Composite dummy bar for stainless steel coated carbon steel liquid-solid composite continuous casting and method

A technology of coating carbon and stainless steel, which is applied in the field of composite dummy rods for carbon steel liquid-solid composite continuous casting coated with stainless steel, can solve the problems of poor surface and interface quality and low stability, and achieve low cost of use and convenience Easy installation and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

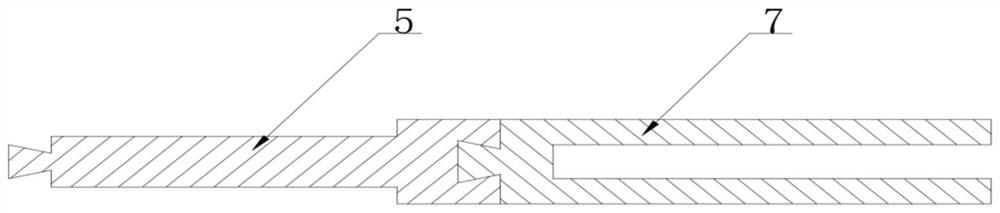

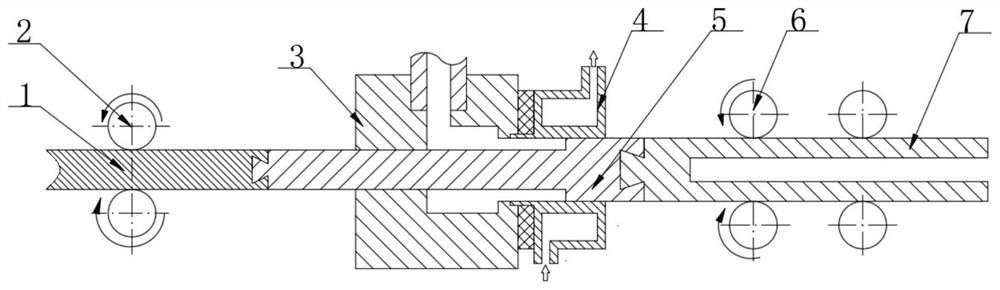

[0024] The 304 stainless steel clad Q235 carbon steel composite slab was prepared by the liquid-solid composite continuous casting method, and the cross-sectional size of the Q235 carbon steel core material was 40×15mm 2 , 304 stainless steel cladding thickness of 4mm. Use boron nitride to process transition connecting rod 5, which is connected with Q235 carbon steel draw bar 7 to form a composite dummy rod; pass the composite dummy rod through the traction device 6, mold 4 and 304 stainless steel liquid insulation chamber 3 in sequence, and connect with the core The Q235 carbon steel core plate 1 in the plate guiding and positioning device 2 is connected and centered, so that the main body of the transition connecting rod 5 is located in the 304 stainless steel liquid heat preservation chamber 7 . After the composite dummy rod is installed, smelting of 304 stainless steel and preheating of the 304 stainless steel liquid insulation chamber 3 are carried out. The liquid is fil...

Embodiment 2

[0026] The 304 stainless steel clad Q235 carbon steel composite slab was prepared by the liquid-solid composite continuous casting method, and the cross-sectional size of the Q235 carbon steel core material was 100×10mm 2 , 304 stainless steel cladding thickness of 2mm. Use boron nitride to process transition connecting rod 5, which is connected with Q235 carbon steel draw bar 7 to form a composite dummy rod; pass the composite dummy rod through the traction device 6, mold 4 and 304 stainless steel liquid insulation chamber 3 in sequence, and connect with the core The Q235 carbon steel core plate 1 in the plate guiding and positioning device 2 is connected and centered, so that the main body of the transition connecting rod 5 is located in the 304 stainless steel liquid heat preservation chamber 7 . After the composite dummy rod is installed, smelting of 304 stainless steel and preheating of the 304 stainless steel liquid insulation chamber 3 are carried out. The liquid is fi...

Embodiment 3

[0028] The 304 stainless steel clad Q235 carbon steel composite slab was prepared by the liquid-solid composite continuous casting method, and the cross-sectional size of the Q235 carbon steel core material was 80×20mm 2 , 304 stainless steel cladding thickness of 5mm. Use boron nitride to process transition connecting rod 5, which is connected with Q235 carbon steel draw bar 7 to form a composite dummy rod; pass the composite dummy rod through the traction device 6, mold 4 and 304 stainless steel liquid insulation chamber 3 in sequence, and connect with the core The Q235 carbon steel core plate 1 in the plate guiding and positioning device 2 is connected and centered, so that the main body of the transition connecting rod 5 is located in the 304 stainless steel liquid heat preservation chamber 7 . After the composite dummy rod is installed, smelting of 304 stainless steel and preheating of the 304 stainless steel liquid insulation chamber 3 are carried out. The liquid is fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com