Lightweight high-ductility cement-based composite material capable of being used for 3D printing and preparation method thereof

A composite material, 3D printing technology, applied in the direction of climate sustainability, additive processing, sustainable waste treatment, etc., can solve problems such as not being able to meet large-scale engineering structures, reducing the buildability of 3D printing, and complex types of raw materials. , to improve the resistance to plastic deformation, the 3D printing process is smooth and fast, and the effect of less variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment provides a kind of preparation method of light sand, comprises the following steps:

[0038] Step 1: The cinder, dolomite and perlite are pulverized by a jaw crusher, and the pulverized material is poured into a ball mill for ball milling for 4-5 hours, and the obtained powder is passed through a 350-mesh sieve. The mass ratio of cinder, dolomite and perlite is 10:1:2, cinder is the main component of light sand, dolomite is mainly used to produce pores of light sand, and perlite is used as auxiliary filling material;

[0039] Step 2. Add the obtained powder into a granulator for stirring at a stirring speed of 150r / min. During the stirring process, spray water mist accounting for 3% of the mass of the powder. When the particle size of the particles is between 80 mesh and 12 mesh Stirring was stopped to obtain semi-finished granules; 0

[0040] Step 3. Transfer the semi-finished granules into a drying kiln, and keep the temperature at 105±5°C for ...

Embodiment 2

[0044] This embodiment provides a light-weight and high-ductility cement-based composite material that can be used for 3D printing, which is obtained by the following preparation steps:

[0045] Step 1. Mix and stir 300 parts of cement, 200 parts of fly ash, 200 parts of rice husk ash, 200 parts of light sand, and 200 parts of glass microspheres to obtain dry material A1;

[0046] Step 2. Pour 15 parts of high-efficiency water reducer into 180 parts of water and stir evenly, then add it to dry material A1 and mix evenly to obtain slurry B1;

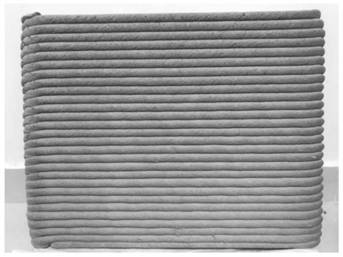

[0047] Step 3, disperse and sprinkle 10 parts of synthetic fibers into the slurry B1, and stir evenly to obtain a lightweight and high-ductility cement-based composite material that can be used for 3D printing. See the specific physical figure in this embodiment figure 1 .

Embodiment 3

[0049] This embodiment provides a light-weight and high-ductility cement-based composite material that can be used for 3D printing, which is obtained by the following preparation steps:

[0050] Step 1. Mix and stir 350 parts of cement, 200 parts of fly ash, 150 parts of rice husk ash, 250 parts of light sand, and 150 parts of glass microspheres to obtain dry material A2;

[0051] Step 2. Pour 18 parts of high-efficiency water reducer into 170 parts of water and stir evenly, then add it to dry material A2 and mix evenly to obtain slurry B2;

[0052] Step 3, disperse and sprinkle 15 parts of synthetic fibers into the slurry B2, and stir evenly to obtain a lightweight and high-ductility cement-based composite material that can be used for 3D printing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com