Steel-titanium composite material fuse high-efficiency additive manufacturing system and preparation method

A composite material and additive manufacturing technology, which is applied in the high-efficiency additive manufacturing system and preparation field of steel-titanium composite material fusion wire, can solve the problems of long preparation and production process, achieve good interlayer bonding strength, high quality, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

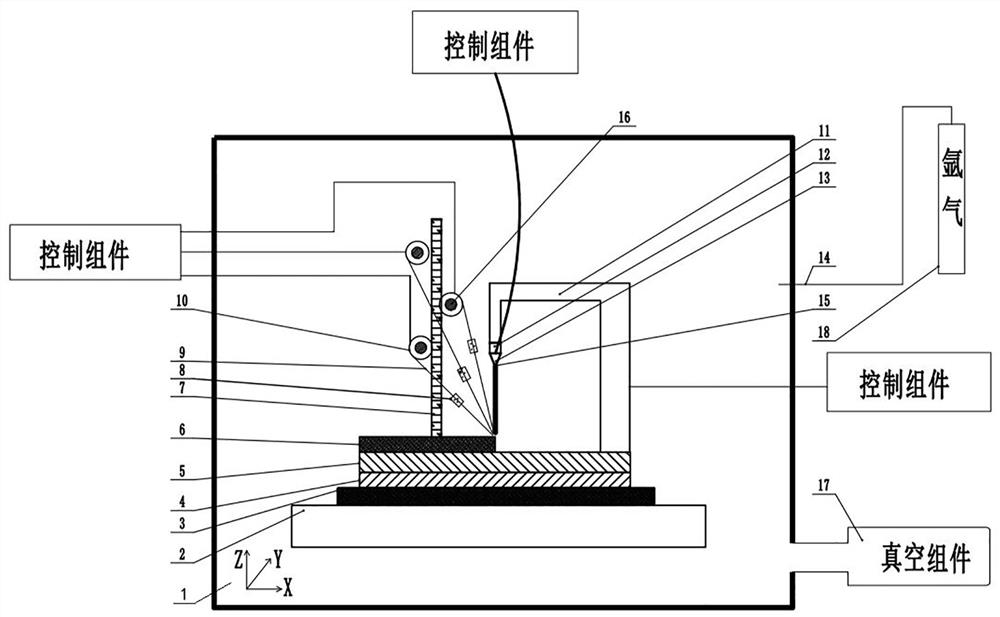

[0035] It should be noted that the structures, proportions, sizes, etc. shown in this specification are only used to cooperate with the content disclosed in the specification for the understanding and reading of those familiar with this technology, and are not used to limit the conditions for the implementation of the present invention , any modification of structure, change of proportional relationship or adjustment of size shall still fall within the scope covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. .

[0036] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

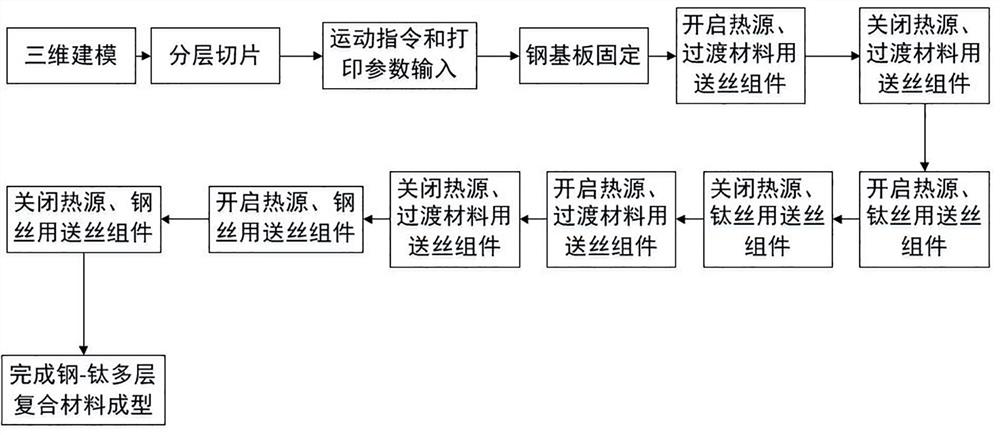

[0038] Such as figure 1 Shown, a kind of preparation method of steel-titanium composite fuse high-efficiency additive, comprises the following steps:

[0039] Step 1) After three-dimensional modeling of the part to be processed of the composite material, use layered slicing software to perform layered slicing and printing path planning on the 3D model obtained from 3D modeling, and output motion command codes that can be recognized by the motion mechanism through the control component;

[0040] Step 2) Adjust the printing parameters of the heat source assembly and the wire feeding assembly through the control assembly, where the printing parameters include heat source power, wire feeding speed and gas flow;

[0041] Step 3) Fix the steel substrate 3 to be processed on the turntable 2 of the movement mechanism in the processing chamber 1, and the turntable 2 of the movement mechanism and the mechanical arm 11 cooperate to move according to the input movement command code to rea...

Embodiment 2

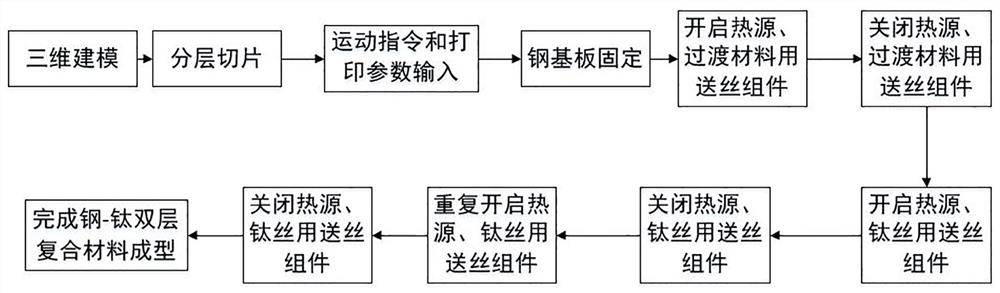

[0051] preferred, such as Figure 4 As shown, the steel-titanium composite material is a double-layer composite structure of steel layer-transition layer-titanium layer-transition layer-steel layer, or steel layer-transition layer-titanium layer-transition layer-steel layer...-transition layer - multilayer composite structure of titanium layer-transition layer-steel layer, wherein the thickness of the steel-titanium composite material is greater than 2 mm, the single layer thickness of the titanium layer 5 is ≥ 1 mm, the single layer thickness of the steel layer 6 is ≥ 1 mm, and the transition layer 4 The thickness is 0.5-1.2 mm, the dilution rate is lower than 3%, and the structure of the steel-titanium composite material is a planar structure or a curved surface structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com