Method for making three-dimension microstructure and

A manufacturing method and microstructure technology, which are applied in the photo-engraving process, optics, opto-mechanical equipment and other directions of the pattern surface, can solve the problem that the continuous surface cannot be used to form shapes, etc., so as to improve the production efficiency, reduce the production cost, and save the plate making. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

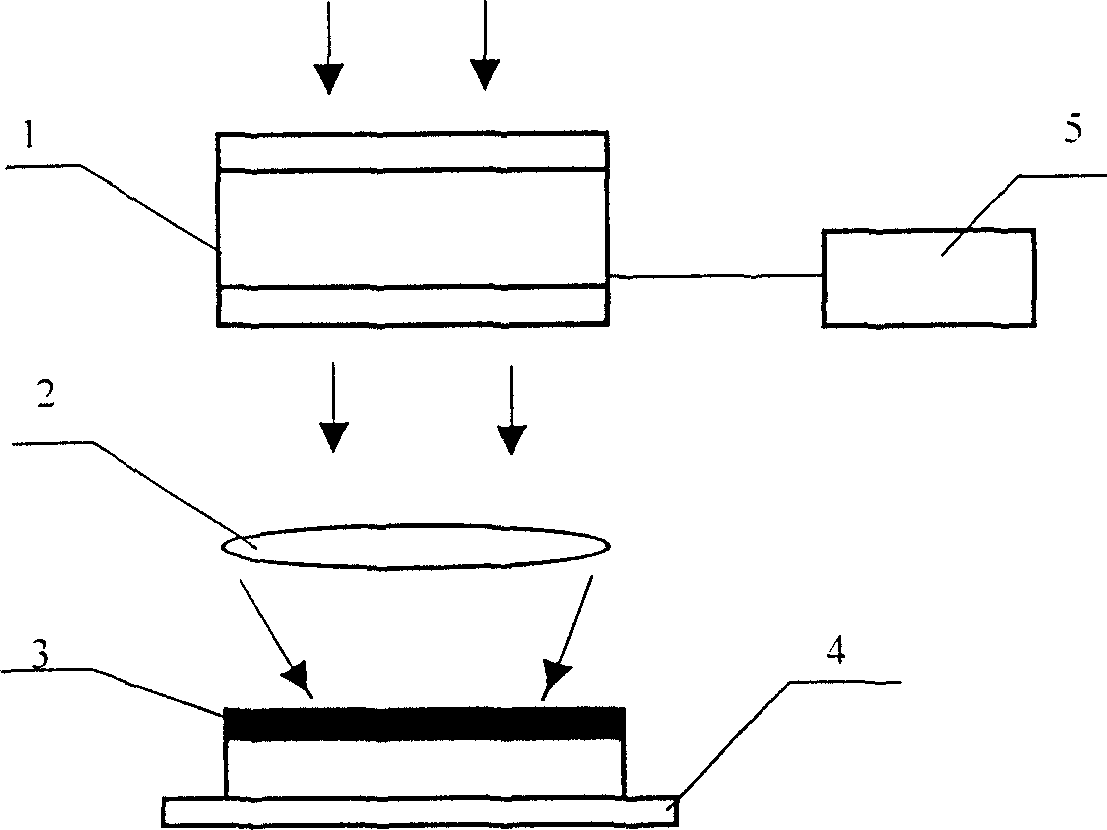

[0030] Such as figure 1 As shown, the exposure device used in the embodiment of the present invention includes a projection exposure lens 2 , an exposure table 4 and a computer 5 . An electrically addressable (or optically addressable) liquid crystal light valve 1 as a real-time mask is placed above the projection exposure lens 2 . The switch of each light-passing unit of the electrical addressing (or optical addressing) liquid crystal light valve 1 is programmed and controlled by the computer 5, which acts as a mask. Each light-passing unit of the liquid crystal light valve 1 corresponds to a sampling point of the mask pattern. Since the switching status of each light-passing unit of the liquid crystal light valve 1 can be continuously refreshed as required, it is called a real-time mask. The projection exposure lens 2 is placed under the liquid crystal light valve 1 . The real-time mask pattern passes through the light-passing unit of the liquid crystal light valve 1 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com