Patents

Literature

31results about How to "Unrestricted structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

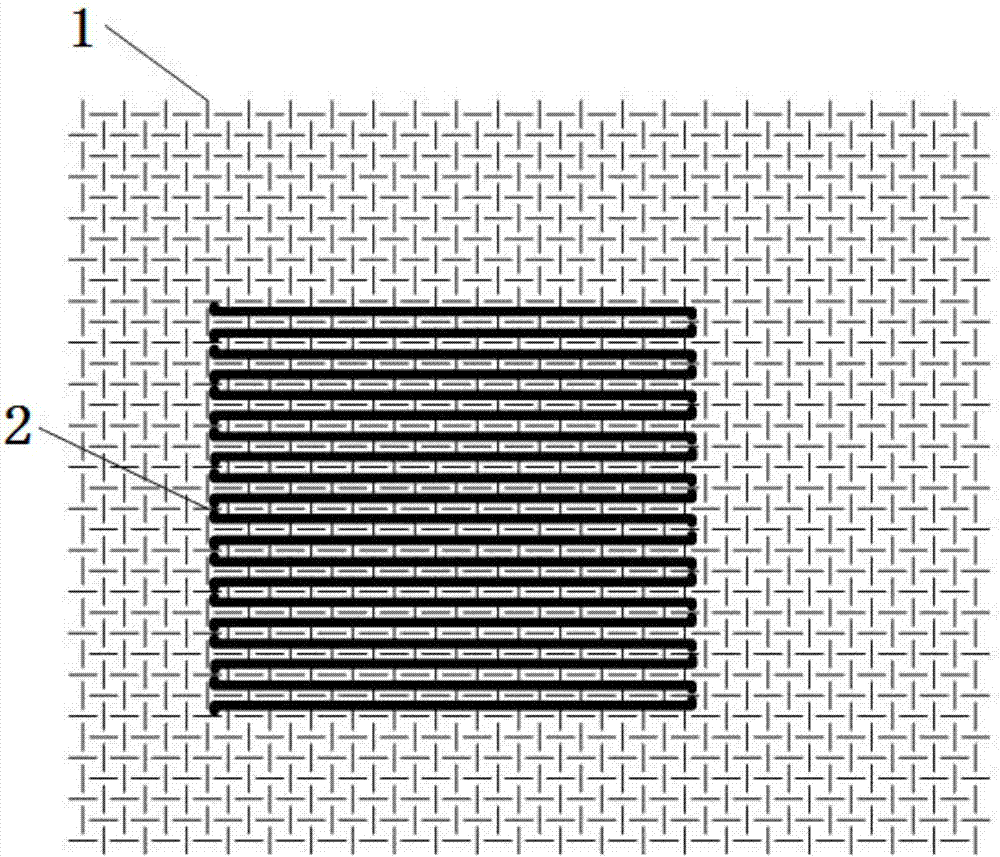

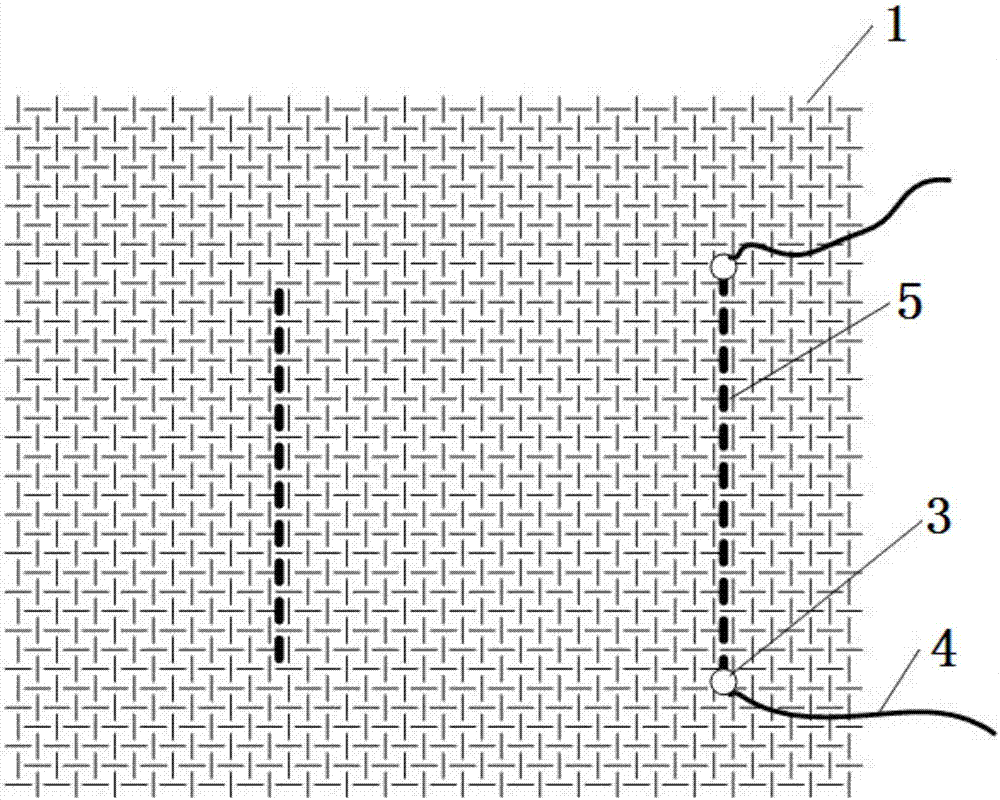

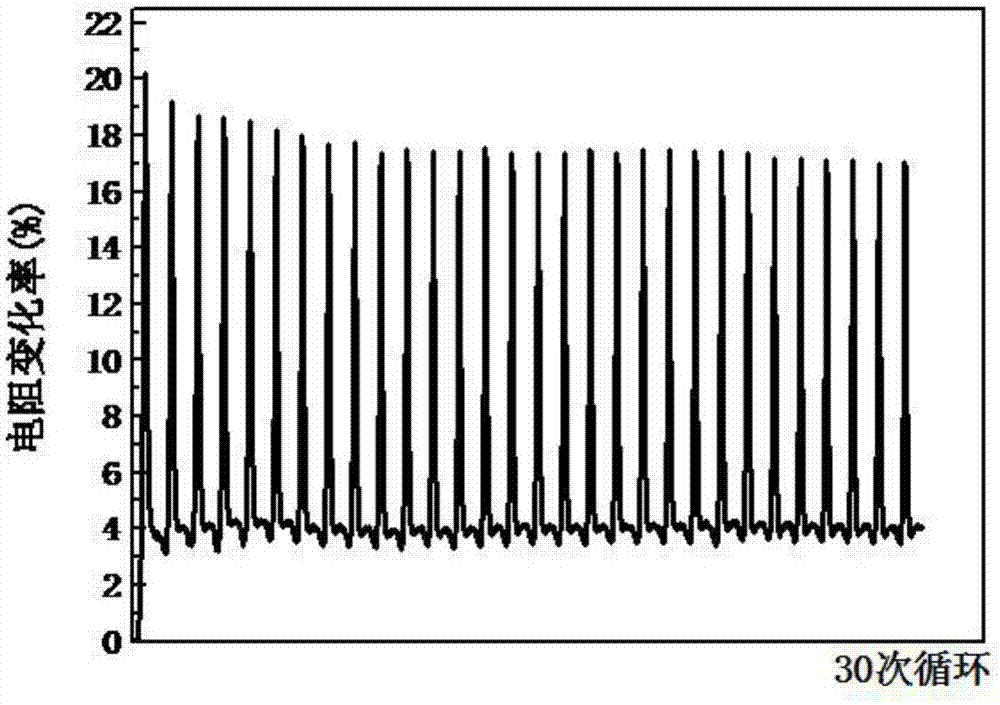

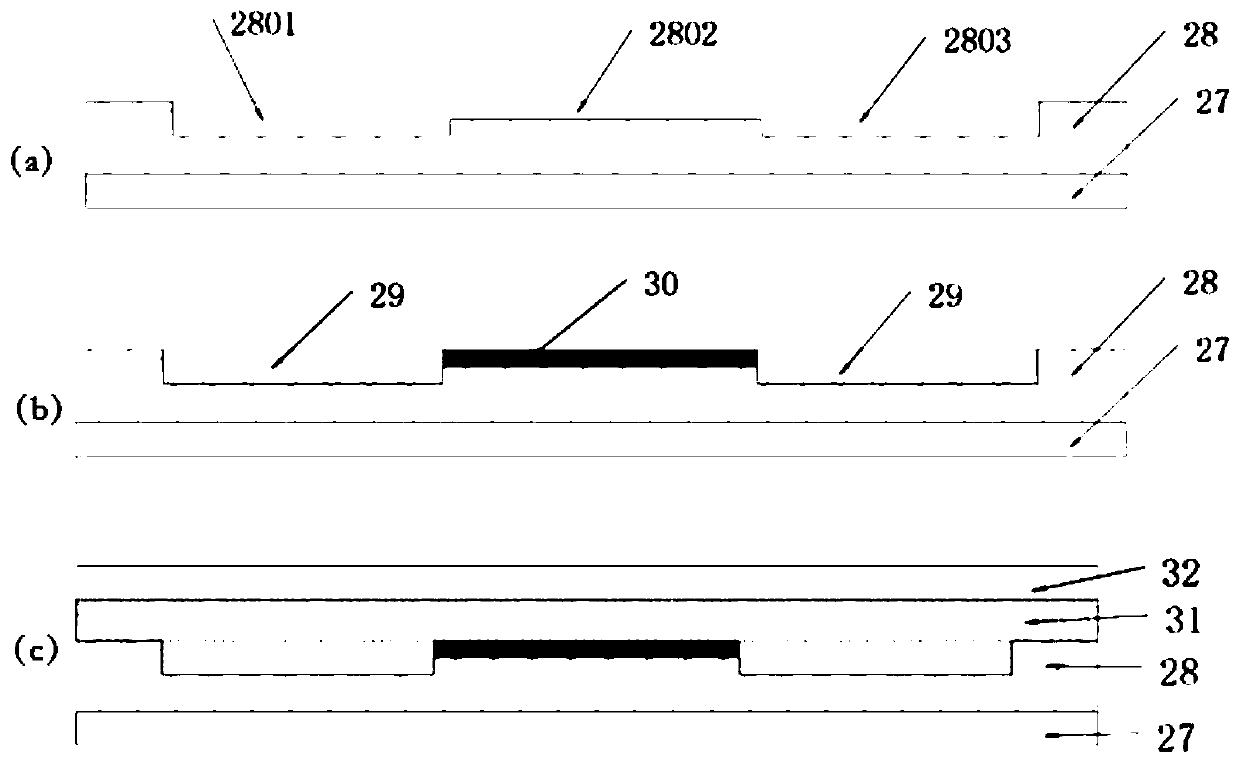

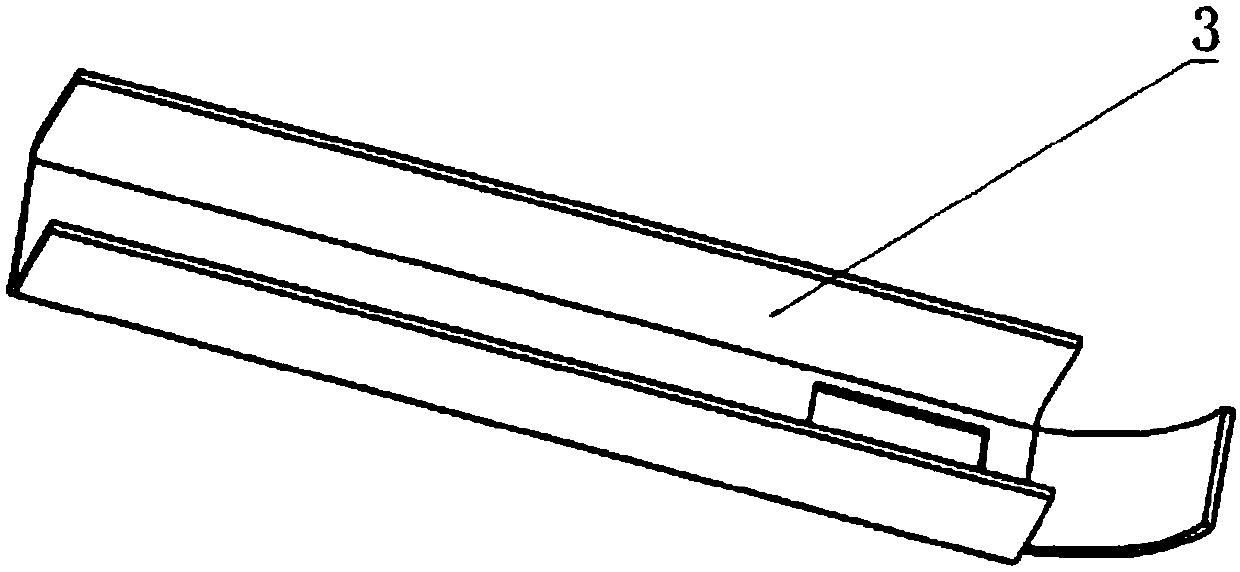

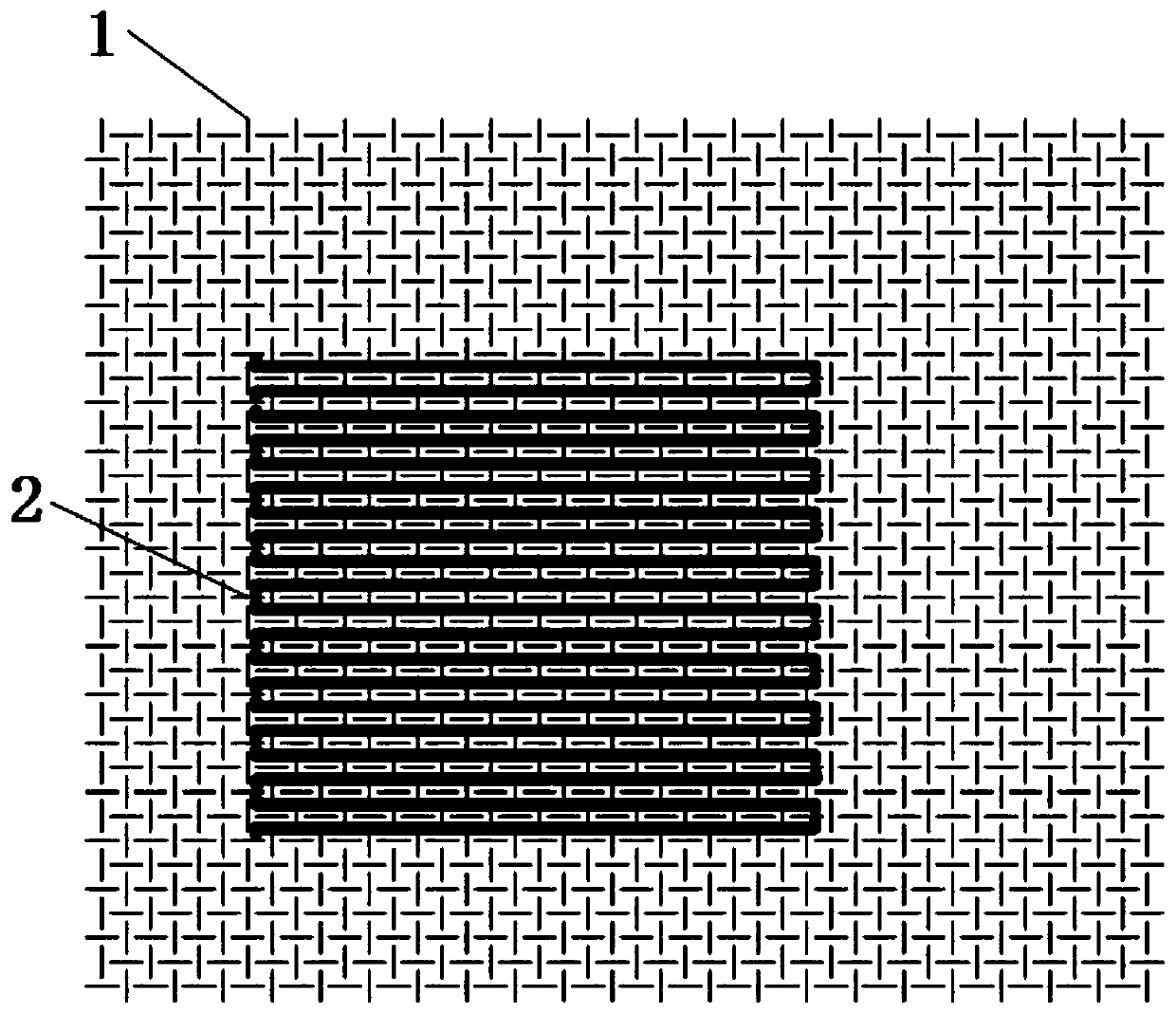

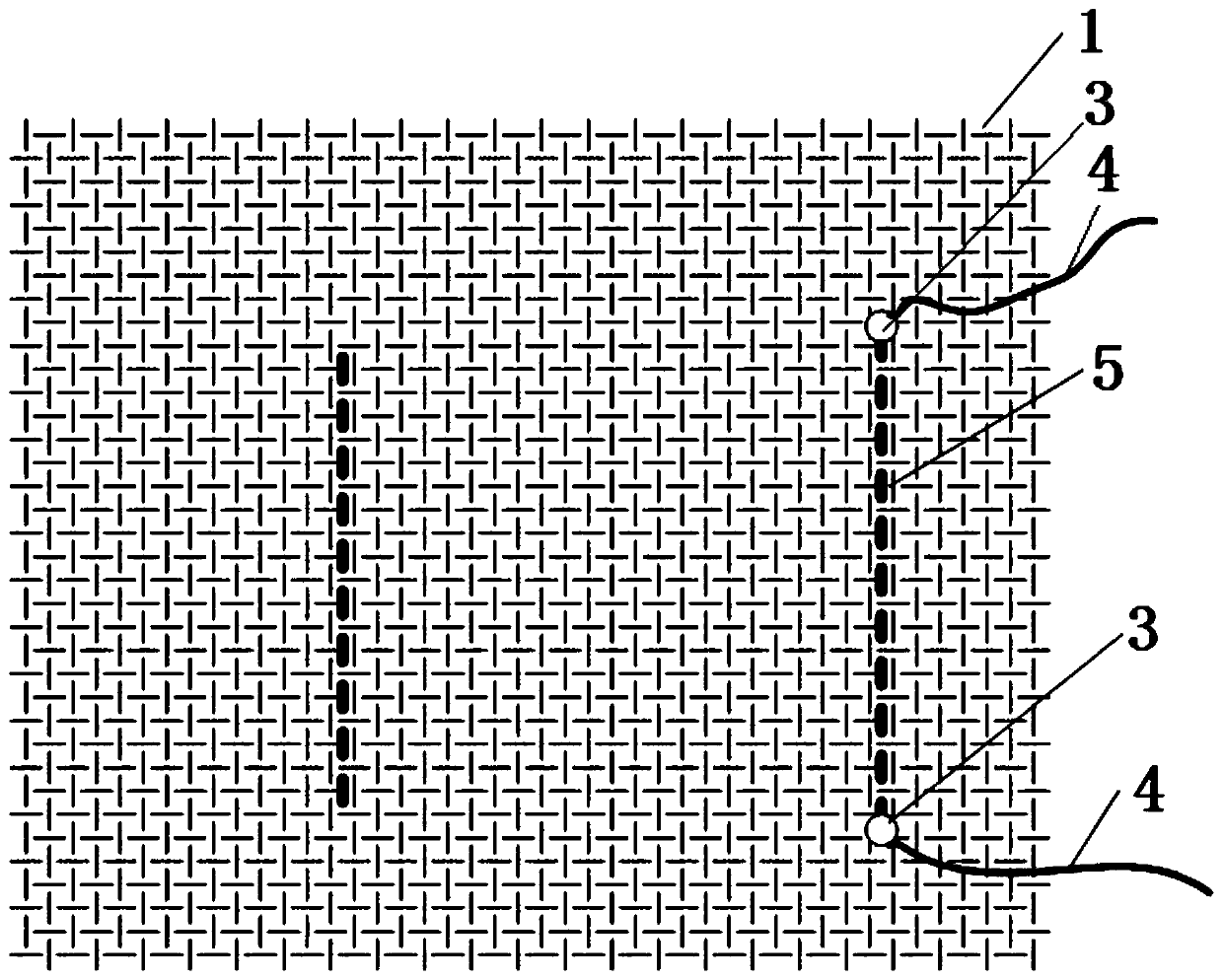

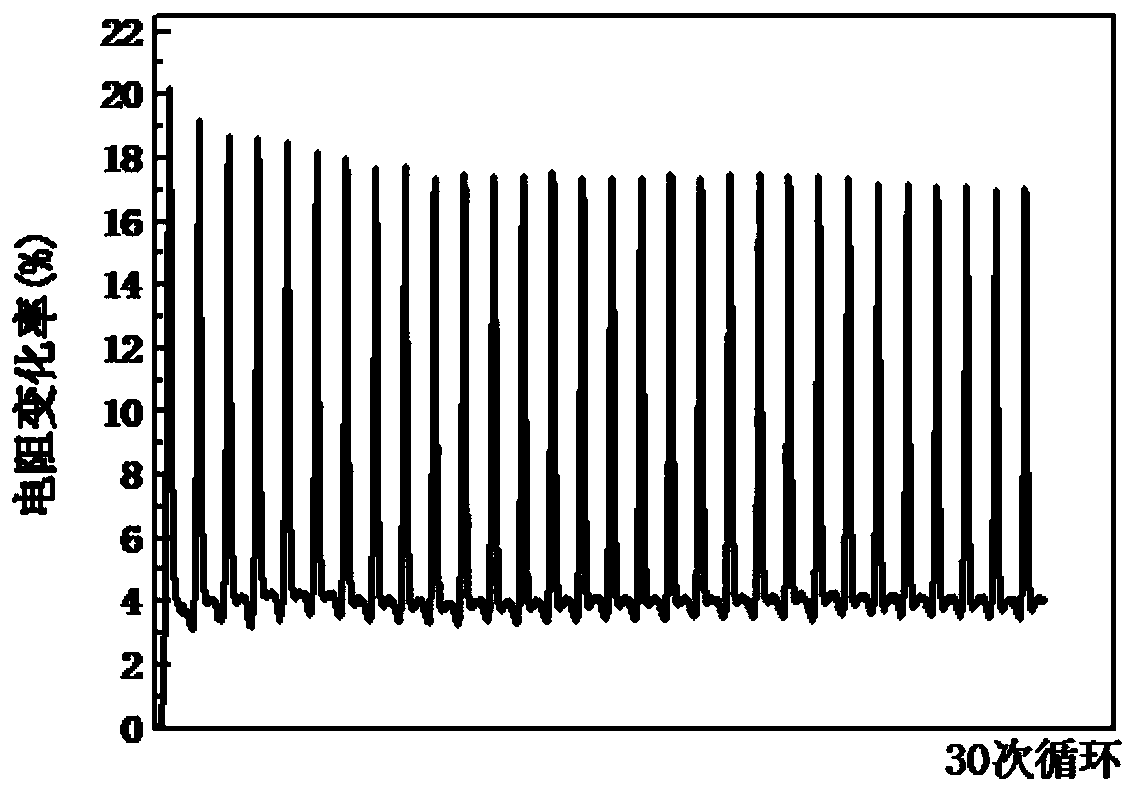

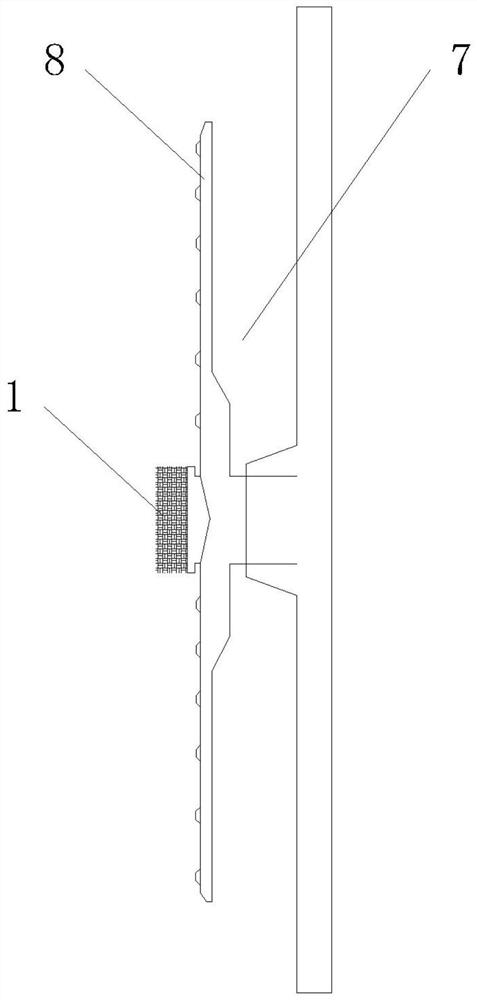

Flexible strain-sensing woven fabric and making process thereof

ActiveCN107385623AThe strain sensing function hasHigh sensitivitySwivel-woven fabricsLappet-woven fabricsYarnSurface pattern

The invention discloses a flexible strain-sensing woven fabric and a making process thereof. The flexible strain-sensing woven fabric comprises non-conducting elastic woven fabric and elastic conducting yarn, wherein the elastic conducting yarn is fixedly connected to the surface of the non-conducting elastic woven fabric as float yarn to form a float pattern, and connectors and leads for electric connection are arranged at the two ends of the elastic conducting yarn. The flexible strain-sensing woven fabric is simple in structure, good in flexibility, high in comfort and washable and has an omnidirectional strain sensing function, continuous production can be achieved, and the woven fabric is high in sensitivity, stability and applicability and has good application prospects in the field of intelligent textiles; besides, the flexible strain-sensing woven fabric has the advantages that the making process is simple, use is convenient, the surface pattern of the strain-sensing fabric can be designed and the fabric has attractiveness; the fabric has high practical value and is worthy of wide application and popularization, and compared with the prior art, the fabric has significant progress.

Owner:上海捻幅智能科技有限公司

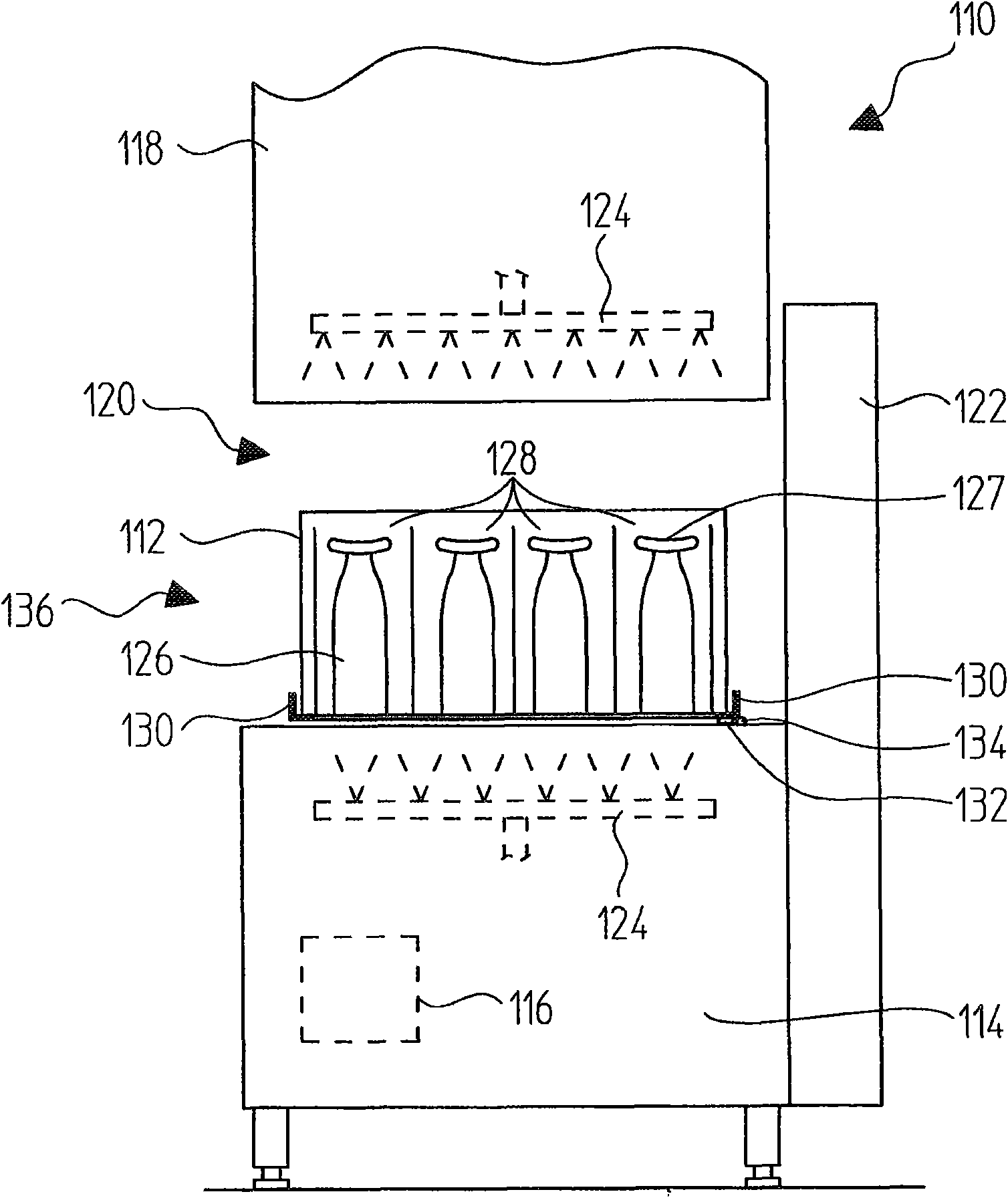

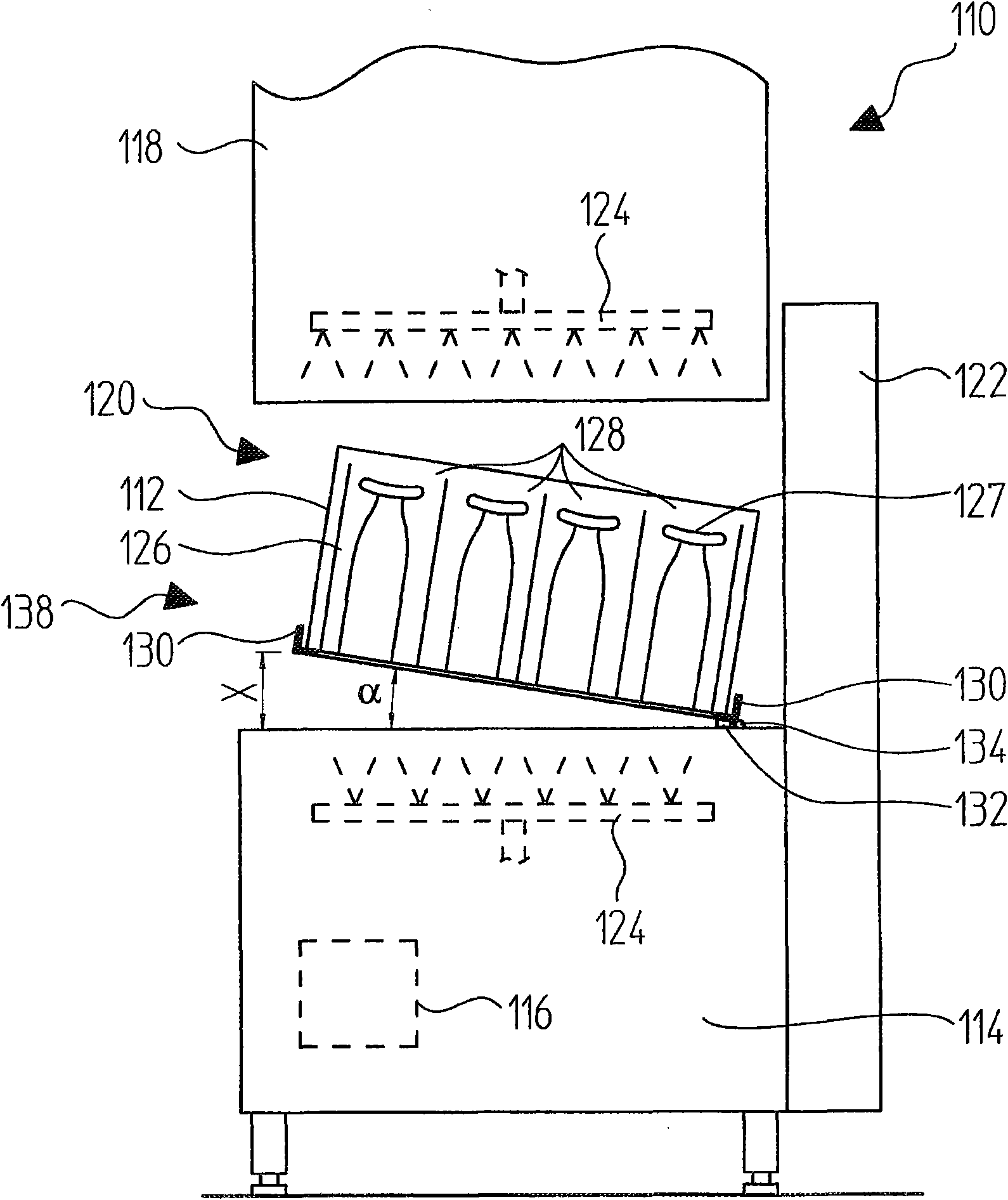

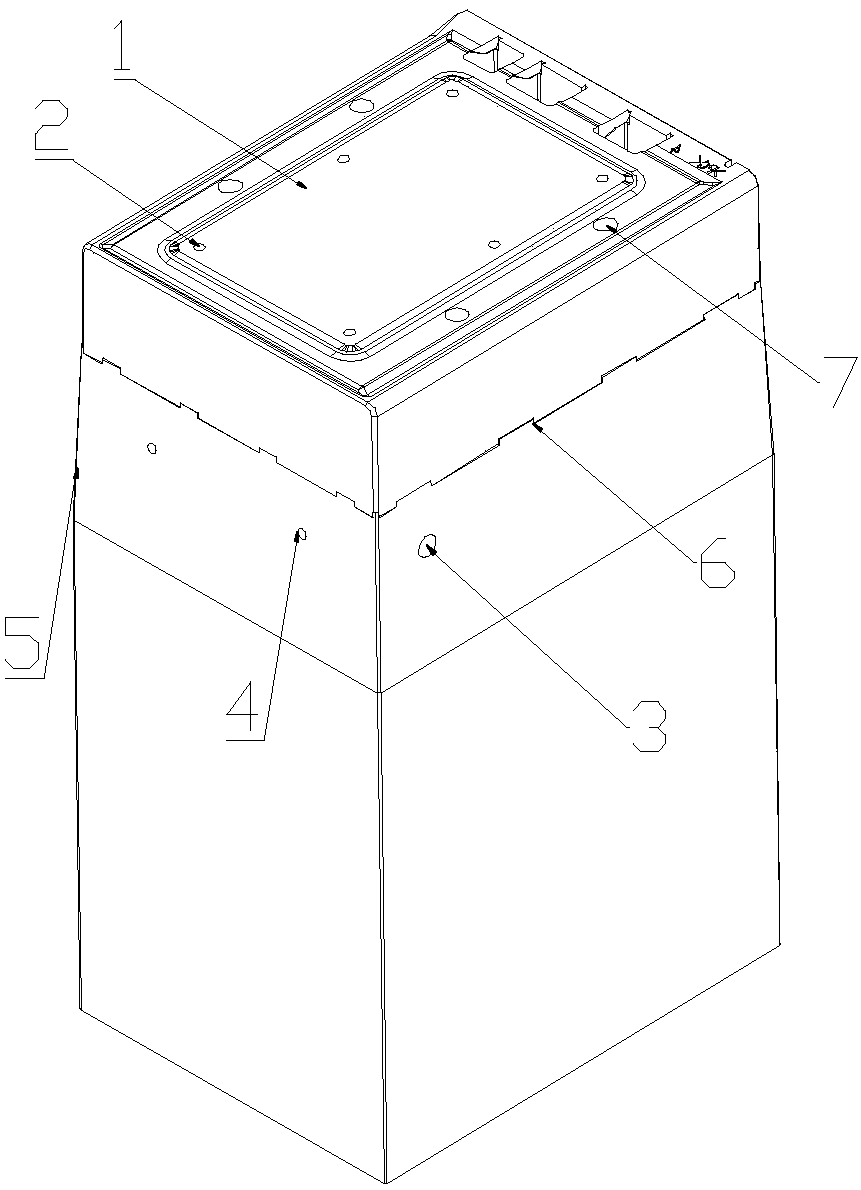

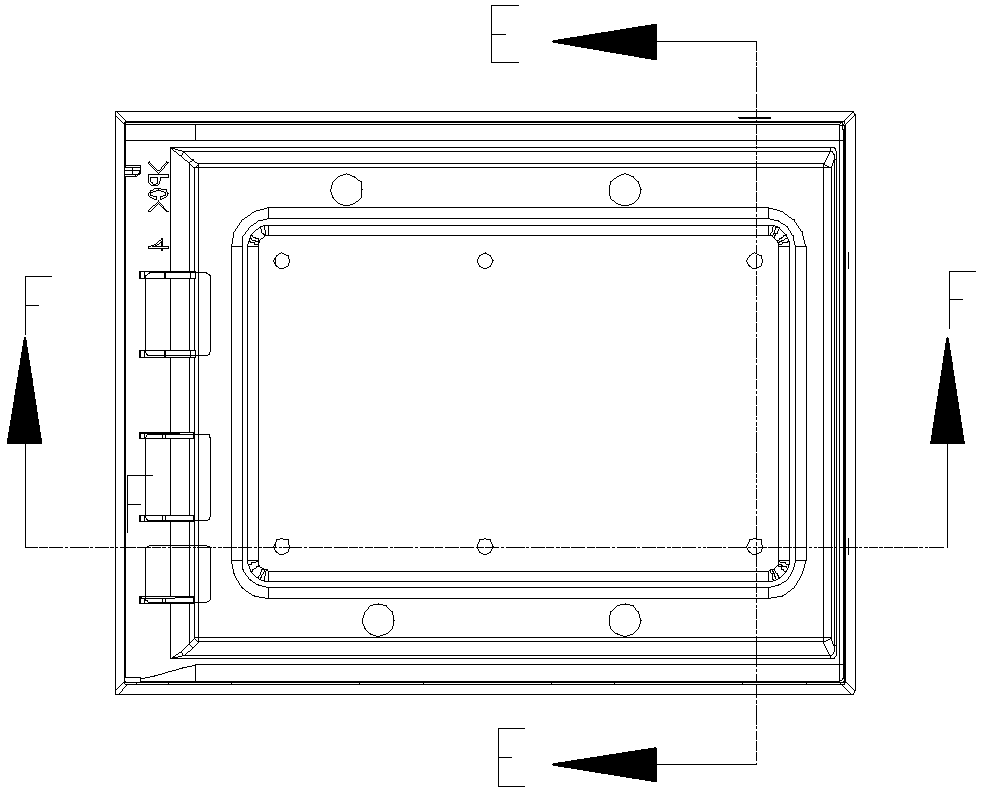

Dish washer with pivot device

InactiveCN101612027AStop pollutionUnrestricted structureTableware washing/rinsing machine detailsWashing processesEngineeringWasher

Owner:MEIKO MASCHENBAU

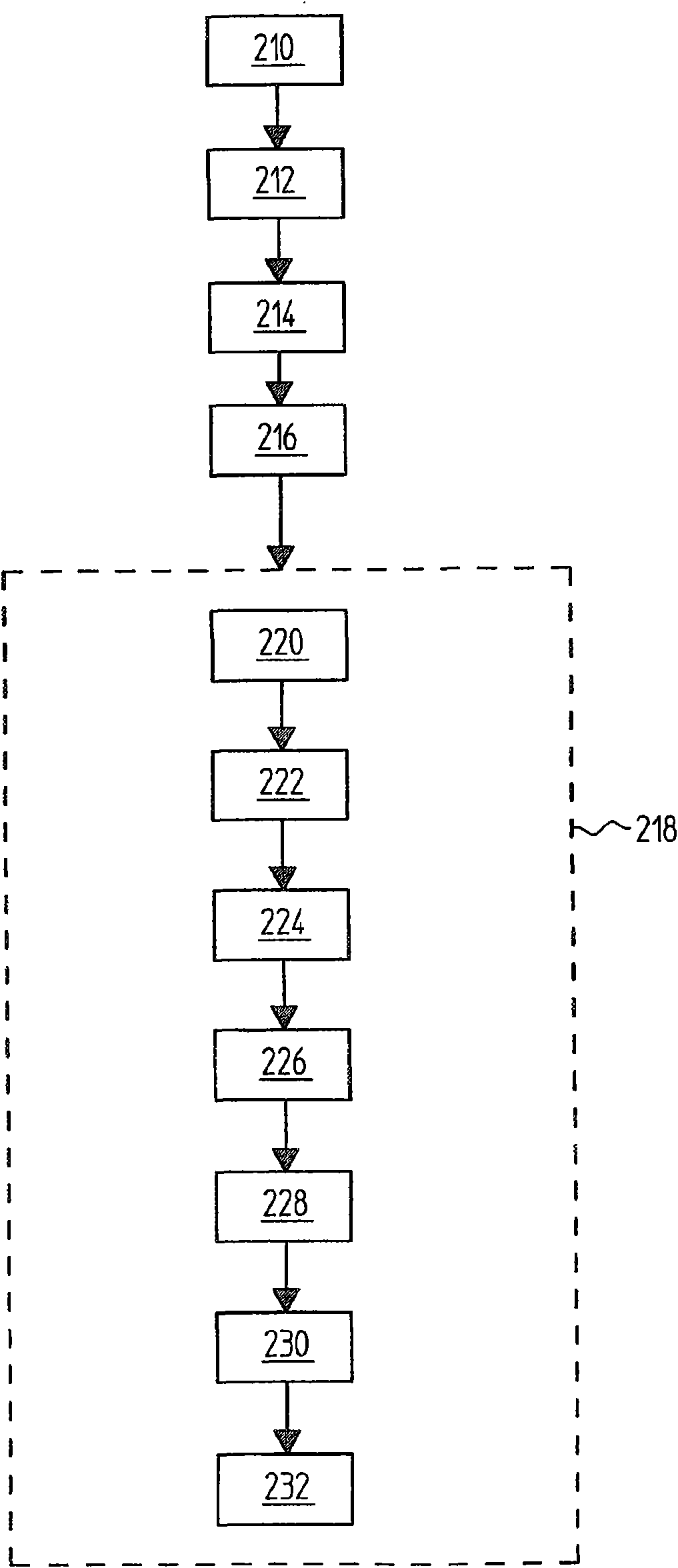

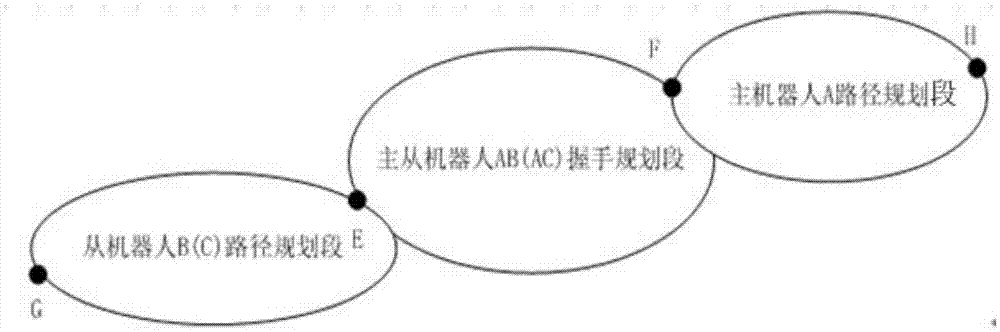

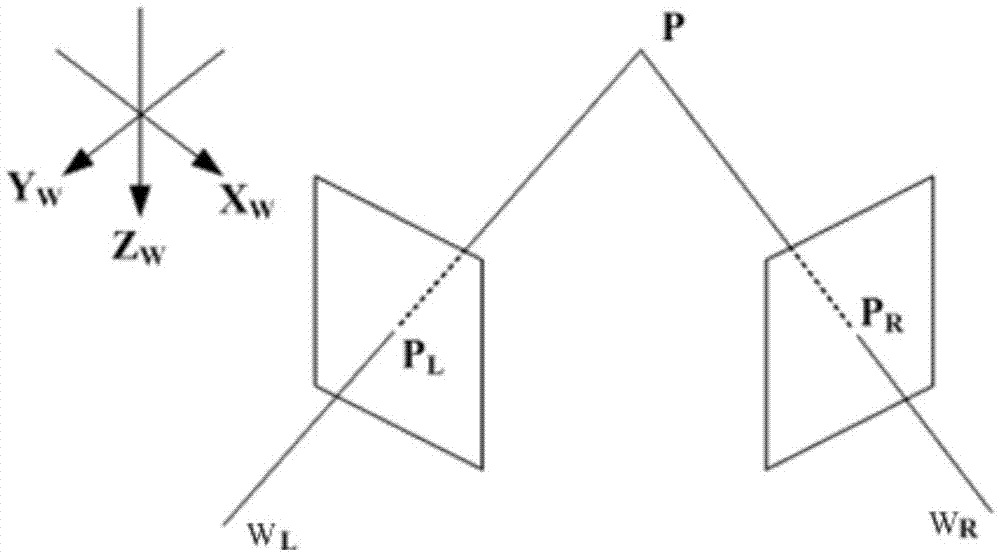

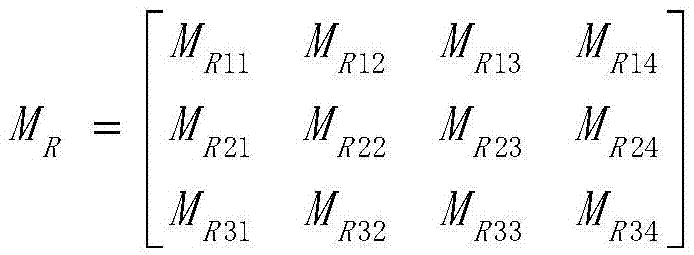

Multi-robot cooperative path planning method

ActiveCN106997201ASolve the handshake avoidance problemUnrestricted structurePosition/course control in two dimensionsVehiclesWork taskSimulation

The invention relates to the field of robot path planning and particularly relates to a multi-robot cooperative path planning method. A workpiece is provided, a main robot and a slave robot are defined, and the main information of the main robot and the slave information of the slave robot are acquired; the main robot adopts an active vision mode to acquire the information of the workpiece; according to the main information and the slave information, a robot model is built, and an environment model is built according to the workpiece information; according to the robot model and the environment model, the main robot determines the working tasks and the working paths of the main robot and the slave robot; and the main robot and the slave robot execute the working tasks according to the working paths. A three-dimensional object is intelligently identified through a binocular active vision system, which is not limited to features of the color and the shape and the like of the object. A sectional path planning technology is adopted, the path optimization efficiency is improved, a handshake collision avoidance problem in multi-robot superimposed motion can be solved, and dynamic adjustment of each joint and online optimization of the path during the multi-robot processing process can be realized.

Owner:SHANGHAI ELECTRICGROUP CORP

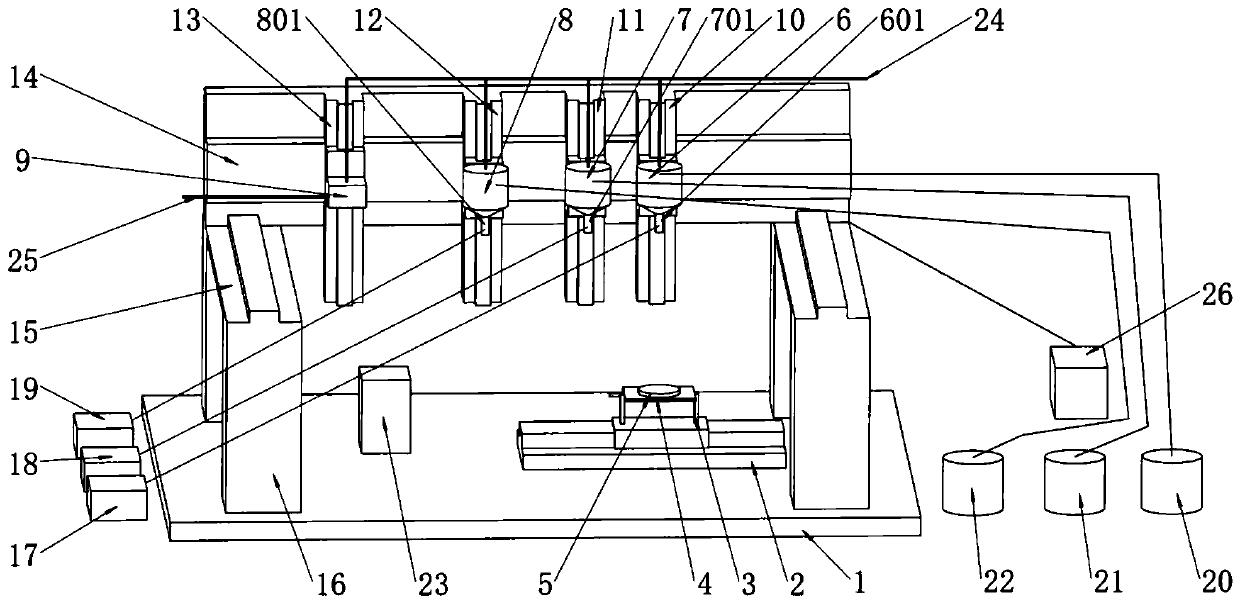

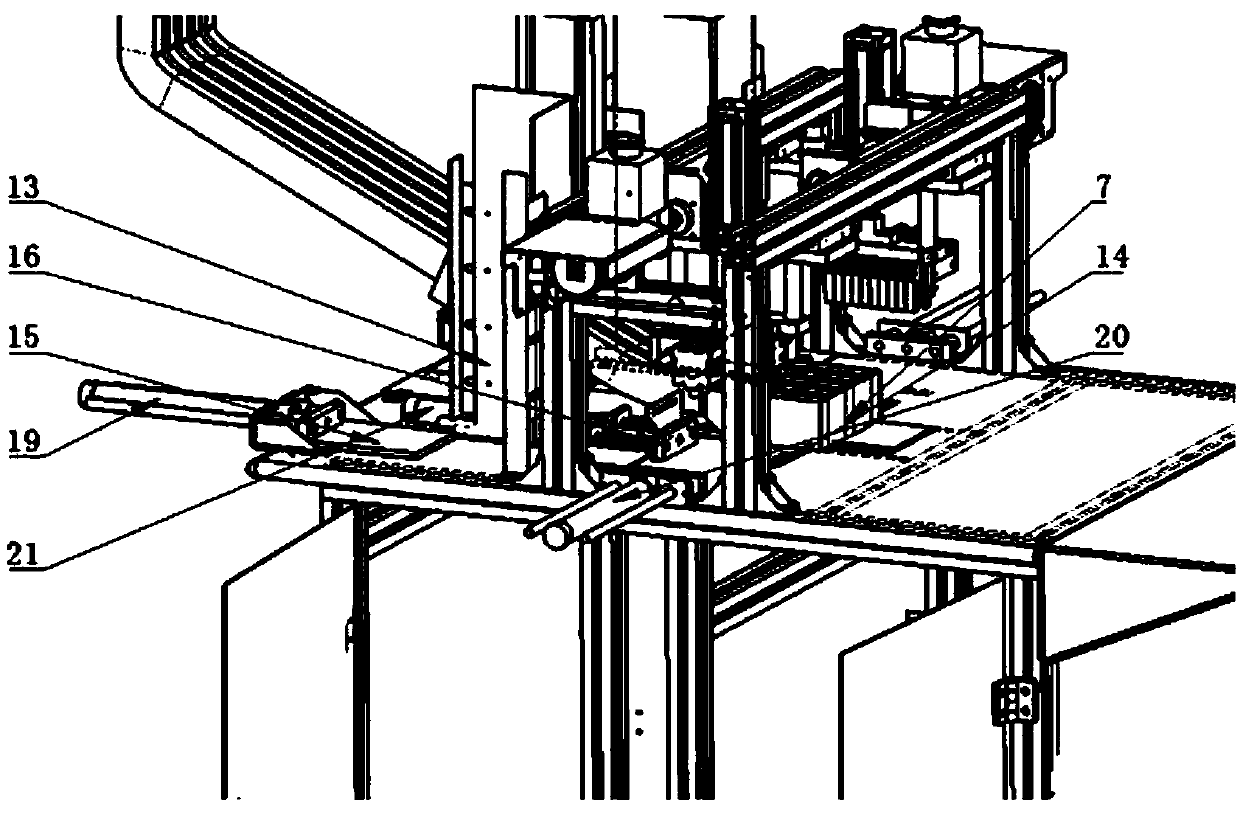

Multi-material 3D printing device for integrally manufacturing stretchable electronic product and working method

PendingCN109732900AAchieving heat curingReduce printing timeManufacturing platforms/substratesManufacturing heating elementsStretchable electronicsMulti material

The invention provides a multi-material 3D printing device for integrally manufacturing a stretchable electronic product and a working method. The device comprises a base and a control module; the base is provided with a three-dimensional workbench, a placing platform, a swing table and a printing bed, wherein the printing bed is arranged on the swing table, and the swing table drives the printingbed with vacuum adsorption and electric heating functions to swing and rotate; and the three-dimensional workbench comprises at least four Z-direction workbenches, the first Z-direction workbench isprovided with a mechanical arm used for grabbing and placing electronic elements, and each of the remaining Z-direction workbenches is provided with a printing nozzle. Movement of the three-dimensional workbench, the swinging table, the mechanical arm and a feeding module are controlled, each printing nozzle executes printing of a flexible base plate, a protective layer, a connecting circuit, an embedded electronic element and a packaging layer of the stretchable electronic product according to a set sequence, and thus integrated manufacturing is realized.

Owner:QINGDAO 5D INTELLIGENT ADDITIVE MFG TECH CO LTD

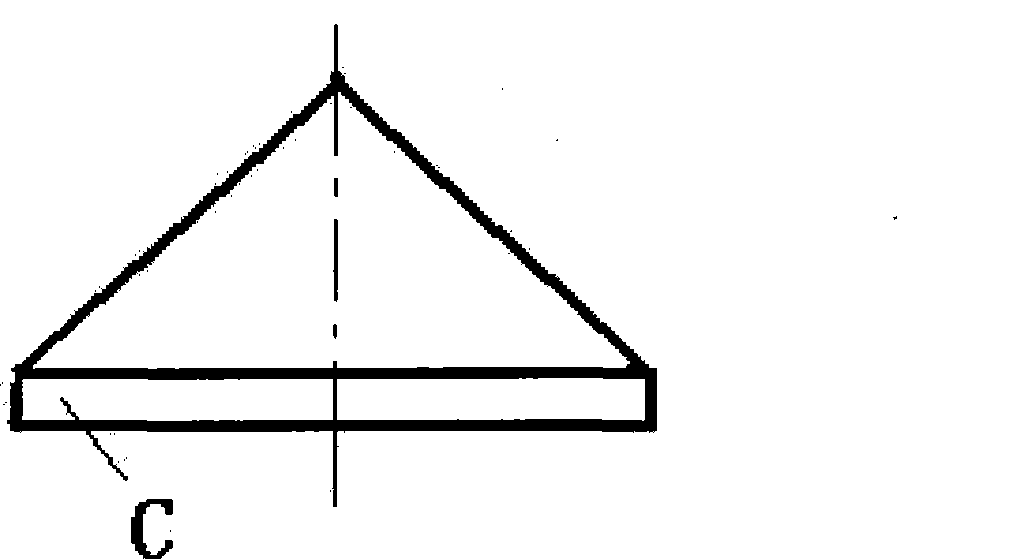

Module group type LED double-light source street lamp

InactiveCN101435553APlay a fine-tuning roleUnrestricted structurePoint-like light sourceOutdoor lightingOptical axisEffect light

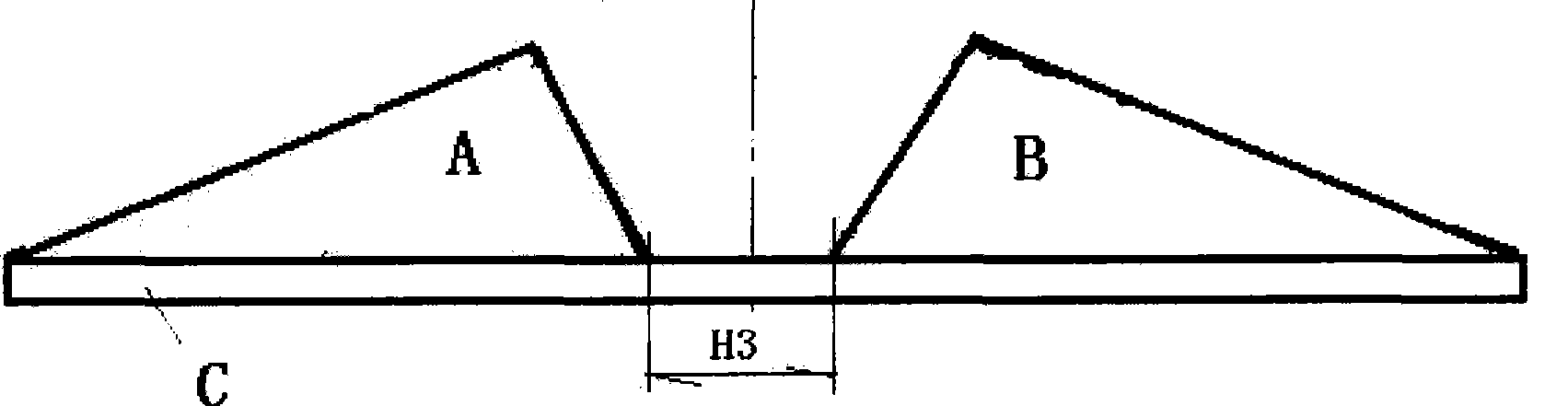

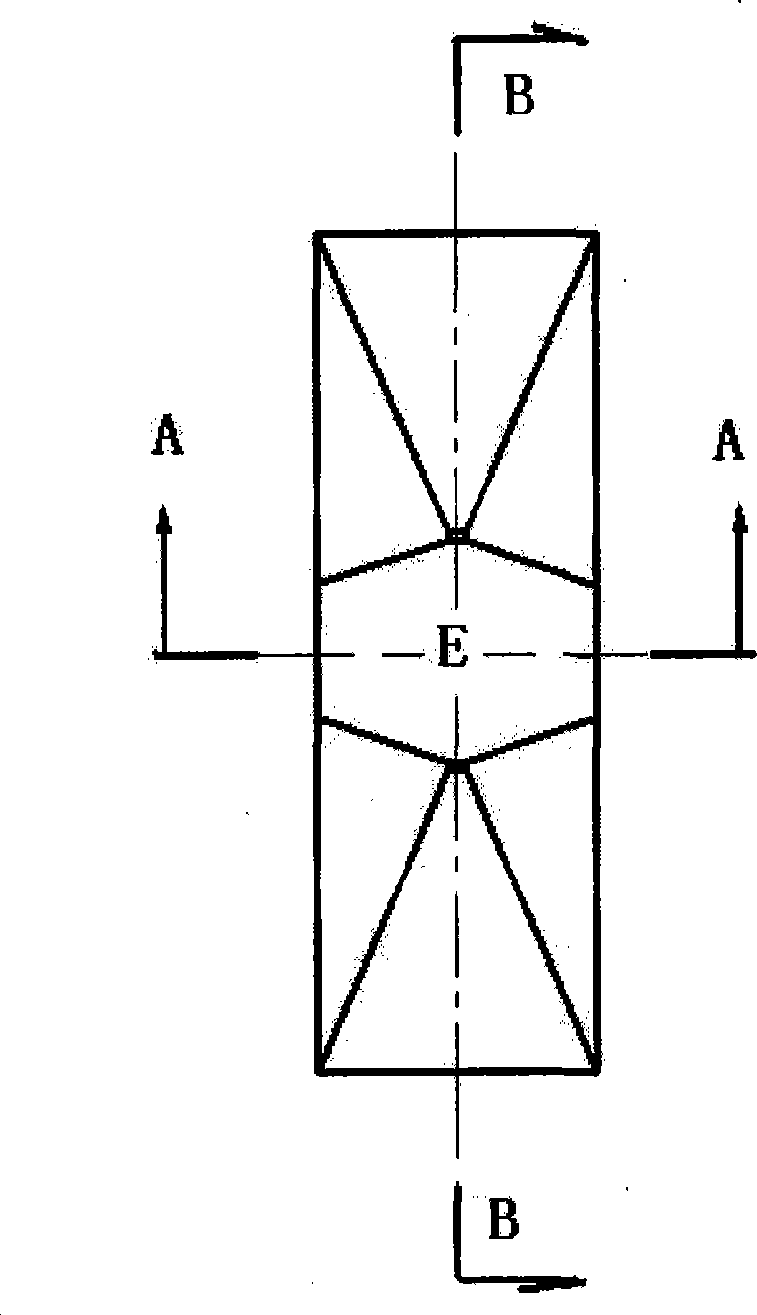

The invention discloses a modular LED double light source street lamp, which comprises a main body of the lamp and a reflection cup. The reflection cup of the lamp comprises reflection areas (A, B), a reflection cup frame (C) and a lamp stand mounting hole (E), the reflection areas (A, B) of the reflection cup consist of reflection planes or reflection surfaces (1, 2, 3, 4, 5, 6) with arc-shaped structures respectively, and are connected into a whole through the reflection cup frame (C) with a thickness H2 within the range of between 1 and 30 millimeters, the lamp stand mounting hole (E) with H3 not less than 15 millimeters is arranged between the reflection areas, a height H1 of the reflection areas is within the range of between 15 and 30 millimeters, an included angle a1 is within the range of between 90 and 150 DEG, an included angle a2 is within the range of between 10 and 30 DEG, an included angle a3 is within the range of between 10 and 100 DEG, an included angle a4 is within the range of between 10 and 30 DEG, the height H1 is within the range of between 15 and 30 millimeters, and an included angle a5 is within the range of between 10 and 100 DEG. A light beam of a modular LED light source is reflected out through a light distributor, thereby effectively solving the axial problem of LED luminescence; the actual lighting effect of the lamp is strengthened through the change of the light distributor and the installation direction of the lamp; the lamp can reach or exceed the requirement of lighting technology and the use effect of lighting grade lamps; and the lamp has remarkable social and economical benefits.

Owner:DONGGUAN CLED OPTOELECTRONIT TECH

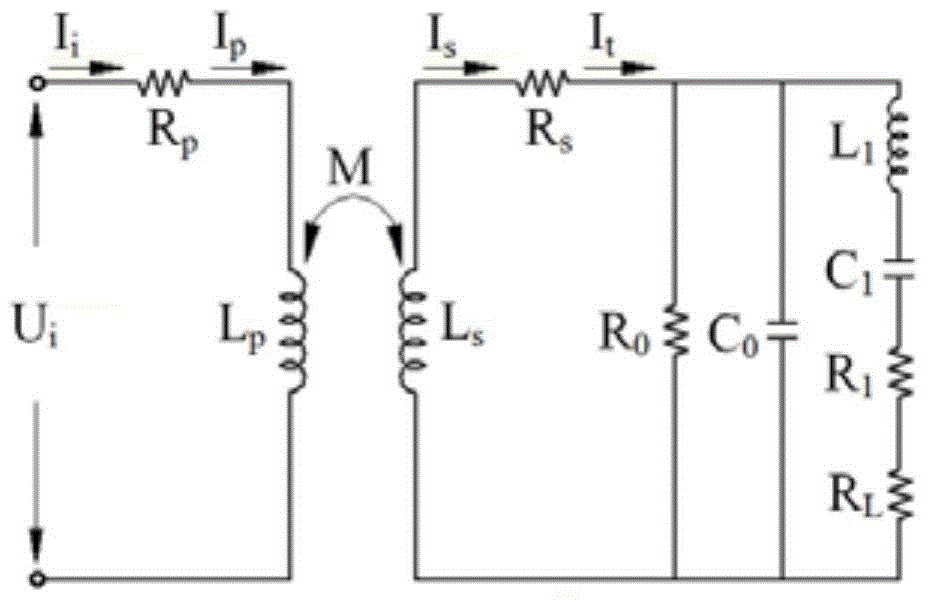

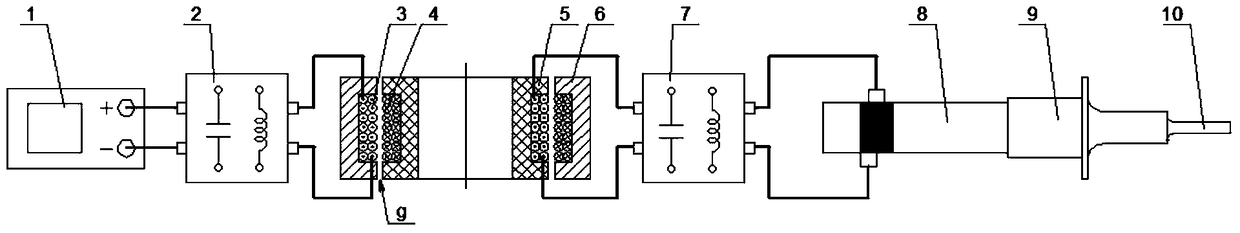

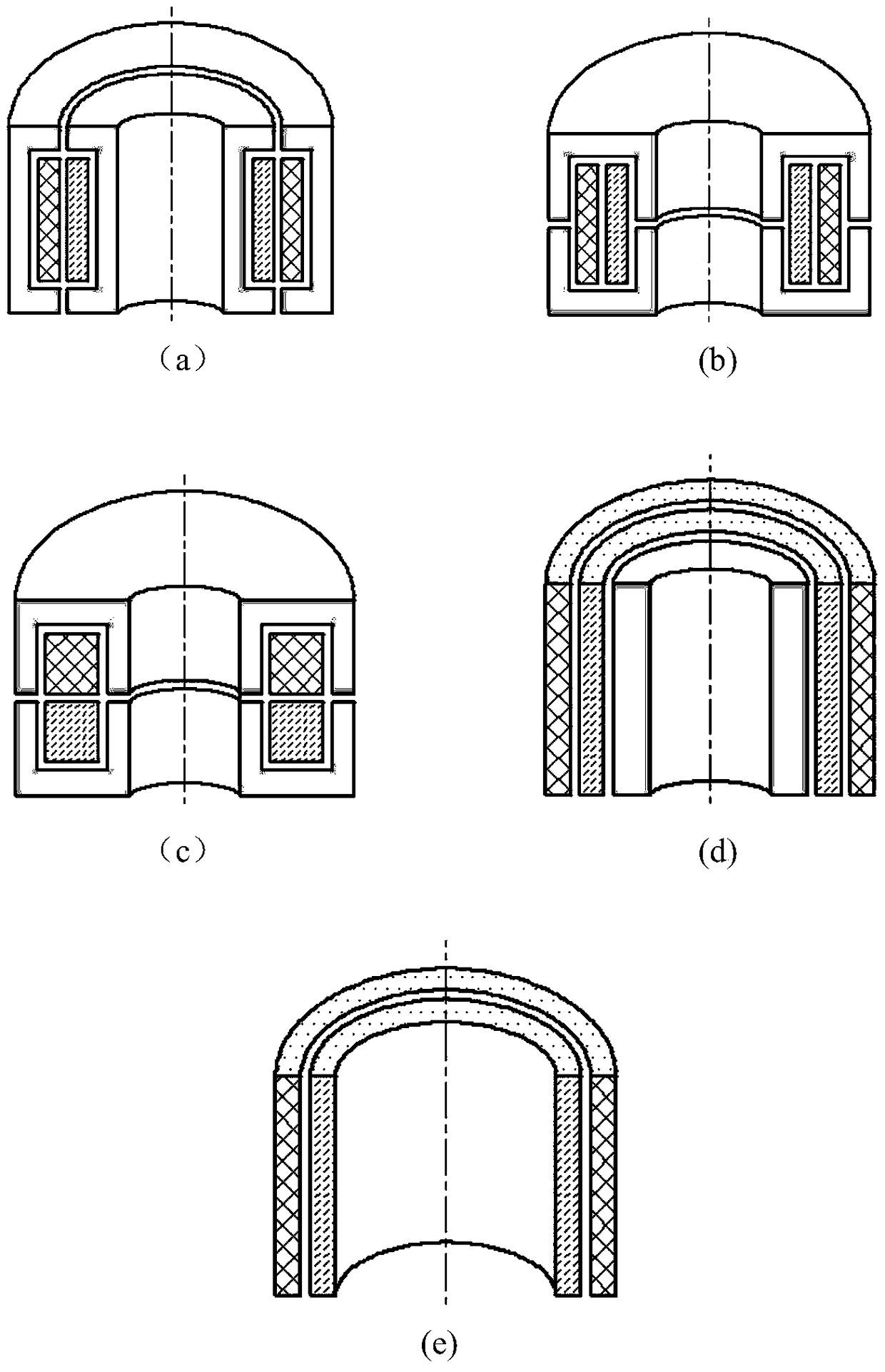

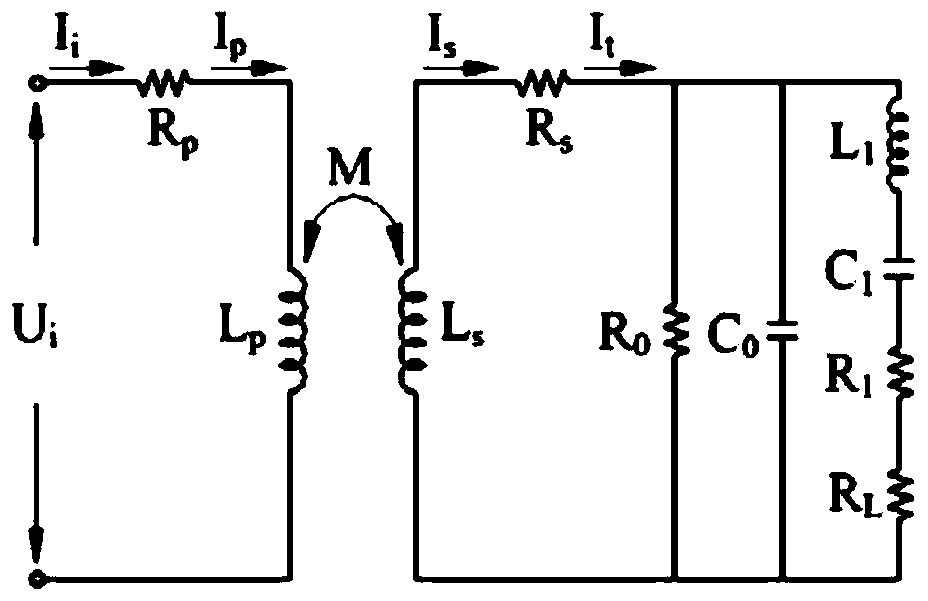

Circuit compensation network of non-contact power supply ultrasonic vibration system based on efficiency

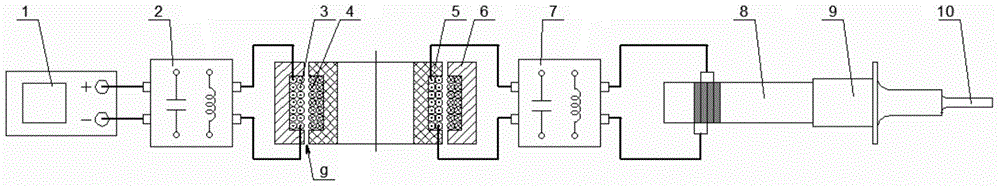

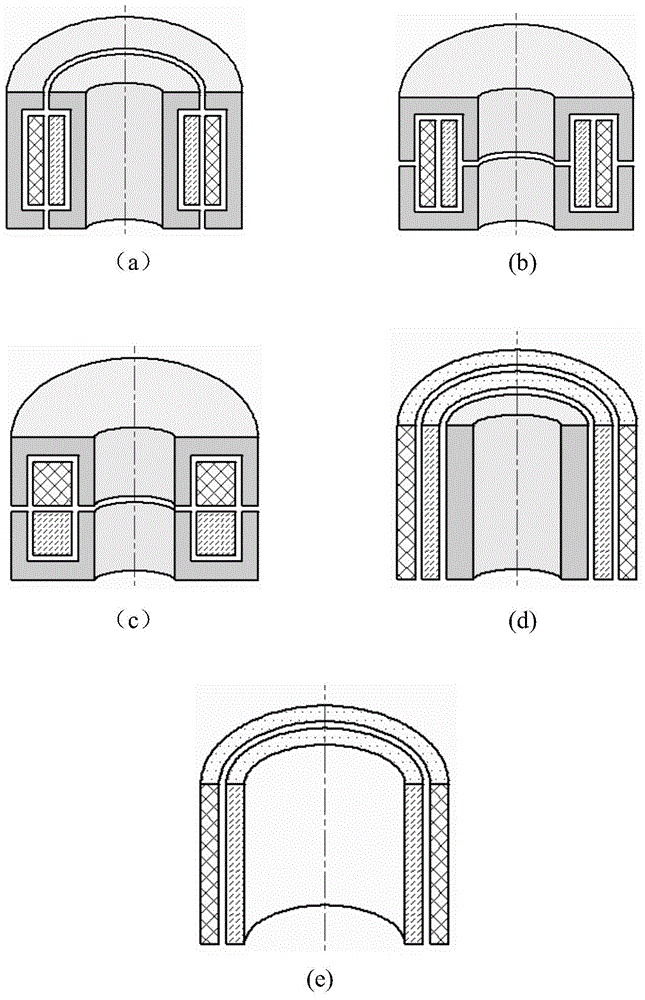

ActiveCN104993605ADoes not involve physical structure sizeUnrestricted structureElectromagnetic wave systemPower flowUltrasonic welding

The invention discloses a circuit compensation network of a non-contact power supply ultrasonic vibration system for realizing maximum transmission efficiency. The circuit compensation network comprises a primary compensation network and a secondary compensation network. The primary compensation network is connected between an ultrasonic power supply and a primary coil of a non-contact electromagnetic coupler to compensate reactive power of the system and make voltage and current output by the power supply in phase. The secondary compensation network is connected between a secondary coil of the non-contact electromagnetic coupler and an ultrasonic vibrator to realize highest-efficiency energy transmission by optimizing the parameters of a secondary compensation element(s), wherein the compensation element(s) is / are an inductor or / and a capacitor. The circuit compensation network of the invention can be applied to rotary ultrasonic machining, ultrasonic welding, and other occasions in which a non-contact electromagnetic coupler needs to be adopted to supply power to an ultrasonic vibrator. Highest-efficiency energy transmission is realized by optimizing the parameters of the secondary compensation element(s).

Owner:TIANJIN UNIV

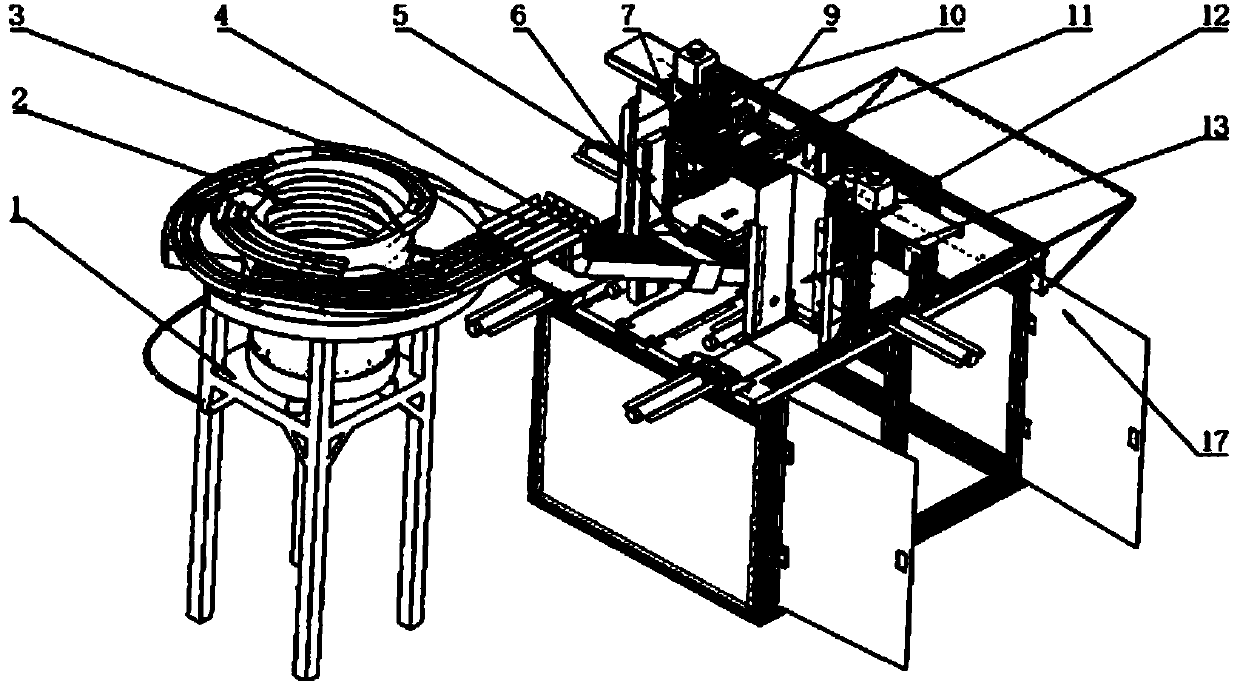

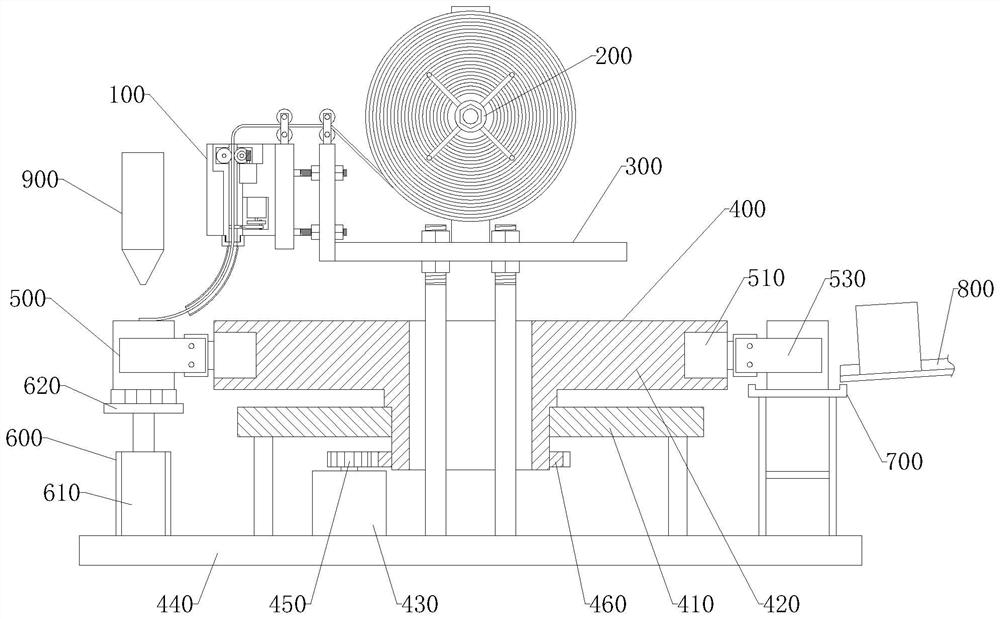

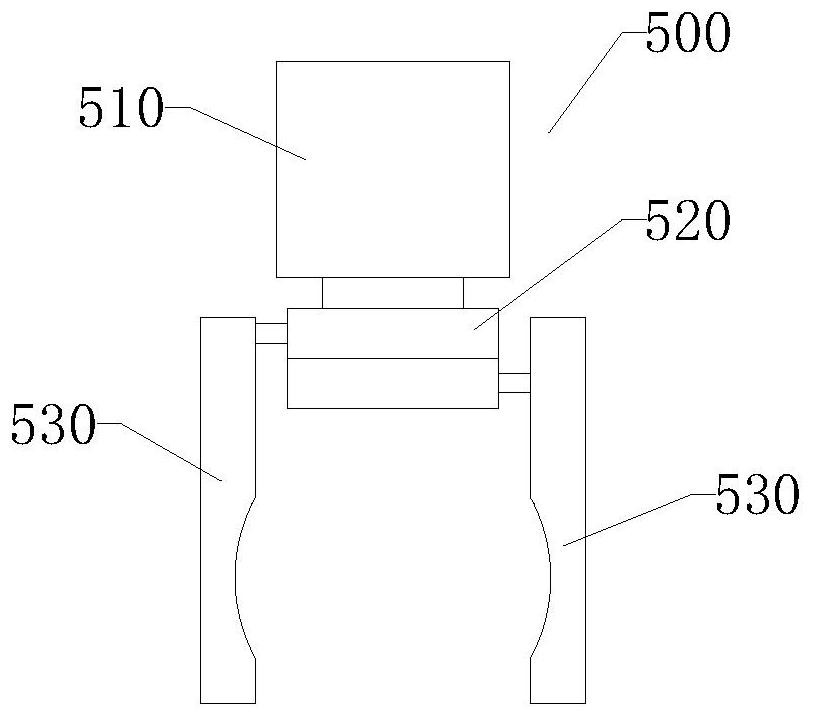

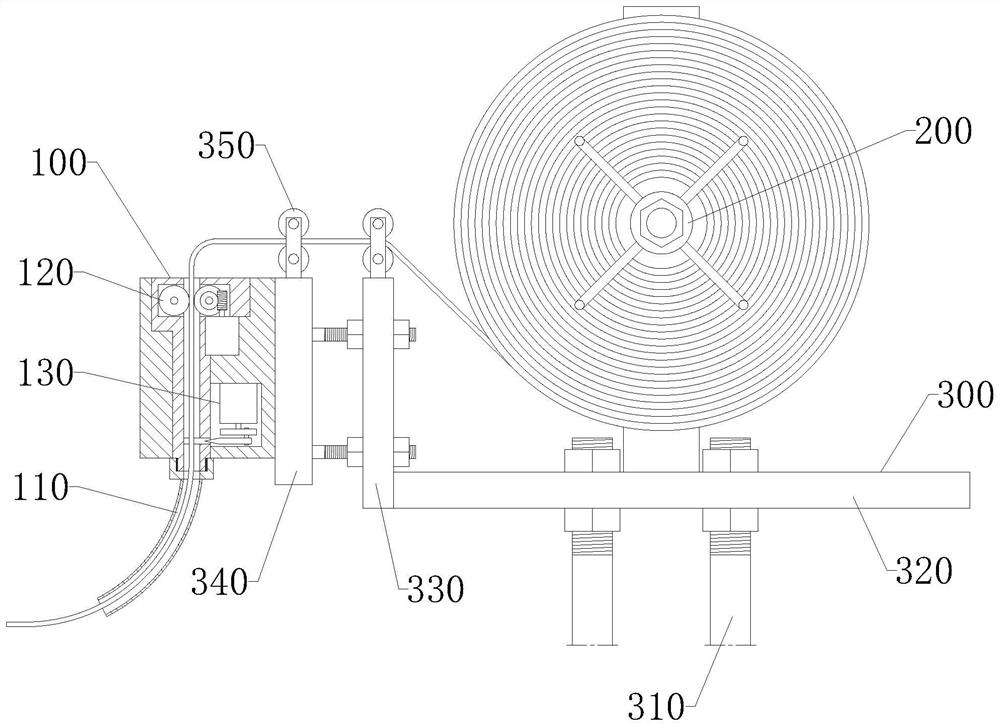

Automatic disk inserting machine of multi-track lighter barrel

ActiveCN107719753AImprove transmission efficiencyOne-way ordered outputIndividual articlesEngineeringStops device

The invention provides an automatic disk inserting machine of a multi-track lighter barrel. The automatic disk inserting machine comprises a base, a rack, a lighter barrel sequencing device, a inserted disk feeding device, a gripping device and a case, and is characterized in that the automatic disk inserting machine further comprises a vibration disk, an L-shaped bracket, a stop device, gas claws, a cylinder and an empty disk storage device; the lighter barrel sequencing device comprises the vibration disk and a sieving plate; the gripping device comprises a movable arm and the gas claws; theinserted disk feeding device comprises a disk feeding mechanism, a disk discharge mechanism, the empty disk storage device and a disk stopping mechanism. According to the automatic disk inserting machine provided by the invention, lighter barrels in the same direction can be screened out through the vibration disk, so that disks are inserted automatically through the disk inserting machine. The automatic disk inserting machine has the advantages that lots of manpower is saved, and the operation is stable and reliable.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

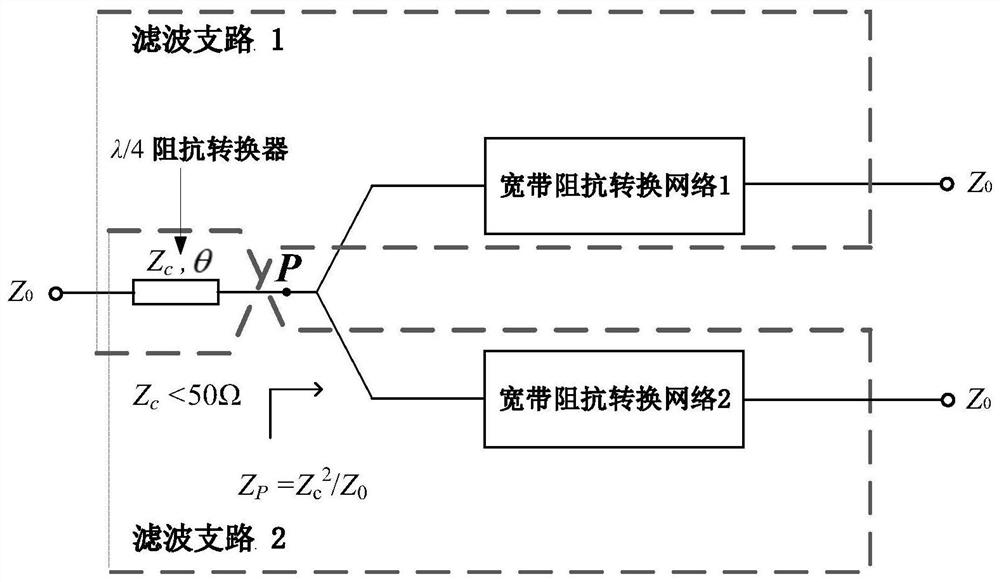

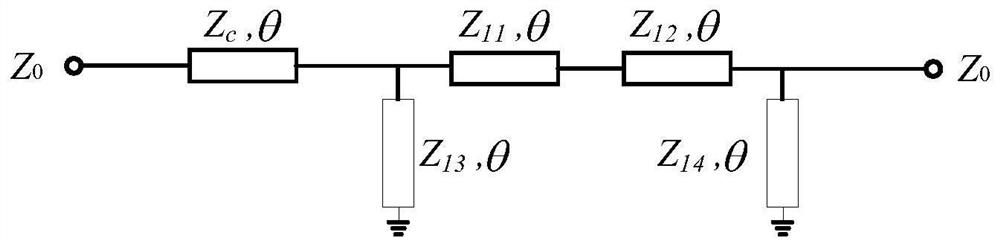

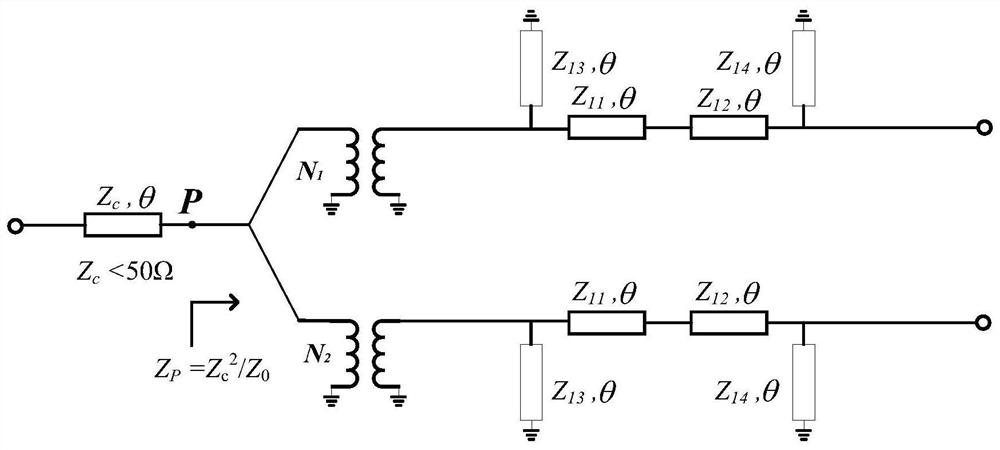

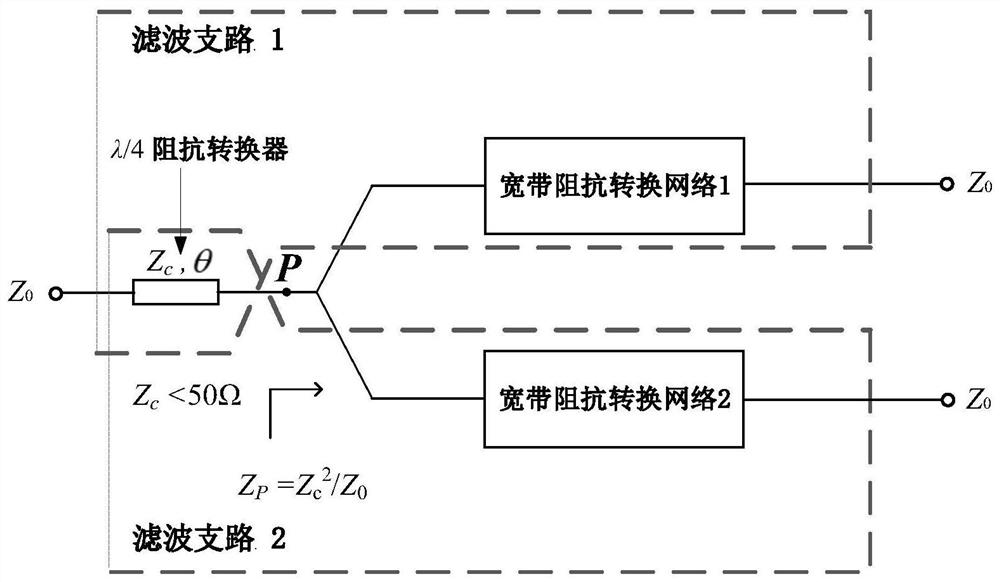

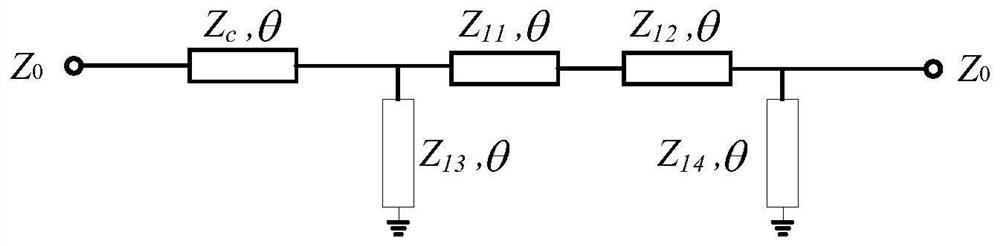

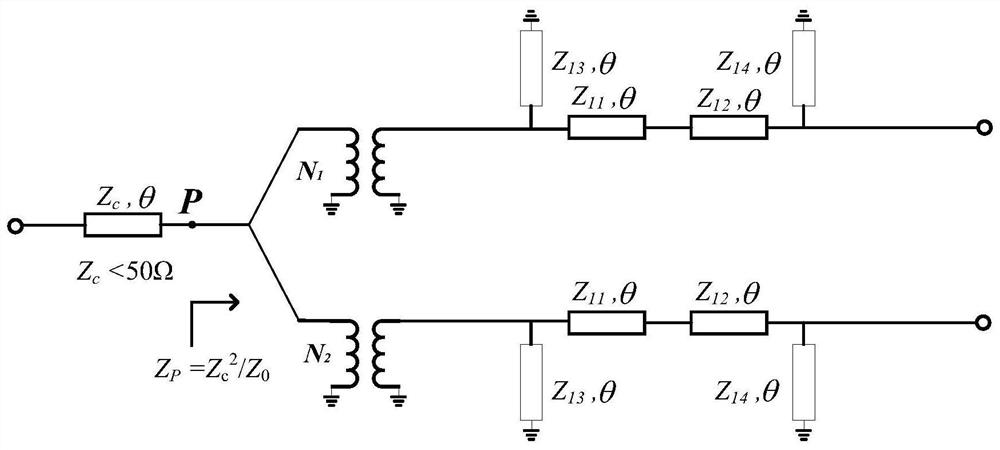

Broadband filtering power divider capable of realizing high power dividing ratio

ActiveCN111834726ALower the input impedance valueImprove the power ratioCoupling devicesHigh bandwidthImpedance Converter

The invention discloses a broadband filtering power divider capable of realizing a high power dividing ratio. The broadband filtering power divider comprises a lambda / 4 impedance converter arranged infront of a power dividing node and a plurality of broadband impedance conversion networks arranged behind the power dividing node and connected in parallel, the lambda / 4 impedance converter is used for reducing the input impedance value at the power division node and an in-band pole is introduced to improve the power division ratio and bandwidth of the power divider at the same time; and the broadband impedance conversion networks are used for forming each filtering power branch together with the lambda / 4 impedance converter so as to jointly realize filtering and power distribution in a broadband range. Compared with the prior art, the power divider has the remarkable advantages of being high in power division ratio, wide in bandwidth and capable of achieving filtering power division implantation. The power divider can be expanded into a multi-path high-power-dividing-ratio filtering power divider, and can be used in a feed network of an array antenna.

Owner:NANJING UNIV OF SCI & TECH

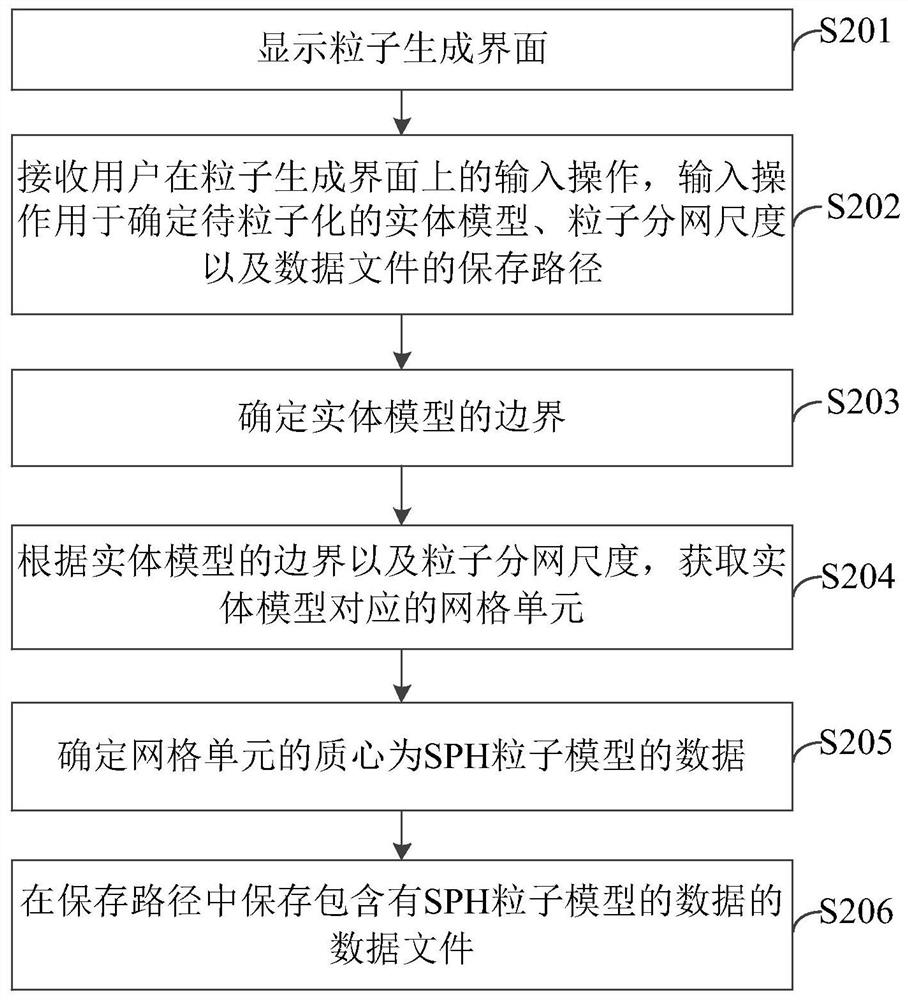

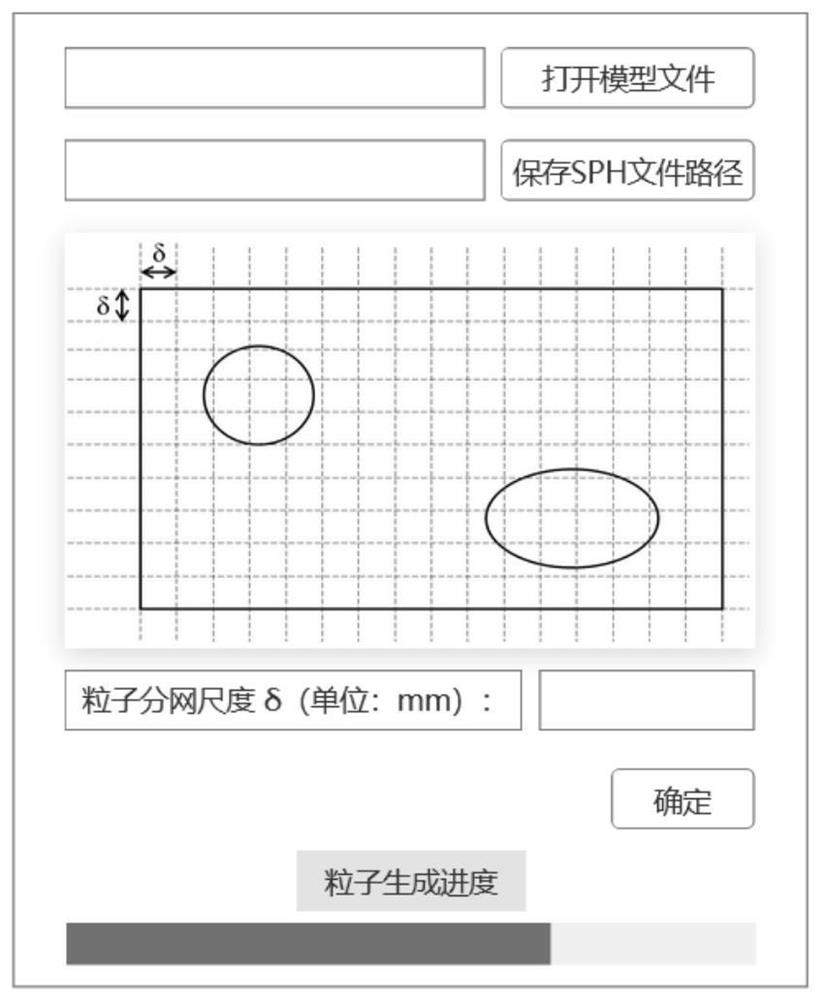

Particle generation method and device, equipment and storage medium

ActiveCN113378435AUnrestricted structureEasy to operateDesign optimisation/simulationSpecial data processing applicationsPhysicsData file

The invention belongs to the technical field of computers, and particularly relates to a particle generation method and device, equipment and a storage medium. The method comprises the following steps: displaying a particle generation interface; receiving an input operation of a user on the particle generation interface, wherein the input operation is used for determining a to-be-pelletized entity model, a particle network division scale and a storage path of a data file; determining the boundary of the entity model; obtaining grid units corresponding to the entity model according to the boundary of the entity model and the particle mesh division scale; determining the mass center of the grid unit as the data of the SPH particle model; and storing a data file containing data of the SPH particle model in the storage path. According to the invention, the data file after the solid model is granulated can be generated and stored through one key, the operation is simple and convenient, and the universality is high.

Owner:QINGDAO HAIER INST OF IND INTELLIGENCE CO LTD +2

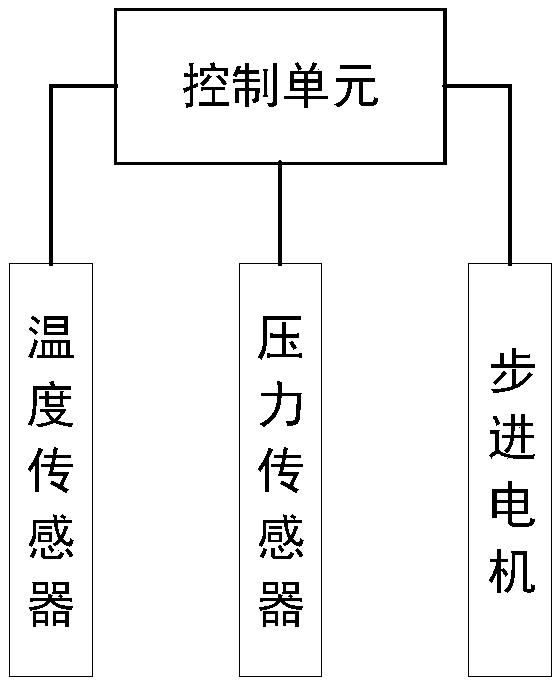

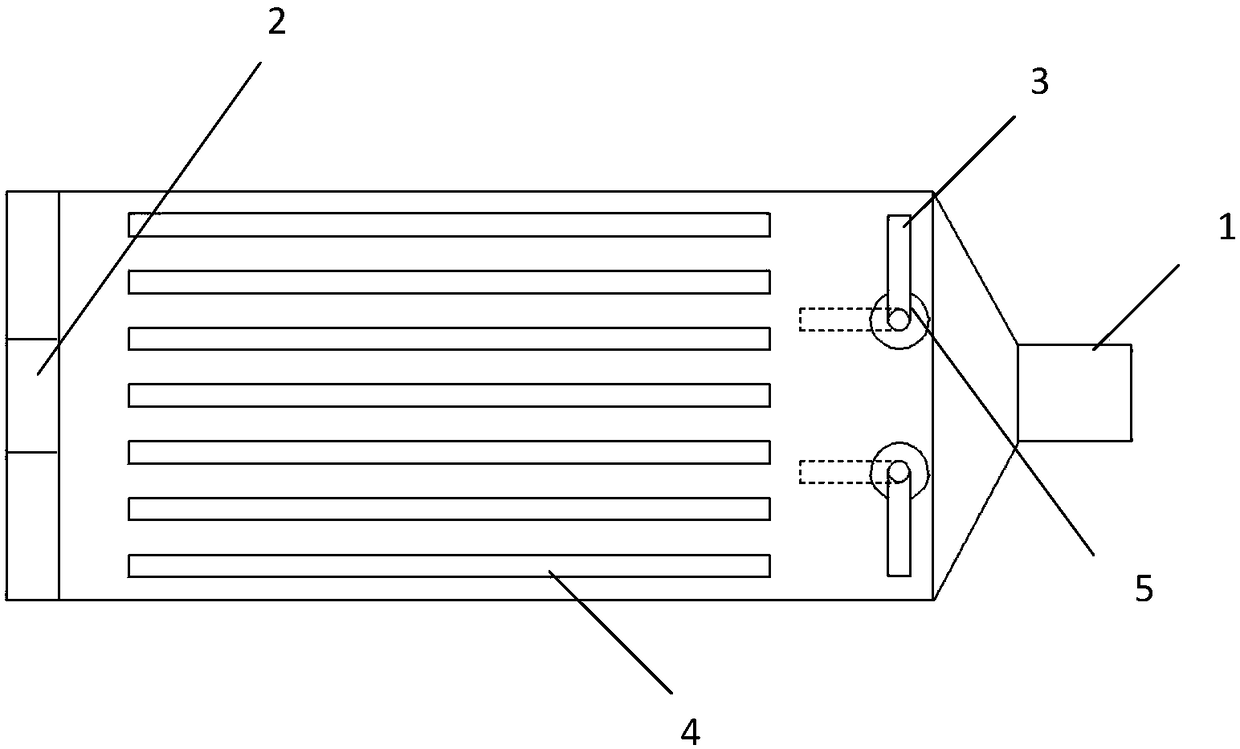

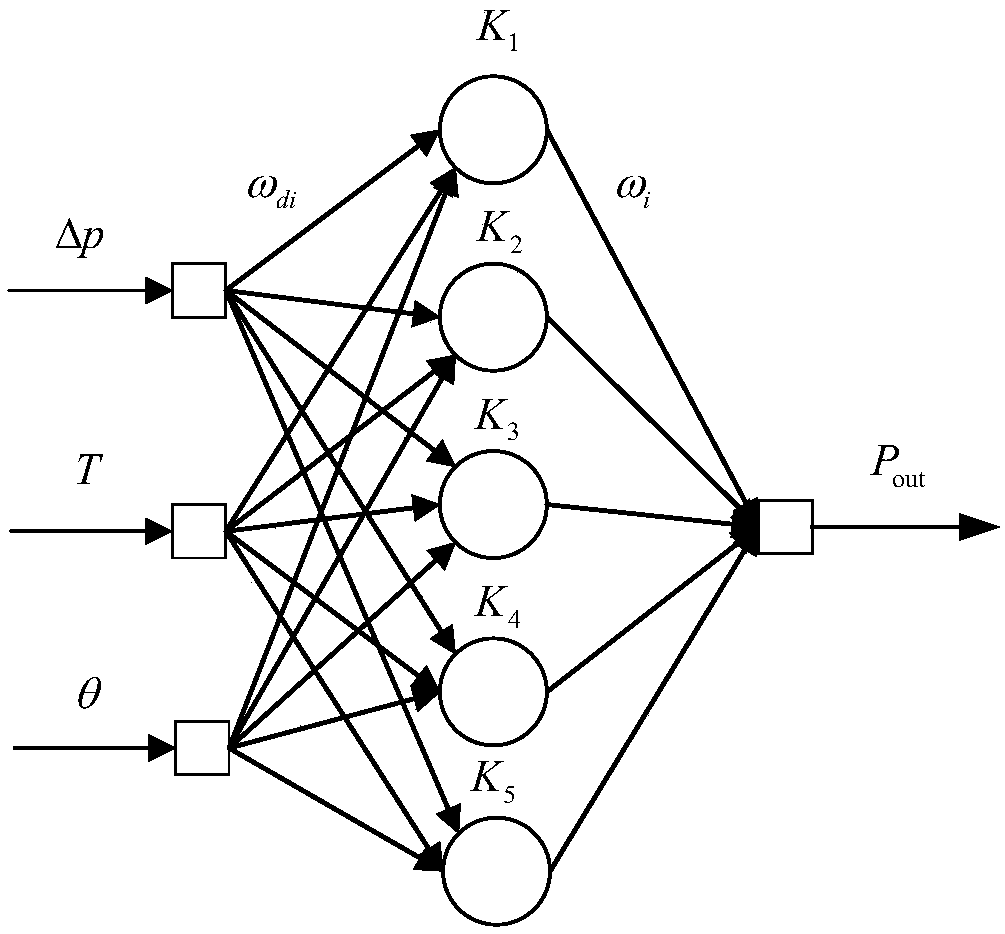

Electronic control system and method based on thermoelectric power generation for automotive exhaust energy recycling equipment

ActiveCN108594895AImprove power generation efficiencyUnrestricted structureInternal combustion piston enginesExhaust apparatusElectronic control systemElectric machine

The invention provides an electronic control system and method based on thermoelectric power generation for automotive exhaust energy recycling equipment. The electronic control system comprises a control unit, a temperature sensor, a pressure sensor and a step motor; the temperature sensor is used for detecting temperature information of automotive exhaust at a gas inlet of the automotive exhaustenergy recycling equipment, and transmitting the temperature information to the control unit; the pressure sensor is used for detecting pressure information of exhaust at the gas inlet and gas outletof the automotive exhaust energy recycling equipment, and transmitting the pressure information to the control unit; the step motor is mounted at the gas inlet of the automotive exhaust energy recycling equipment and is connected with a retaining plate of the automotive exhaust energy recycling equipment; the control unit adds the received temperature information and pressure information and N position angles of the step motor into a neural network of an internal storage, and performs calculating to obtain a motor position angle at which the automotive exhaust energy recycling equipment has maximum generation power; the control unit controls the step motor to drive the retaining plate to rotate to an opening position where the generation power is maximum; therefore, power-generating efficiency of the automotive exhaust energy recycling equipment is improved.

Owner:JIANGSU UNIV

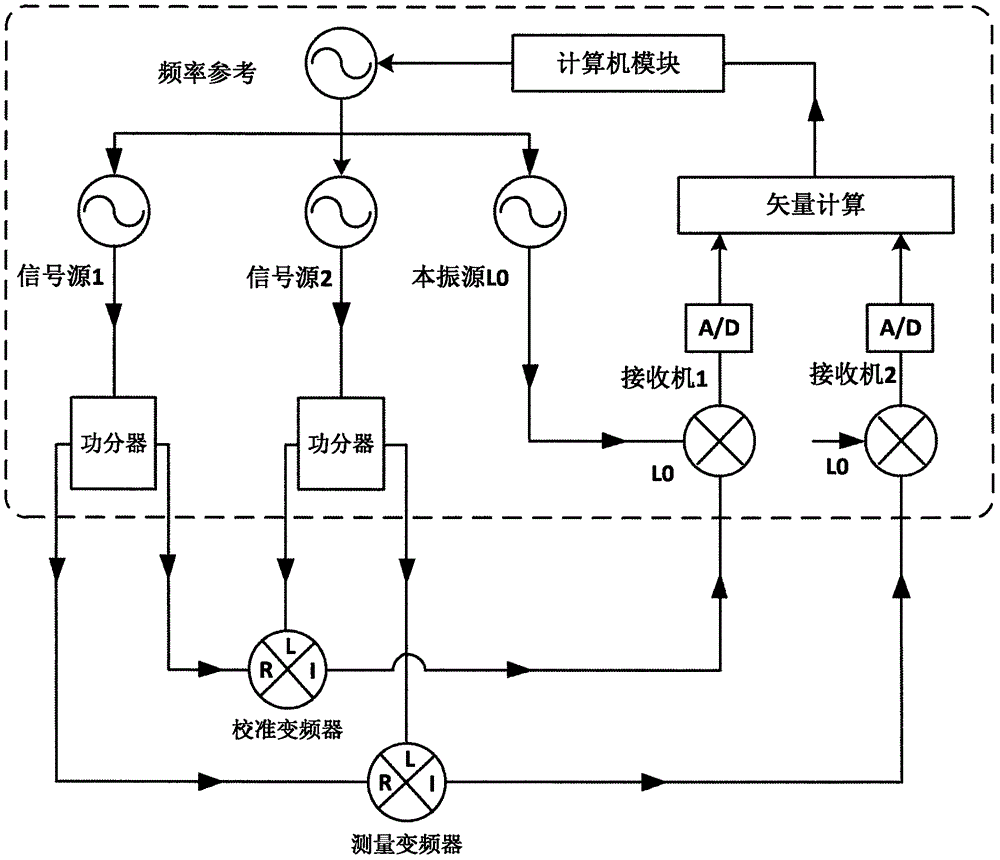

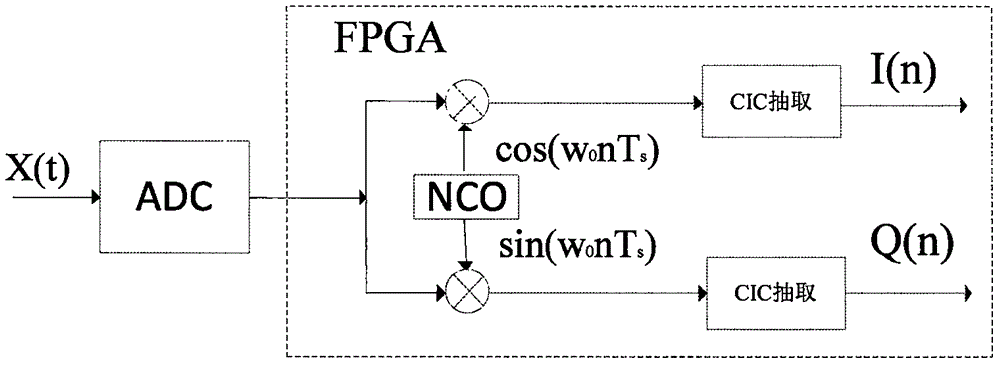

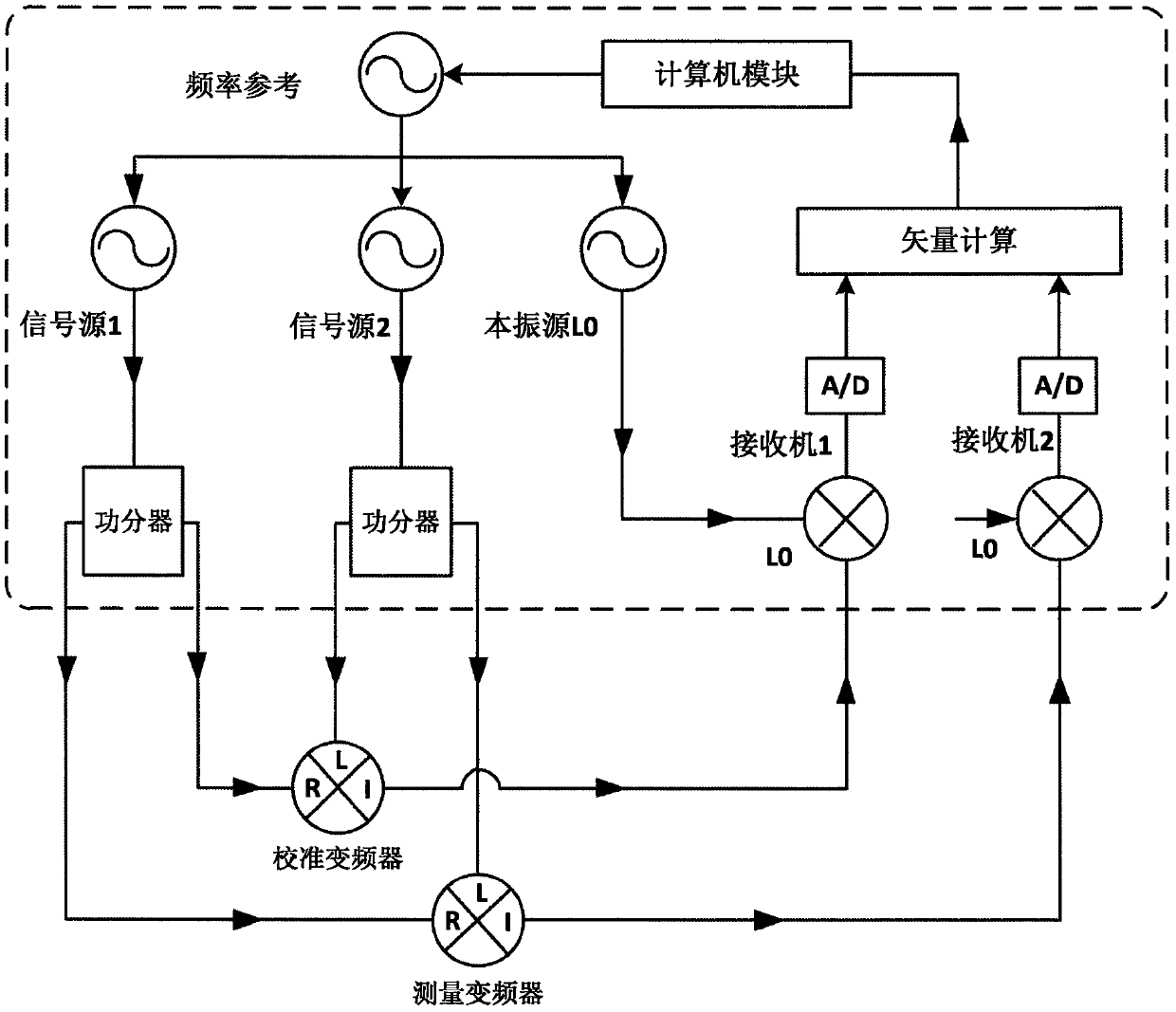

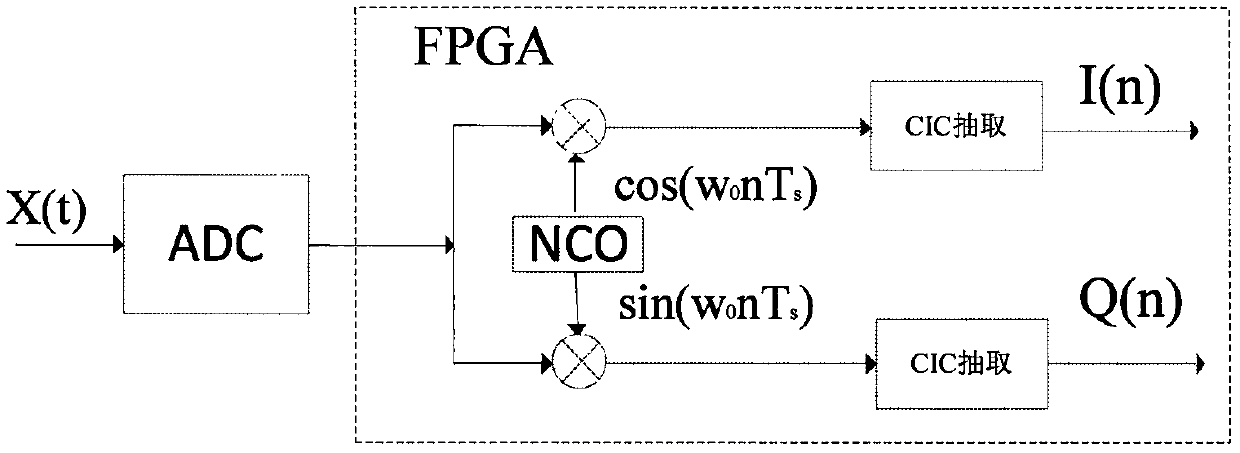

Frequency converter phase consistency testing device and method

ActiveCN106771712ASimplify the calibration processLow costVoltage-current phase angleElectrical testingFrequency changerConsistency test

The invention provides a frequency converter phase consistency testing device; the frequency converter passing the test can serve as a calibration frequency converter and a reference frequency converter, thus carrying out phase consistency test for a tested frequency converter; internal excitation employs the same frequency basis reference, signals of a first signal source are divided into two routes by a power divider, and the signals are applied to radio frequency input ports of the calibration frequency converter and reference / test frequency converter; signals of the second signal source are divided into two routes, and the signals are applied to local oscillator drive ports of the calibration frequency converter and reference / test frequency converter; the calibration frequency converter output is connected with a first receiver, and the reference / test frequency converter output is connected with a second receiver; the local oscillator source down-converting the signals received by the first and second receivers to an intermediate frequency; the intermediate frequency signals are digitally sampled and vector calculation is carried out, thus obtaining complex number signals and sending same to a computer module. The frequency converter phase consistency testing device and method are not limited by the frequency converter internal structure, the calibration process is simple, and the hardware cost is lower.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

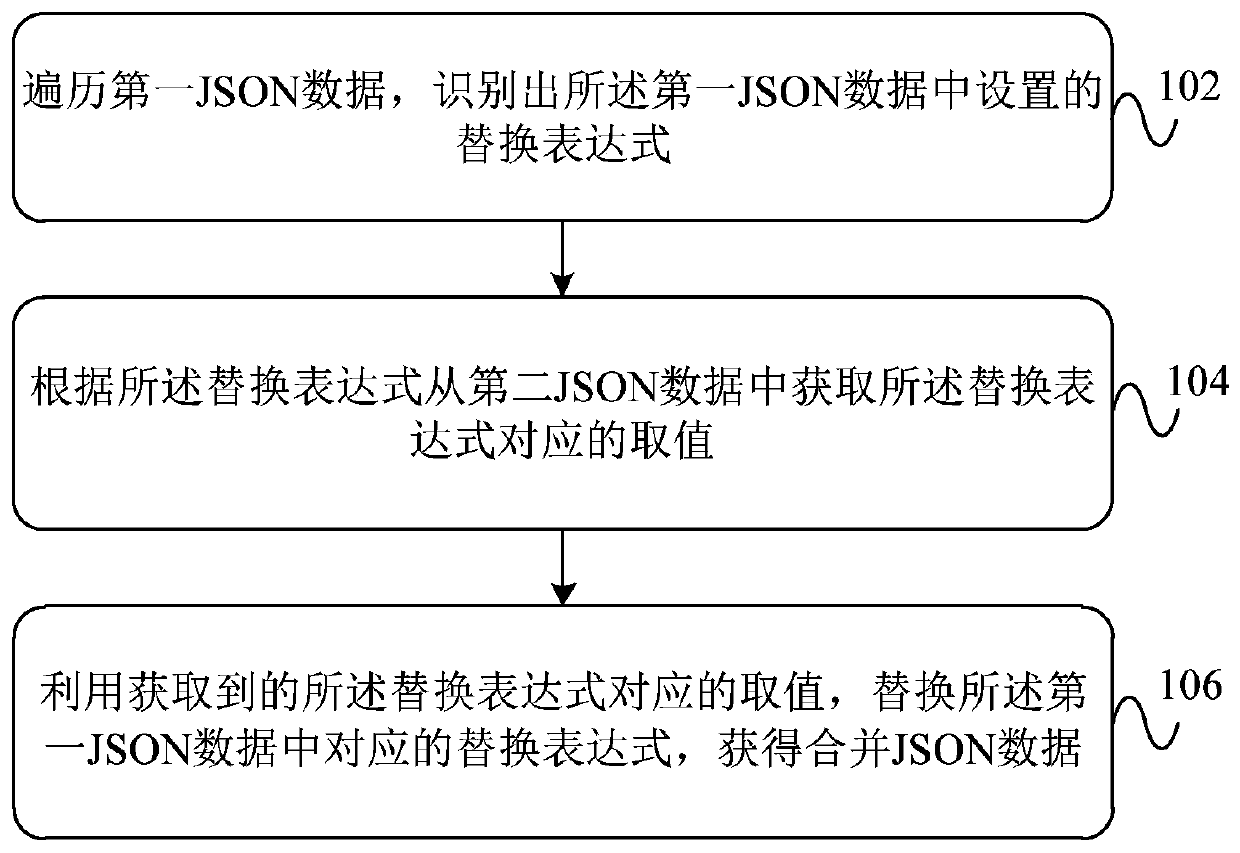

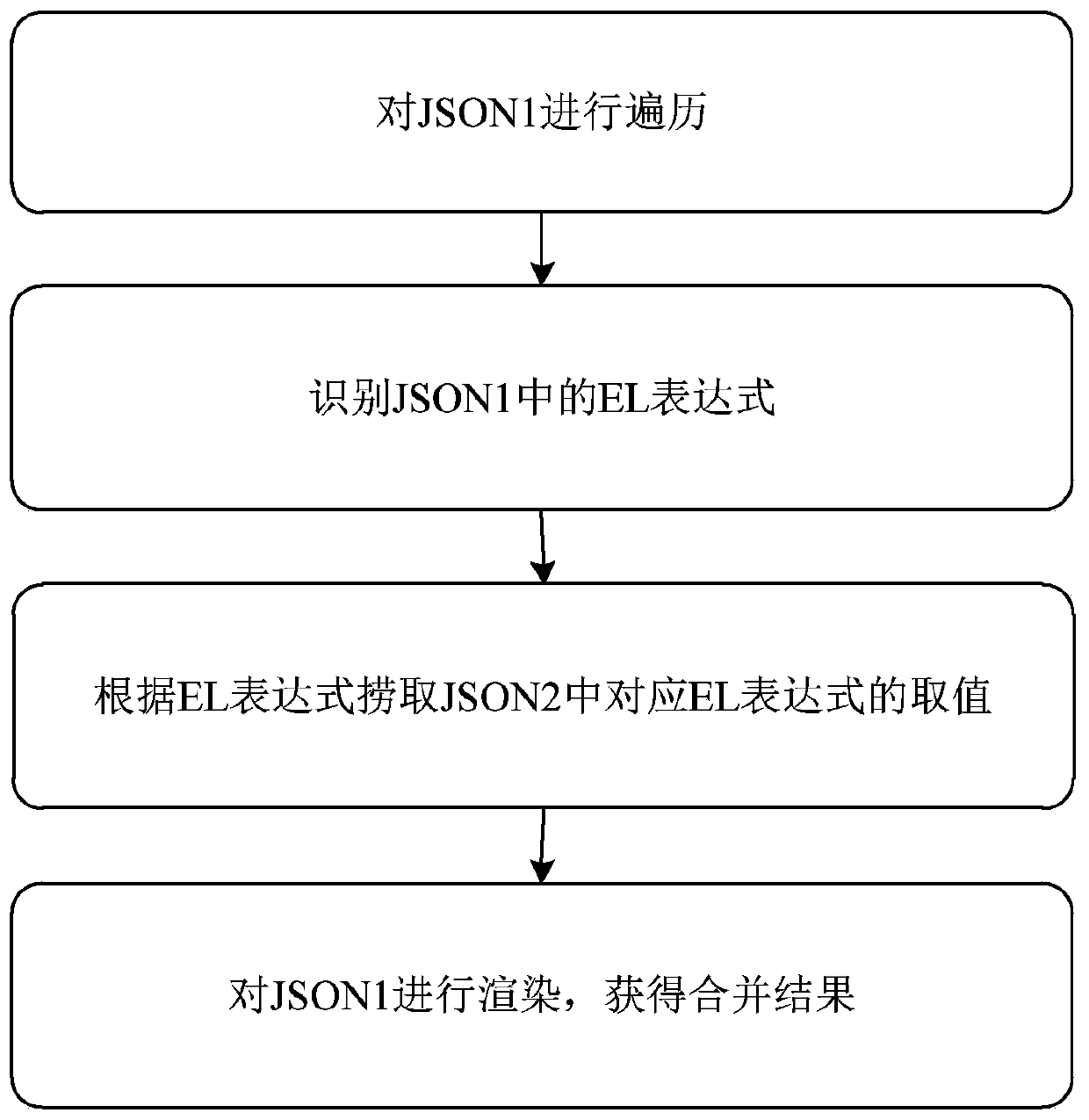

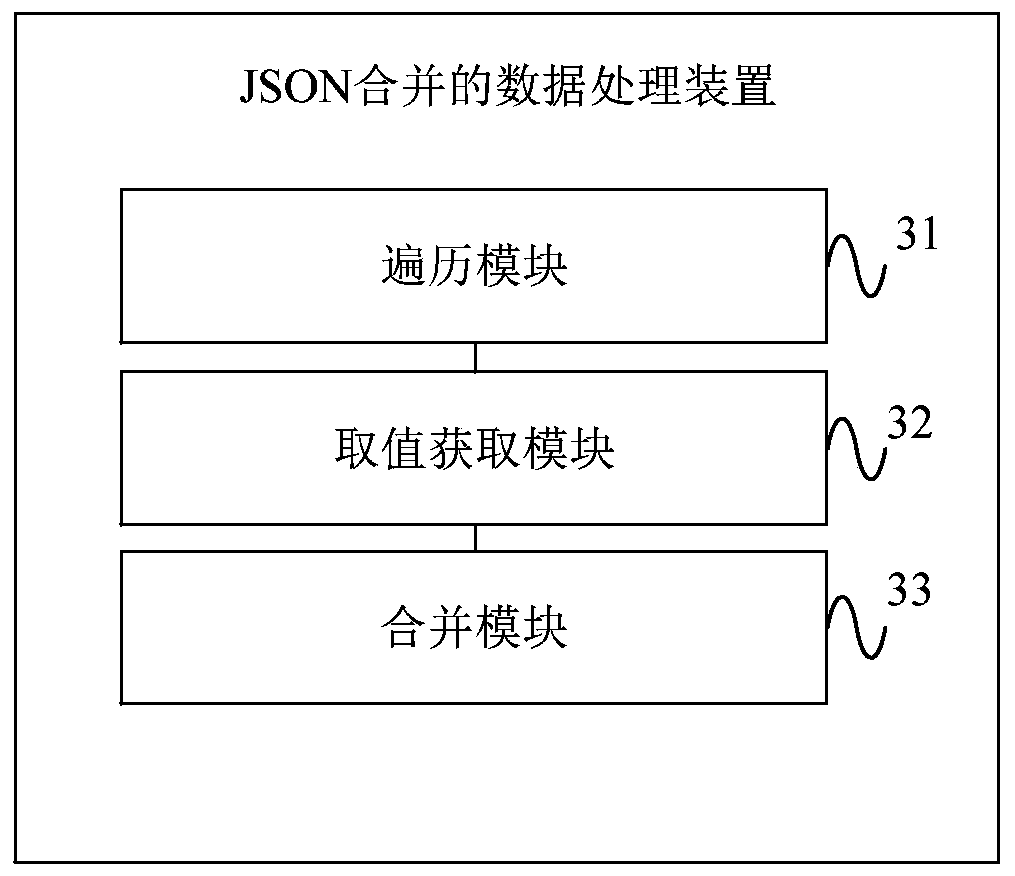

JSON combined data processing method and device

PendingCN110244938AMerge fitMeet custom needsCode compilationCreation/generation of source codeBusiness requirementsComputer science

The invention provides a JSON combined data processing method and device, and the method comprises the steps: setting a replacement expression in first JSON data, directionally obtaining a value corresponding to the replacement expression in second JSON data, and carrying out the parameter replacement of the replacement expression in the first JSON data. The formats of the replacement expressions can be set according to different service requirements, the replacement parameters are defined, the self-defined requirement of JSON merging is met, and the flexibility of JSON merging is improved. Moreover, JSON merging is carried out in a parameter replacement mode, the JSON merging efficiency can be improved, the structure of the JSON is not limited, the method is suitable for JSON merging of a complex structure, and the application range is wide.

Owner:ADVANCED NEW TECH CO LTD

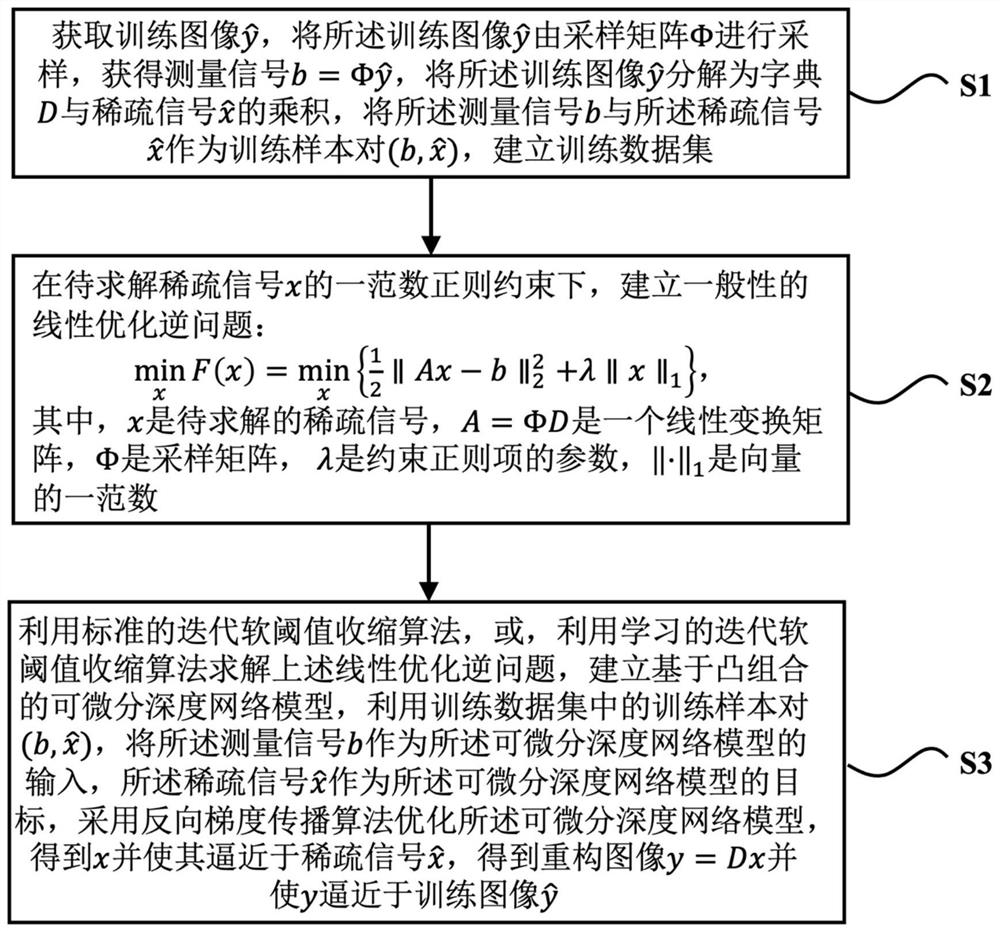

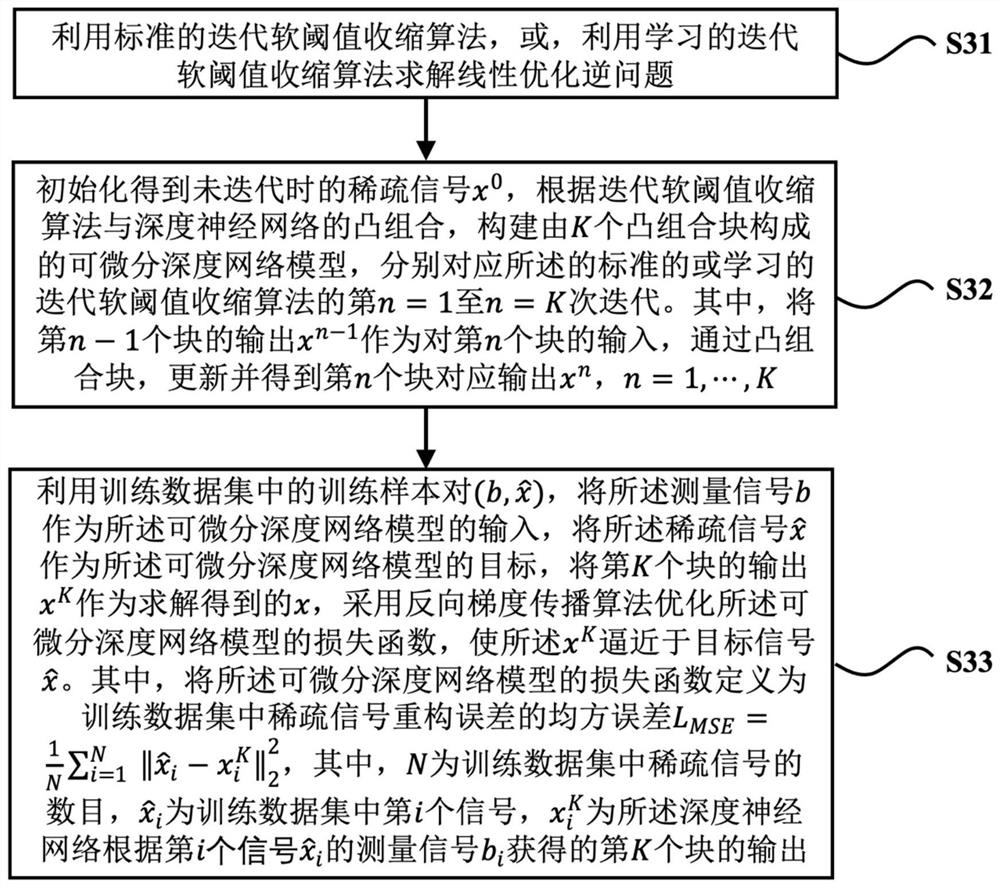

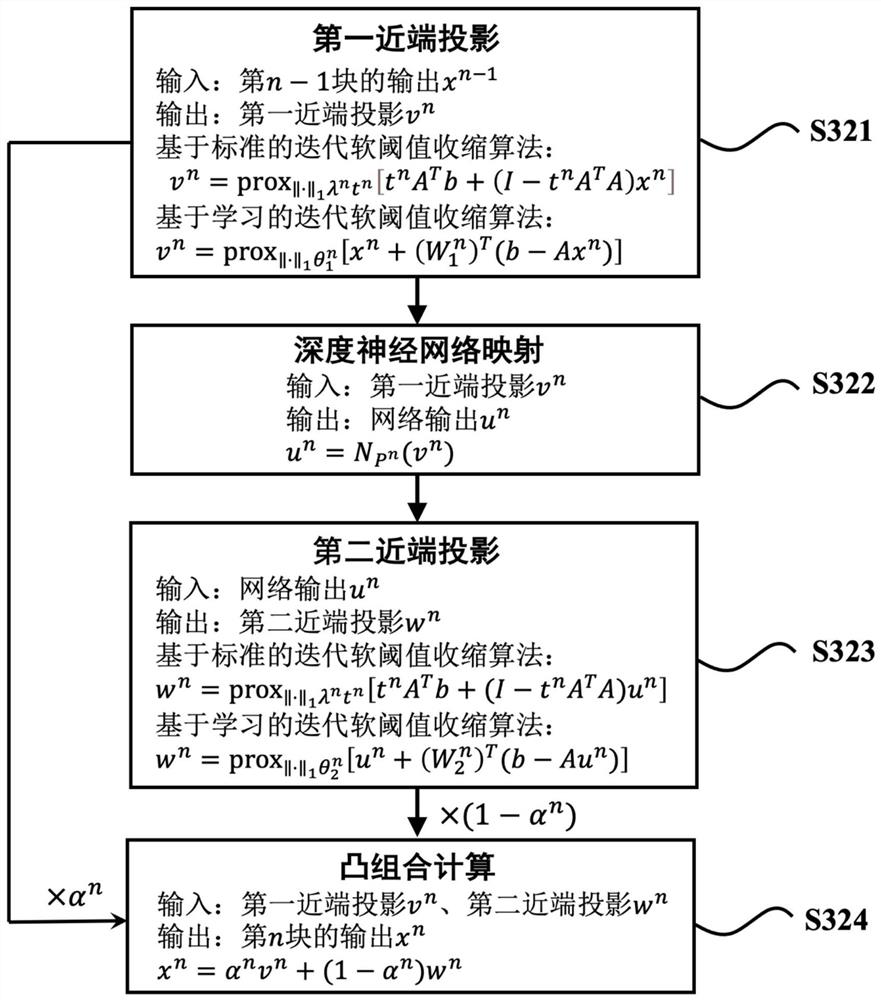

Image processing method, system and device and storage medium

PendingCN113674172AGuaranteed convergenceGuaranteed reconstruction accuracyImage enhancementImage analysisImage denoisingImaging processing

The invention provides an image processing method, system and device and a storage medium, which are used for image sparse reconstruction, image denoising, compressed sensing image reconstruction or image restoration. The image processing method comprises the following steps: establishing a general linear optimization inverse problem under the norm regular constraint of a sparse signal; on the basis of a standard or learned iterative soft threshold shrinkage algorithm, establishing a differentiable deep network model based on convex combination to solve the problem; introducing a deep neural network of any structure in the solving step to accelerate the solving step, and reducing the number of iterations required for convergence of the algorithm. According to the method, a traditional iterative optimization algorithm and a deep neural network of any structure are combined, the image reconstruction performance is improved, rapid convergence is ensured, and the current demand of image sparse reconstruction is met.

Owner:SHANGHAI JIAO TONG UNIV

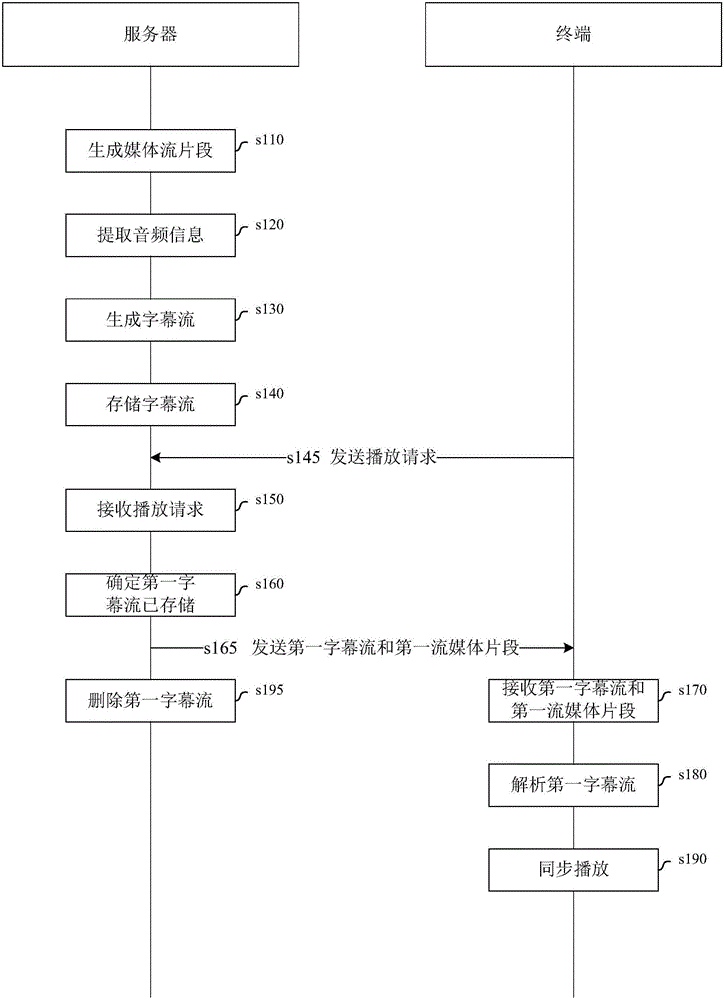

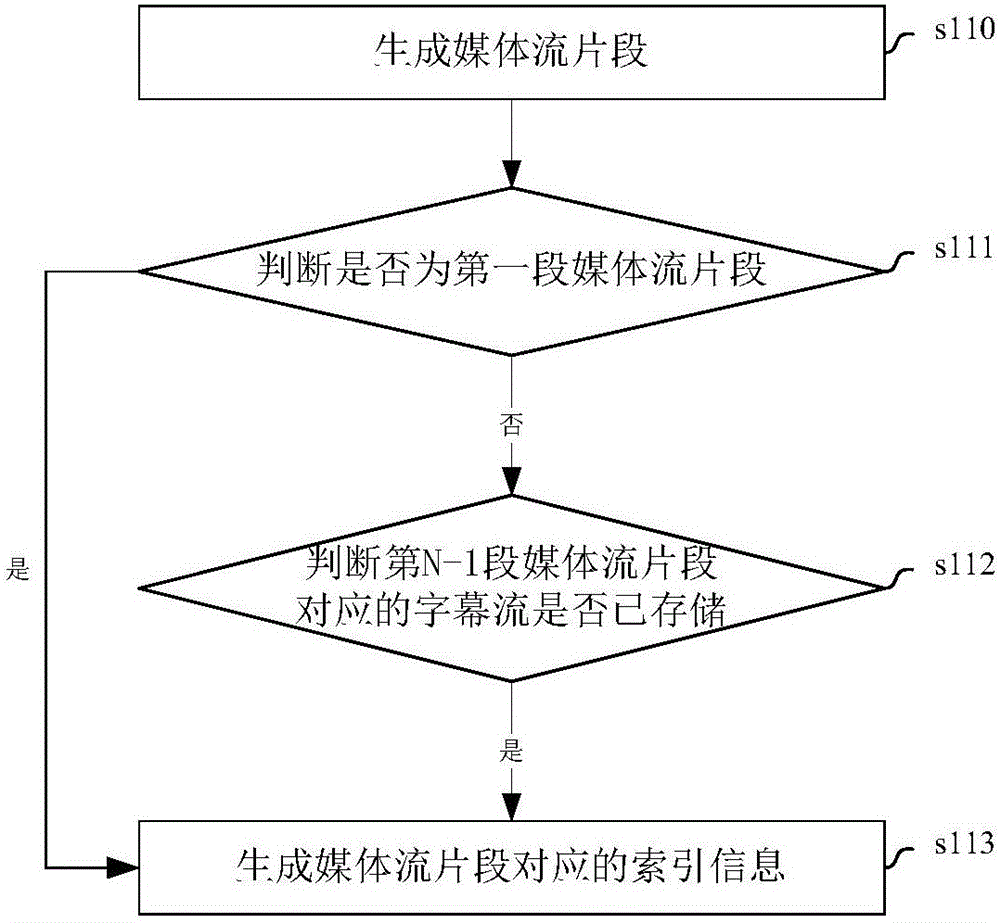

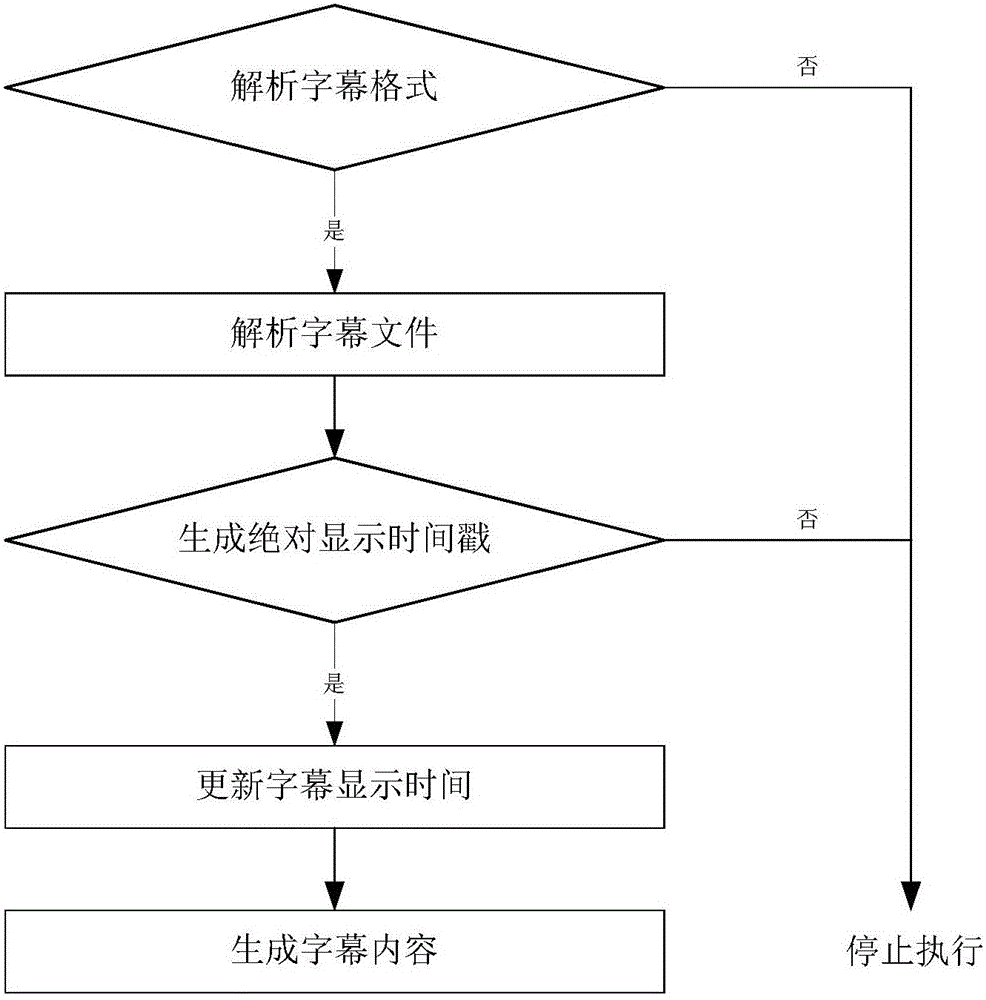

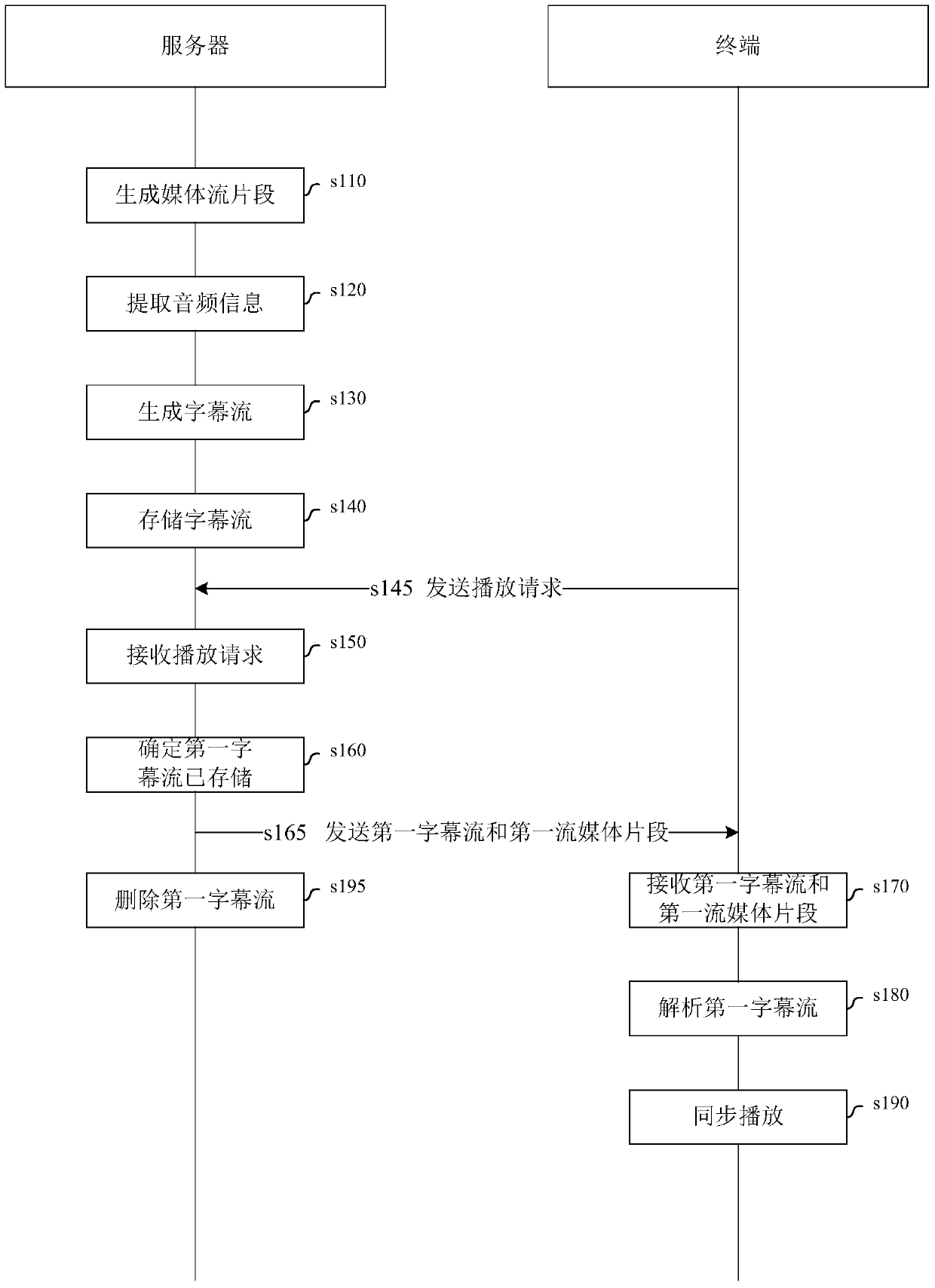

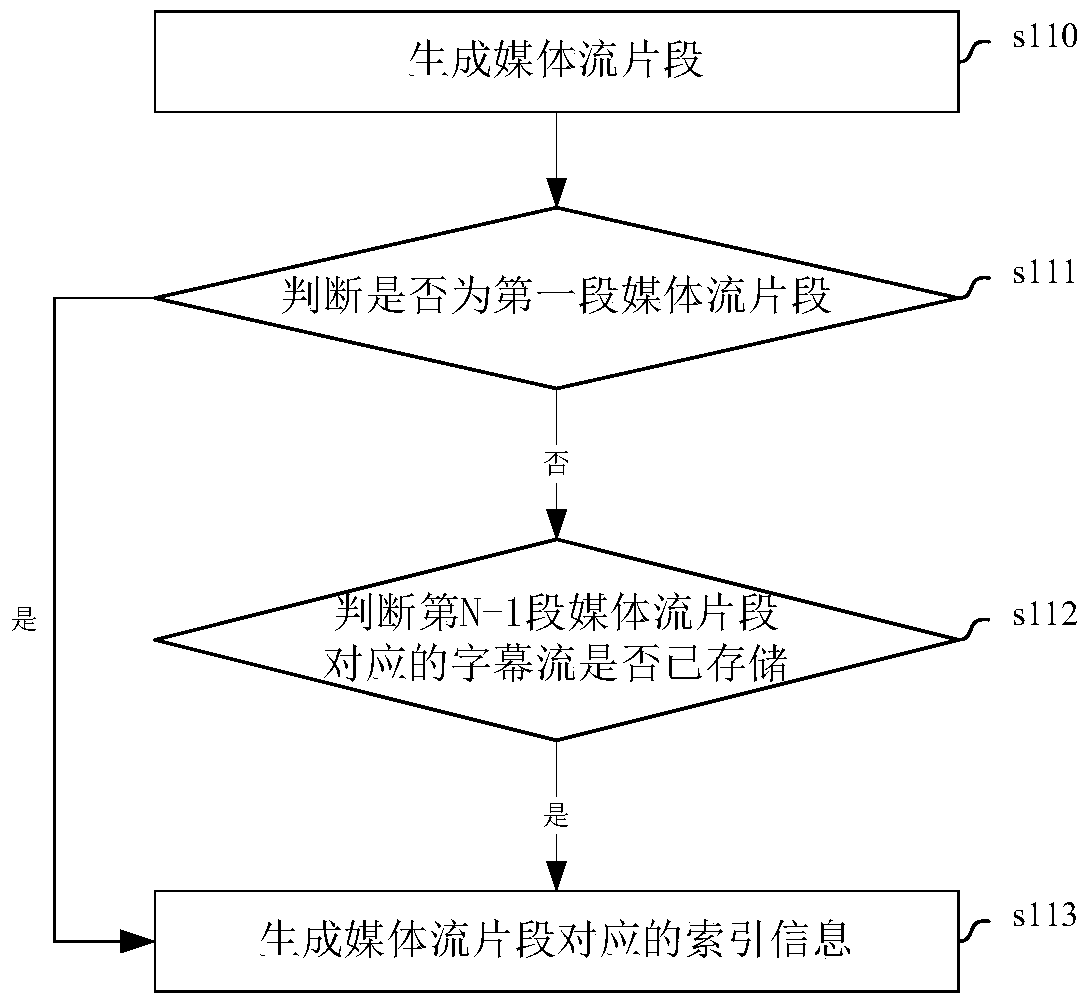

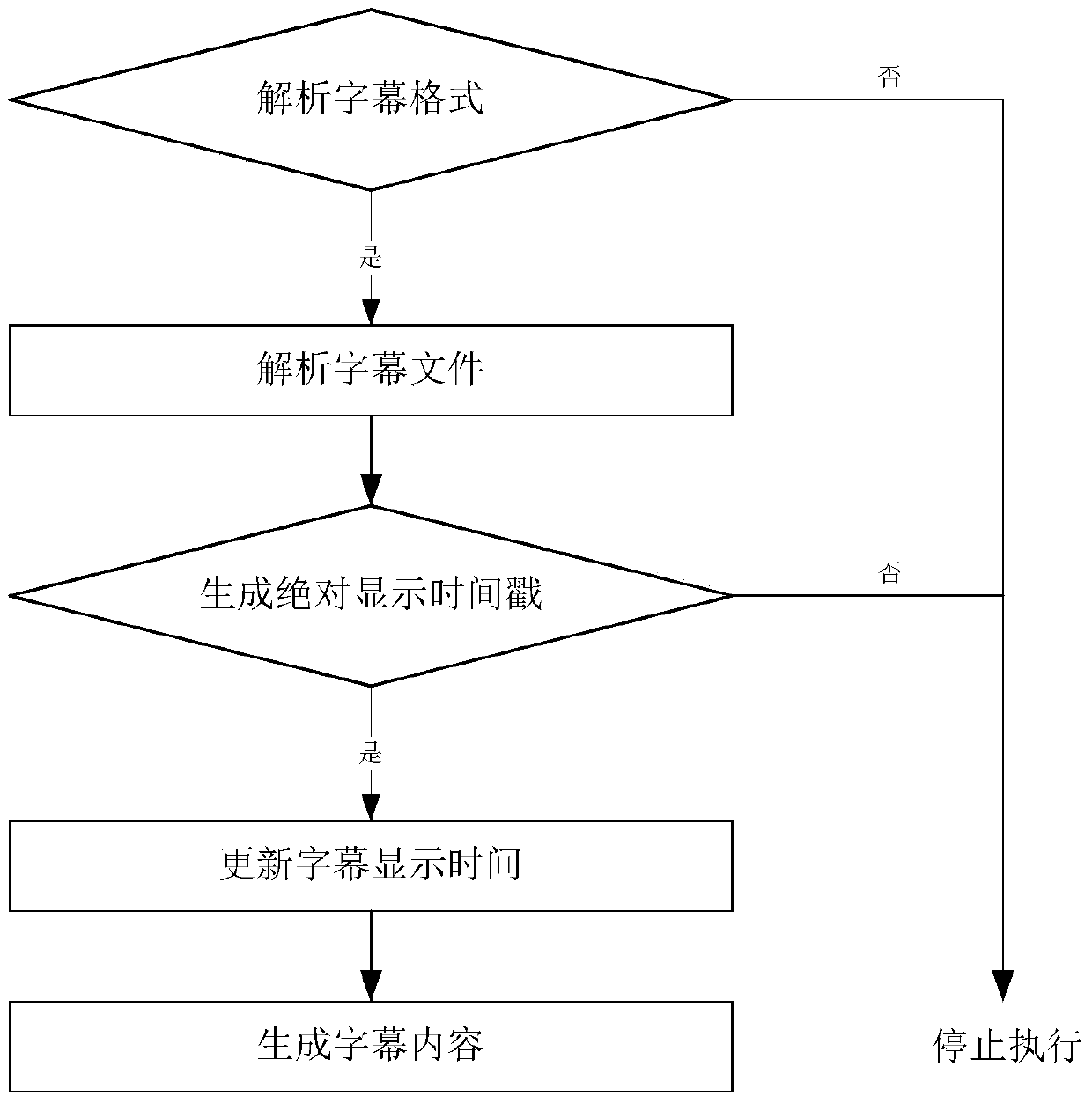

Real-time subtitle playing method and real-time subtitle playing system

ActiveCN106454547AUnrestricted structureImprove experienceSelective content distributionComputer terminalReal-time computing

The invention discloses a real-time subtitle playing method and a real-time subtitle playing system. The real-time subtitle playing method comprises steps that a media stream segment is divided into a plurality of media stream fragments; the audio information of each of the media stream fragments is extracted; subtitle streams are generated according to the audio information, and comprise subtitle files and index information corresponding to the subtitle files; the plurality of subtitle streams are stored; a playing request transmitted by a terminal is received, and the playing request is used to search a first subtitle stream corresponding to a first media stream fragment; when the first subtitle stream is stored, the first subtitle stream and the first media stream fragment are transmitted to the terminal, and then the terminal is used to parse the first subtle stream to acquire first subtitle content, and then the first subtitle content and the first media stream fragment are played synchronously. The subtitle content and the media stream fragments are synchronously played during direct broadcast.

Owner:ZHENGZHOU SEANET TECH CO LTD

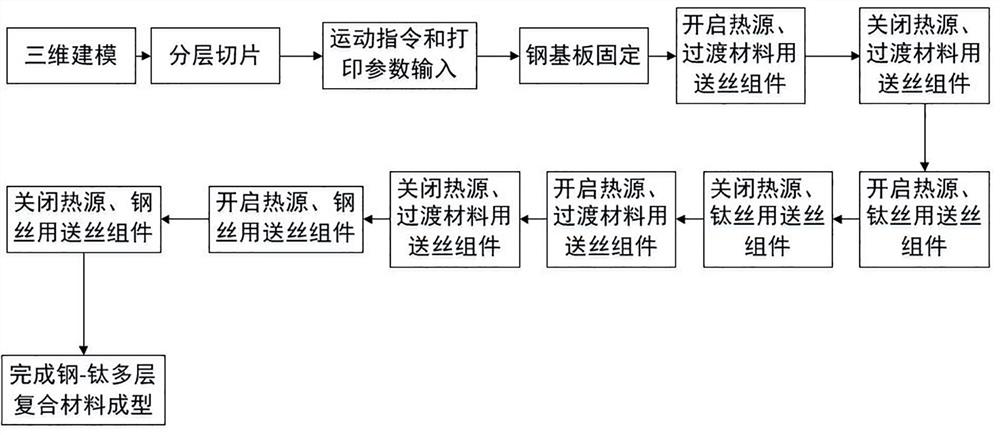

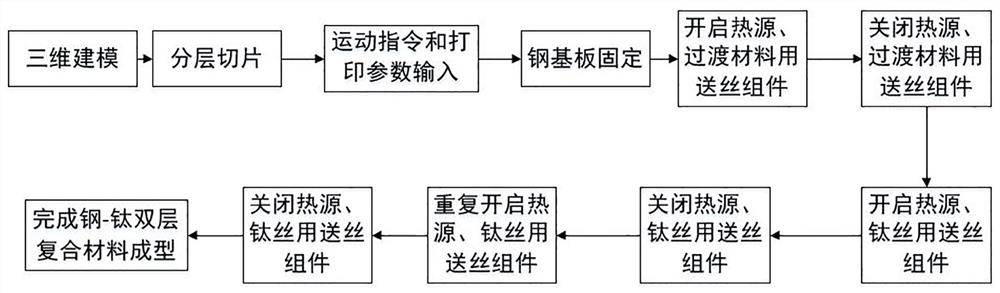

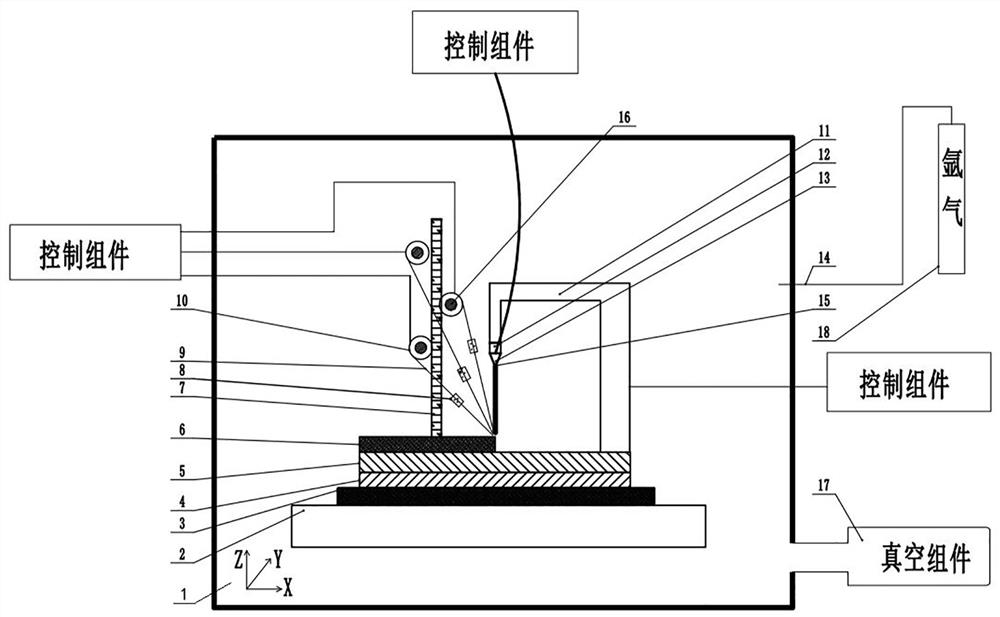

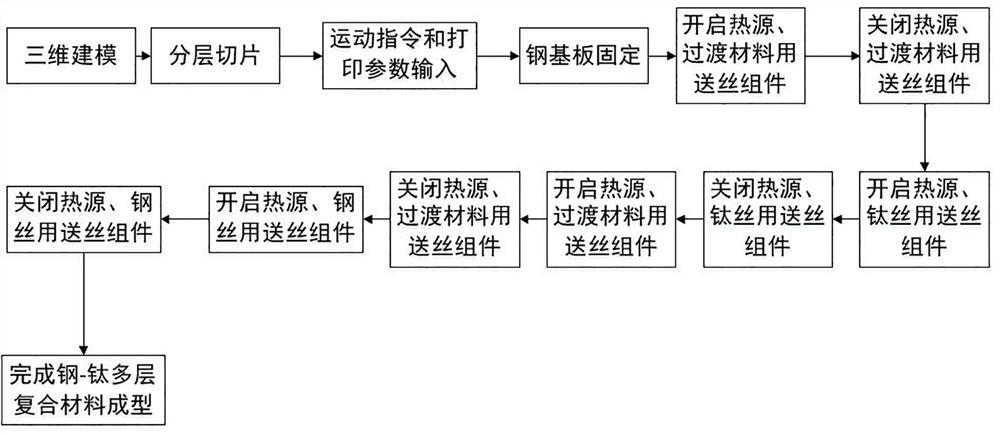

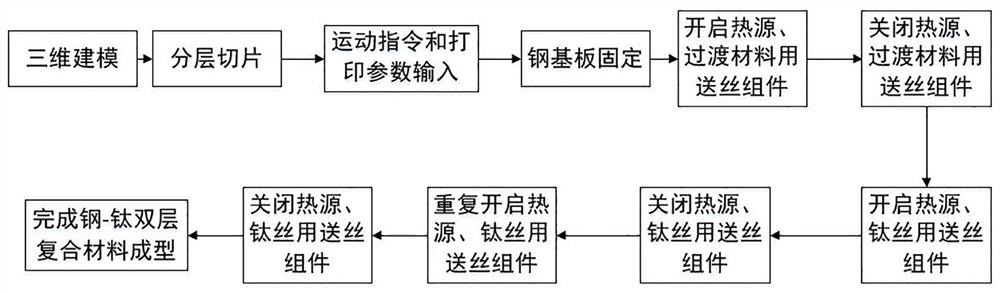

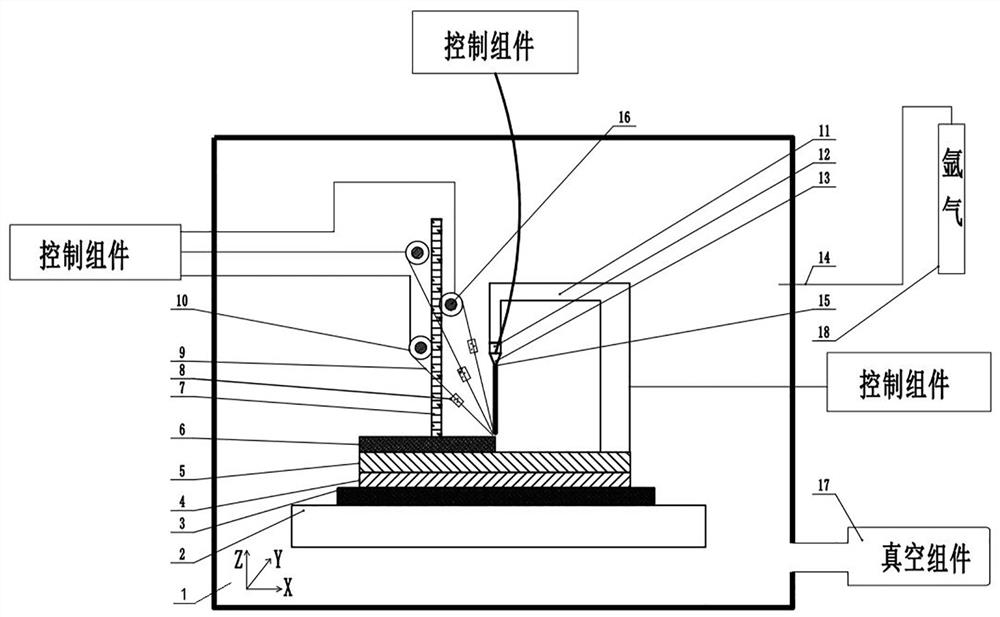

Steel-titanium composite material fuse high-efficiency additive manufacturing system and preparation method

ActiveCN111992719AUnrestricted structureAbandon pollutionAdditive manufacturing apparatusIncreasing energy efficiencyTitaniumAdditive layer manufacturing

The invention belongs to the technical field of fuse high-efficiency additive manufacturing, and discloses a steel-titanium composite material fuse high-efficiency additive manufacturing system and preparation method. The method comprises the following steps that firstly the three-dimensional modeling of a to-be-processed part of a composite material is carried out, the layered slicing is carriedout, printing parameters are adjusted through a control assembly, a to-be-processed steel substrate is fixed, a heat source and a wire feeding assembly for a transition material are started to complete one-layer fused deposition of a transition layer, then the heat source and the wire feeding assembly for a titanium wire are started to complete one-layer fused deposition of a titanium layer, the opening and closing of the wire feeding assembly for the transition material, the wire feeding assembly for the titanium wire and the wire feeding assembly for a steel wire are correspondingly adjustedaccording to the requirements of a to-be-processed part, and the fuse high-efficiency additive of the multi-layer steel-titanium composite material is completed. According to the steel-titanium composite material fuse high-efficiency additive manufacturing system and preparation method, the adopted technology is flexible in the technology, high in flexibility, short in period and friendly to theenvironment, and the prepared steel-titanium composite material can be steel-titanium double-layer composite or steel-titanium-steel-titanium multi-layer composite as well, and the number and mode ofcomposite layers are not limited.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

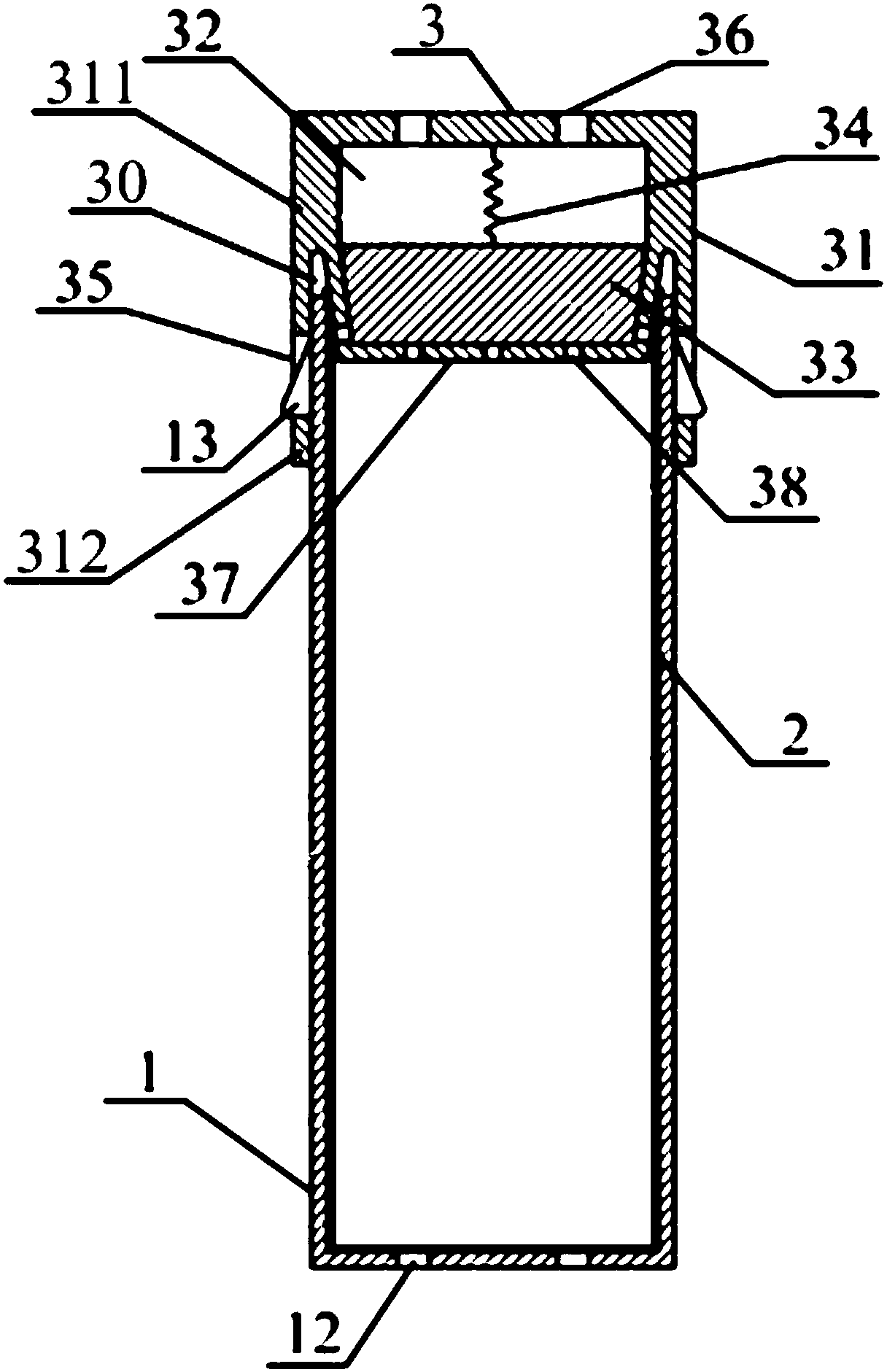

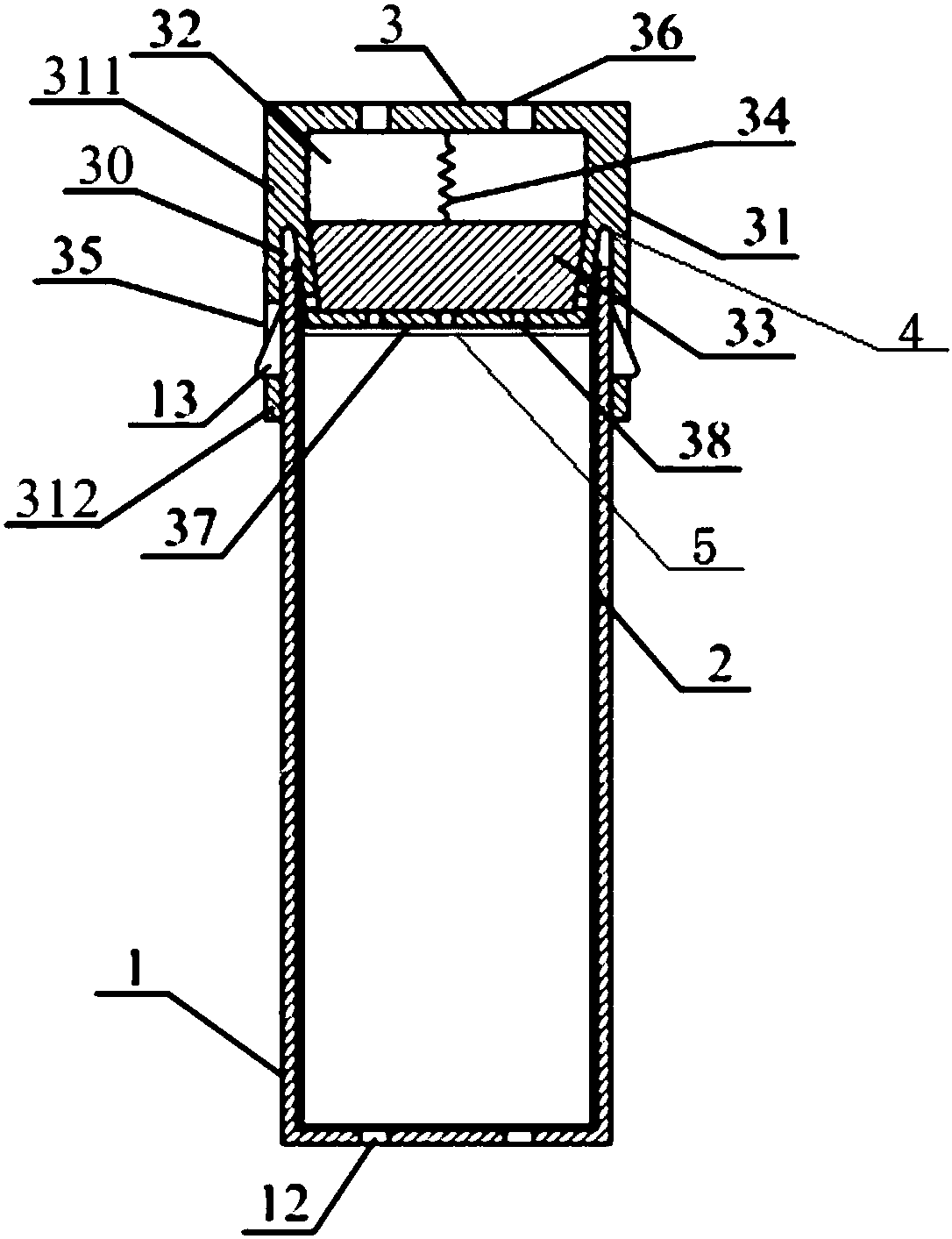

Sealing device suitable for object pressed under ultrahigh pressure and method

InactiveCN108248957AUnrestricted structureQuick and easy product fillingPackaging by pressurising/gasifyingUltra high pressureEngineering

The invention relates to an ultrahigh-pressure sealing device and a using method of the ultrahigh-pressure sealing device, in particular to a sealing device suitable for an object pressed under ultrahigh pressure and a using method of the sealing device. The sealing device is characterized in that the sealing device comprises an end cover, a magnetic movable block, an elastic assembly, an inner cylinder and an outer cylinder; the end cover is composed of an end cover shell and an end cover protrusion; the magnetic movable block is placed in the end cover protrusion; the elastic assembly is mounted between the magnetic movable block and the end cover shell; and the inner cylinder is mounted in the outer cylinder, and the inner cylinder and the outer cylinder are combined and then embedded in an annular groove defined by the end cover shell and the end cover protrusion. The sealing device has the advantages that the structure shape is not limited, product filling is rapid, mechanizationand automation are easy to achieved, vacuum packaging and non-vacuum packaging can be met through structure arrangement, and free selection is conducted according to the actual condition.

Owner:ZIGONG INNOVATION CENT OF ZHEJIANG UNIV

A high-efficiency additive manufacturing system and preparation method of steel-titanium composite fuse wire

ActiveCN111992719BUnrestricted structureLong cycleAdditive manufacturing apparatusIncreasing energy efficiencyTitaniumAdditive layer manufacturing

The invention belongs to the technical field of fuse high-efficiency additive manufacturing, and discloses a steel-titanium composite material fuse high-efficiency additive manufacturing system and preparation method. The method comprises the following steps that firstly the three-dimensional modeling of a to-be-processed part of a composite material is carried out, the layered slicing is carriedout, printing parameters are adjusted through a control assembly, a to-be-processed steel substrate is fixed, a heat source and a wire feeding assembly for a transition material are started to complete one-layer fused deposition of a transition layer, then the heat source and the wire feeding assembly for a titanium wire are started to complete one-layer fused deposition of a titanium layer, the opening and closing of the wire feeding assembly for the transition material, the wire feeding assembly for the titanium wire and the wire feeding assembly for a steel wire are correspondingly adjustedaccording to the requirements of a to-be-processed part, and the fuse high-efficiency additive of the multi-layer steel-titanium composite material is completed. According to the steel-titanium composite material fuse high-efficiency additive manufacturing system and preparation method, the adopted technology is flexible in the technology, high in flexibility, short in period and friendly to theenvironment, and the prepared steel-titanium composite material can be steel-titanium double-layer composite or steel-titanium-steel-titanium multi-layer composite as well, and the number and mode ofcomposite layers are not limited.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

A kind of flexible strain sensing woven fabric and its manufacturing process

ActiveCN107385623BThe strain sensing function hasHigh sensitivitySwivel-woven fabricsLappet-woven fabricsYarnSurface pattern

The invention discloses a flexible strain sensing woven fabric and a manufacturing process thereof. The flexible strain sensing woven fabric comprises a non-conductive elastic woven fabric and elastic conductive yarns, and the elastic conductive yarns are consolidated as embossed yarns A relief pattern is formed on the surface of the non-conductive elastic woven fabric, and the two ends of the elastic conductive yarn are provided with joints and lead wires for electrical connection. The flexible strain sensing woven fabric provided by the present invention has simple structure, good softness, high comfort, can be washed with water, can realize continuous production, has strain sensing function in all directions, and has high sensitivity and good stability of the woven fabric. It has good application prospects in the field of intelligent textiles and wide applicability; in addition, the present invention also has the advantages of simple manufacturing process, convenient use, designable surface patterns of strain sensing fabrics, aesthetics, etc., and has strong practical value. It is worthy of widespread popularization and application, and has significant progress compared with the prior art.

Owner:上海捻幅智能科技有限公司

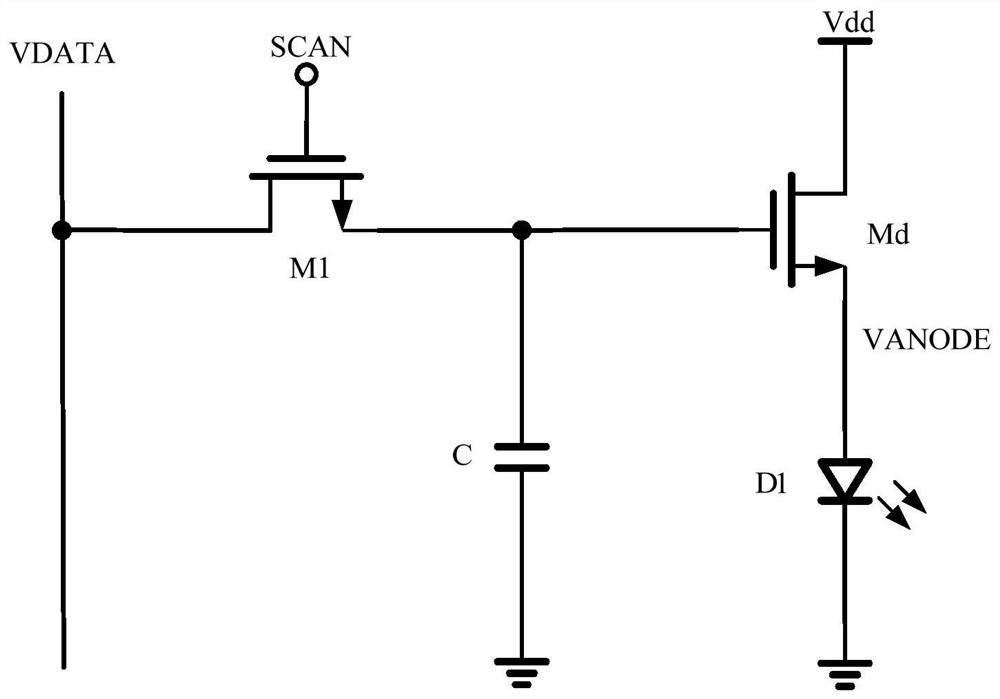

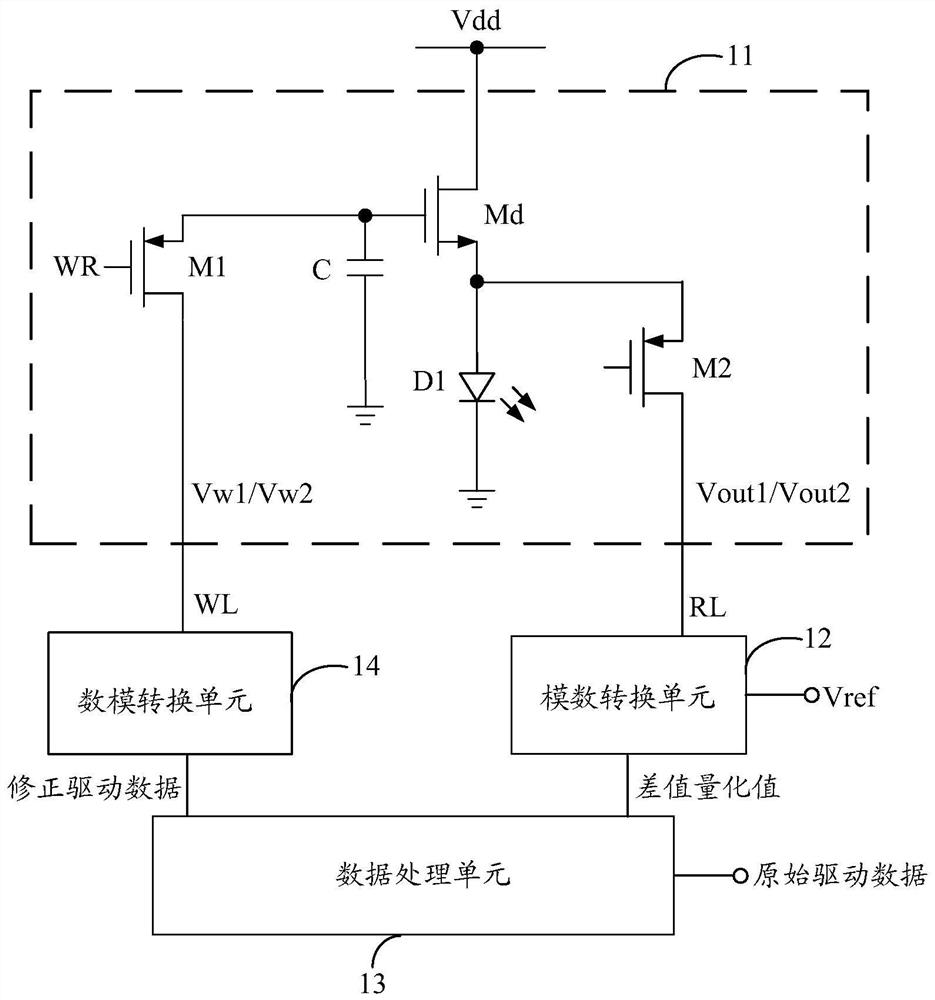

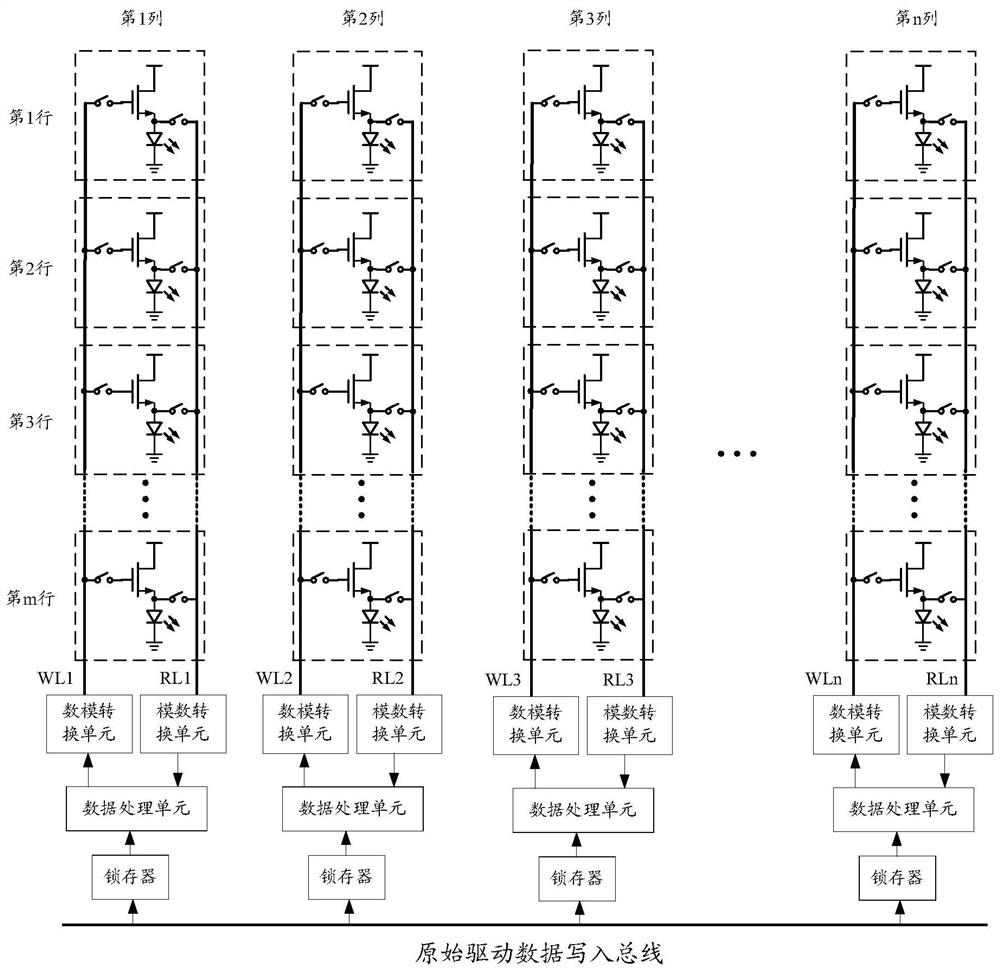

Calibration device, display chip and display

ActiveCN113920938AUnrestricted structureComplex structureStatic indicating devicesDigital conversionAnalog to digital conversion

The invention provides a calibration device, a display chip and a display, the calibration device is suitable for being coupled with at least one pixel unit, and the pixel unit is suitable for receiving a selection signal and a reference write-in voltage and providing an initial output voltage based on the reference write-in voltage when the selection signal is an effective level. The calibration device comprises an analog-to-digital conversion unit which is suitable for obtaining a first voltage difference value between a reference voltage and an initial output voltage and performing analog-to-digital conversion on the first voltage difference value to obtain a difference value quantized value, and the difference value quantized value corresponds to a pixel unit providing the initial output voltage.

Owner:BRIGATES MICROELECTRONICS KUNSHAN

Mold 3D exhaust system for molding thin-wall plastic products

The invention discloses a mold 3D exhaust system for molding thin-wall plastic products. Multiple exhaust ports are formed in a mold core, and are distributed in front and back rows; along each exhaust port, a vertical exhaust way is provided in an extending manner; the front row of vertical exhaust ways communicate through a front longitudinal air way horizontally arranged; the back row of vertical exhaust ways communicate through a back longitudinal air way; the front longitudinal air way and the back longitudinal air way extend to the side surfaces of an exhaust gradient gap part to form longitudinal exhaust ports, and communicate through a transverse air way therebetween; the transverse air way extends to the side surface of the exhaust gradient gap part to form a transverse exhaust port; and a main exhaust air way communicating with the transverse air way communicates with the external of a mold. When the mold is used for injection molding, gas in a molding cavity is quickly and timely exhausted outside the cavity, so that the molding filling time and the molding period are shortened by 35% or above, the exhaust problem is thoroughly solved, and such defects as gas marks and burns on the surfaces of products caused by gas trapping are prevented.

Owner:苏州川鹏塑料有限公司

A method and system for broadcasting real-time subtitles

ActiveCN106454547BUnrestricted structureImprove experienceSelective content distributionSubtitleMediaFLO

The invention discloses a real-time subtitle playing method and a real-time subtitle playing system. The real-time subtitle playing method comprises steps that a media stream segment is divided into a plurality of media stream fragments; the audio information of each of the media stream fragments is extracted; subtitle streams are generated according to the audio information, and comprise subtitle files and index information corresponding to the subtitle files; the plurality of subtitle streams are stored; a playing request transmitted by a terminal is received, and the playing request is used to search a first subtitle stream corresponding to a first media stream fragment; when the first subtitle stream is stored, the first subtitle stream and the first media stream fragment are transmitted to the terminal, and then the terminal is used to parse the first subtle stream to acquire first subtitle content, and then the first subtitle content and the first media stream fragment are played synchronously. The subtitle content and the media stream fragments are synchronously played during direct broadcast.

Owner:ZHENGZHOU SEANET TECH CO LTD

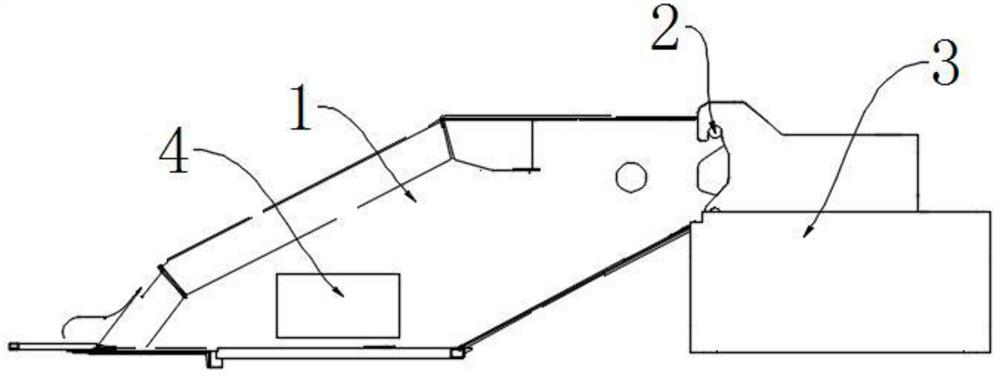

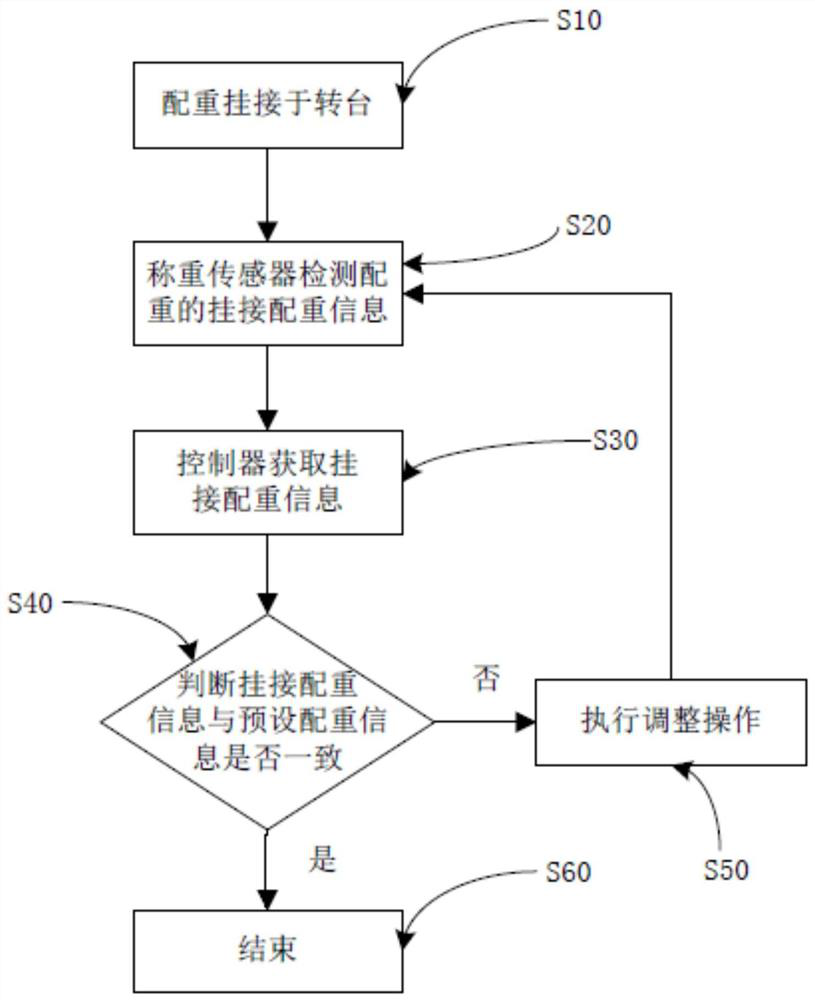

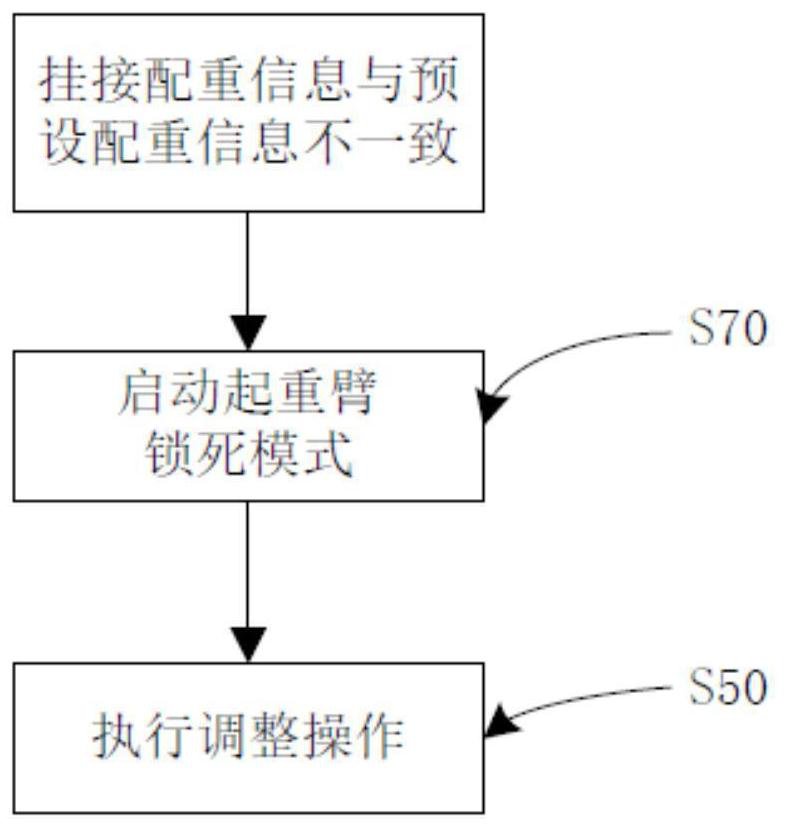

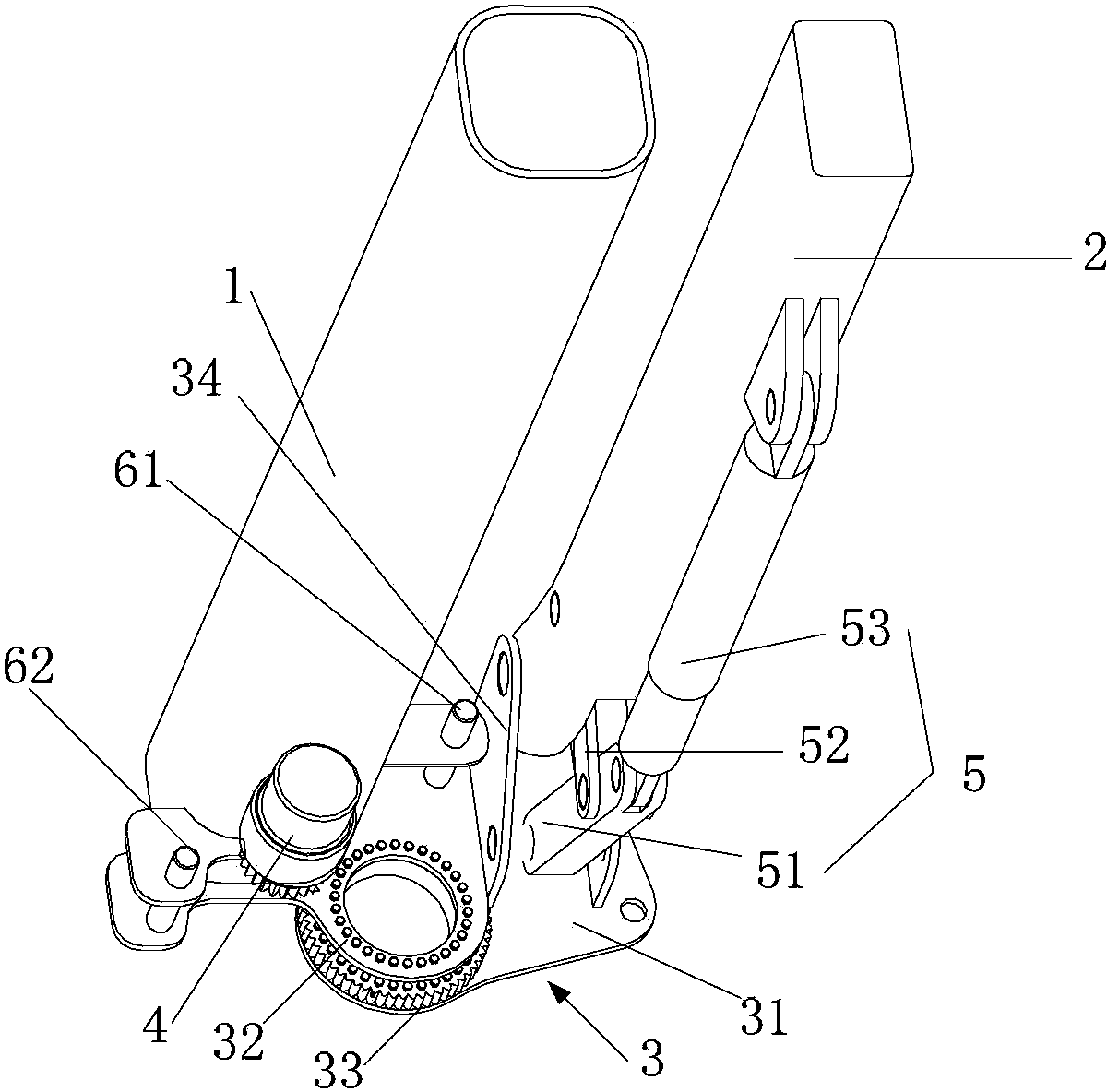

Crane counterweight identification method and device and crane

PendingCN112850521AIncrease job securityIncrease success rateCranesLoad-engaging elementsControl engineeringControl theory

The invention provides a crane counterweight identification method and device and a crane. The crane counterweight identification method comprises the following steps of enabling a controller to detect that a rotary table is hung with a counterweight, wherein the rotary table is provided with a weighing sensor in advance; enabling the controller to receive the hanging counterweight information of the counterweight detected by the weighing sensor; judging whether the hanging counterweight information is consistent with preset counterweight information or not; and if the hanging counterweight information is inconsistent with the preset counterweight information, executing an adjustment operation. In the crane counterweight identification method and device and the crane, the counterweight is hung on the rotary table provided with the weighing sensor, the weighing sensor detects the hanging counterweight information of the counterweight and transmits the hanging counterweight information to the controller, and the controller judges whether the counterweight information is consistent or not to determine whether the crane can continue working or not, so that the problem of wrong hanging of the counterweight caused by reasons such as misoperation of personnel can be effectively reduced, and the operation safety of the crane is improved; and the counterweight recognition is not influenced by factors such as light and weather, the structure of the counterweight is not limited, and the counterweight recognition success rate is high.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

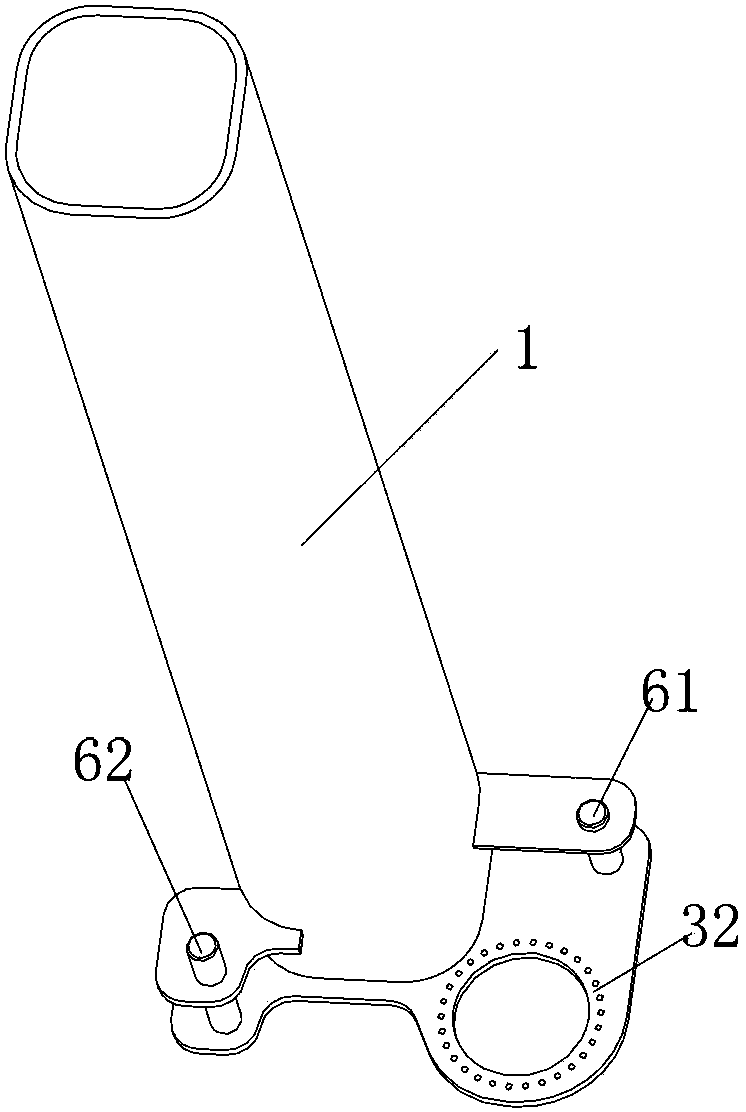

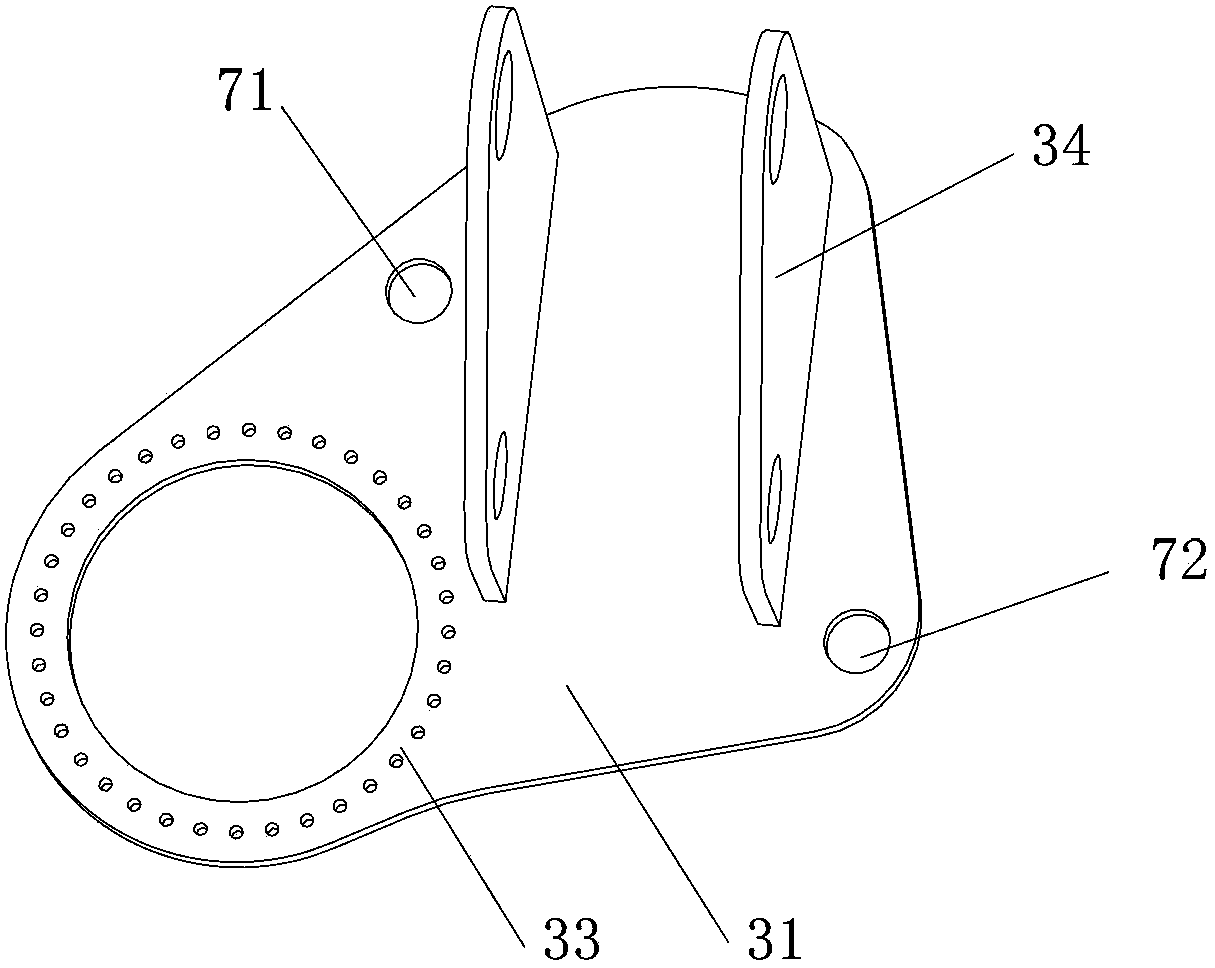

Arm frame and engineering machinery

The invention provides an arm frame. The arm frame comprises a first arm frame, a second arm frame, a variable amplitude mechanism for unfolding and folding the second arm frame, a rotary mechanism, a rotary drive device and a positioning device, wherein the rotary mechanism is mounted at one end of the first arm frame, and one end of the second arm frame is connected with the rotary mechanism; the rotary mechanism is driven by the rotary drive device to rotate so that the second arm frame can rotate around a rotary shaft line of the rotary mechanism; and after the second arm frame rotates to a position at an angle, the rotary mechanism is fixed through the positioning device so that the first arm frame and the second arm frame are kept in the angular relationship. The invention further discloses engineering machinery comprising the arm frame. Owing to the technical scheme, the eccentric load between the first arm frame and the second arm frame during operation can be removed, the stability of the whole vehicle can be improved, and the structures of the first arm frame and the second arm frame are not limited. Therefore, the arm frame is wide in range of application and is flexible and convenient.

Owner:BEIJING SANY HEAVY MASCH CO LTD

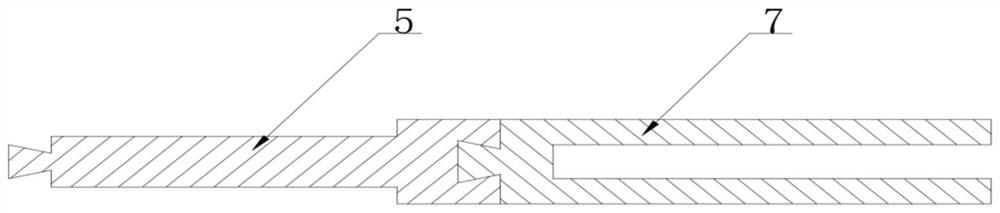

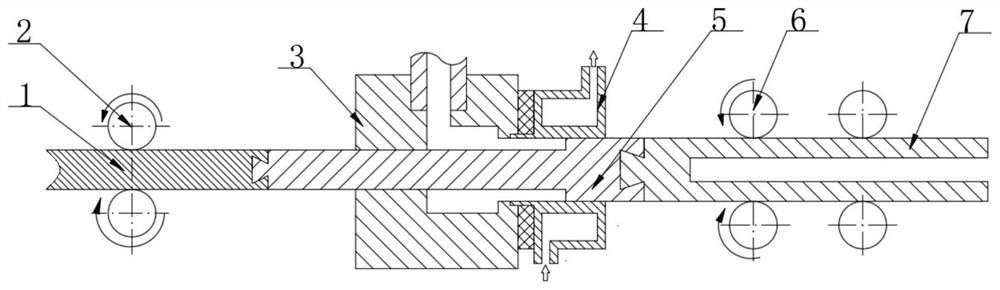

Composite dummy bar for stainless steel coated carbon steel liquid-solid composite continuous casting and method

The invention discloses a composite dummy bar for stainless steel coated carbon steel liquid-solid composite continuous casting and a method, and belongs to the technical field of composite continuous casting. The composite dummy bar for liquid-solid composite continuous casting of the 304 stainless steel coated Q235 carbon steel composite plate blank is composed of a transition connecting rod and a traction rod which are resistant to high temperature and corrosion of 304 stainless steel liquid and low in heat conductivity, the composite dummy bar of a special structure is used for effectively controlling fusing or surface oxidation of a Q235 carbon steel core plate before liquid-solid composite continuous casting of the 304 stainless steel coated Q235 carbon steel composite plate blank, and the continuous casting stability and the compounding quality of the 304 stainless steel and the Q235 carbon steel are ensured. The composite dummy bar for stainless steel coated carbon steel liquid-solid composite continuous casting has the advantages that the device is simple in structure, convenient to mount and reusable, widens the liquid-solid composite continuous casting process window of the 304 stainless steel coated Q235 carbon steel composite slab, and is beneficial to improving the surface and interface quality of the 304 stainless steel coated Q235 carbon steel composite slab.

Owner:UNIV OF SCI & TECH BEIJING +1

A Broadband Filter Power Divider Capable of Realizing High Power Split Ratio

ActiveCN111834726BLower the input impedance valueImprove the power ratioCoupling devicesConvertersTelecommunications

Owner:NANJING UNIV OF SCI & TECH

Circuit Compensation Network of Efficiency-Based Non-contact Powered Ultrasonic Vibration System

ActiveCN104993605BDoes not involve physical structure sizeUnrestricted structureCircuit arrangementsUltrasonic weldingInductor

The invention discloses a circuit compensation network for a non-contact power supply ultrasonic vibration system seeking to achieve maximum transmission efficiency, including a primary side compensation network and a secondary side compensation network, and the primary side compensation network is connected to an ultrasonic power supply and a non-contact electromagnetic coupler Between the primary side coils, it is used to compensate the reactive power of the system, so that the output voltage and current of the power supply are in the same phase. The secondary side compensation network is connected between the non-contact electromagnetic coupler secondary side coil and the ultrasonic vibrator. parameters to achieve energy transmission with the highest efficiency, and the compensation components are inductors and / or capacitors. The invention can be applied to occasions such as rotary ultrasonic processing, ultrasonic welding and the like where a non-contact electromagnetic coupler is required to supply power to ultrasonic vibrators, and realizes energy transmission with the highest efficiency by optimizing compensation element parameters.

Owner:TIANJIN UNIV

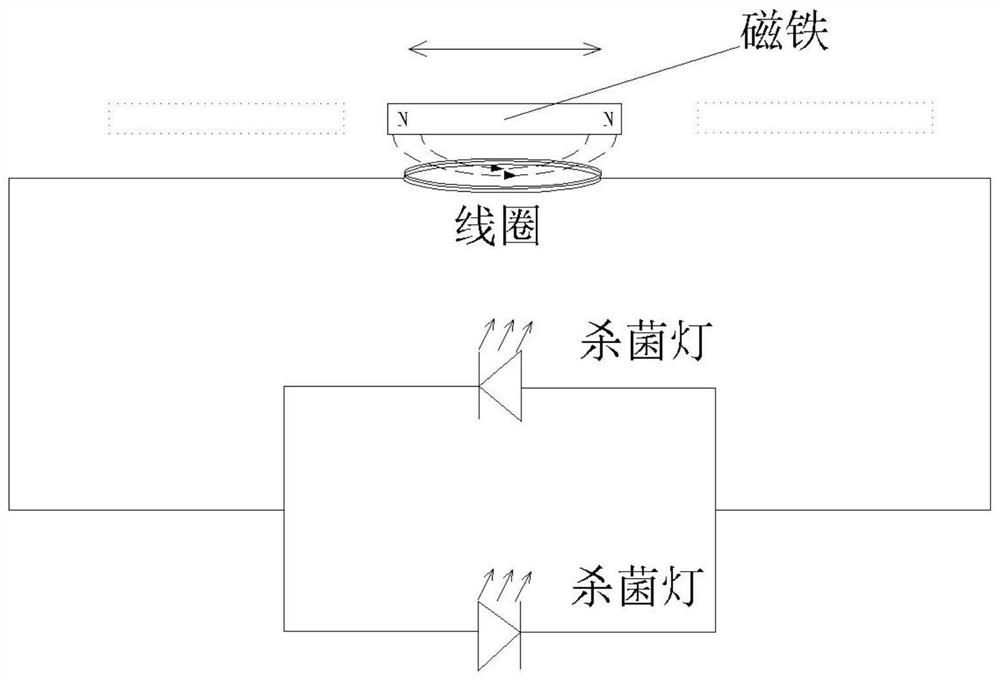

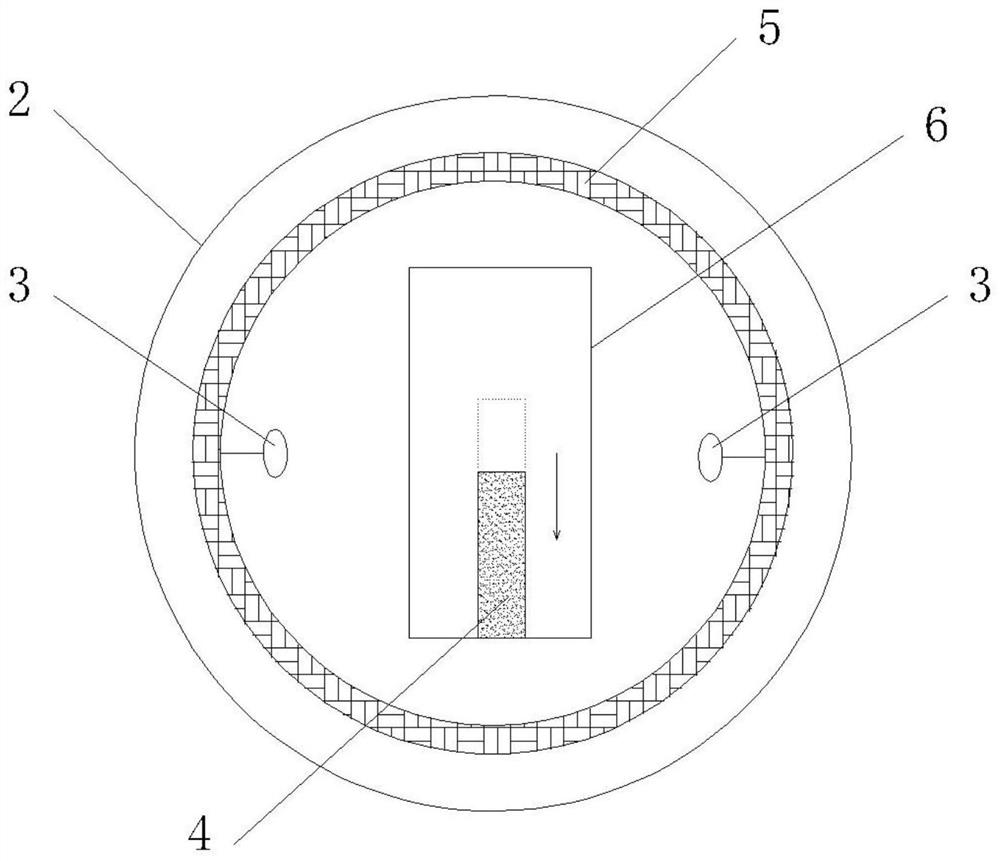

Dish-washing machine with sterilization module and sterilization method of dish-washing machine

PendingCN113116268AWith bactericidal functionSolve the problems that need to be elicitedTableware washing/rinsing machine detailsUltraviolet lightsEngineering

The invention relates to a dish-washing machine with a sterilization module and a sterilization method of the dish-washing machine. The dish-washing machine comprises a sterilization device mounted on a vertical sprayer, and the sterilization module comprises one or more ultraviolet lamps and a power supply device for supplying power to the ultraviolet lamps. The power supply device comprises a coil in circuit connection with the ultraviolet lamps and a magnet capable of reciprocating within a certain range, the magnet moves along with rotation of the vertical sprayer, and the coil cuts magnetic induction lines to generate a voltage to supply power to the ultraviolet lamps. The ultraviolet lamps are arranged to sterilize irradiated water and air so that the dish-washing machine has a sterilization function. A self-generating mode is adopted, the problem that a power line needs to be led out in the prior art is solved, and the manufacturing cost is greatly reduced. The sterilization device is an integrated structure, installation is convenient, and the structure is not limited.

Owner:QINGDAO HAIER DISHWASHER +1

Capacitor lead welding tool

PendingCN114734114ARealize processingAvoid confictFilament handlingSoldering ironCapacitanceWire cutting

The invention discloses a capacitor lead welding tool which comprises a capacitor core feeding mechanism and a lead feeding mechanism, the capacitor core feeding mechanism comprises a rotating mechanism and a clamping mechanism, the clamping mechanism is used for clamping a capacitor core, and the rotating mechanism can drive the clamping mechanism to rotate among a feeding station, a tin welding station and a discharging station in sequence. The clamping mechanism can drive a capacitor core to rotate by 180 degrees at a tin welding station so as to weld leads at the two ends of the capacitor core, the lead feeding mechanism comprises a lead winder and a lead feeding head, the leads are wound on the lead winder, one end of each lead is connected into the lead feeding head, and the lead feeding head is used for conveying the leads and cutting the leads into segments. The lead feeding head can convey the lead from one side of the capacitor core to the end face of the capacitor core at a tin welding station. According to the welding tool, automatic assembly line machining can be achieved, the lead can be fed from the side of the capacitor core during welding, conflict with a welding head can be avoided, and the welding position is not limited.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

An inverter phase consistency test device and method

ActiveCN106771712BUnrestricted structureSimplify the calibration processElectrical testingVoltage-current phase angleFrequency changerConsistency test

The present invention proposes a phase consistency test device for frequency converters. The frequency converters that pass the test are used as calibration frequency converters and reference frequency converters, and the phase consistency test is performed on the test frequency converters to be tested; the internal excitation adopts the same frequency reference standard, the first The first signal source divides the signal into two paths through the power divider, which acts on the RF input port of the calibration frequency converter and the reference / test frequency converter; the second signal source divides the signal into two paths through the power divider, and acts on the calibration frequency converter and the local oscillator drive port of the reference / test inverter; the output of the calibration inverter is connected to the first receiver, the output of the reference / test inverter is connected to the second receiver, and the first receiver and the second receiver are connected through the local oscillator source. The received signal of the receiver is down-converted to an intermediate frequency, and then the intermediate frequency signal is processed by digital sampling and vector calculation, and the obtained complex signal is transmitted to the computer module. The invention is not limited to the internal structure of the frequency converter, the calibration process is simple, and the hardware cost is lower.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

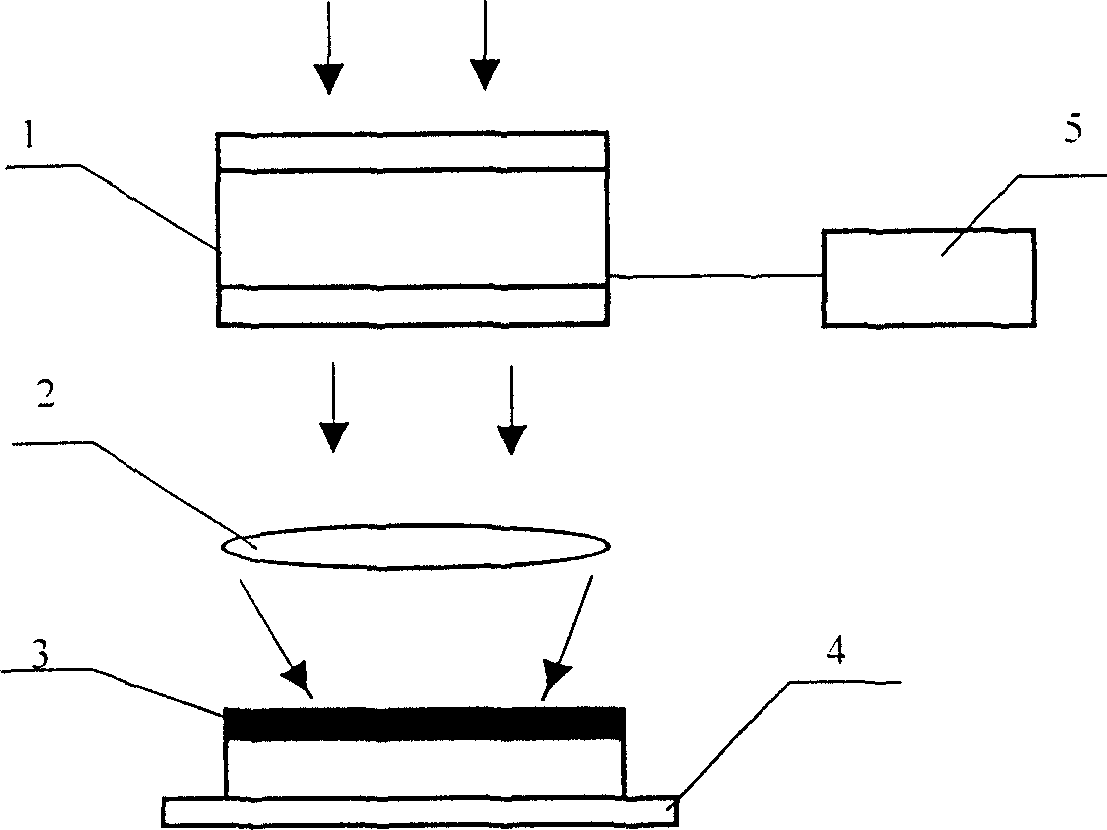

Method for making three-dimension microstructure and

InactiveCN1223906CAvoid overlayAvoid Alignment ProcessPhotomechanical apparatusOptical elementsLiquid crystal light valveProjection lens

The invention discloses a manufacturing method of three-deimensional micro-structure and exposal device it used. This method uses masking graph engendered by computer to expose the sensitive material repeatedly, then, it moves the exposal platform and exposes various area of sensitive material; in the end, it develops and forms random successive three-dimensional micro-structure. Exposal device used in this method includes computer, liquid crystal light valve, projection lens and exposal platform. The invention can make micro-structure component which has a large general area, avoids oif expensive and time consuming plate-making craft, reduces the manufacturing cost of micro-structure and further enhances the manufacturing efficiency and precision.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com