio of bleached hardwood pulp is 80:20;

[0061] ② Configure the online slurry

[0062] Wet strength agent (polyamide epichlorohydrin resin PAE), quaternary ammonium salt type softener, non-silicon defoamer were added in sequence in the slurry, the addition amount was 0.6wt%, 0.05wt%, 0.03wt% respectively; The dosage of calcium carbonate (above 1000 mesh) is 1.0wt%, and after fully mixing and reacting in ...

Embodiment 2

[0077] (1) preparation of online slurry;

[0078] ① stock preparation

[0079] Among them, the bleached coniferous wood pulp board is disintegrated by a hydropulper, and beating is performed after screening and slag removal, with a beating degree of 35°SR, to obtain bleached softwood pulp for use; wherein the bleached hardwood pulp board is passed through a hydropulper Disintegration, screening, beating after slag removal, beating degree is 30 ° SR, to obtain bleached hardwood pulp, standby;

[0080] The proportioning in the pulp pool is bleached softwood pulp: the mass ratio of bleached hardwood pulp is 85:15;

[0081] ② Configure the online slurry

[0082] Wet strength agent (polyamide epichlorohydrin resin PAE), quaternary ammonium salt type softener, non-silicon defoamer were added in sequence in the slurry, the addition amount was 1.0wt%, 0.1wt%, 0.06wt%; The dosage of calcium carbonate (above 1000 mesh) is 1.2wt%, and after fully mixing and reacting in the slurry stor...

Embodiment 3

[0097] (1) preparation of online slurry;

[0098] ① stock preparation

[0099] Among them, the bleached softwood pulp board is disintegrated by a hydraulic pulper, and after screening and slag removal, it is beaten to a beating degree of 40°SR to obtain bleached softwood pulp for use; the bleached hardwood pulp board is crushed by a hydraulic pulper Solution, beating after screening and deslagging, beating degree is 35 ° SR, obtains bleached hardwood pulp, for subsequent use;

[0100] In the pulp pool, the ratio is bleached softwood pulp: the mass ratio of bleached hardwood pulp is 90:10;

[0101] ② Configure the online slurry

[0102] Wet strength agent (polyamide epichlorohydrin resin PAE), quaternary ammonium salt type softener, non-silicon defoamer were added in turn in the slurry, the addition amount was 1.6wt%, 0.2wt%, 0.1wt%; The dosage of calcium carbonate (above 1000 mesh) is 1.5wt%, and after fully mixing and reacting in the slurry storage tank, sizing is carried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com