A kind of flexible strain sensing woven fabric and its manufacturing process

A sensor and fabric technology, applied in the direction of fabrics, embossed fabrics, digging fabrics, etc., can solve the problems of low sensitivity of fabrics and high resistance of conductive fibers, and achieve the effect of good softness, good stability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

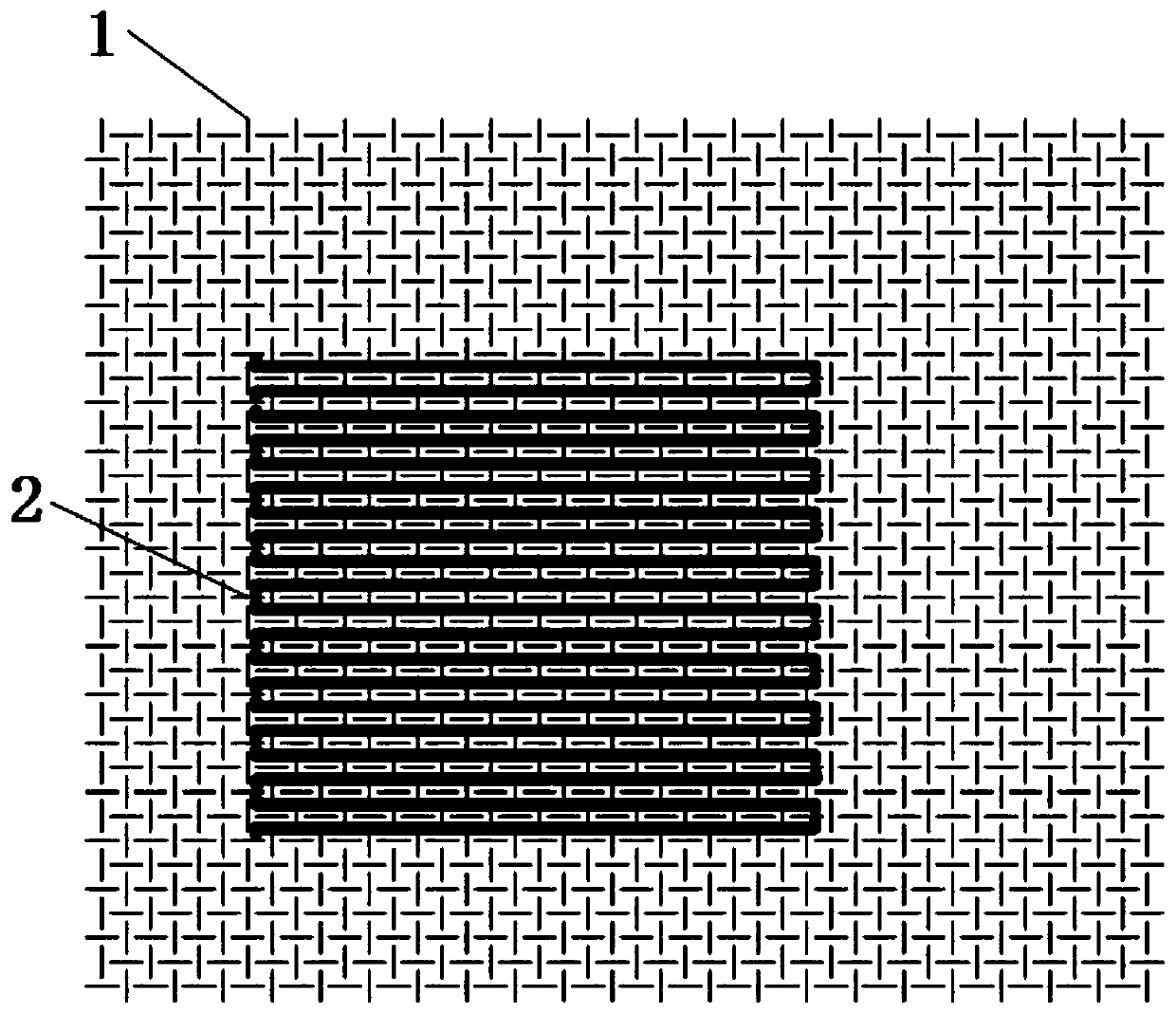

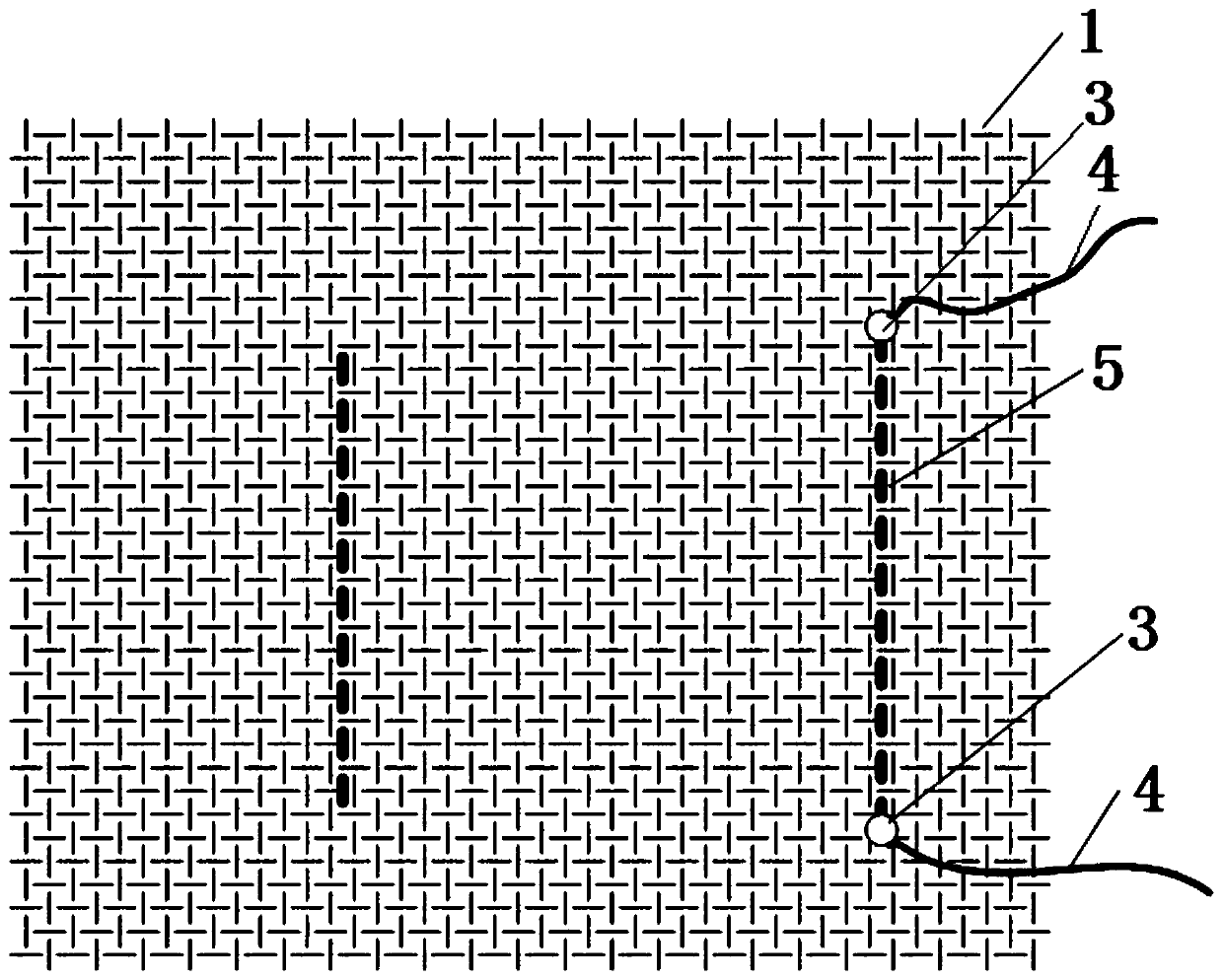

[0040] Such as figure 1 and figure 2Shown: a kind of flexible strain sensing woven fabric provided by the present invention, comprises non-conductive elastic woven fabric 1 and elastic conductive yarn 2, and described elastic conductive yarn 2 is consolidated on non-conductive elastic woven fabric as embossed yarn Embossed patterns are formed on the surface of 1, and joints 3 and leads 4 for electrical connection are provided at both ends of the elastic conductive yarn 2.

[0041] Such as figure 1 As shown, the number of the elastic conductive yarn 2 is one, and the elastic conductive yarn 2 is arranged as an embossed yarn on the non-conductive elastic woven fabric surface 1 in the weft direction to form a square embossed pattern.

[0042] Such as figure 2 As shown, the elastic conductive yarn 2 forms an interlacing point 5 with the weft yarn of the non-conductive elastic woven fabric 2 only at the edge of the weft direction of the embossed pattern, and the elastic conduc...

Embodiment 2

[0054] Such as Figure 4 and Figure 5 Shown: a kind of flexible strain sensing woven fabric provided by the present invention, comprises non-conductive elastic woven fabric 1 and elastic conductive yarn 2, and described elastic conductive yarn 2 is consolidated on non-conductive elastic woven fabric as embossed yarn Embossed patterns are formed on the surface of 1, and joints 3 and leads 4 for electrical connection are provided at both ends of the elastic conductive yarn 2.

[0055] Such as Figure 4 As shown, the number of the elastic conductive yarn 2 is one, and the elastic conductive yarn 2 is arranged as an embossed yarn on the surface 1 of the non-conductive elastic woven fabric in the weft direction to form a plurality of square embossed patterns arranged side by side.

[0056] Such as Figure 5 As shown, the elastic conductive yarn 2 forms an interlacing point 5 with the weft yarn of the non-conductive elastic woven fabric 2 only at the edge of the weft direction o...

Embodiment 3

[0065] Such as Figure 6 and Figure 7 Shown: a kind of flexible strain sensing woven fabric provided by the present invention, comprises non-conductive elastic woven fabric 1 and elastic conductive yarn 2, and described elastic conductive yarn 2 is consolidated on non-conductive elastic woven fabric as embossed yarn Embossed patterns are formed on the surface of 1, and joints 3 and leads 4 for electrical connection are provided at both ends of the elastic conductive yarn 2.

[0066] Such as Figure 6 As shown, the number of the elastic conductive yarns 2 is two, and the elastic conductive yarns 2 are arranged as embossed yarns in the weft direction on the surface 1 of the non-conductive elastic woven fabric to form overlapping embossed patterns. When the fabric is stretched, the relative position of the conductive yarn in the overlapping area changes, which can further increase the resistance change rate and realize the gain effect of resistance change.

[0067] Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com