Refrigeration film, product comprising refrigeration film

A product and radiation refrigeration technology, which is applied in the field of refrigeration film products and refrigeration films, can solve the problems of low bond strength, fault peeling of refrigeration films, and low surface energy of fluorine-containing resins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

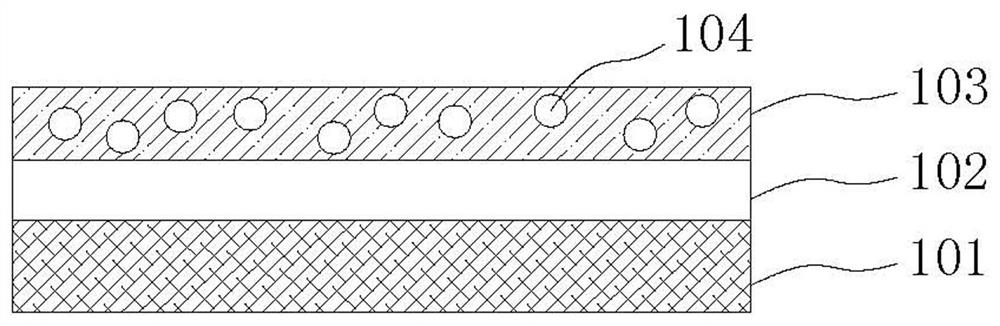

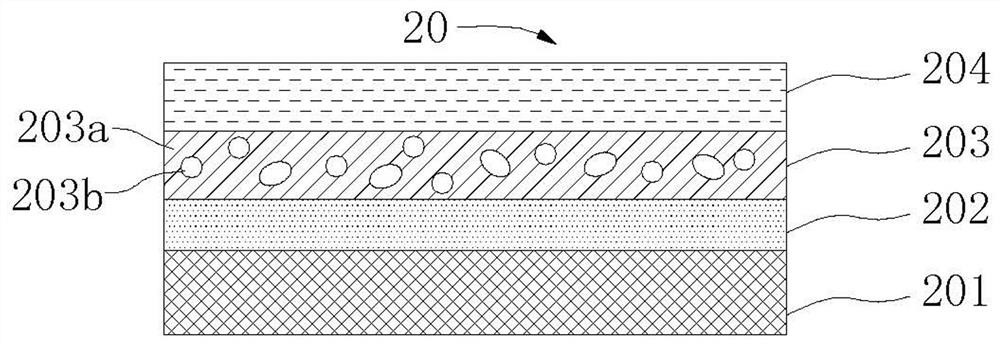

[0070] BOPET with a thickness of 30 μm is provided as a base layer, and a silver reflective layer with a thickness of 100 nm is obtained by magnetron sputtering on the base layer.

[0071] The SiC functional additive with a particle size of 2 μm (refractive index 2.67) was dispersed in the acrylate adhesive (refractive index 1.48) to obtain a mixed solution, and the mass percentage of the SiC functional additive in the mixed solution was 2%. Then the mixed solution was coated on the silver reflective layer and cured to obtain an adhesive layer with a thickness of 3 μm.

[0072] A polyvinylidene fluoride film with a thickness of 25 μm is provided, and the first surface of the polyvinylidene fluoride film is surface-treated by plasma surface treatment, so that the first surface contains hydroxyl or carbonyl polar groups, and then the surface is treated The polyvinylidene fluoride film is laminated on the adhesive layer, and the first surface of the polyvinylidene fluoride film i...

Embodiment 2

[0074] BOPET with a thickness of 50 μm is provided as a base layer, and a silver reflective layer with a thickness of 80 nm is obtained by magnetron sputtering on the base layer.

[0075] SiO with a particle size of 5 μm 2The functional additive (refractive index 1.54) is dispersed in the acrylate adhesive (refractive index 1.48) to obtain a mixed solution, in which SiO 2 The mass percentage of functional additives is 5%. Then the mixed solution was coated on the silver reflective layer and cured to obtain an adhesive layer with a thickness of 8 μm.

[0076] A polyvinylidene fluoride film with a thickness of 35 μm is provided, and the first surface of the polyvinylidene fluoride film is surface-treated by plasma surface treatment, so that the first surface contains hydroxyl or carbonyl polar groups, and then the surface is treated The polyvinylidene fluoride film is laminated on the adhesive layer, and the first surface of the polyvinylidene fluoride film is bonded to the ad...

Embodiment 3

[0078] BOPET with a thickness of 75 μm is provided as a base layer, and a silver reflective layer with a thickness of 300 nm is obtained by magnetron sputtering on the base layer.

[0079] The SiC functional additive with a particle size of 15 μm (refractive index 2.67) was dispersed in the acrylate adhesive (refractive index 1.48) to obtain a mixed solution, and the mass percentage of the SiC functional additive in the mixed solution was 0.5%. Then the mixed solution was coated on the silver reflective layer and cured to obtain an adhesive layer with a thickness of 20 μm.

[0080] A polyvinylidene fluoride film with a thickness of 20 μm is provided, and the first surface of the polyvinylidene fluoride film is surface treated by plasma surface treatment, so that the first surface contains hydroxyl or carbonyl polar groups, and then the surface is treated The polyvinylidene fluoride film is laminated on the adhesive layer, and the first surface of the polyvinylidene fluoride fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com