Preparation method of high-temperature-resisting aerogel material

An airgel and high-temperature-resistant technology, which is applied in the field of preparation of high-temperature-resistant airgel materials, can solve problems such as insufficient temperature resistance, potential safety hazards, and failure to consider material temperature resistance, so as to overcome shrinkage, inhibit sintering, The effect of inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

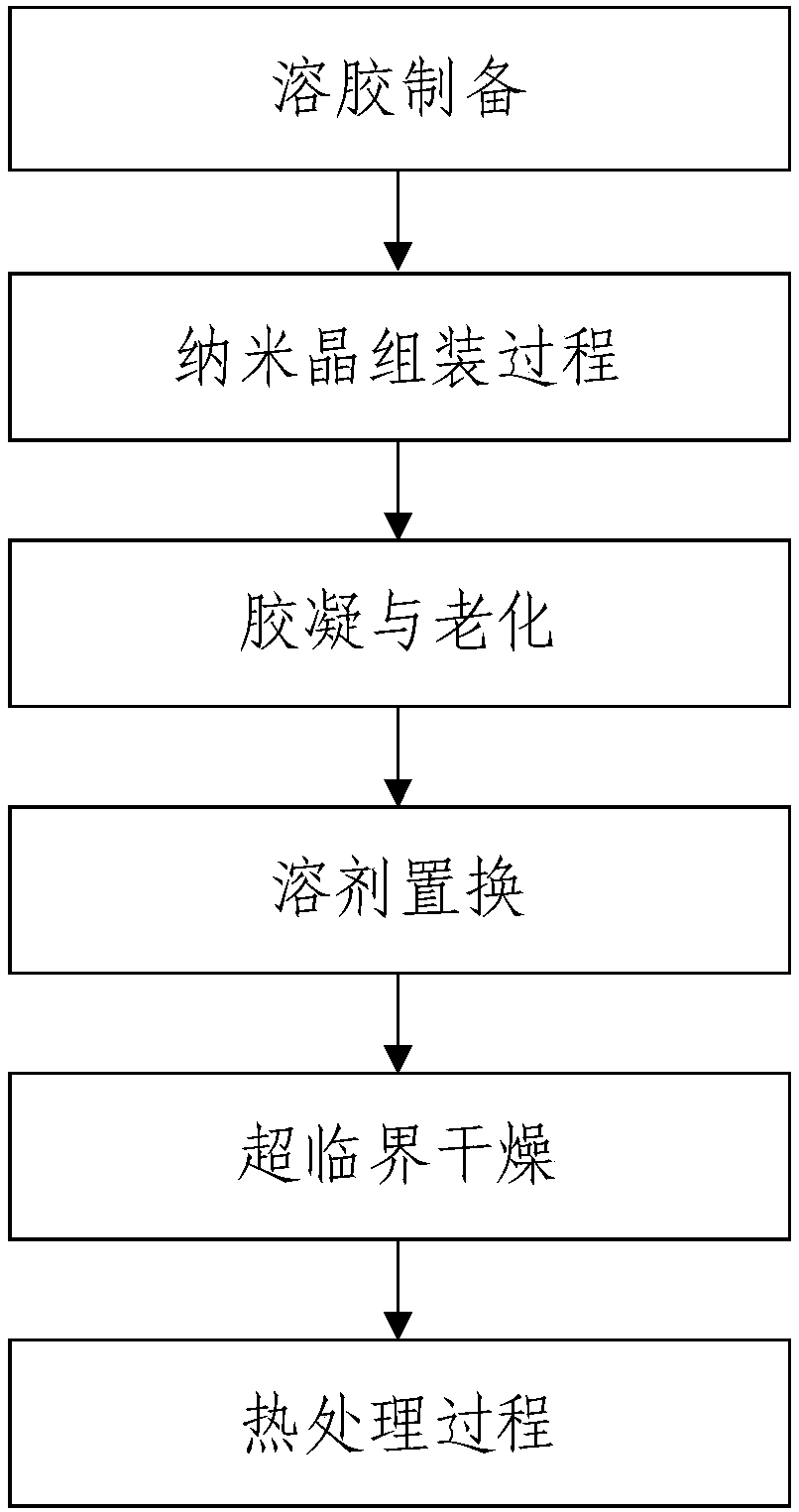

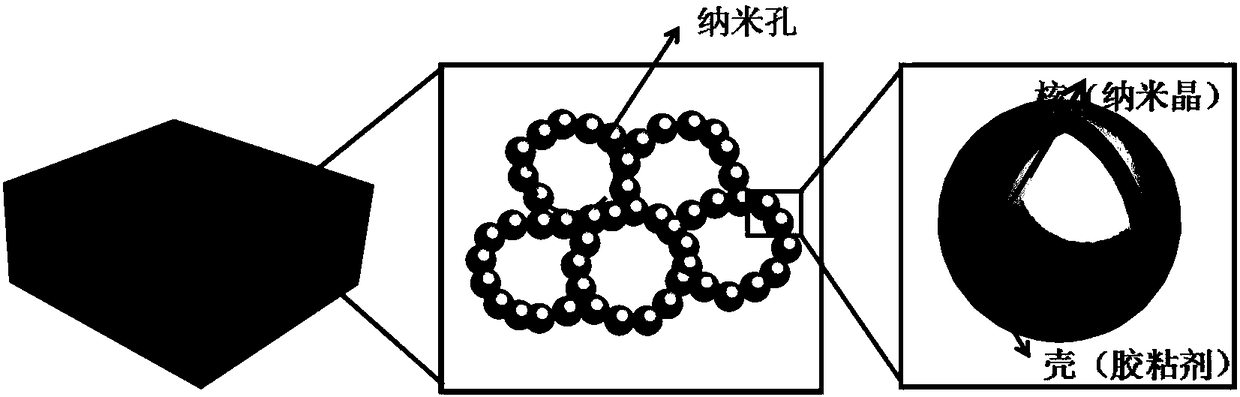

[0036] The present invention provides a kind of preparation method of high temperature resistant airgel material, described method comprises the following steps:

[0037] (1) Preparation of sol: Silicone sol is prepared by using organosilicon ester as raw material, acid reagent as catalyst and organic solvent as dispersant. The organic silicon ester is preferably methyl orthosilicate or ethyl orthosilicate; the acidic reagent is selected from the group consisting of hydrochloric acid, hydrofluoric acid and nitric acid, and the concentration of the acidic reagent is 0.001~0.1mol / L ( For example, 0.001, 0.005, 0.01, 0.02, 0.03, 0.04, 0.05, 0.06, 0.07, 0.08, 0.09 or 0.1mol / L); the organic solvent is selected from the group consisting of methanol, ethanol, acetone and acetonitrile.

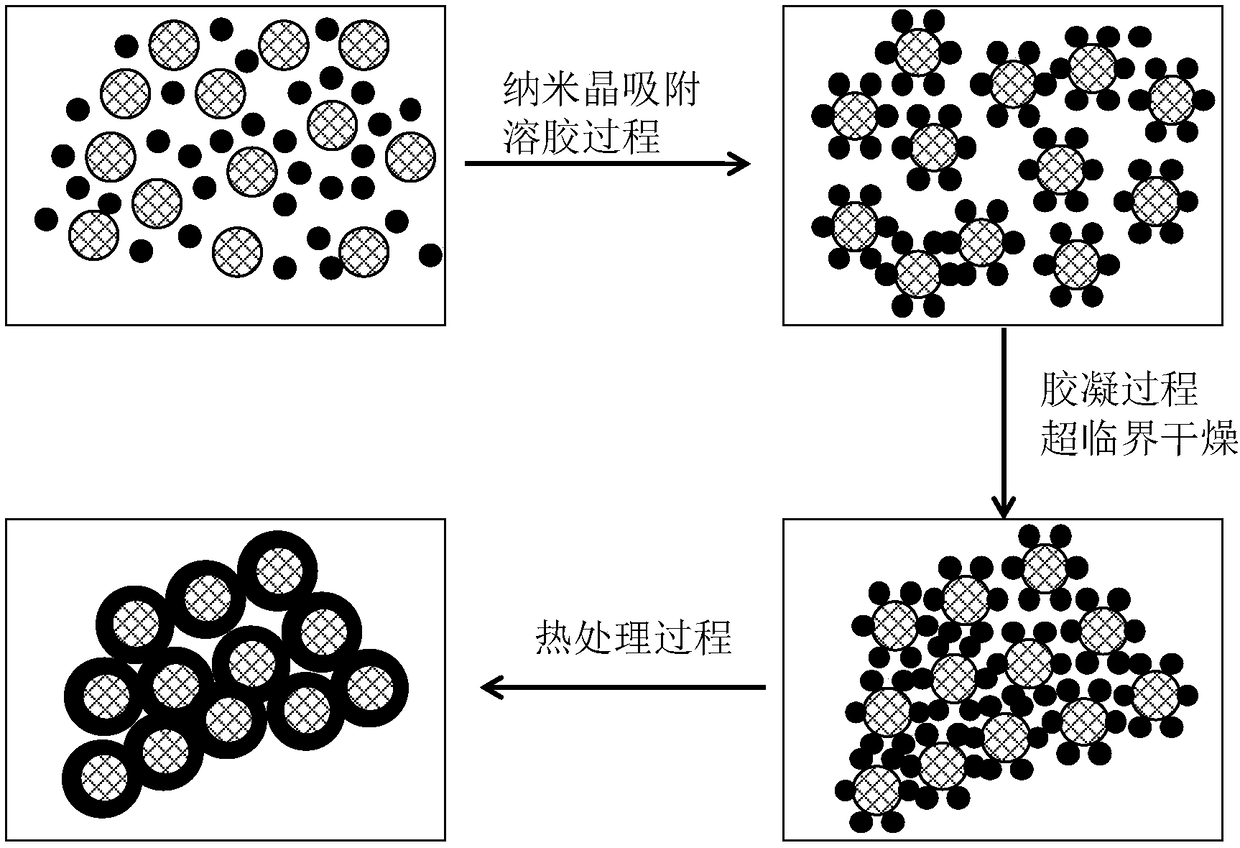

[0038] (2) Nanocrystal assembly process: dissolving oxide nanopowder in an organic solvent to obtain the first mixed solution, then adding the silica sol prepared in step (1) to the first mixed soluti...

Embodiment 1

[0054] ①sol preparation

[0055] Weigh 160 g of methyl orthosilicate and 160 g of acetonitrile into a 500 mL beaker, seal it with a plastic wrap and perform magnetic stirring for 1 min. After mixing evenly, add 60g of hydrochloric acid with a concentration of 0.003mol / L as a catalyst. This process needs to be added slowly and stirred by magnetic force for 5 minutes; add the above mixed solution into a 1000mL three-necked flask, heat and magnetically stir at 70°C, And accompanied by reflux for 30 minutes, the first solution of the siliceous sol precursor was obtained; 160 g of methyl orthosilicate was added to the obtained first solution of the siliceous sol precursor, and heating and magnetic stirring were continued at 70° C., and the reaction was carried out for 16 hours. A siliceous sol (silica sol) is obtained. Dilute the siliceous sol, distill 300 g of the solvent contained in the siliceous sol, add 600 g of acetonitrile and mix evenly to obtain the diluted siliceous sol,...

Embodiment 2

[0068] Embodiment 2 is basically the same as Embodiment 1, except that: during the heat treatment process, the heat treatment temperature is 1100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com