Manufacture method of sheets of V-shaped plate heat exchanger

A technology of a plate heat exchanger and a manufacturing method, applied in the directions of manufacturing tools, forming tools, heat exchange equipment, etc., can solve the problems of uneven flow of metal structure, uneven surface of plates, uneven thinning of plates, etc. Shortened processing time, neat and beautiful appearance, and uniform drawing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

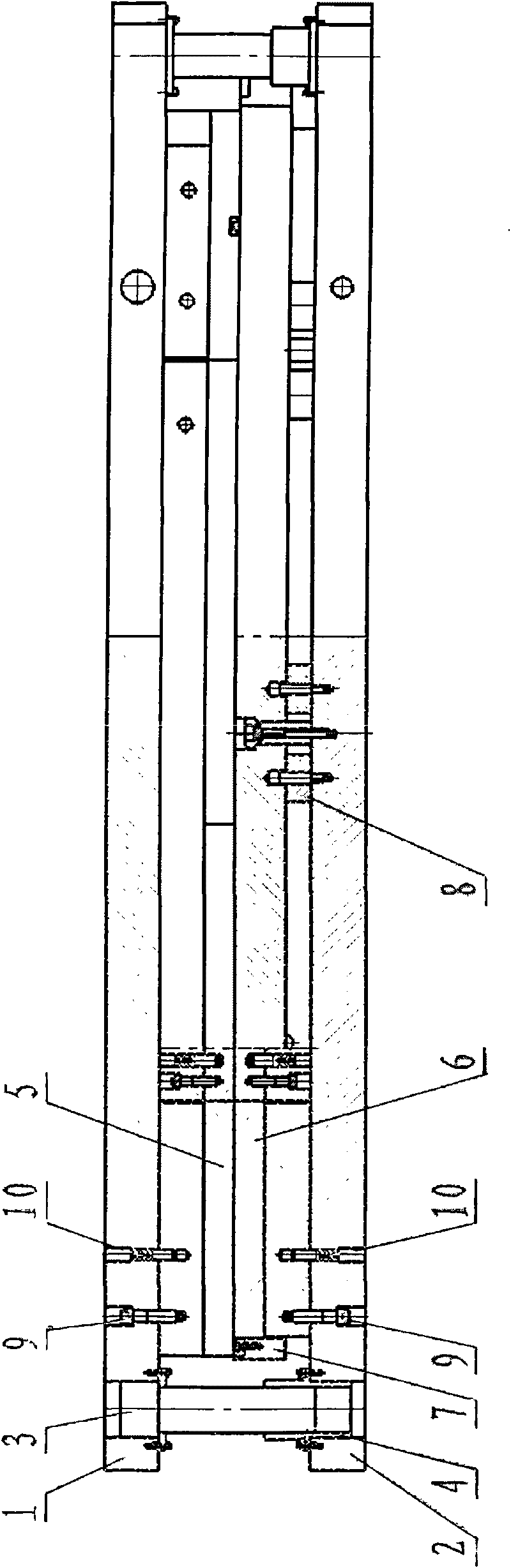

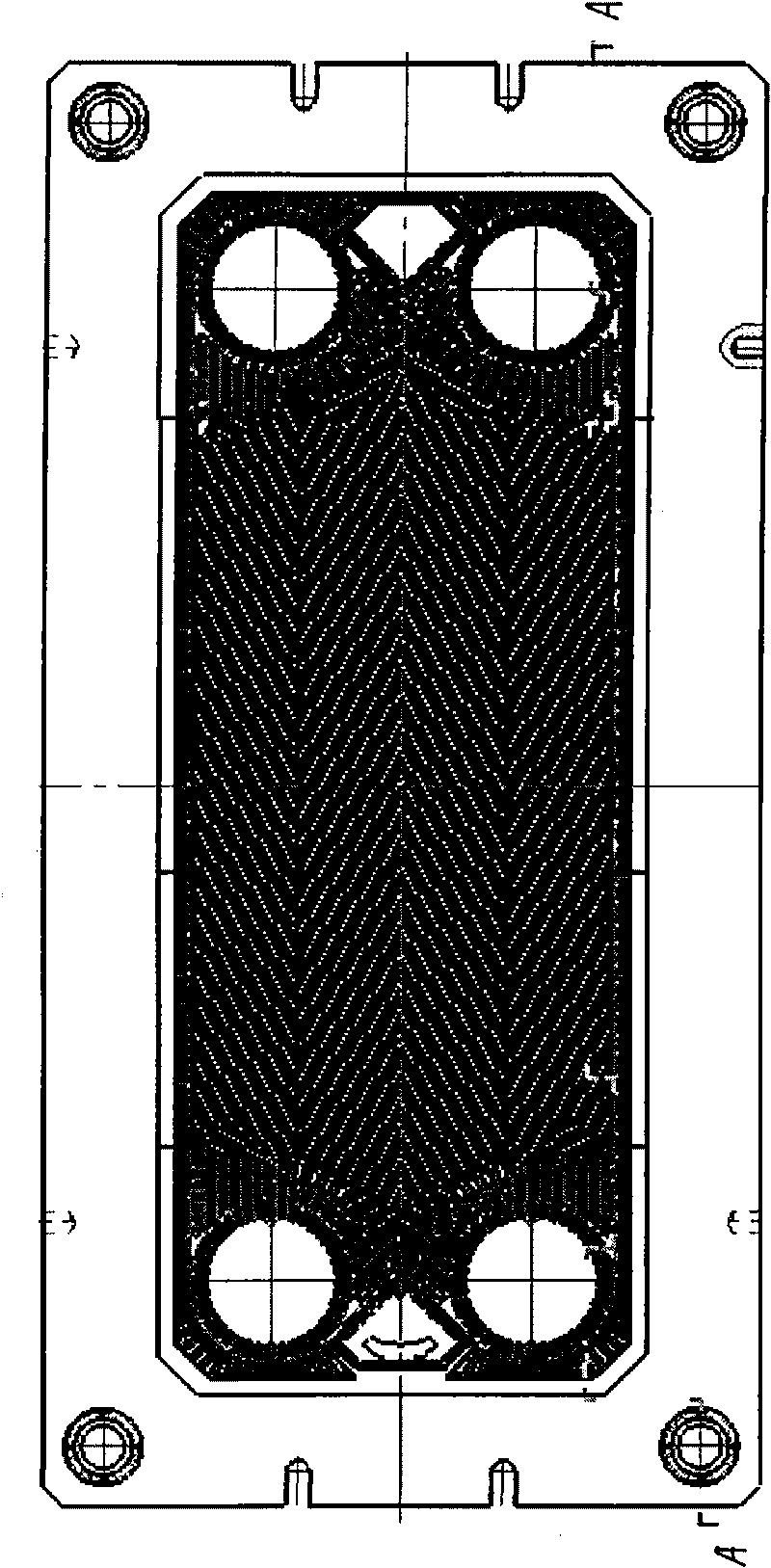

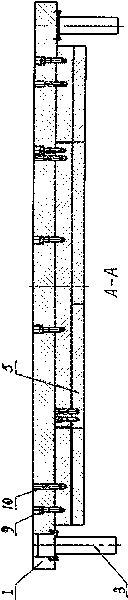

[0026] 1. Plate pressing (by figure 1 , 2 , 3, 4, 5)

[0027] The plate pressing process is realized by the pressing die, and the pressing die includes an upper template 1, a lower template 2, a guide post 3, a guide sleeve 4, a punch insert 5, a die insert 6, an inner Hex bolt 9, pin 10. The splicing of the convex and concave mold inserts 5 and 6 takes the angle of the gasket groove and the angle of the corrugation as the parting surface, and the pressing die also includes a blank holder 7 and a polyurethane binder block 8. When pressing, the blank holder 7 first Press the periphery of the plate tightly, and then press the corrugated mold. A plurality of polyurethane binder blocks 8 are arranged between the lower template 2 and the blank holder ring 7. When pressing, there is a certain pressing force first, and then press down to form. Make the surface stretched evenly after processing.

[0028] 2. The overall blanking of the plate (by Image 6 , 7 , 8, and 9)

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com