Omnibearing self-aligning method for detector-optical fiber coupling

A technology of optical fiber coupling and detectors, which is applied in the direction of instruments, using optical devices to transmit sensing components, etc., can solve the problems of inability to realize automatic and accurate positioning, high requirements for operating environment and production technology, and high instability, so as to improve the disposable Success rate, save human resource costs, and improve labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

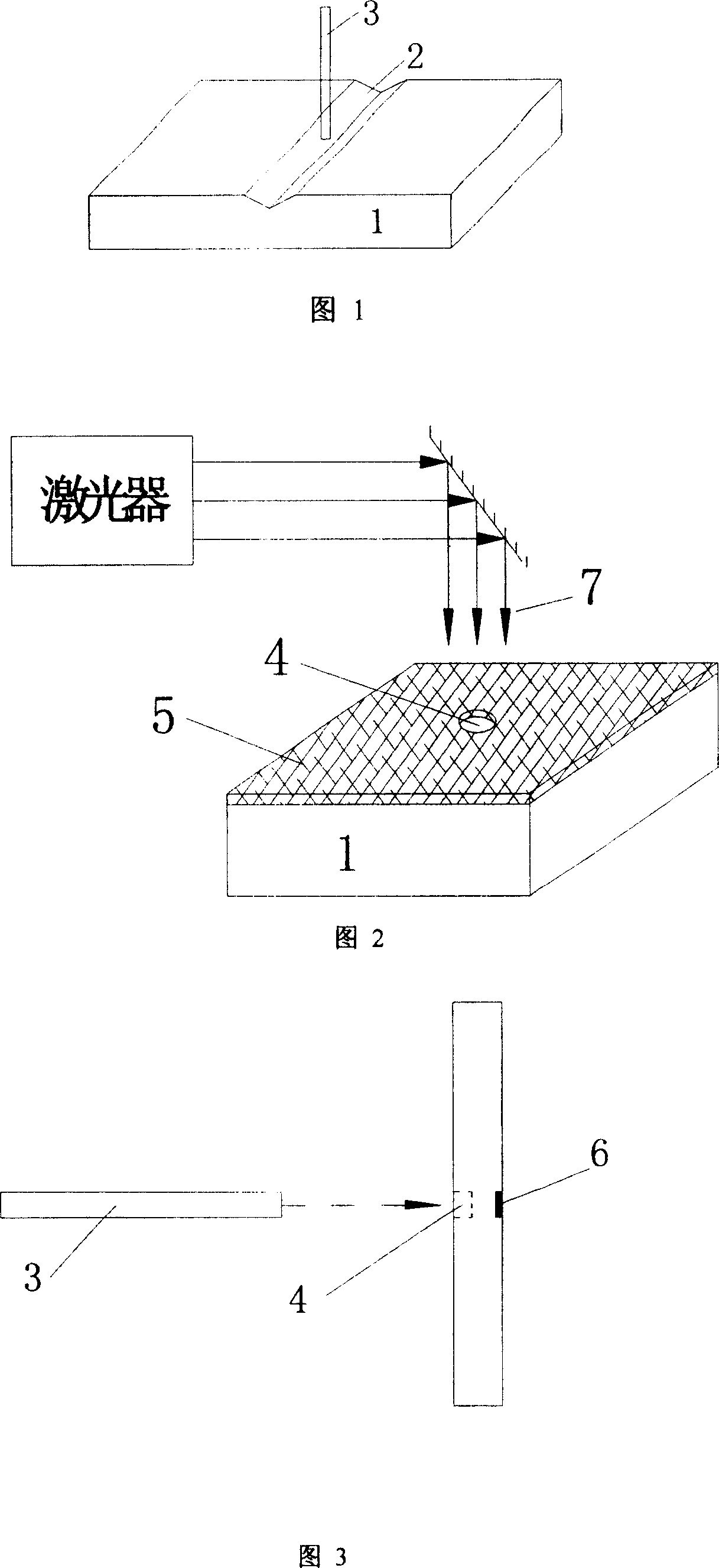

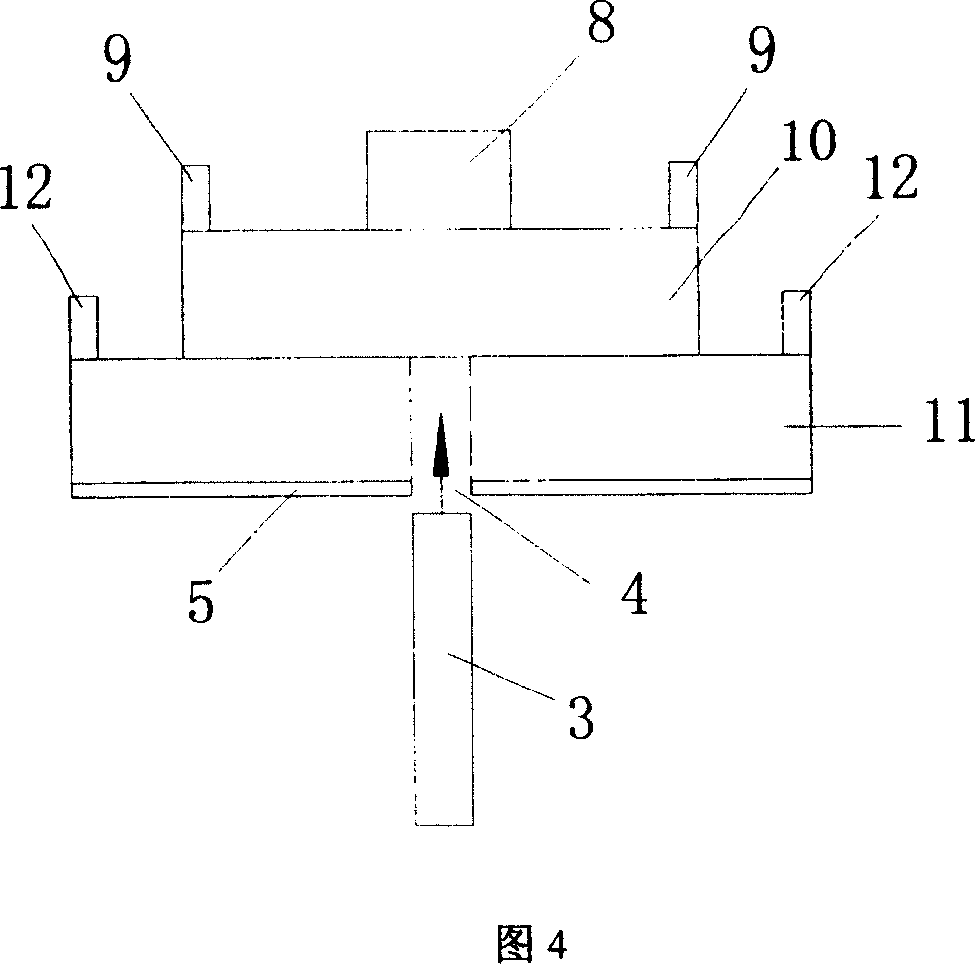

[0038] Realize the detector-fiber omnidirectional self-alignment coupling of InP substrate photodetector with pigtail (as shown in Figure 4)

[0039] Step 1 Prepare the semiconductor InP substrate, and determine the P + The location of the diffusion region 8, the front side of the semiconductor substrate P + The position of the diffusion region 8 corresponds to the InP backside N of the semiconductor substrate + The position of the diffusion area 11 is exactly the position of the corroded circular hole 4, i.e. the position where the light of the back optical fiber 3 is incident; The diameter of the optical fiber 3 is subject to the fact that the optical fiber 3 is inserted into the corroded hole 4 and does not shift; the depth of the hole of the corroded hole 4 is subject to the fact that the optical fiber 3 is inserted into the corroded hole 4 and does not fall off, as shown in Figure 4;

[0040] Step 2 Use the resist film 5 to cover the back surface of the semiconductor su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com