A high-ductility fiber-reinforced cement-based composite material for 3D printing and its preparation method

A fiber-reinforced cement and composite material technology, which is applied in the field of cement-based composite material admixtures and 3D high-ductility fiber-reinforced cement-based composite materials, can solve the problems of inability to meet the printability, buildability, interlayer bonding strength, etc. Guaranteed structural integrity and mechanical properties, good buildability, and controllable lateral deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An admixture composition that can improve the applicability of concrete 3D printing, its specific components and dosage are shown in the following table 1:

[0041] Table 1

[0042] Component type Dosage (%) diatomite 18 Ultrafine slag powder 15 Hydroxyethyl Methyl Cellulose Ether 0.5 Lithium salt accelerator 10 Sodium Gluconate Retarder 5 Terpolymer rubber powder of ethylene, vinyl chloride and vinyl laurate 8 Calcium oxide expansion agent 6.5 Naphthalene series superplasticizer 5

Embodiment 2

[0044] An admixture composition that can improve the applicability of concrete 3D printing, its specific components and dosage are shown in Table 2 below:

[0045] Table 2

[0046] Component type Dosage (%) Silica fume 10 rice husk ash 7 xanthan gum 0.2 Sodium metasilicate 10 Sodium citrate retarder 4.8 Vinyl acetate, ethylene and higher fatty acid vinyl ester ternary copolymer rubber powder 10 ettringite expansion agent 16 Polycarboxylate High Performance Water Reducer 5

Embodiment 3

[0048] An admixture composition that can improve the applicability of concrete 3D printing, its specific components and dosage are shown in Table 3 below:

[0049] table 3

[0050] Component type Dosage (%) Nano silica 10 diatomite 7 Silica fume 8 Methylcellulose 0.2 Aluminum sulfate solution 7 Phosphate cellulose retarder 1.8 Acrylate and Styrene Copolymer Powder 2 Calcium oxide expansion agent 2 Polycarboxylate High Performance Water Reducer 2

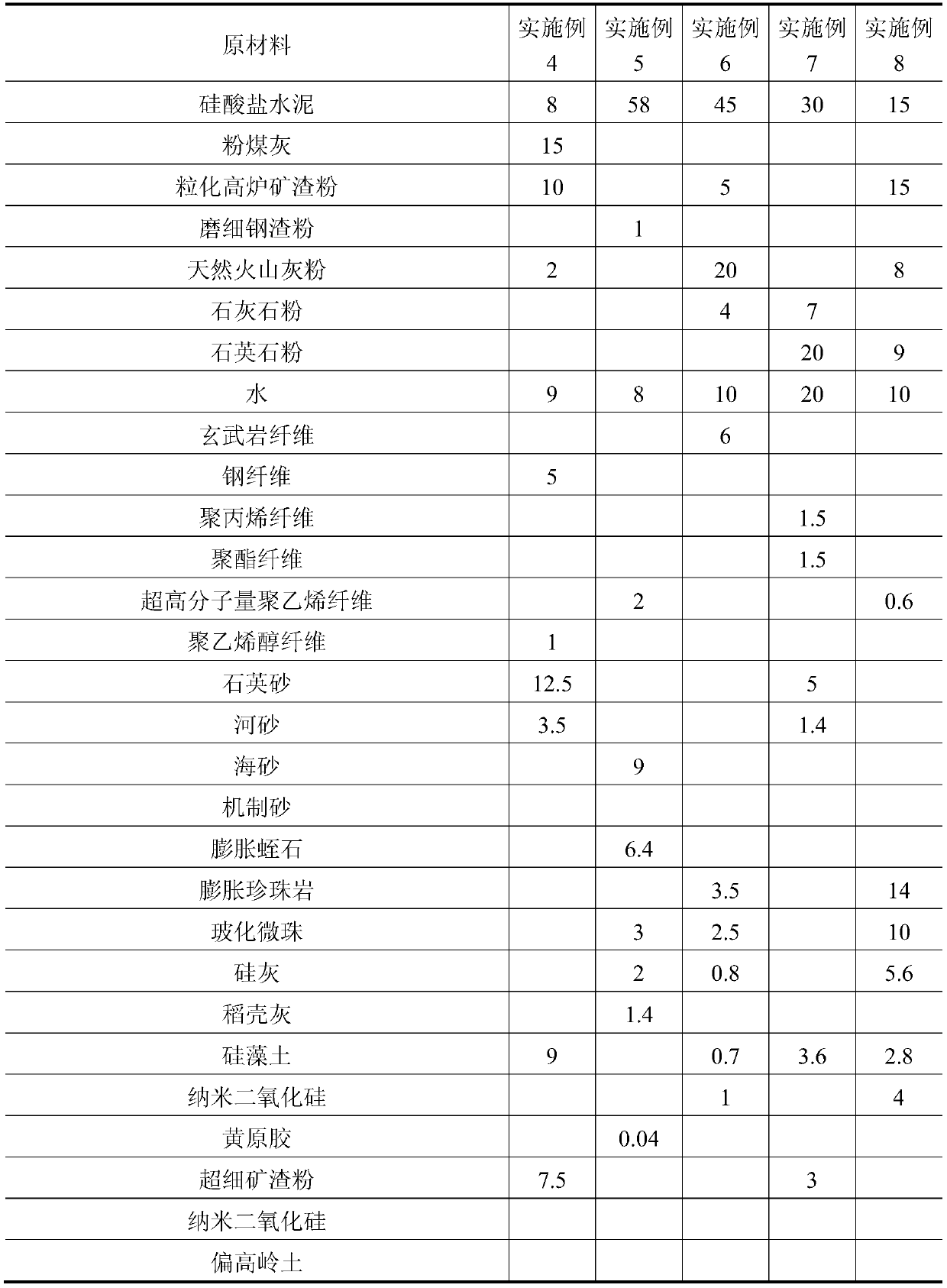

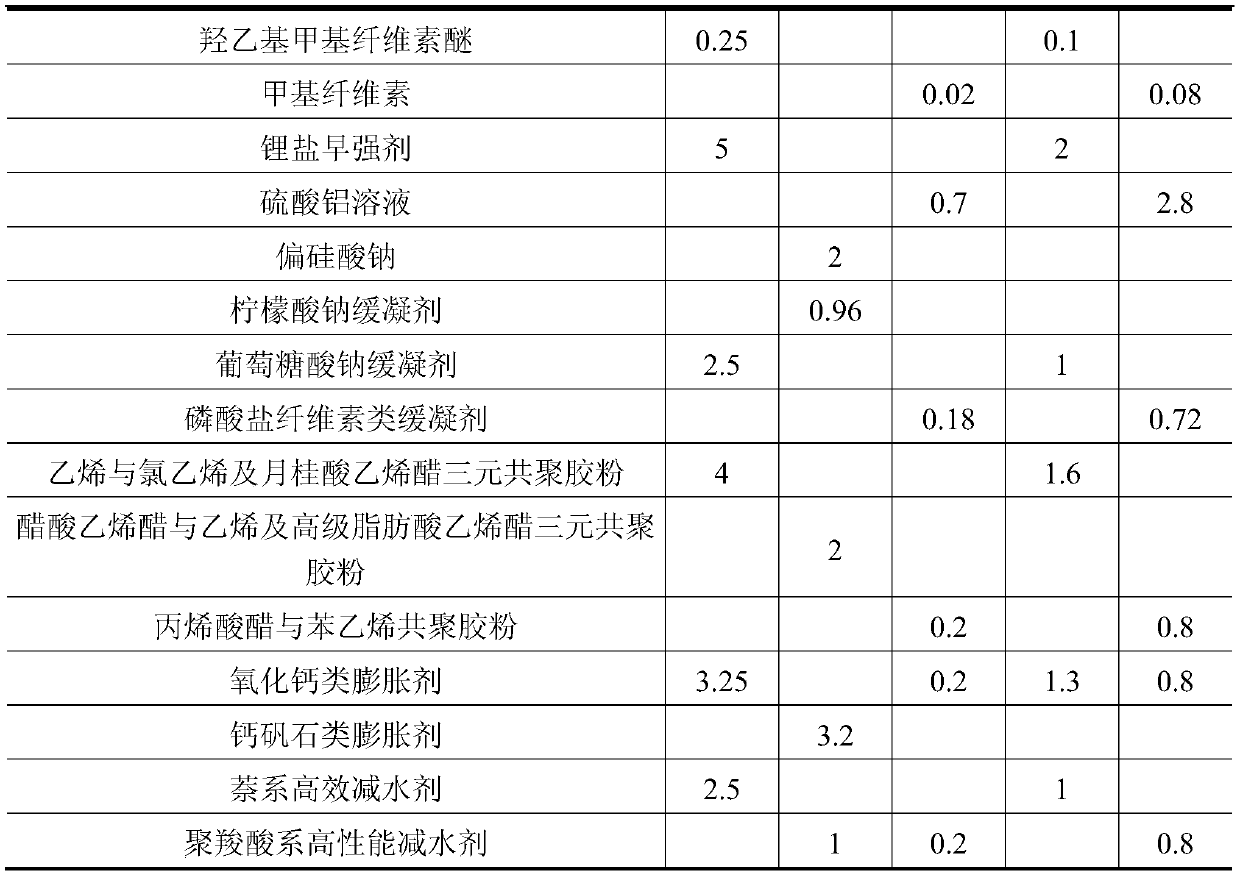

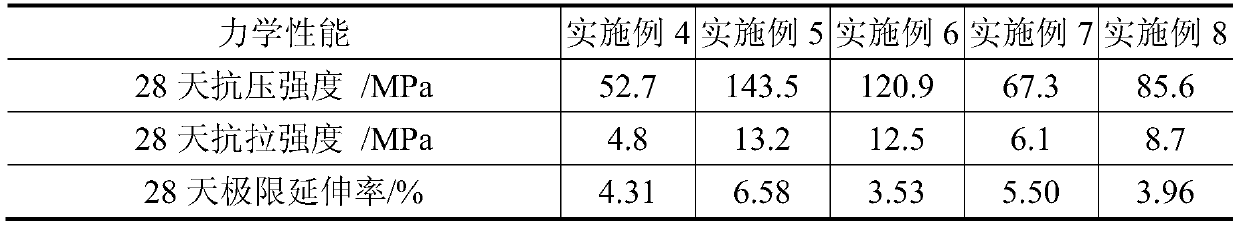

[0051] Examples 4-8 are high-ductility fiber-reinforced cement-based composite materials for 3D printing prepared by using Portland cement, wherein the admixture composition described in Example 1 is added in Examples 4 and 7, and Example 1 5 added the admixture composition described in Example 2, and added the admixture composition described in Example 3 in Example 6. The mixing ratio of each embodiment is shown in Table 4, and the mechanical properties of the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com