Steam turbine having a cooling apparatus

A technology of steam and fluid machinery, which is applied in the direction of mechanical equipment, engine components, engine functions, etc., and can solve the problems that the internal shell cannot be adjusted and the actual conditions of the heat shield cannot be changed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

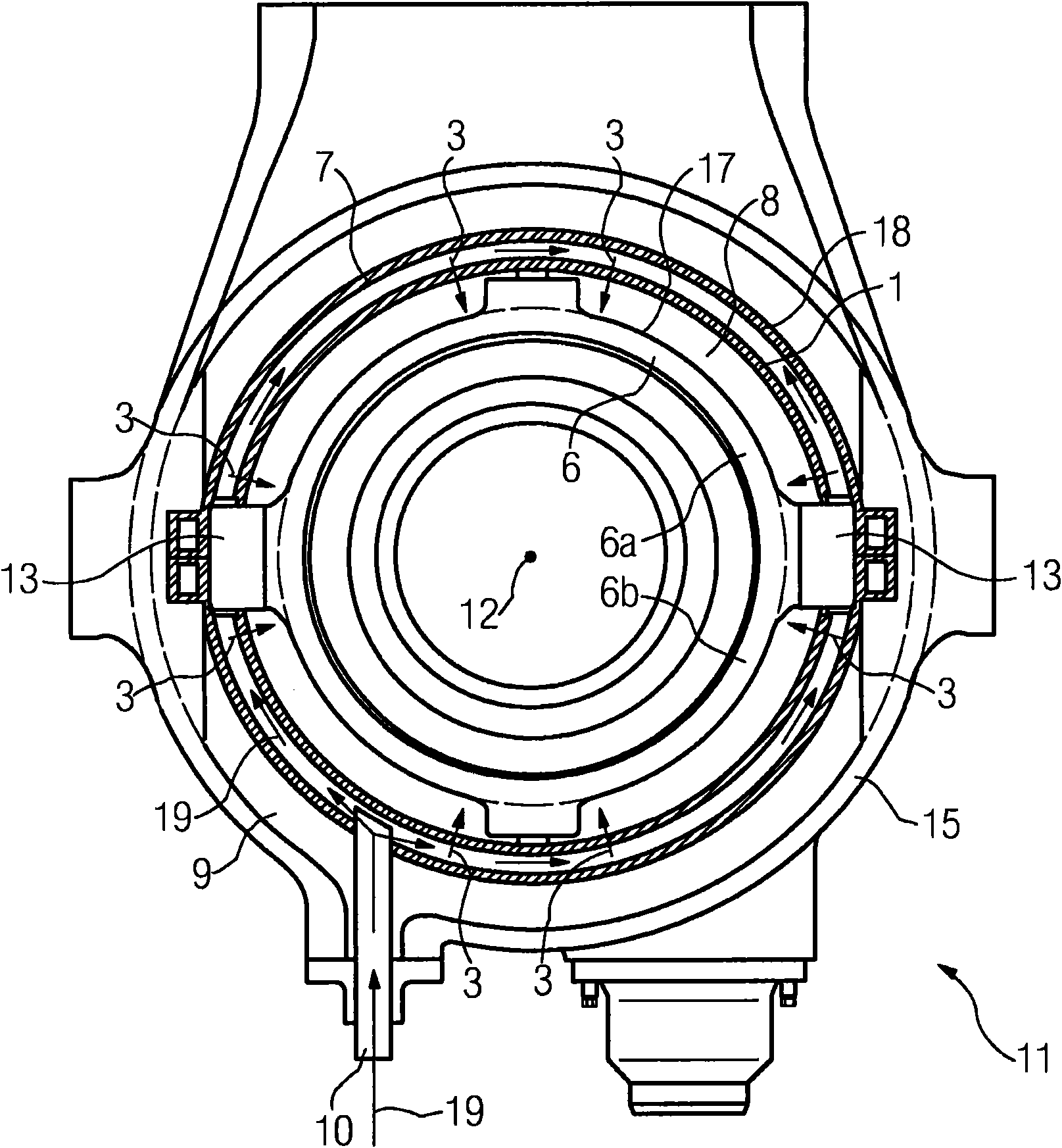

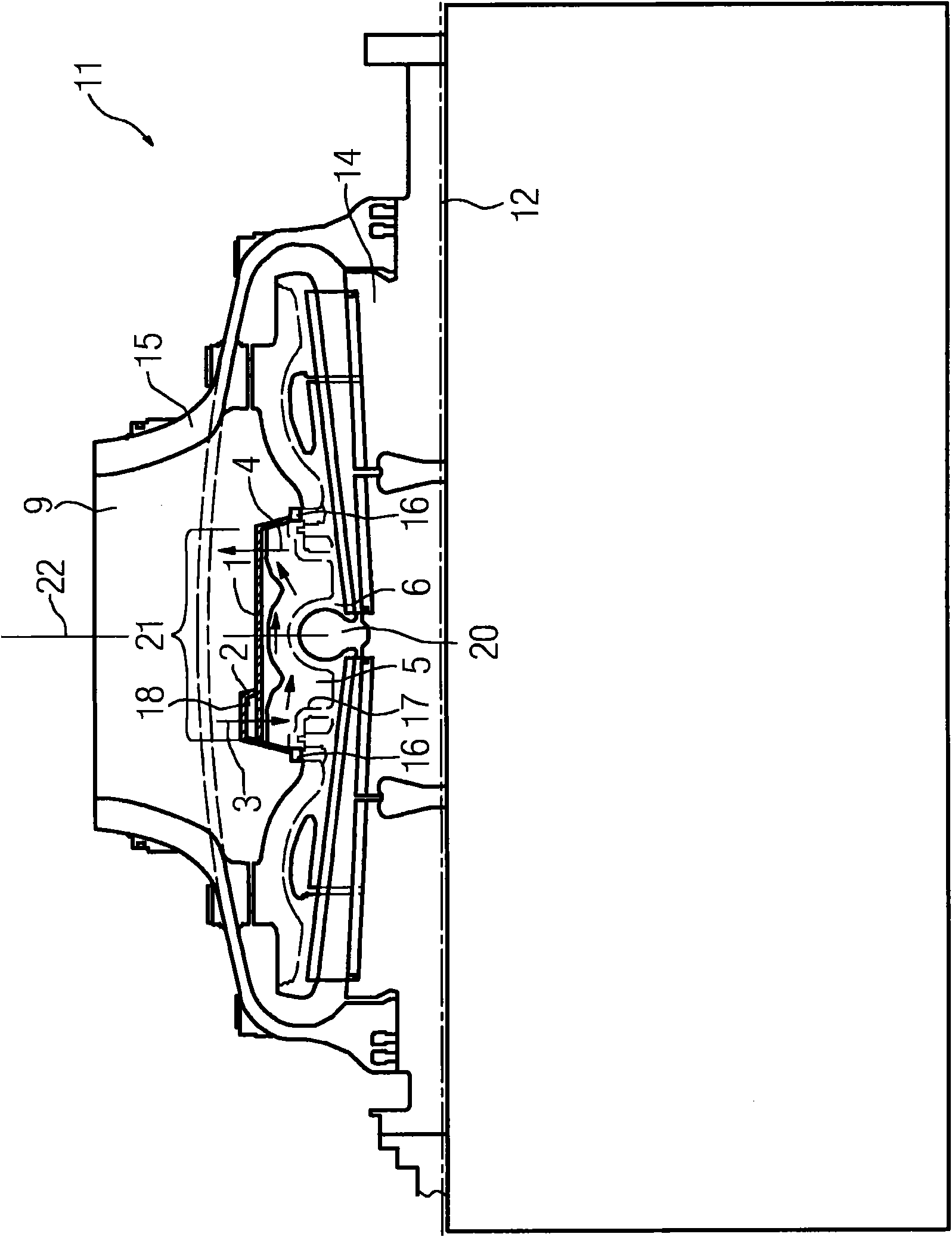

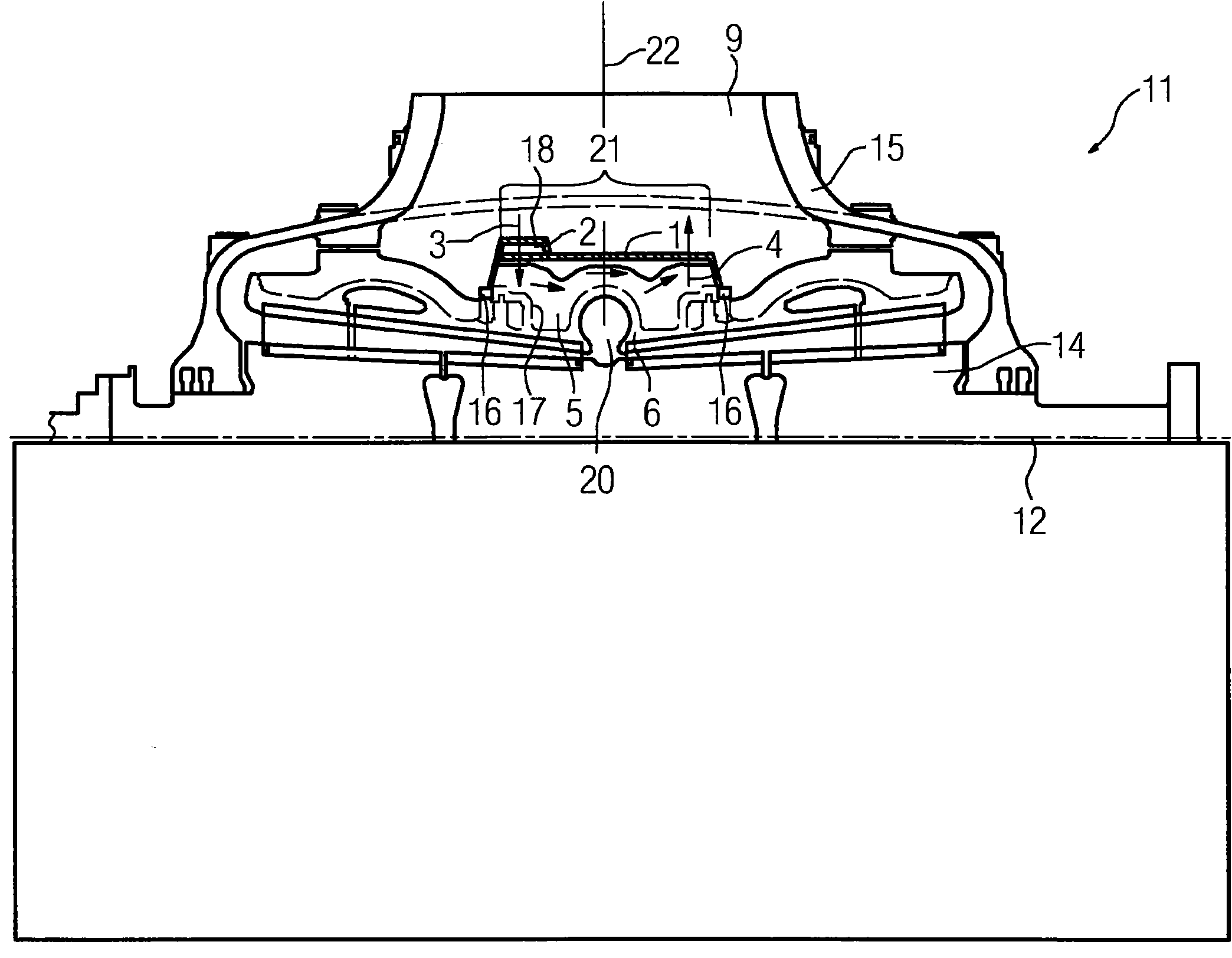

[0022] figure 1 A cross-sectional view along the axial direction of the medium-pressure part-turbine 11 is shown. The medium-pressure part-turbine 11 comprises an inner housing 6 that is substantially rotationally symmetrical about an axis of rotation 12 , wherein the inner housing 6 is composed of an upper inner housing part 6 a and an inner housing lower part 6 b . The inner housing upper part 6 a is connected to the inner housing lower part 6 b via a flange 13 and via screws, not shown in detail. For the sake of clarity, other components, such as the rotor 14, are not shown in detail.

[0023] An outer housing 15 is arranged around the inner housing 6 . In order to shield against heat, the housing 1 is arranged around the inner housing 6 . The outer casing 1 can be made of sheet steel and can be arranged on the inner housing 6 via a thermally movable seal 16 . During operation, intermediate-pressure waste steam is present in the waste steam chamber 9 , which has a signi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com