Patents

Literature

33results about How to "Meet custom needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

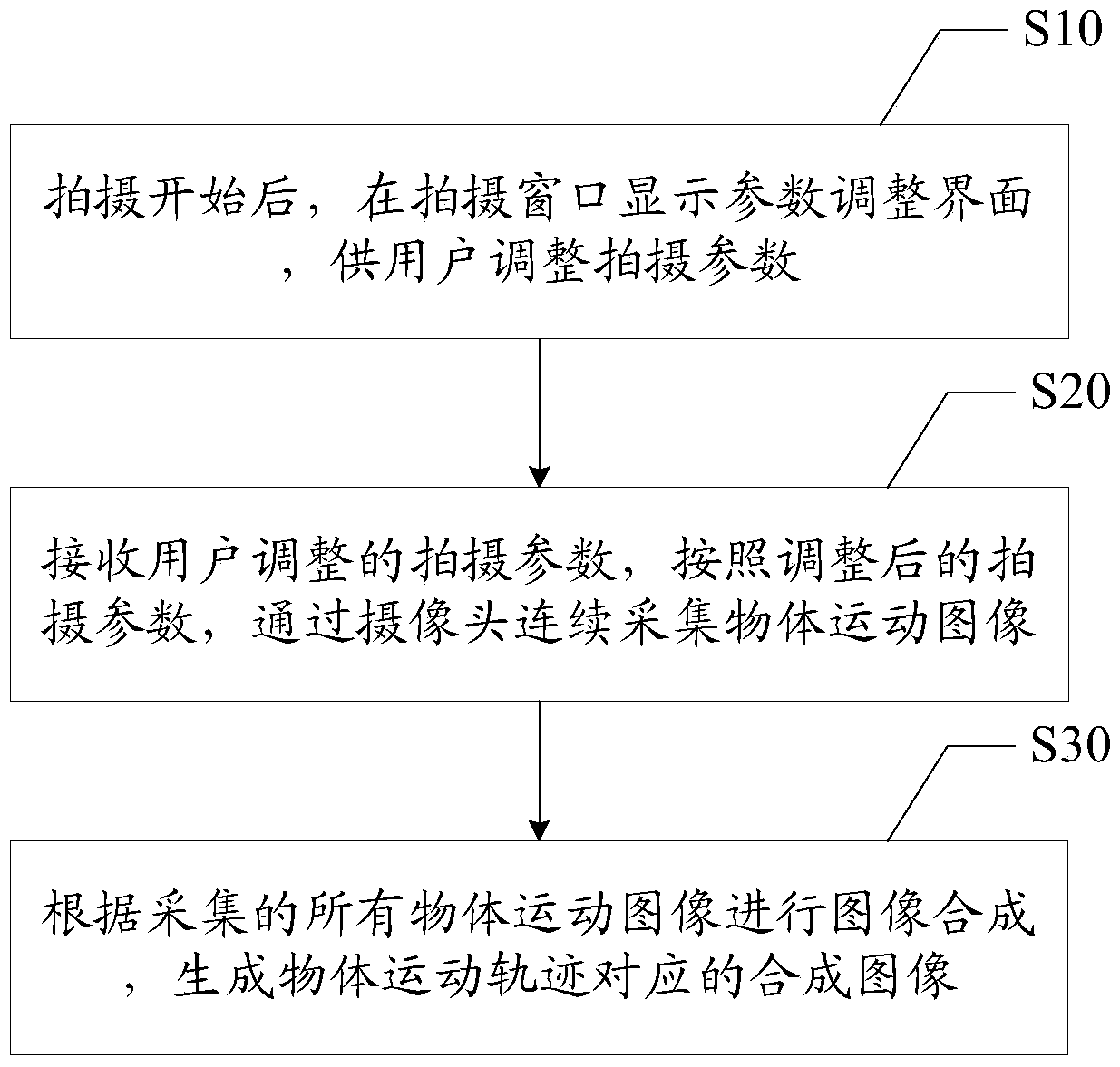

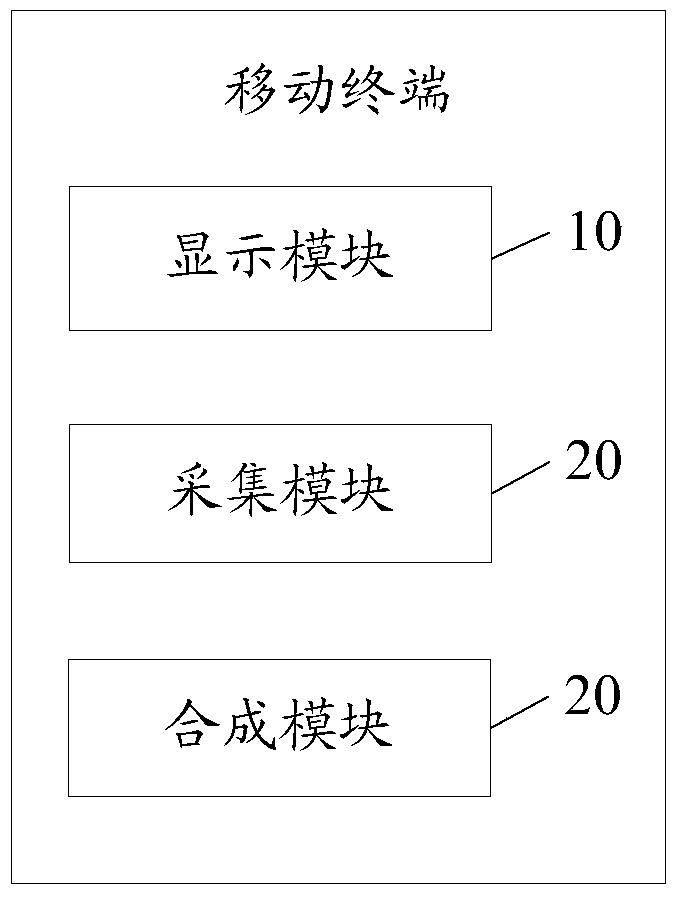

Object motion track shooting method and mobile terminal

ActiveCN104125407AMeet custom needsTelevision system detailsColor television detailsObject motionComputer graphics (images)

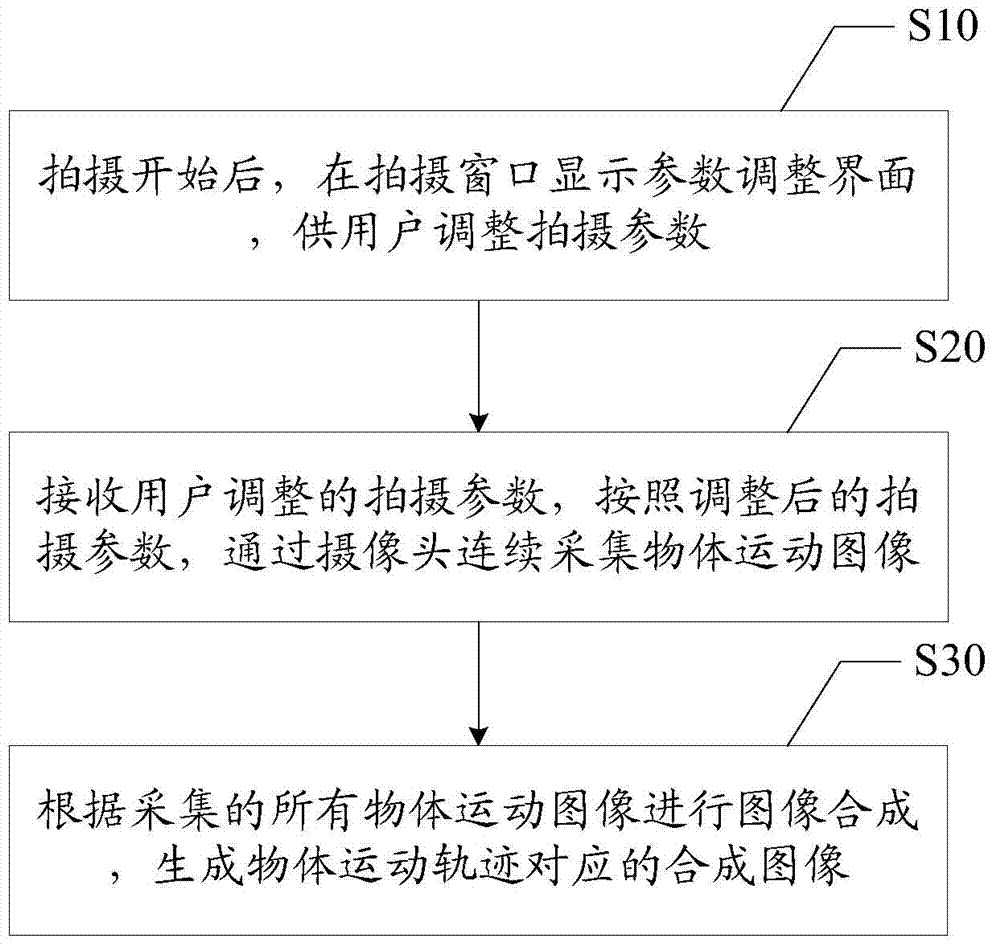

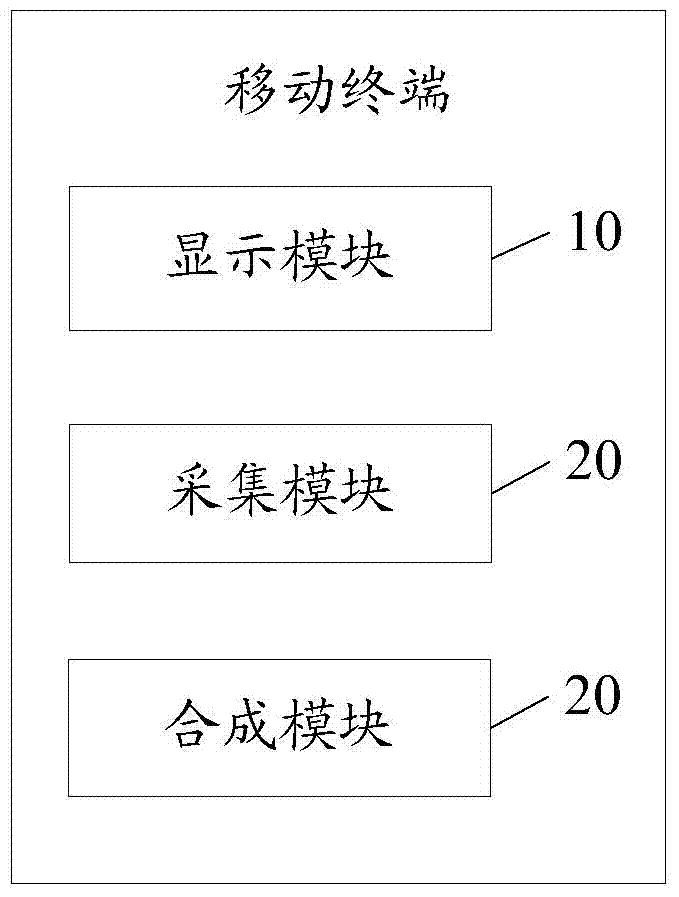

The invention discloses an object motion track shooting method. The object motion track shooting method comprises the following steps of, after a shooting process starts, displaying a parameter adjusting interface inside a shooting window for a user to adjust shooting parameters; receiving the shooting parameters adjusted by the user; according to the adjusted shooting parameters, continuously collecting object motion images through a camera; according to all the collected object motion images, performing image synthesis to generation a synthesized image corresponding to an object motion track. The invention also discloses a mobile terminal. According to the object motion track shooting method, the parameter adjusting interface for adjusting the shooting parameters is displayed during the shooting process, the object motion images are collected according to the adjusted shooting parameters and synthesized into the synthesized image corresponding to the object motion track, and the user can adjust the shooting parameters according to actual demands during the shooting process, so that the shot object motion track images can meet the custom requirements of the user.

Owner:NUBIA TECHNOLOGY CO LTD

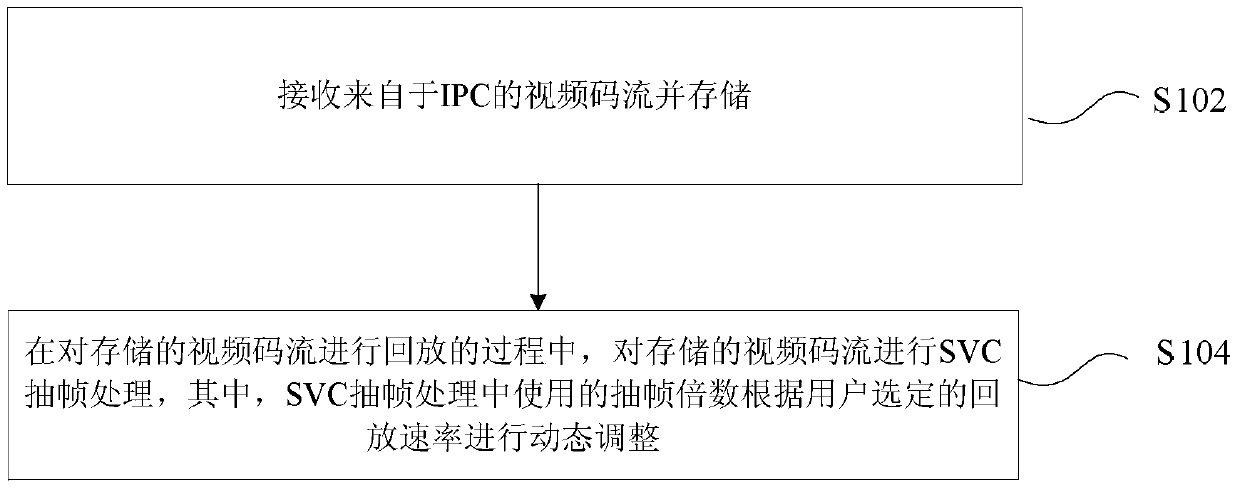

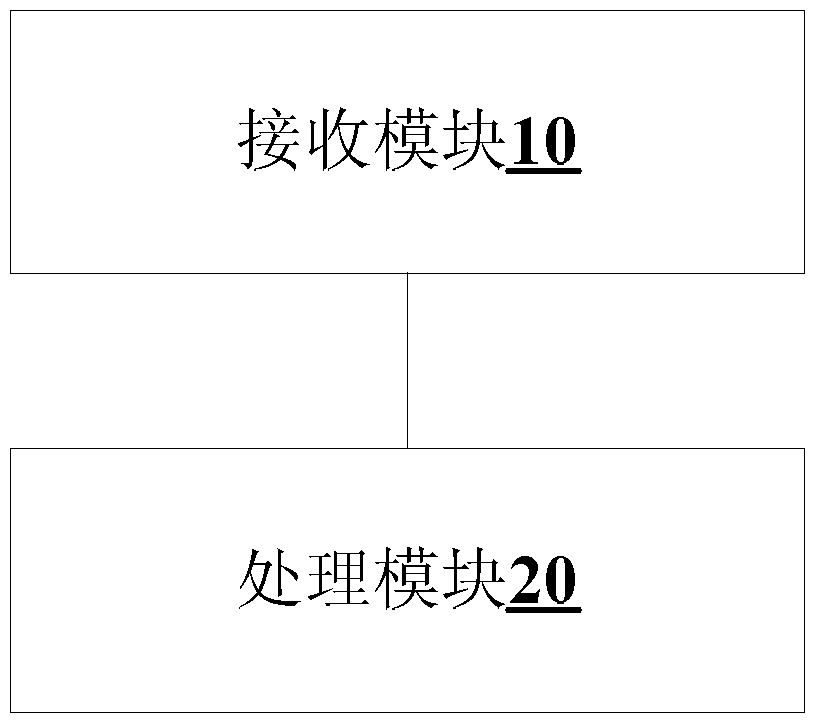

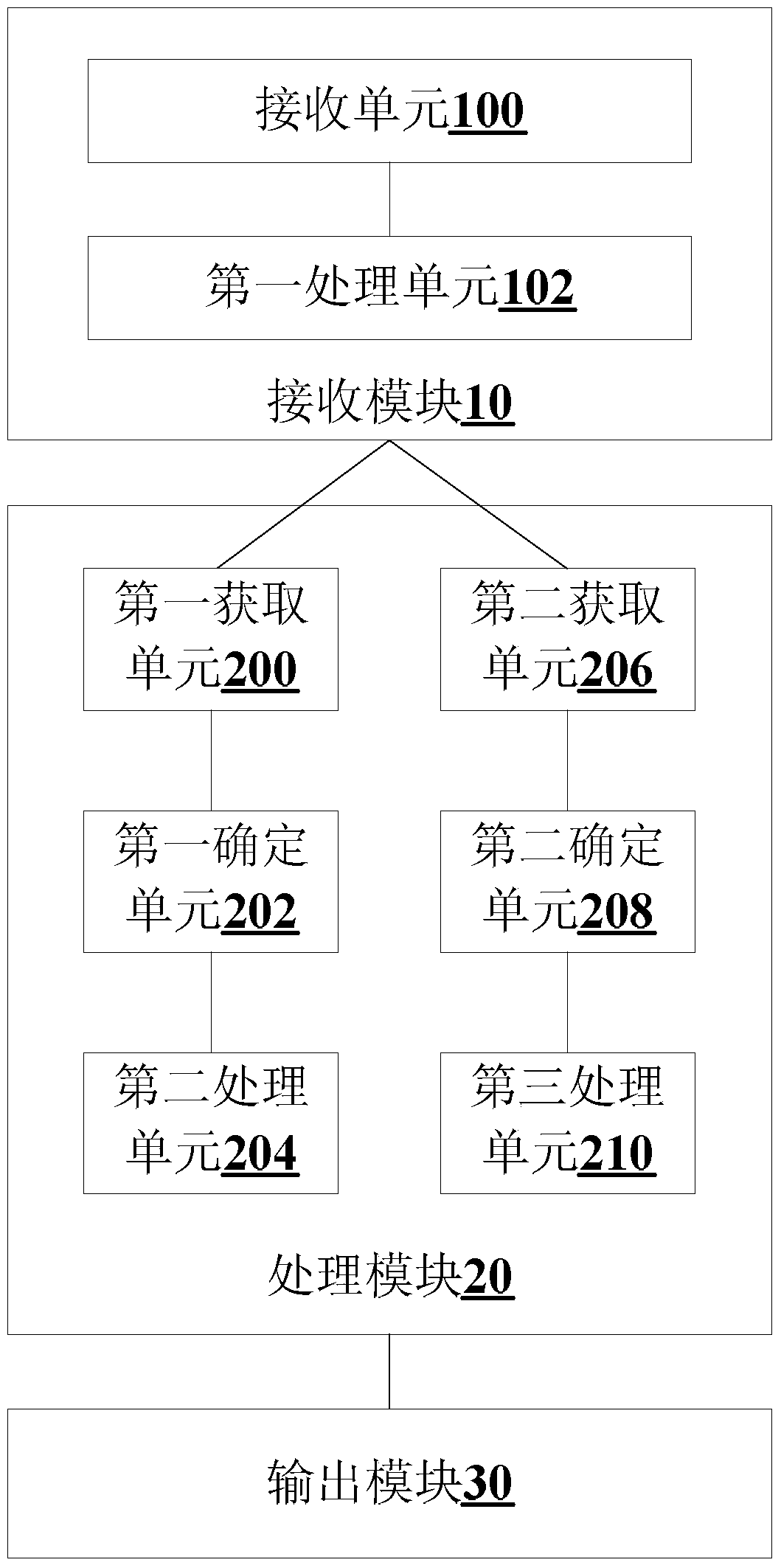

Video bitstream frame extraction process and device

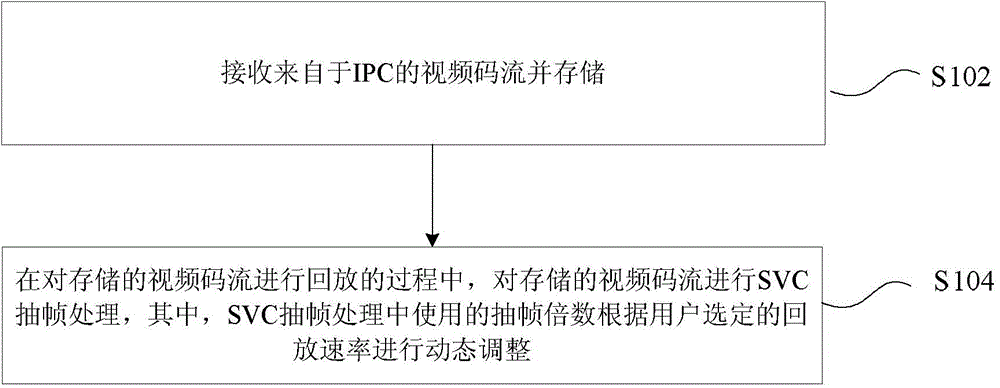

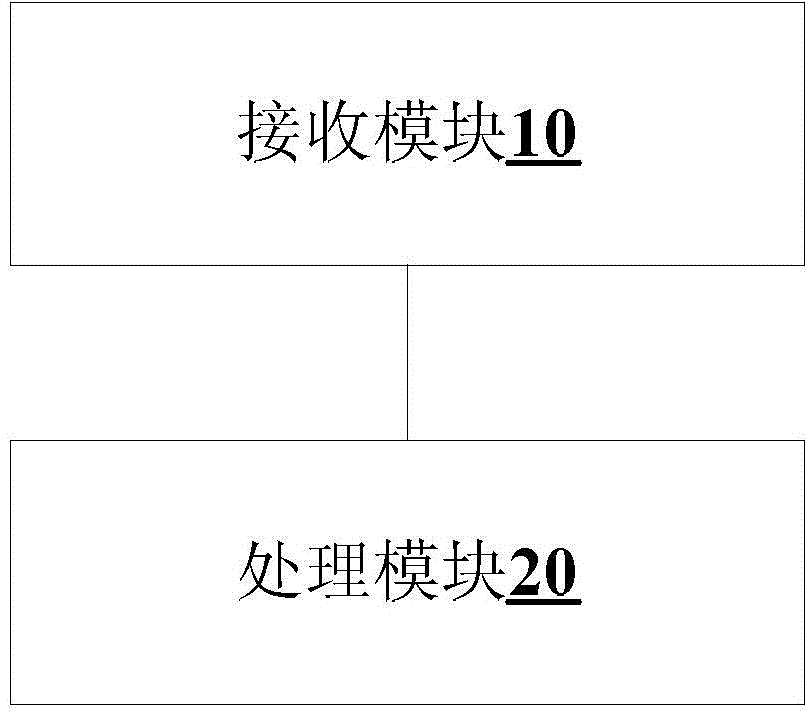

ActiveCN104639951AIncrease playback speedMeet custom needsSelective content distributionVideo bitstreamMultiple use

The present invention discloses a video bitstream frame extraction process and device. The aforementioned process comprises receiving and storing video bitstreams from an IPC; and during playing back the stored video bitstreams, conducting an SVC frame extraction process on the stored video bitstreams, wherein the frame extraction multiple used in the SVC extraction process is dynamically adjusted according to a playback rate selected by a user. According to the technical solution provided in the present invention, the process and device effectively improve the speed for playing video bitstreams during a quick playback process.

Owner:HANGZHOU HIKVISION DIGITAL TECH

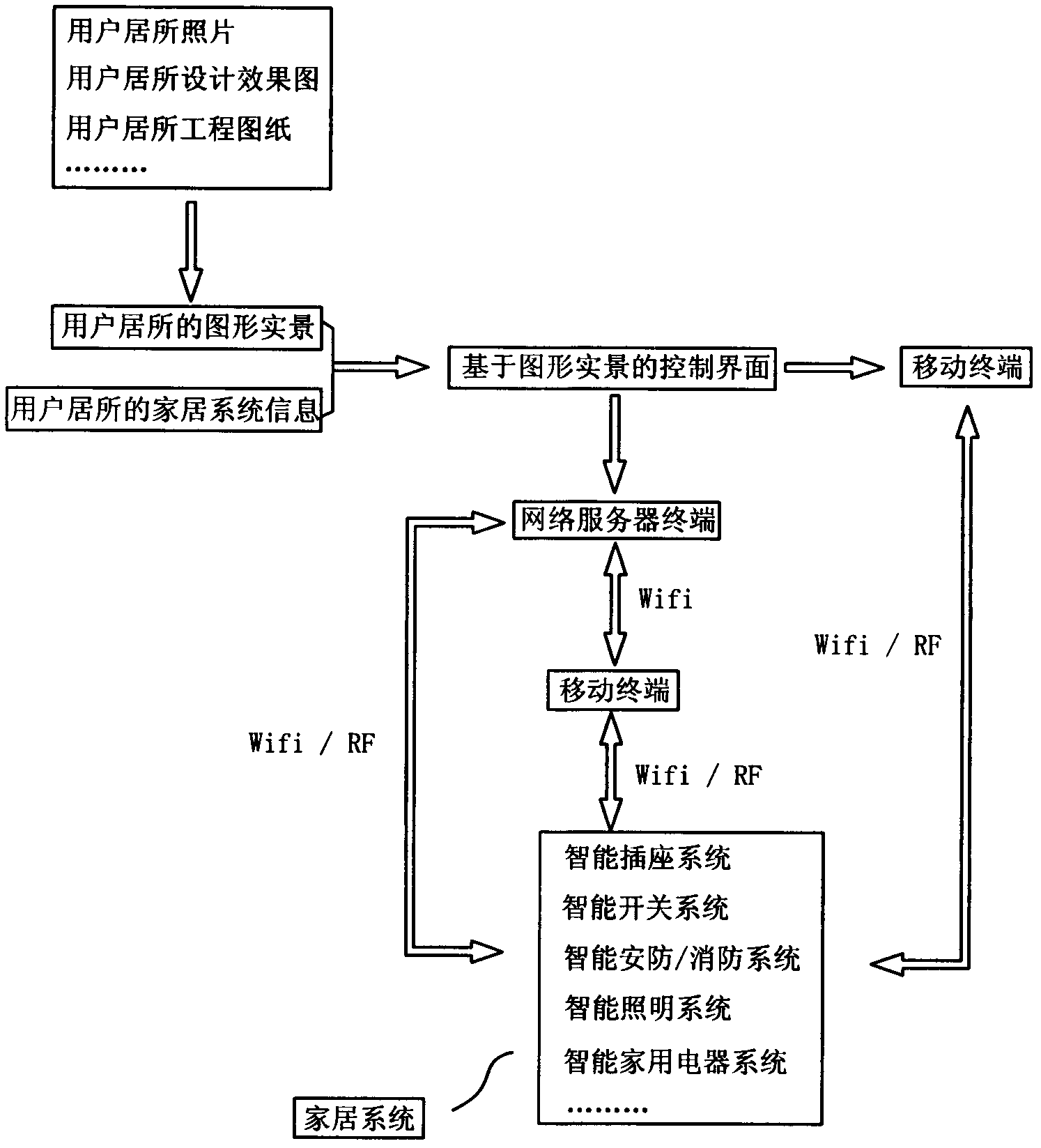

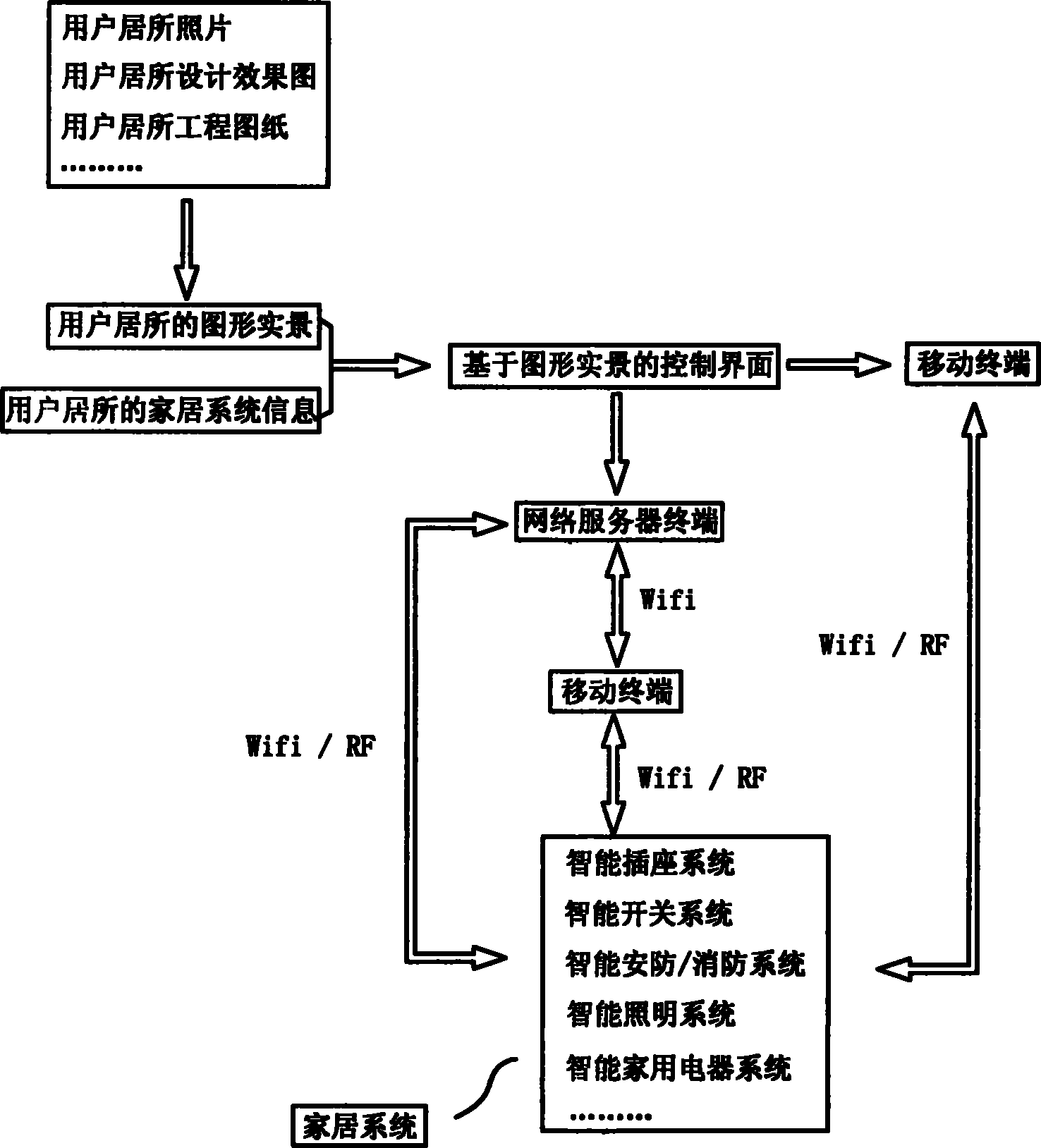

Home furnishing control system and method based on real-scene interface

InactiveCN102662374AMeet custom needsEasy to operateProgramme total factory controlGraphicsResidence

The invention discloses a home furnishing control system and method based on a real-scene interface. The method comprises the following steps of: firstly, constructing an image real scene of a user residence based on more than one of pictures, design effect sketches and engineering drawings; inputting the image real scene and home furnishing system information into a network server terminal and / or a mobile terminal to construct a control interface based on the image real scene; or constructing a control interface and inputting into the network server terminal and / or the mobile terminal; selecting a home furnishing subsystem in the image real scene shown by the control interface in the mobile terminal by a user; and realizing the adjustment of a working state of the selected home furnishing subsystem by a wireless network. The system comprises the control interface based on the image real scene, the network server terminal and / or the mobile terminal in which the control interface based on the image real scene is input, and the home furnishing system composed of the plurality of home furnishing subsystems. The home furnishing control system and method can meet self-customizing requirements of the user, are suitable for different dwelling sizes and are simple and direct to operate.

Owner:刘书军

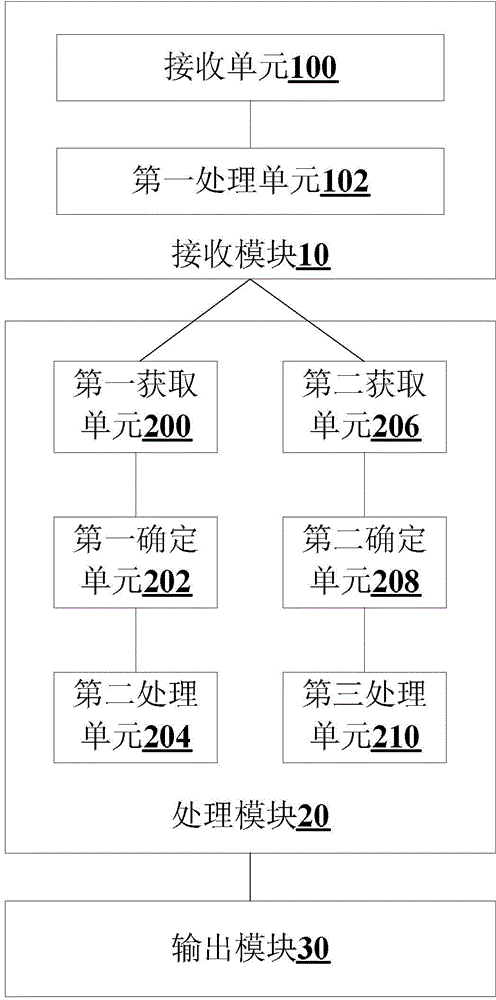

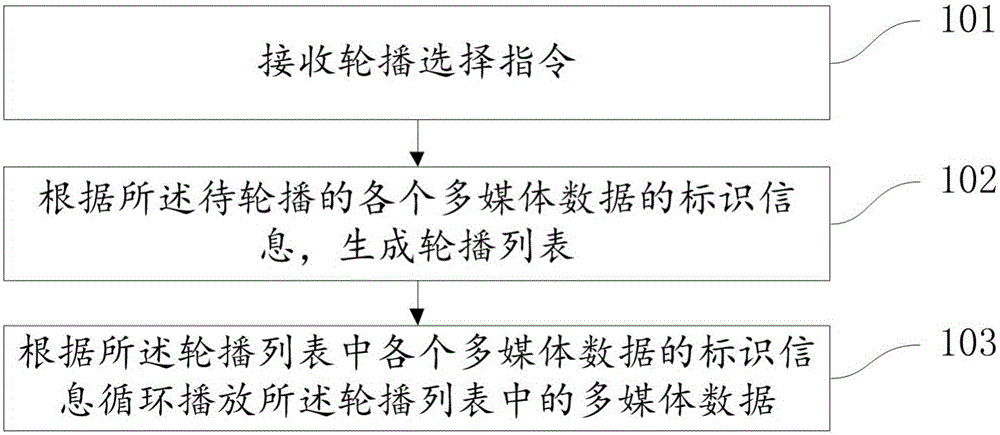

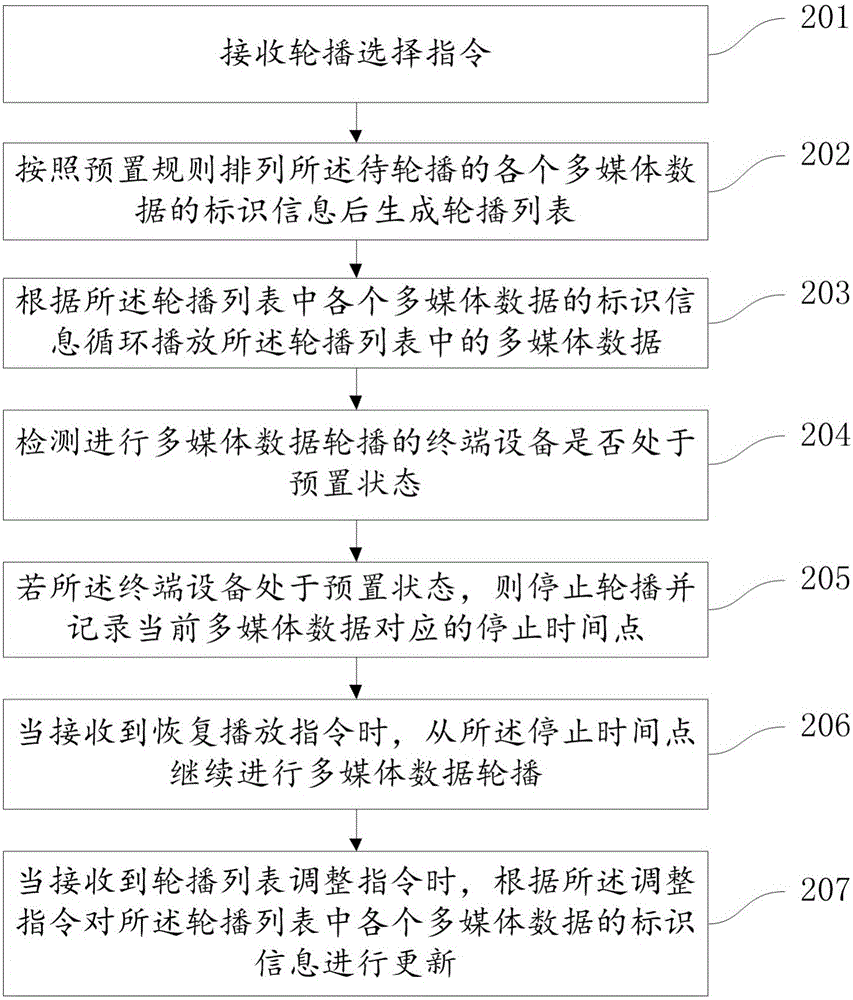

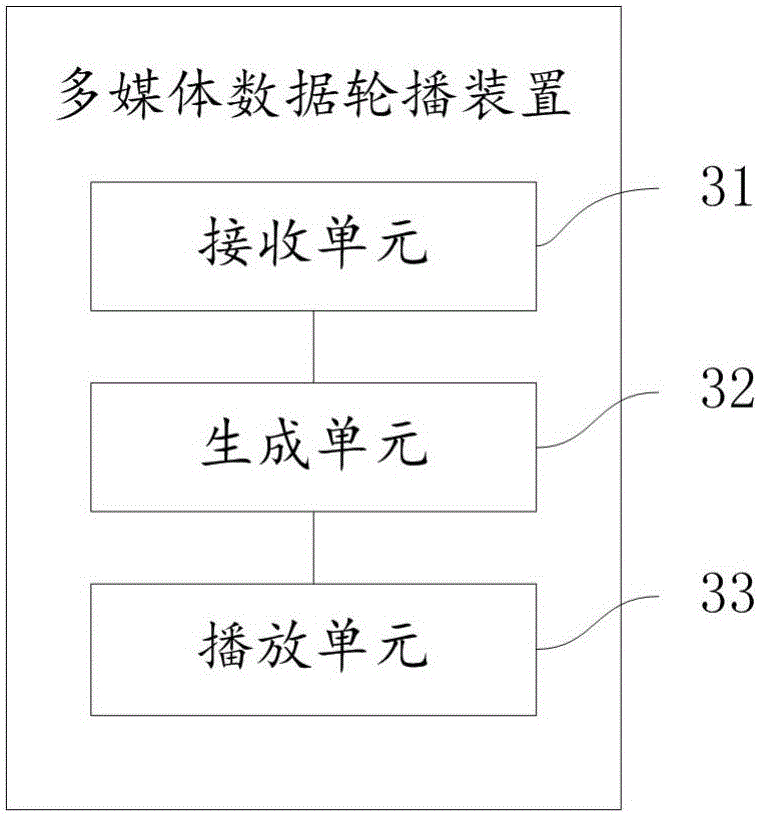

Multimedia data carousel method and device

InactiveCN105939489AReduce network costsEasy to watchSelective content distributionInformation technologyComputer network

The embodiment of the invention provides a multimedia data carousel method and device, relates to the technical field of information, and mainly aims to configure corresponding multimedia resources according to user requirements, and save network server resources. The technical scheme adopted in the embodiment of the invention is as follows: a carousel selection instruction is received; identification information of various multimedia data to be subjected to carousel is carried in the carousel selection instruction; a carousel list is generated according to the identification information of various multimedia data to be subjected to carousel; and the multimedia data in the carousel list is circularly played according to the identification information of various multimedia data in the carousel list. The multimedia data carousel method and device disclosed by the invention are mainly used for carousel of the multimedia data.

Owner:LETV HLDG BEIJING CO LTD +1

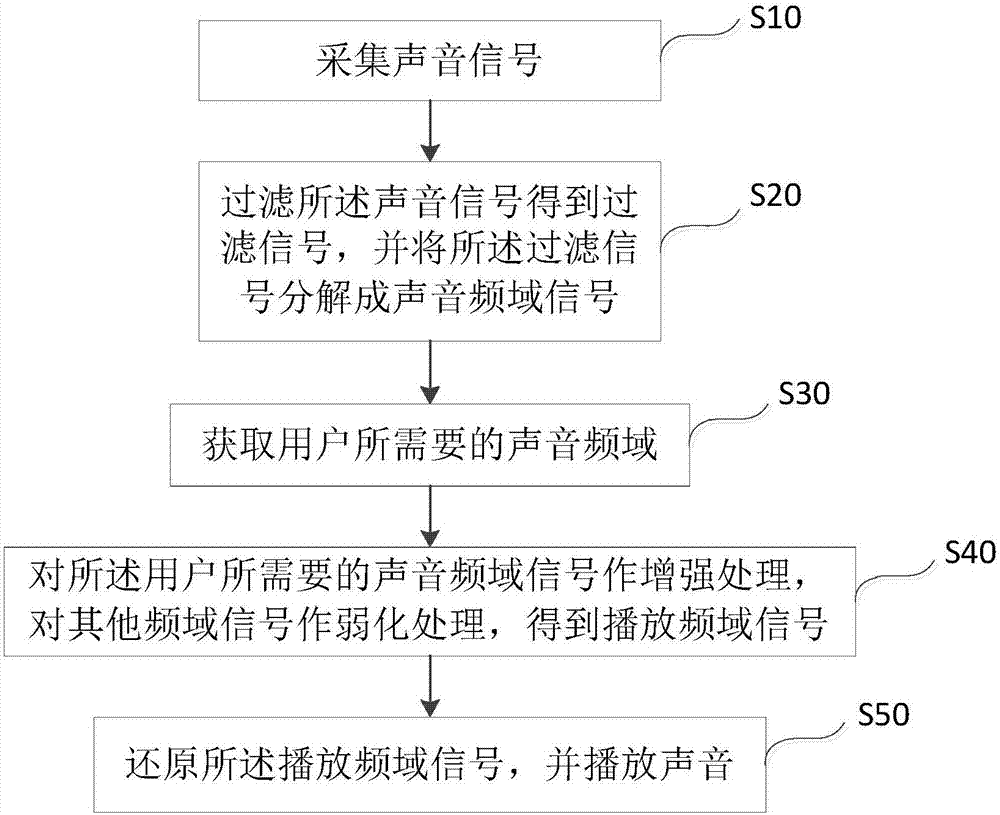

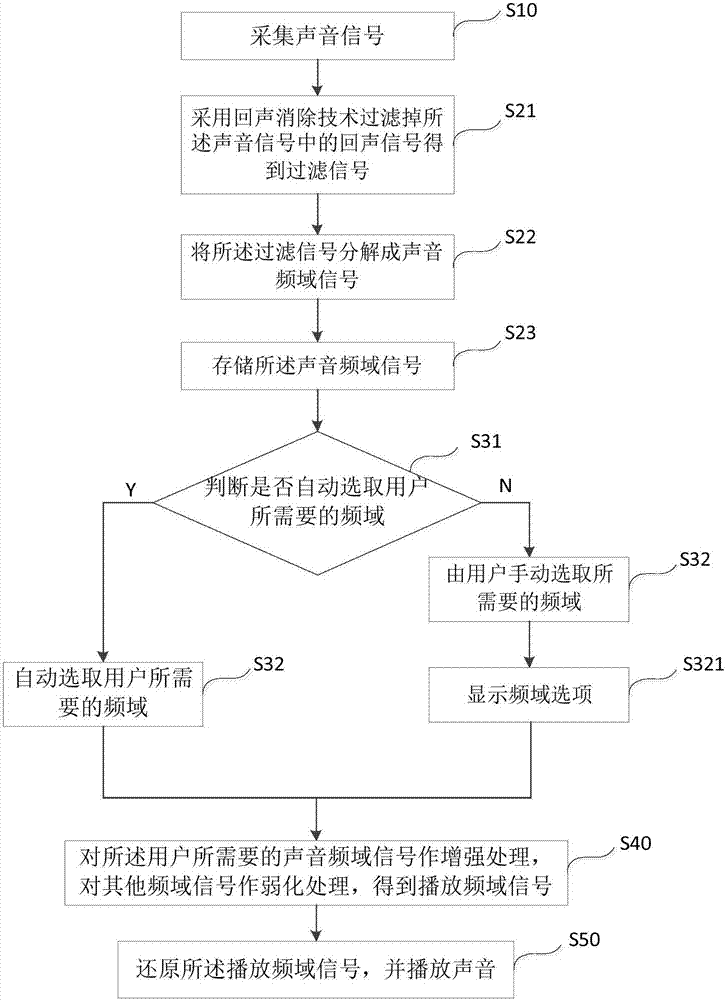

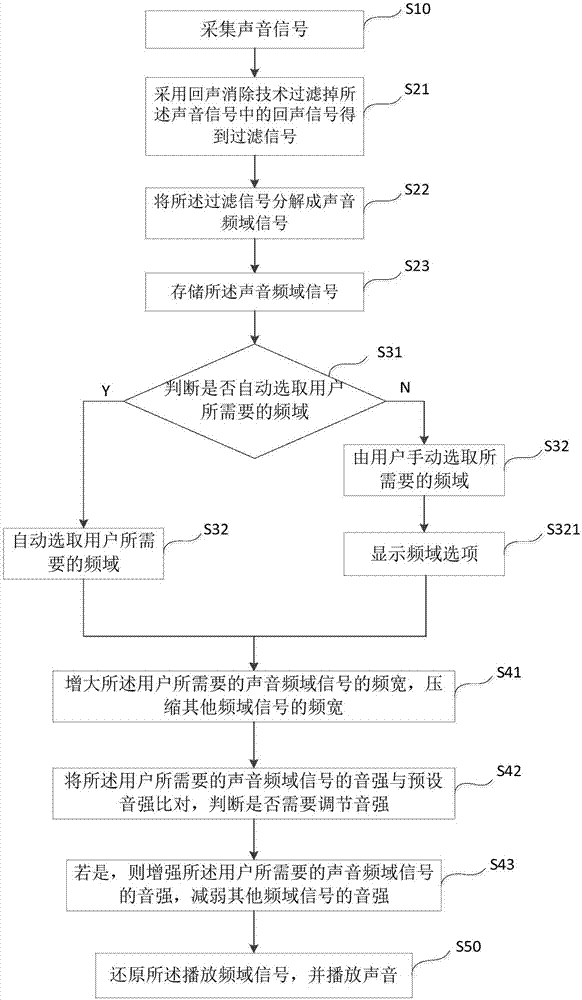

Method and system for reducing noise based on frequency characteristics

PendingCN107452394ASimple and clear identificationIncrease interactive funSpeech analysisTelephone set constructionsUsers perceptionsNatural property

The invention discloses a method and a system for reducing noise based on frequency characteristics. The method comprises the following steps: S10: acquiring a sound signal; S20: filtering the sound signal, so as to obtain a filtered signal, and decomposing the filtered signal into sound frequency domain signals; S30: acquiring a sound frequency domain which is required by a user; S40: implementing enhancement processing on a sound frequency domain signal which is required by the user, and implementing weakening processing on signals of other frequency domains, so that a playing frequency domain signal is obtained; and S50: reducing the playing frequency domain signal and playing sound. The method provided by the invention, which reduces the noise on the basis of the natural properties of the sound, is easy to implement and broad in application scope; and a voice scheme can be freely selected, so that voice delivery becomes more intuitive and valid, user perception is clearer and voice is easier to recognize.

Owner:台州市吉吉知识产权运营有限公司

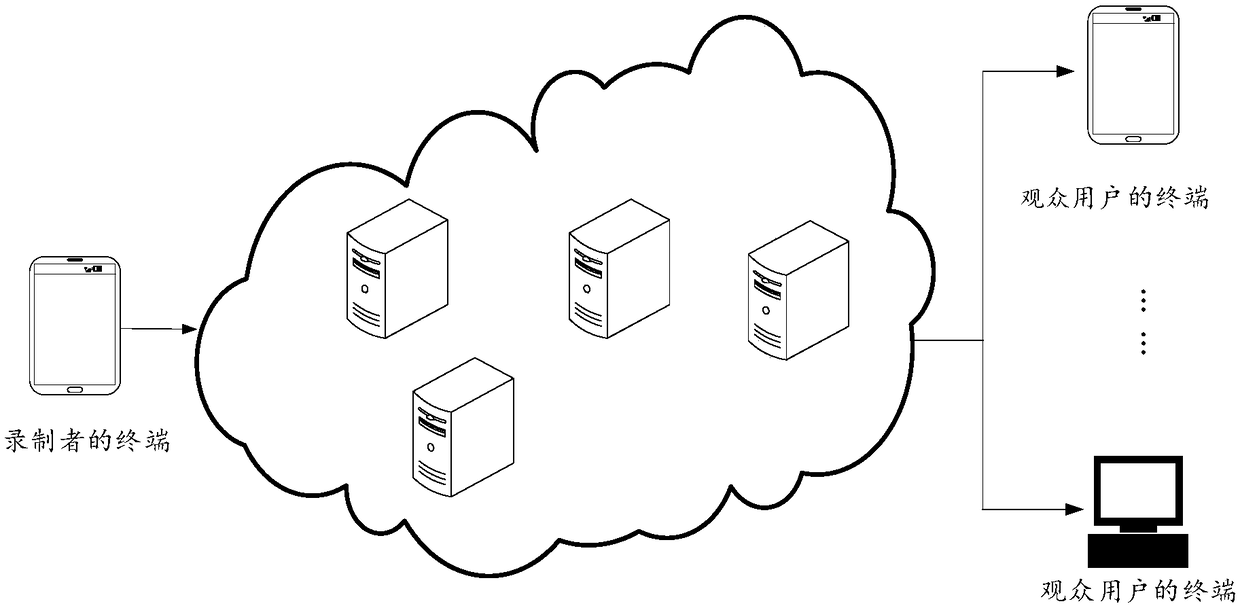

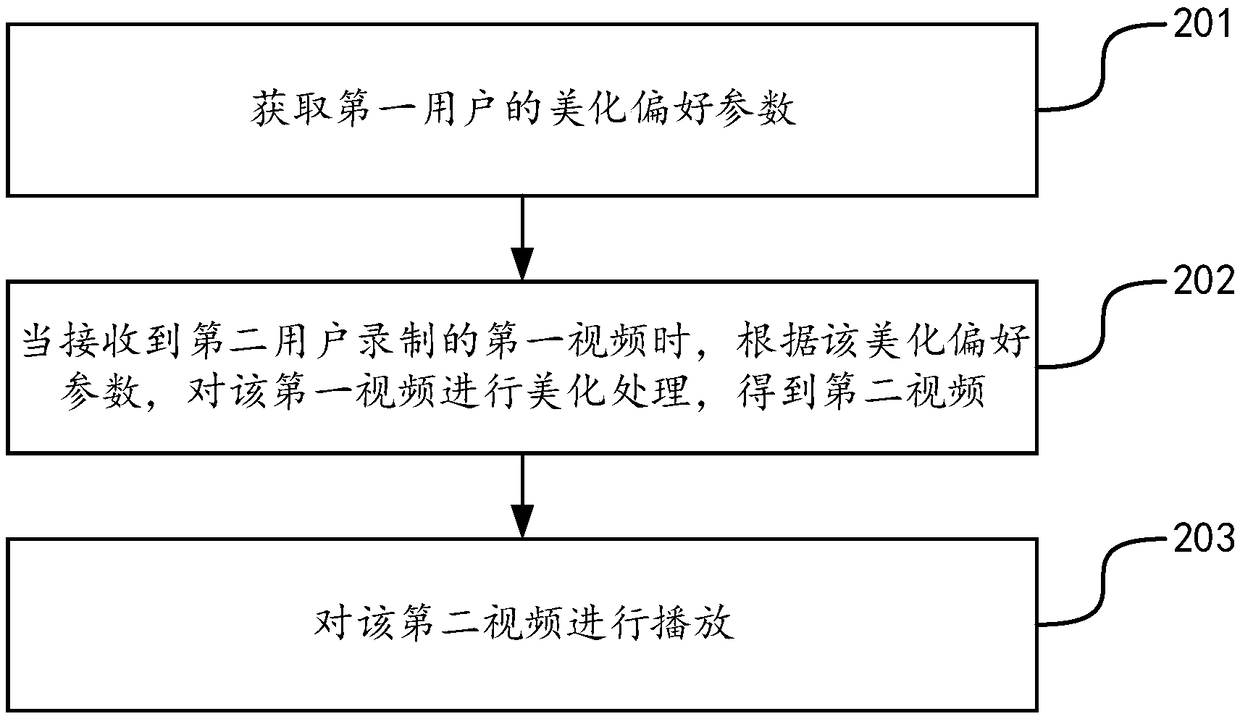

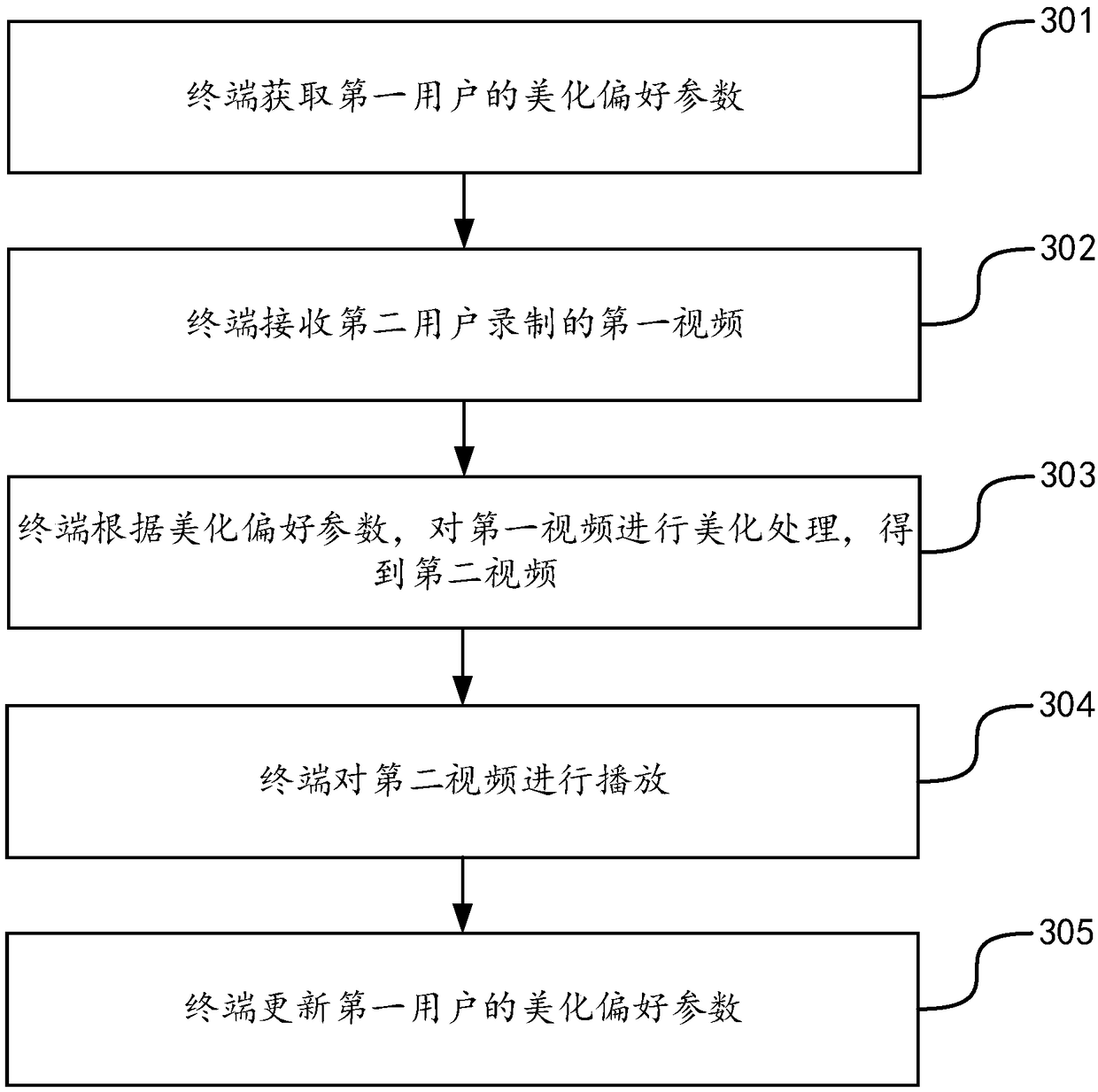

Video playing method, device, equipment and storage medium

InactiveCN109035180AImprove accuracyImprove playbackImage enhancementImage analysisLandscapingComputer graphics (images)

Owner:GUANGZHOU KUGOU TECH

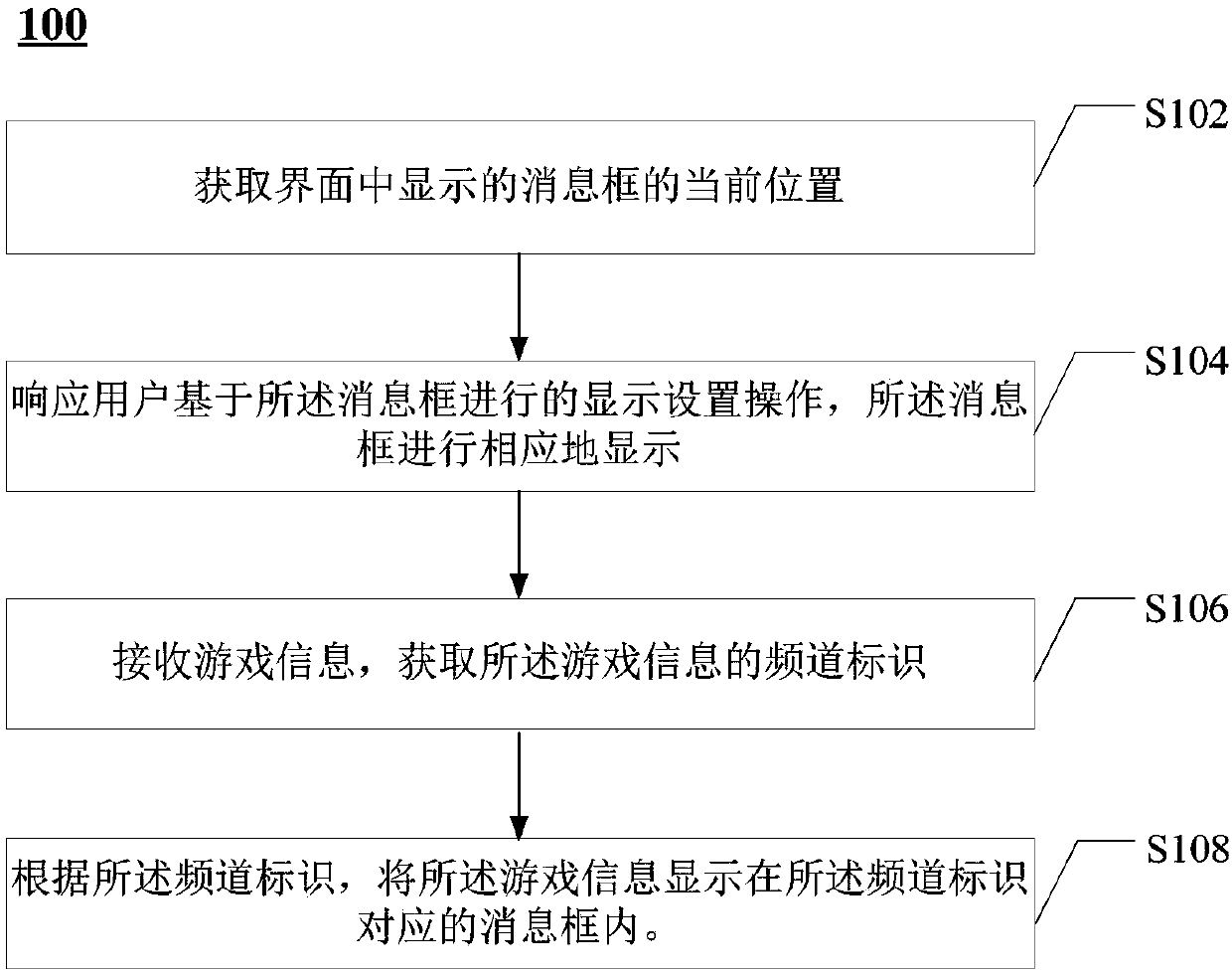

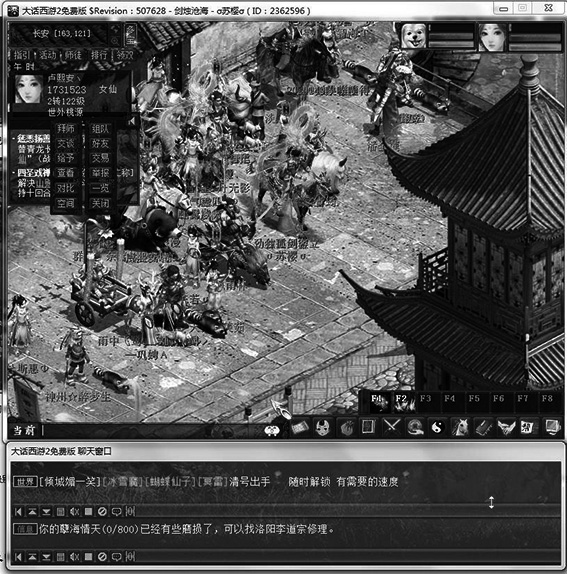

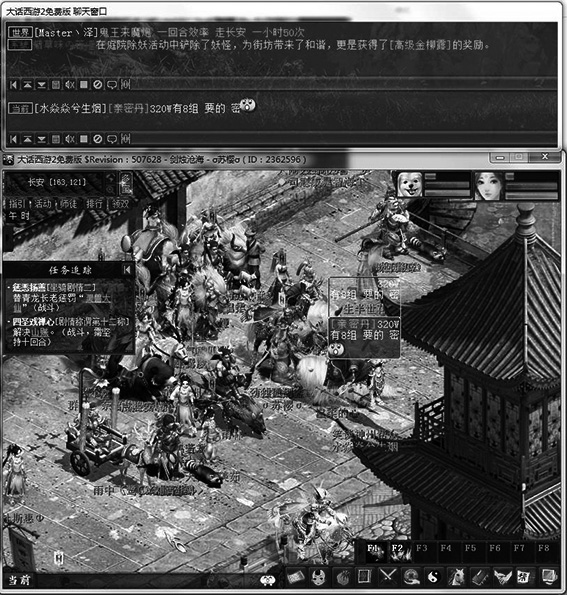

Game information display method and device

The invention provides a game information display method and device capable of displaying game information in message boxes. The game information display method comprises the steps that current positions of the message boxes displayed in an interface are acquired; display setting operations performed by users are responded to on the basis of the message boxes, and the message boxes are correspondingly displayed; game information is received, and a channel identifier of the game information is obtained; according to the channel identifier, the game information is displayed in the message boxescorresponding to the channel identifier. By means of the game information display method, the game information viewing efficiency of the users can be improved, and the better game experience is provided for the users.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

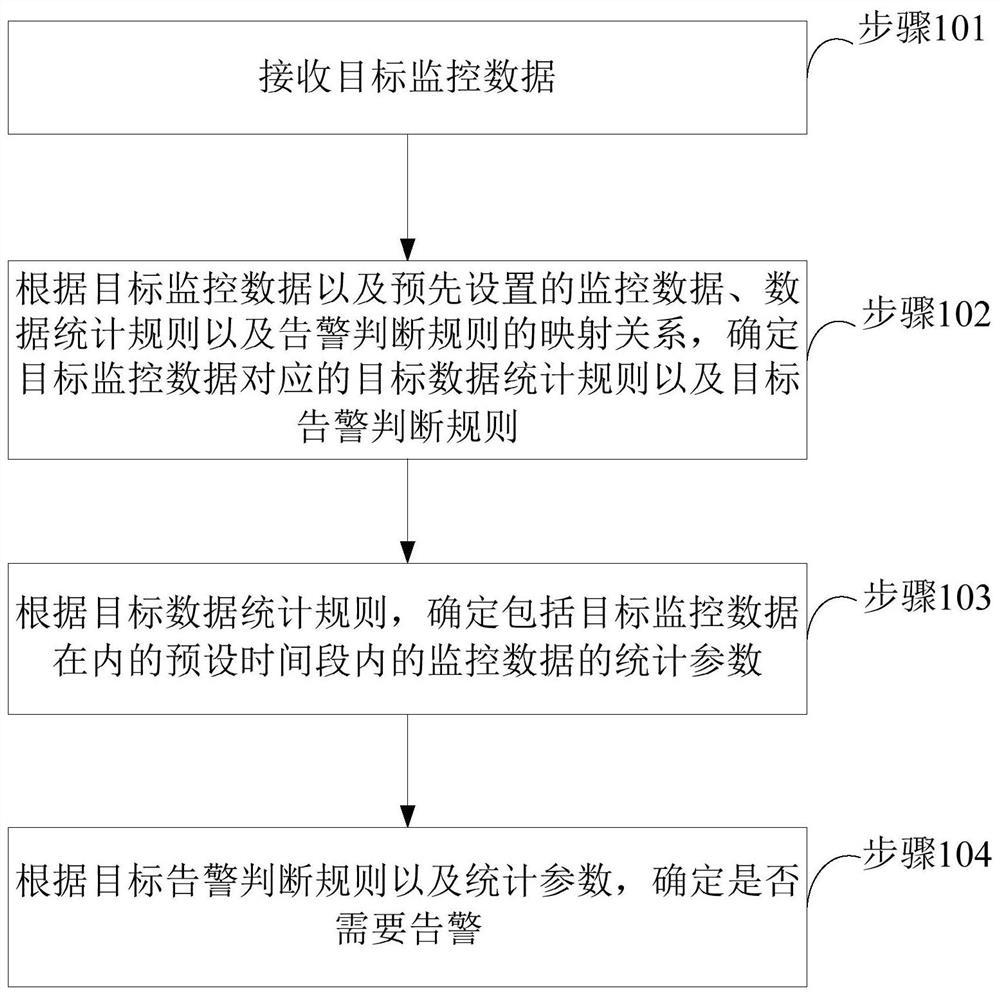

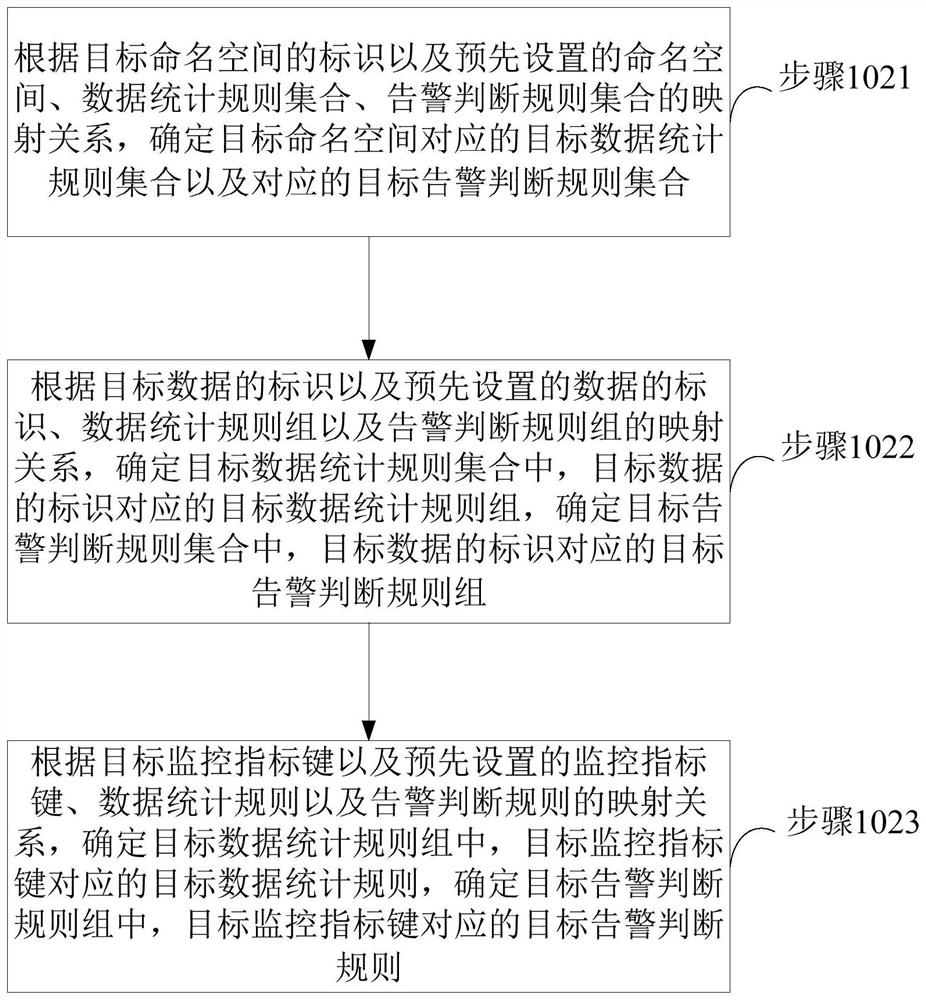

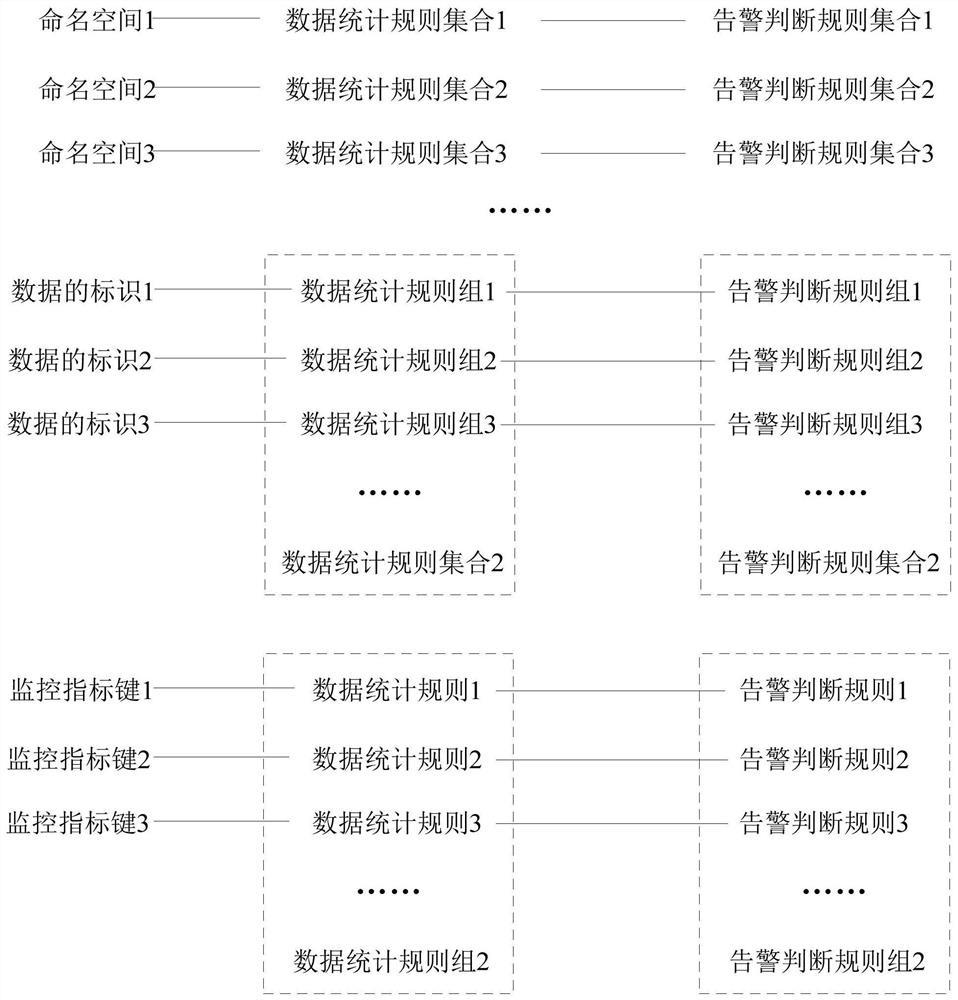

Monitoring alarm method and device, equipment and storage medium

PendingCN111934920AMeet custom needsImprove experienceHardware monitoringData switching networksEngineeringData mining

The embodiment of the invention relates to a monitoring alarm method and device, equipment and a storage medium. The method comprises the following steps: receiving target monitoring data, wherein thetarget monitoring data is data predefined by a user; according to the target monitoring data and a preset mapping relationship among the monitoring data, a data statistics rule and an alarm judgmentrule, determining a target data statistical rule and a target alarm judgment rule corresponding to the target monitoring data; determining statistical parameters of the monitoring data in a preset time period including the target monitoring data according to the target data statistical rule; determining whether alarm is needed or not according to the target alarm judgment rule and the statisticalparameters. According to the monitoring alarm method, the target monitoring data, the target data statistics rule and the target alarm judgment rule can be flexibly configured based on the requirements of the user; the user-defined requirements of the user are met, and the user experience is improved.

Owner:北京青云科技股份有限公司

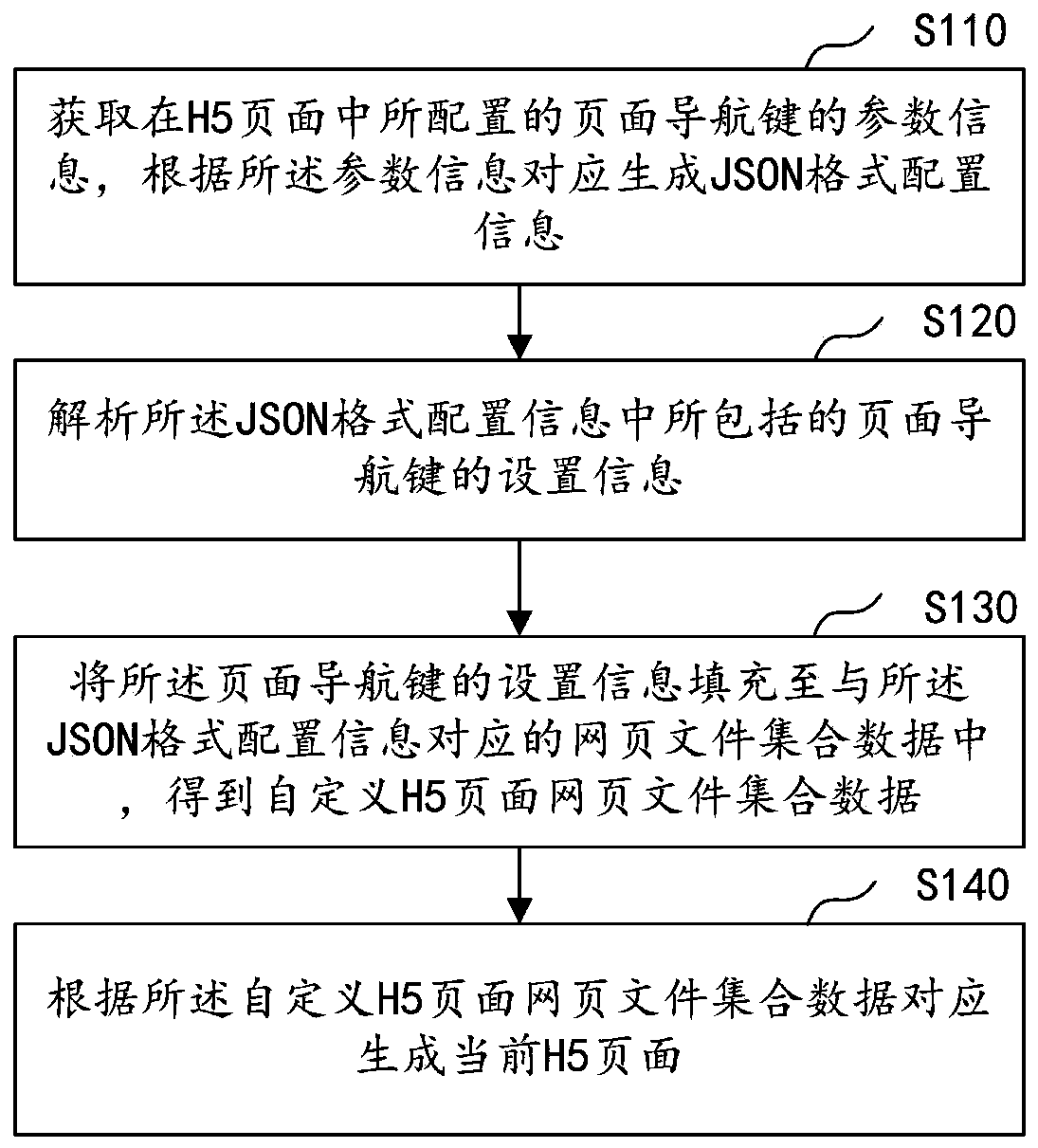

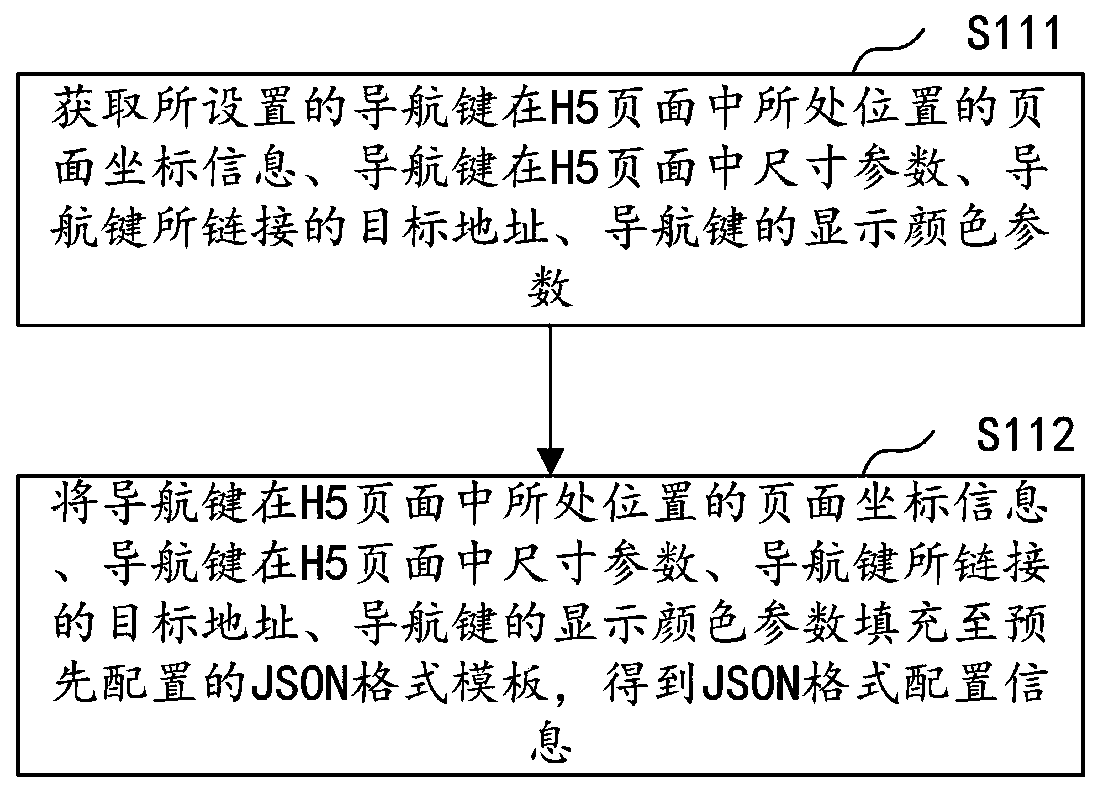

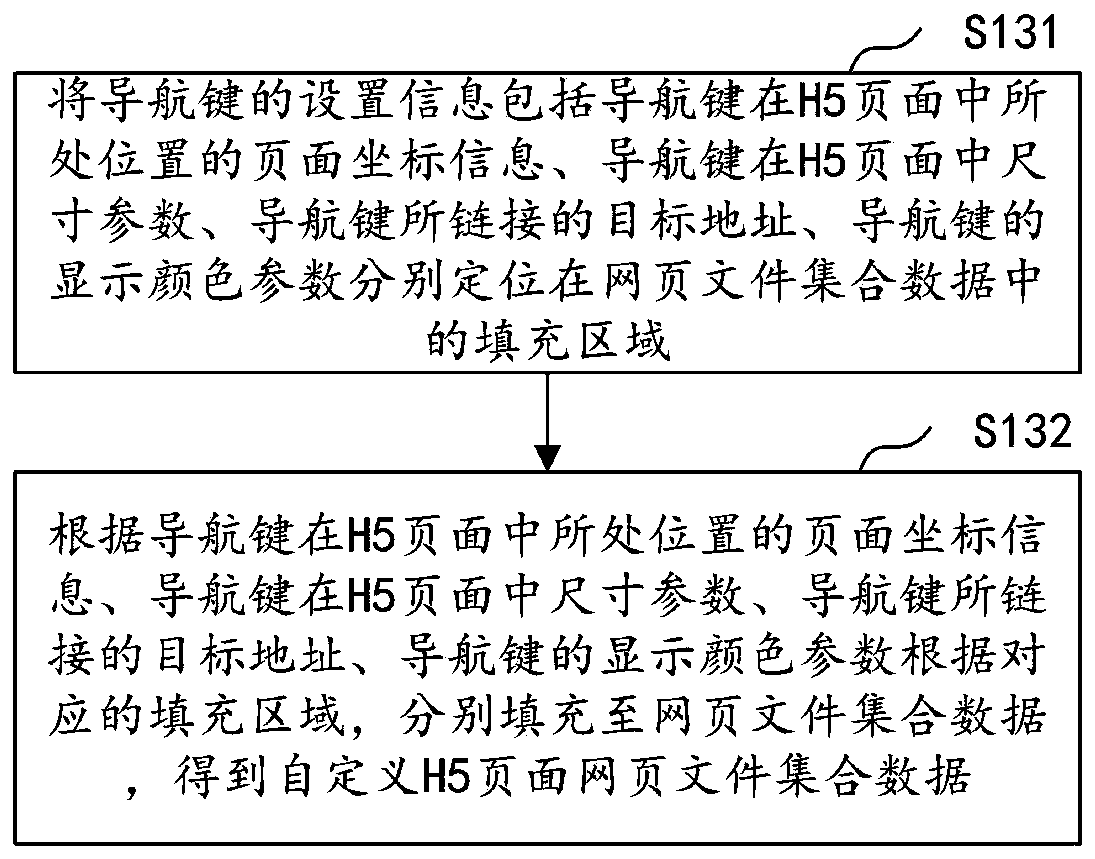

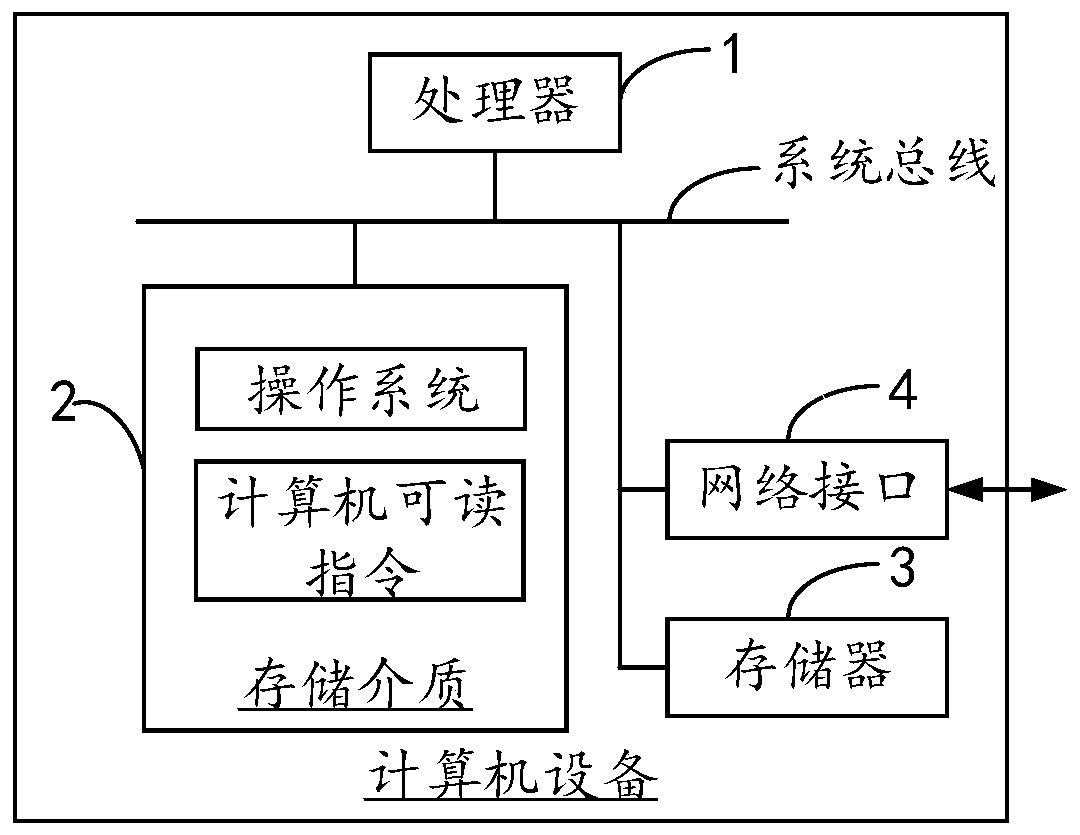

H5 navigation bar button configuration method and device, computer equipment and storage medium

PendingCN109800368AImplementation of custom requirementsMeet custom needsProgram loading/initiatingWeb data browsing optimisationPush outJSON

The invention discloses an H5 navigation bar button configuration method and device, computer equipment and a storage medium. The method comprises the following steps: acquiring parameter informationof a page navigation key configured in an H5 page, and correspondingly generating JSON format configuration information according to the parameter information; analyzing setting information of a pagenavigation key included in the JSON format configuration information; filling webpage file set data corresponding to the JSON format configuration information with the setting information of the pagenavigation key to obtain custom H5 page webpage file set data; and correspondingly generating a current H5 page according to the user-defined H5 page webpage file set data. According to the method, the JSON format configuration information is adopted to control the navigation bar button and the self-definition requirement of the whole H5 page, when a new page is pushed out, the H5 issues the JSONformat configuration information of the whole page and the H5 page to be pushed out, a client does not need to send a version again, and various H5 self-definition requirements are met.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

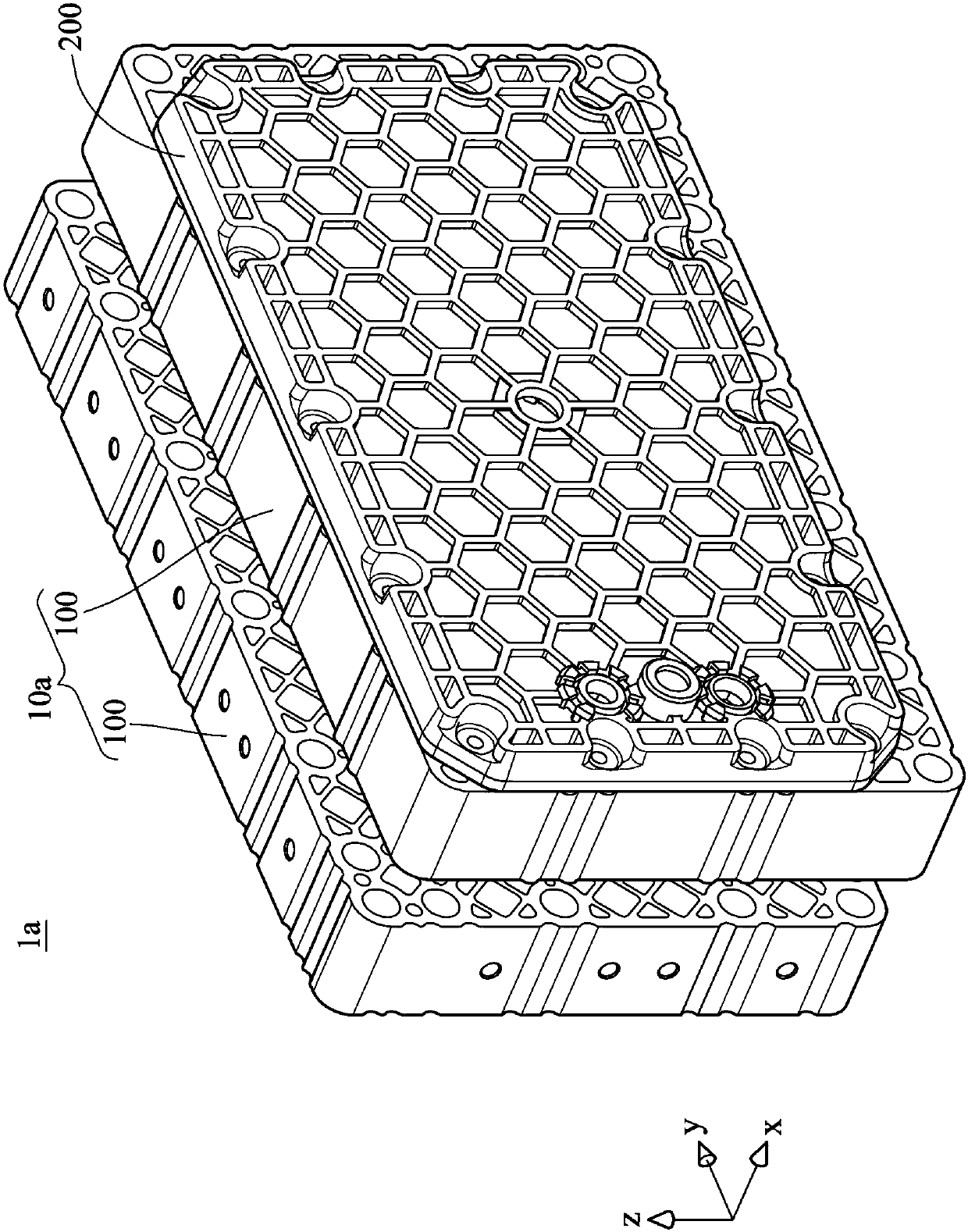

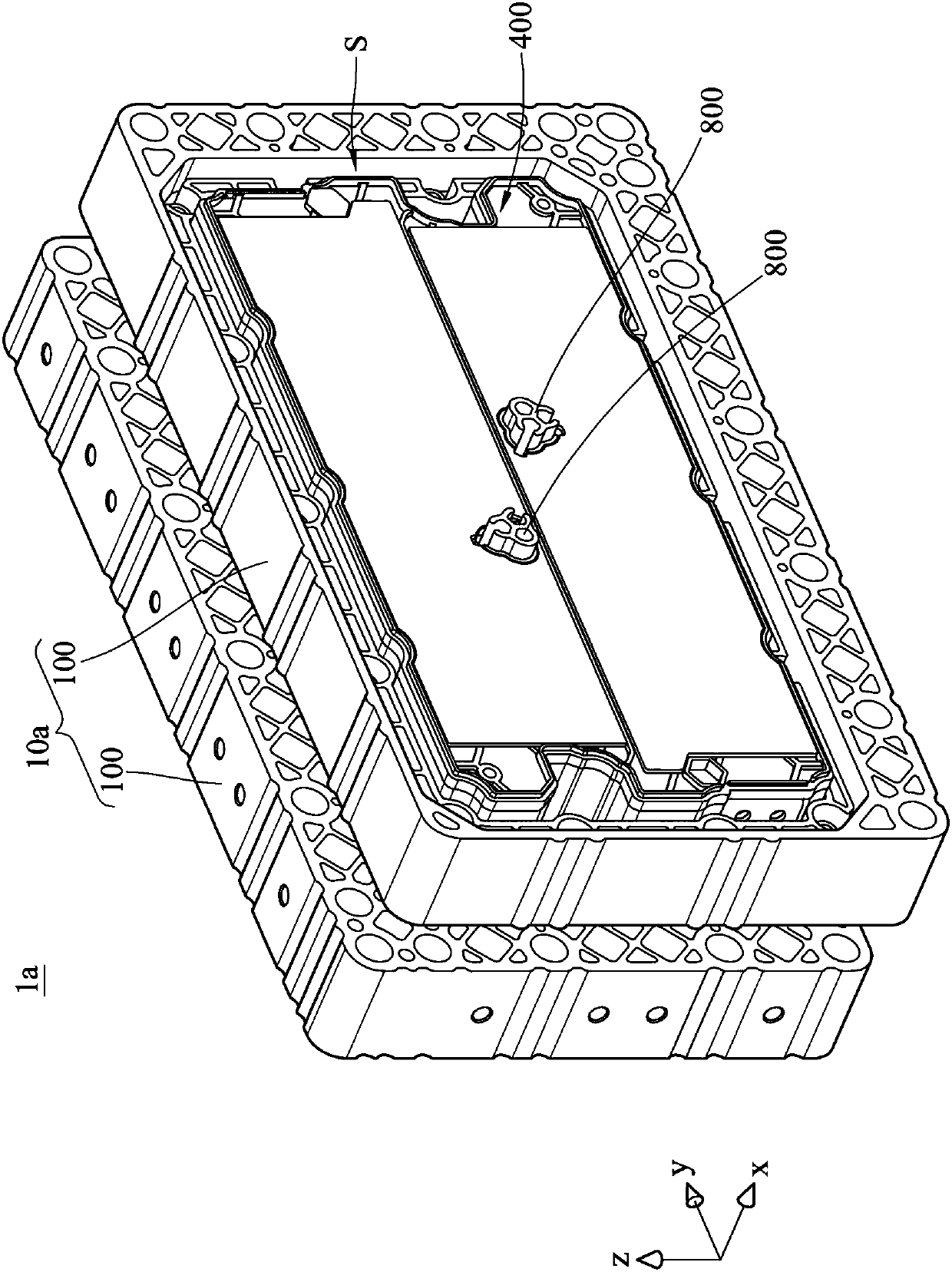

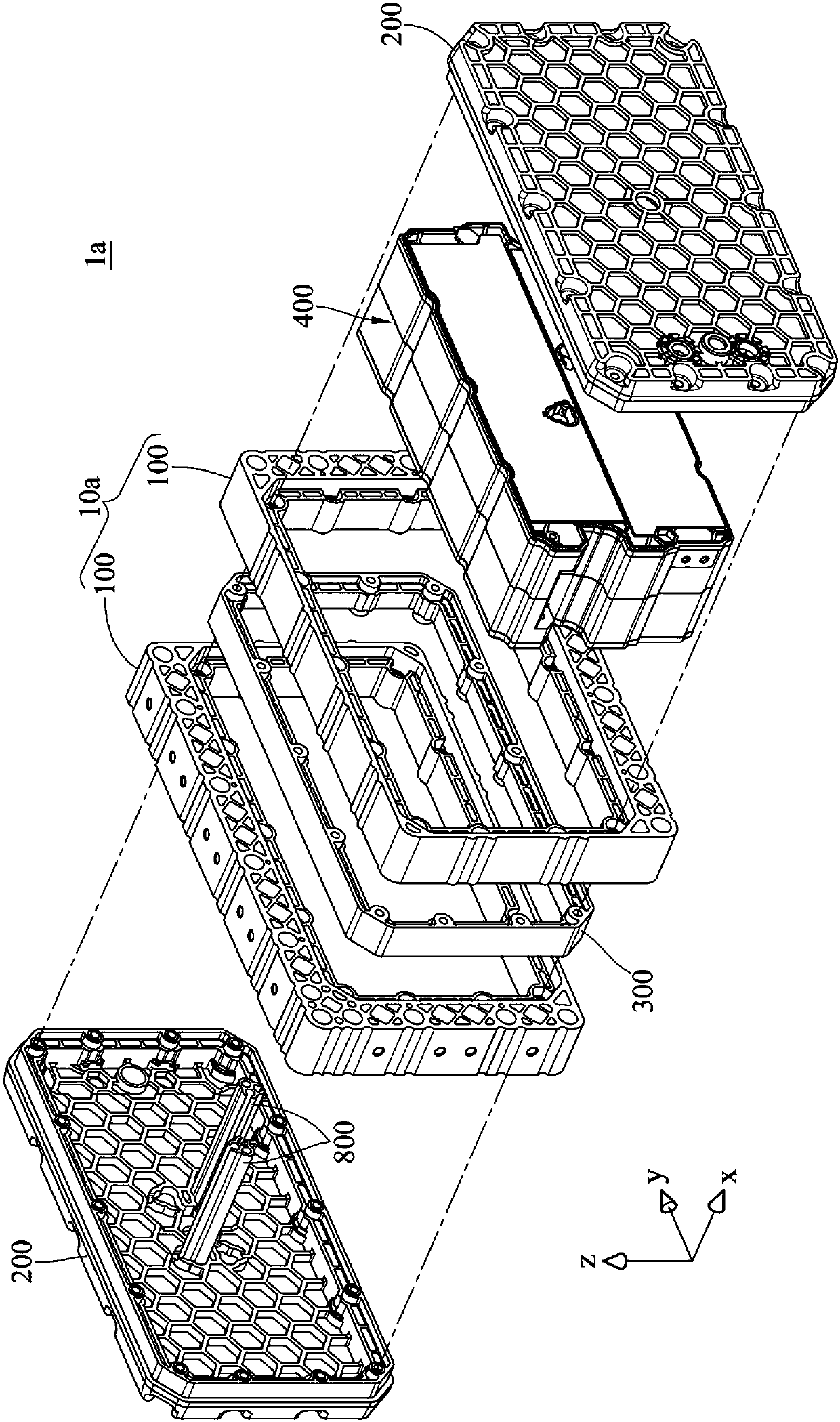

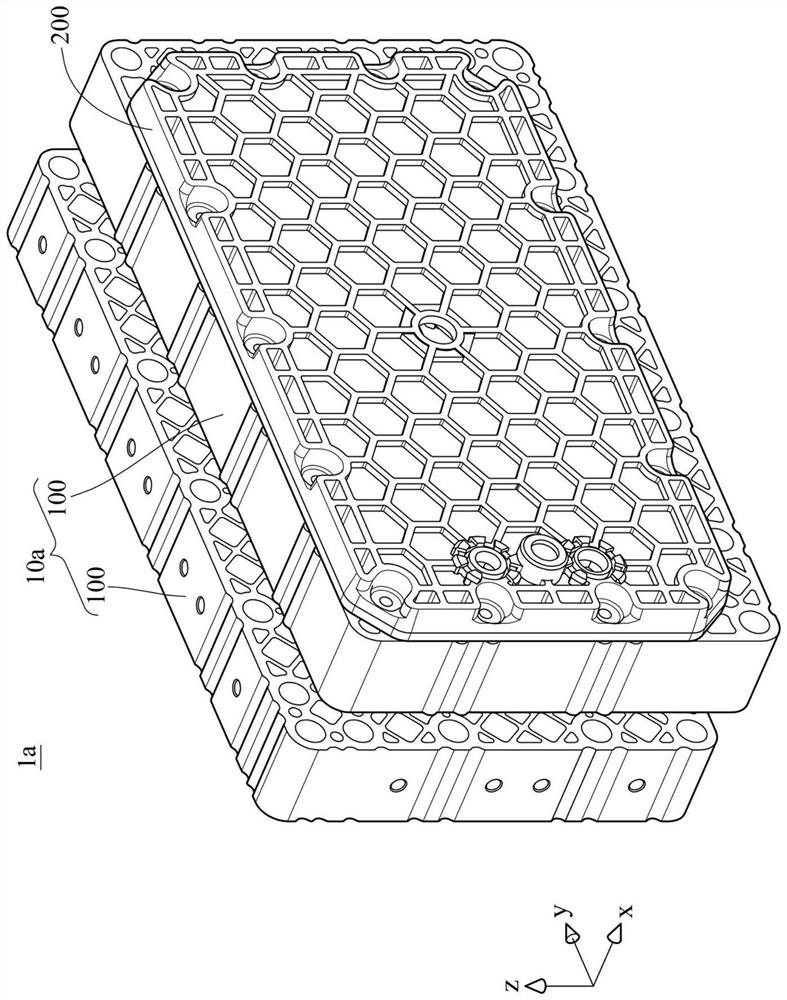

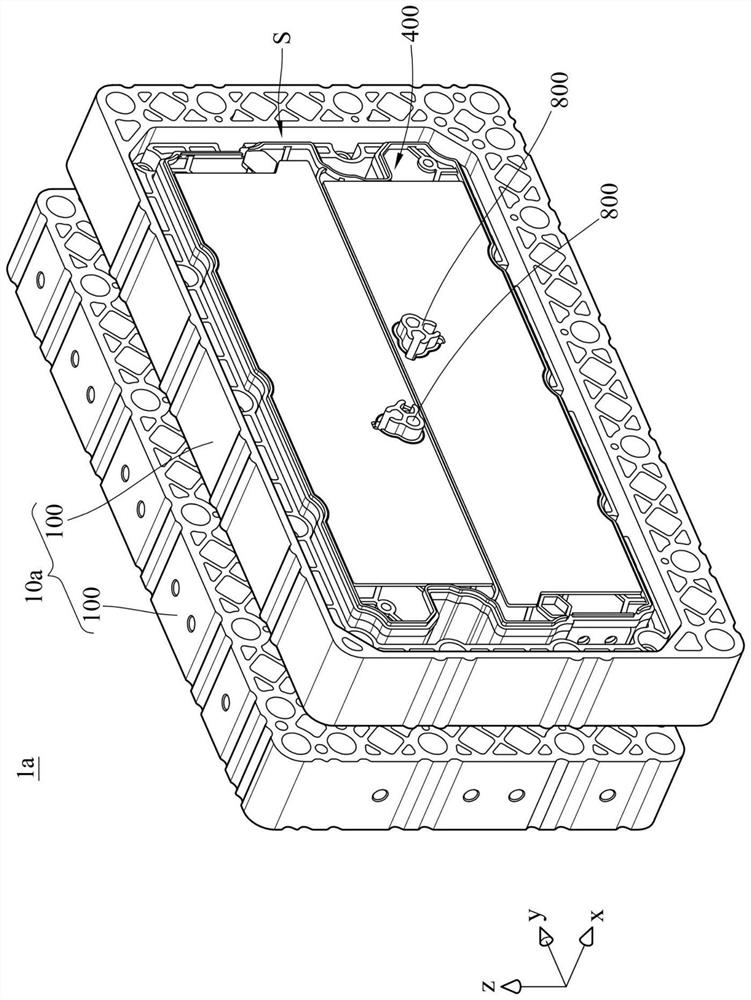

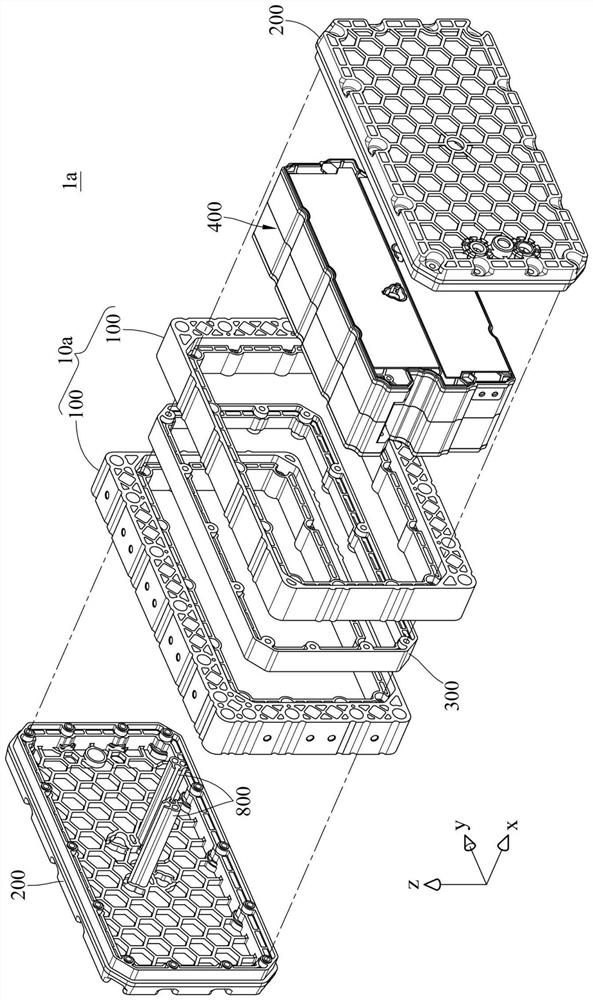

Frame body, frame body assembly and battery module

ActiveCN109962186AHigh degree of freedom of combinationEfficient use ofCell component detailsBatteriesMultiple frameButt joint

A frame body comprises an assembly frame, a first assembly part and a second assembly part. The assembly frame surrounds an accommodating slot. The first assembly part is connected to one side of theassembly frame and extends in a direction away from the accommodating slot, so that one side with the first assembly part on the frame body is thicker than the other side. The second assembly part islocated on the other side, adjacent to the first assembly part, of the assembly frame, and extends in another direction away from the accommodating slot, so that one side with the second assembly parton the frame body is thicker than the other side. The structure shape of the frame body after butt joint has various changes. The degree of combination freedom is high, and multiple frame bodies canbe assembled along different axial directions.

Owner:林建廷

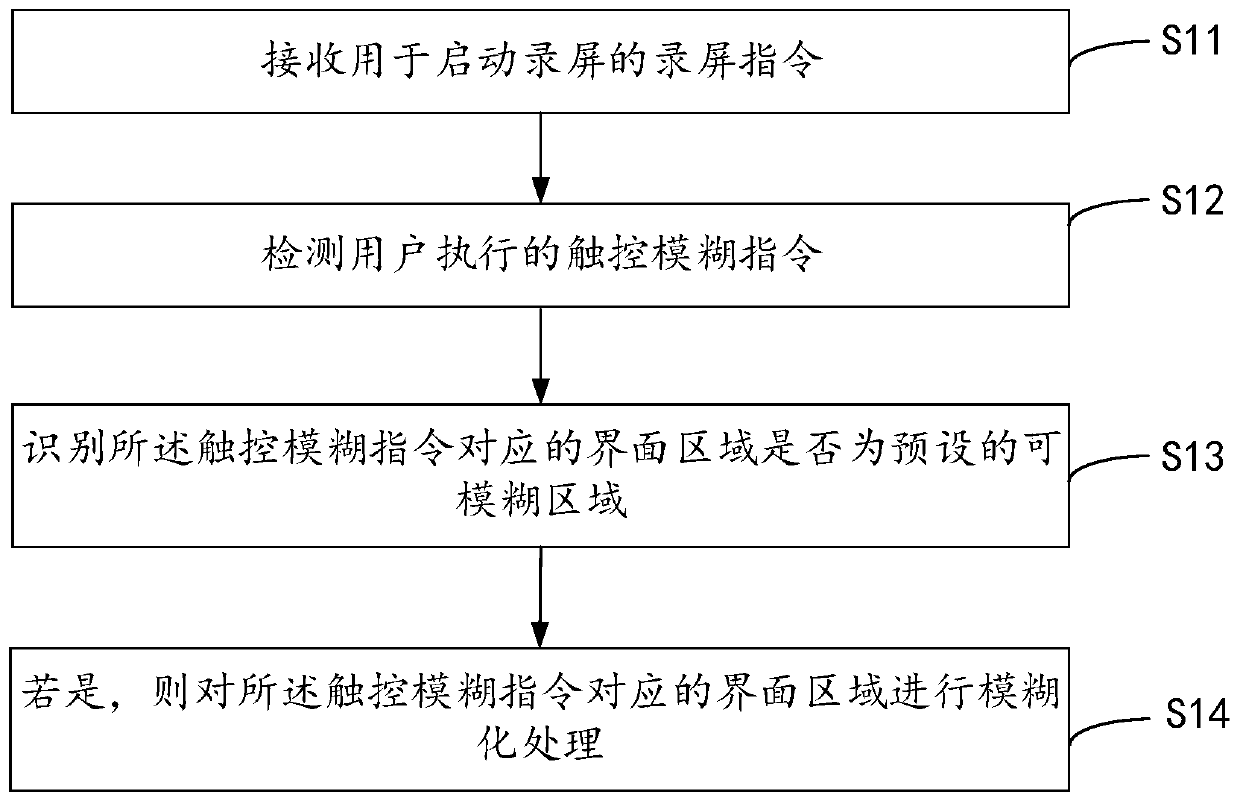

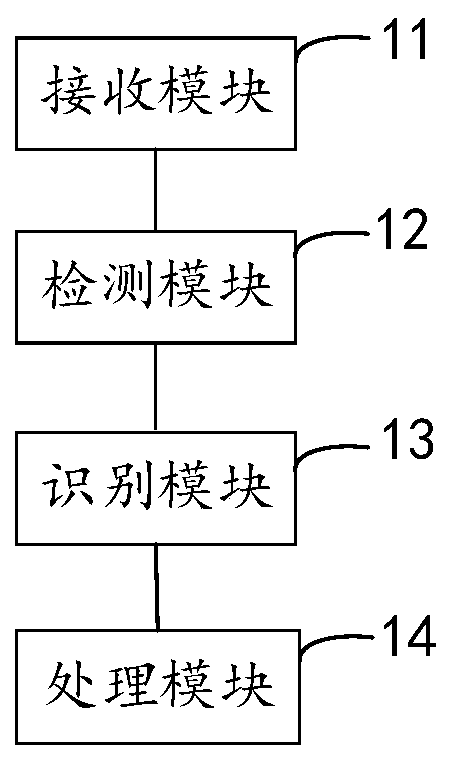

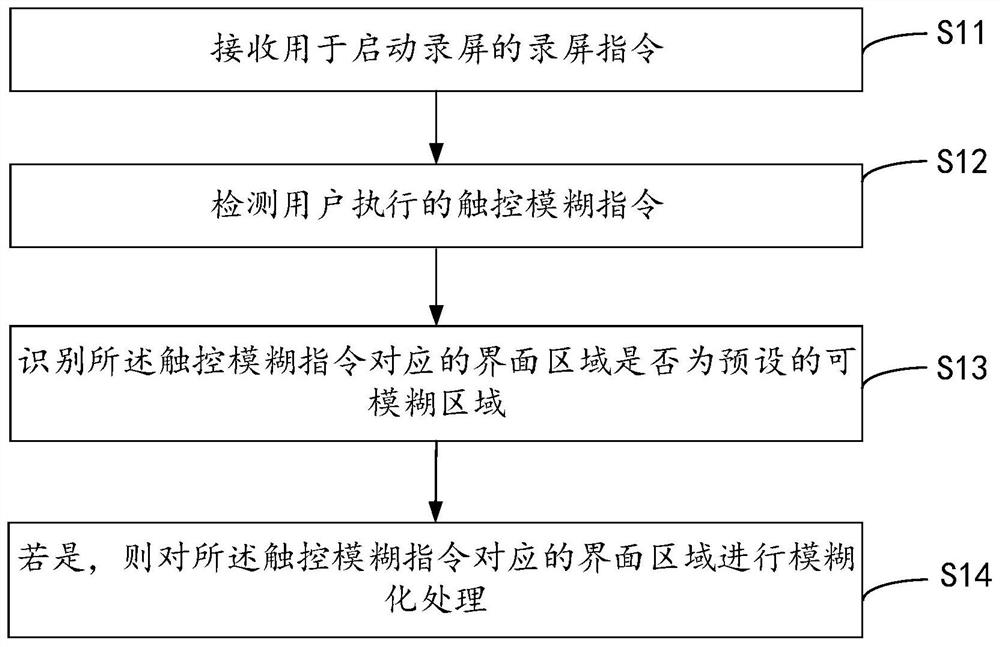

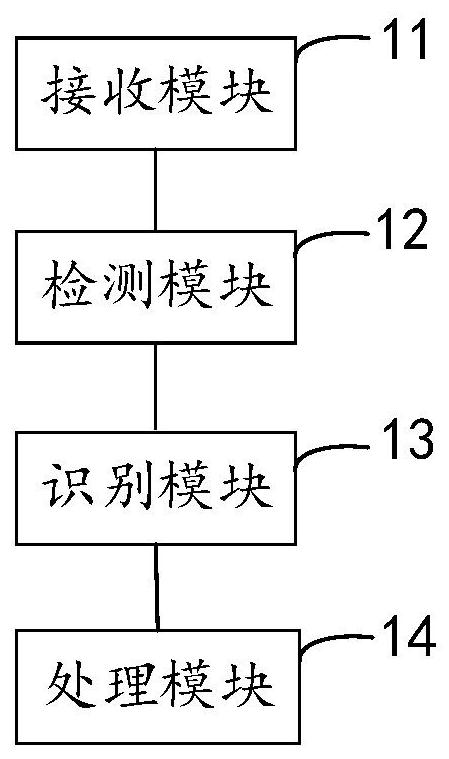

Screen recording method and device

ActiveCN109828715AImplement custom obfuscationFacilitates fuzzingInput/output processes for data processingComputer hardwareHuman–computer interaction

The invention provides a screen recording method and device. The method comprises: receiving a screen recording instruction used for starting screen recording; Detecting a touch fuzzy instruction executed by a user; Identifying whether an interface area corresponding to the touch fuzzy instruction is a preset fuzzy area or not; And if yes, performing fuzzification processing on an interface area corresponding to the touch fuzzy instruction. According to the screen recording method provided by the invention, the user-defined fuzzy processing can be carried out on the preset fuzzy region of thescreen recording video through the touch operation carried out on the screen recording interface by the user.

Owner:PING AN TECH (SHENZHEN) CO LTD

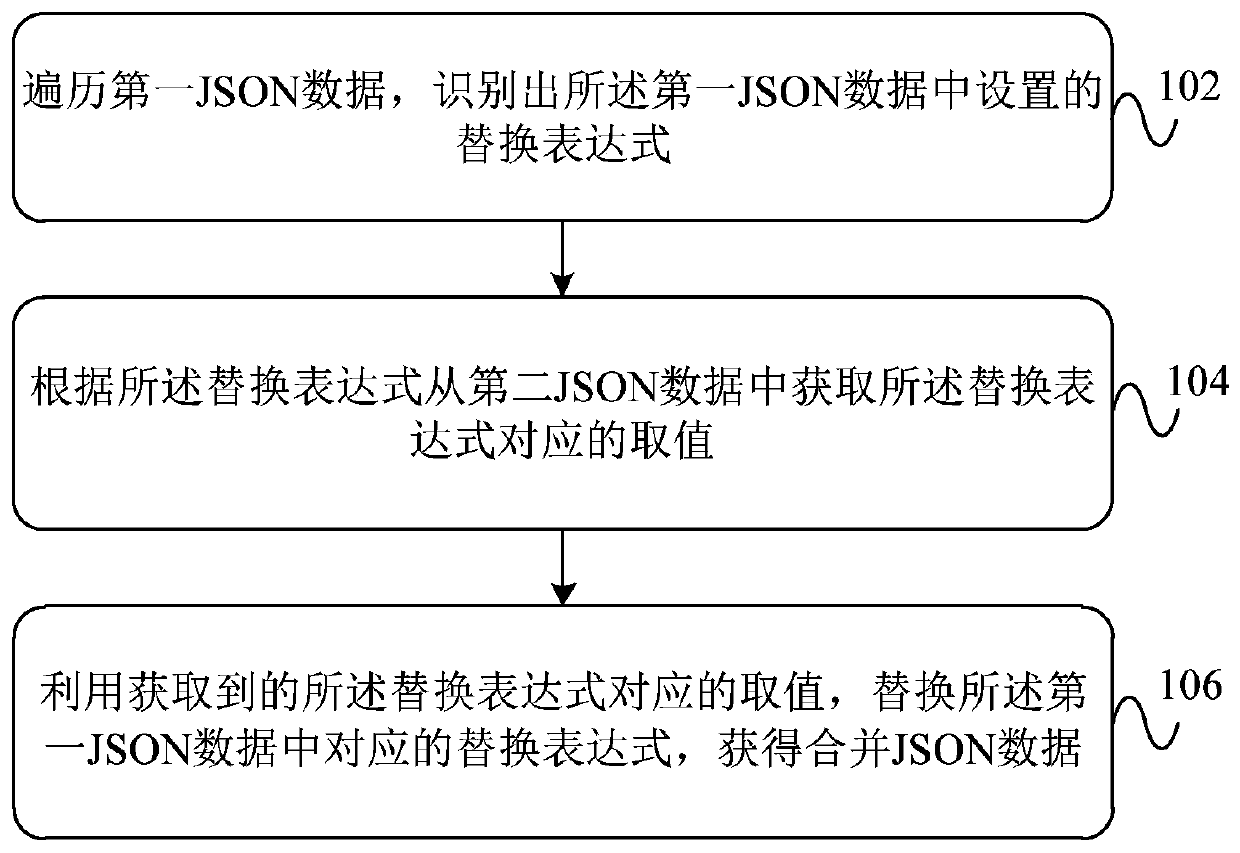

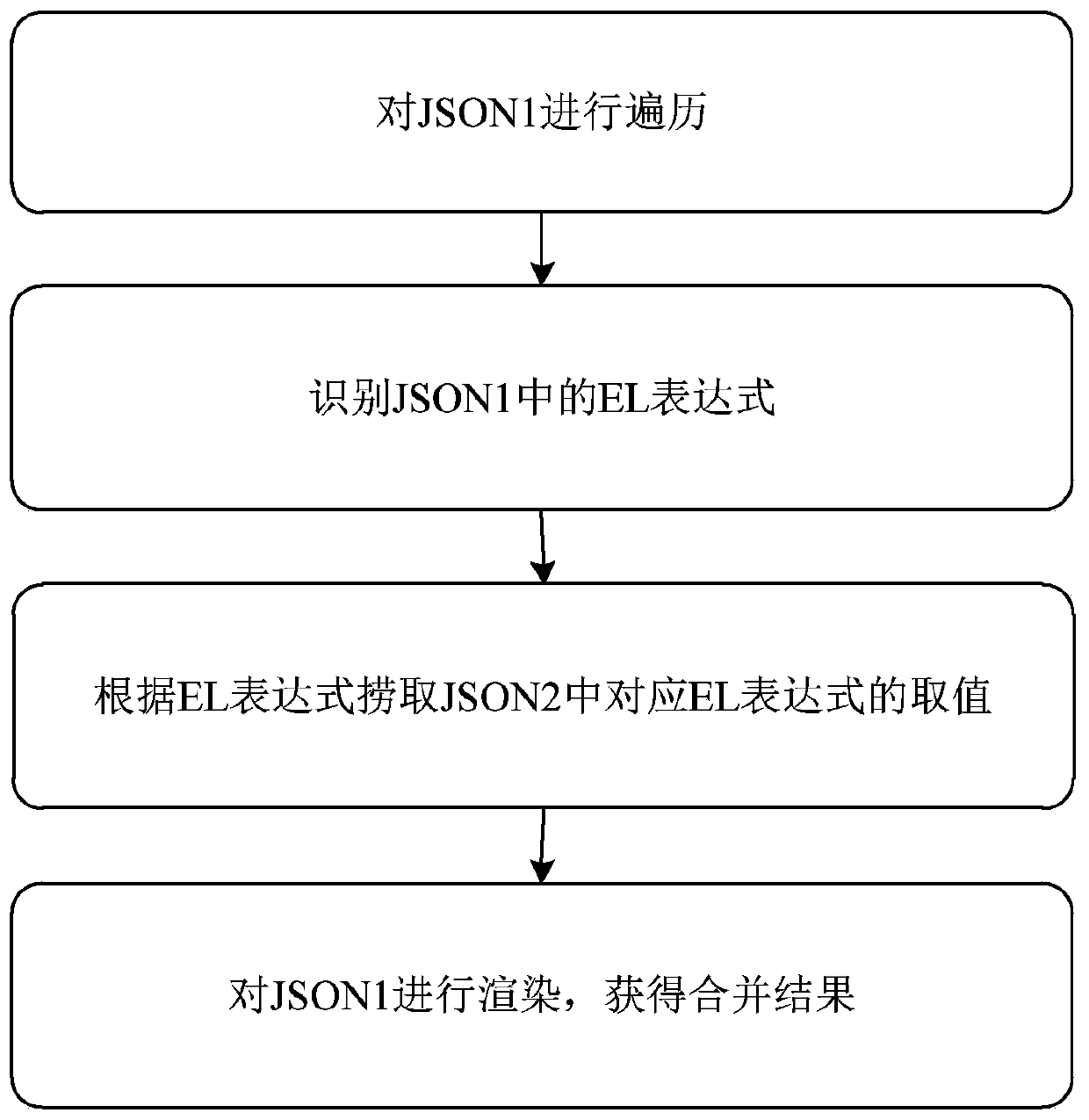

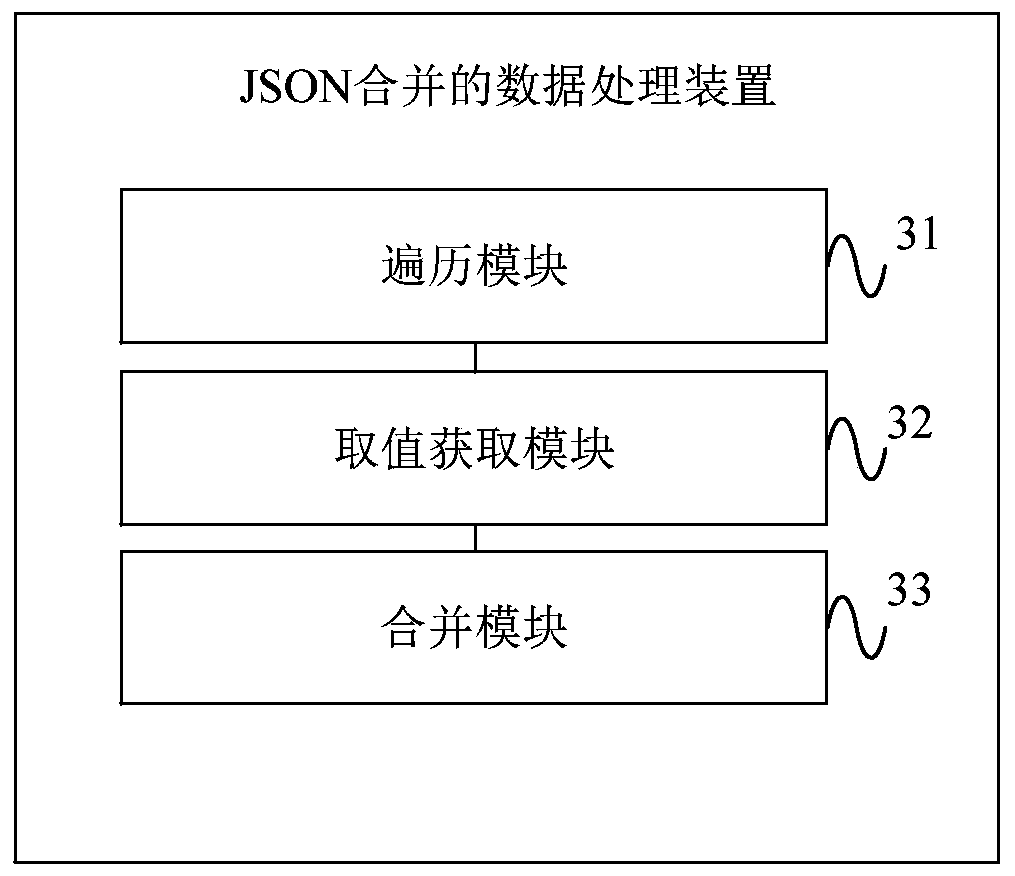

JSON combined data processing method and device

PendingCN110244938AMerge fitMeet custom needsCode compilationCreation/generation of source codeBusiness requirementsComputer science

The invention provides a JSON combined data processing method and device, and the method comprises the steps: setting a replacement expression in first JSON data, directionally obtaining a value corresponding to the replacement expression in second JSON data, and carrying out the parameter replacement of the replacement expression in the first JSON data. The formats of the replacement expressions can be set according to different service requirements, the replacement parameters are defined, the self-defined requirement of JSON merging is met, and the flexibility of JSON merging is improved. Moreover, JSON merging is carried out in a parameter replacement mode, the JSON merging efficiency can be improved, the structure of the JSON is not limited, the method is suitable for JSON merging of a complex structure, and the application range is wide.

Owner:ADVANCED NEW TECH CO LTD

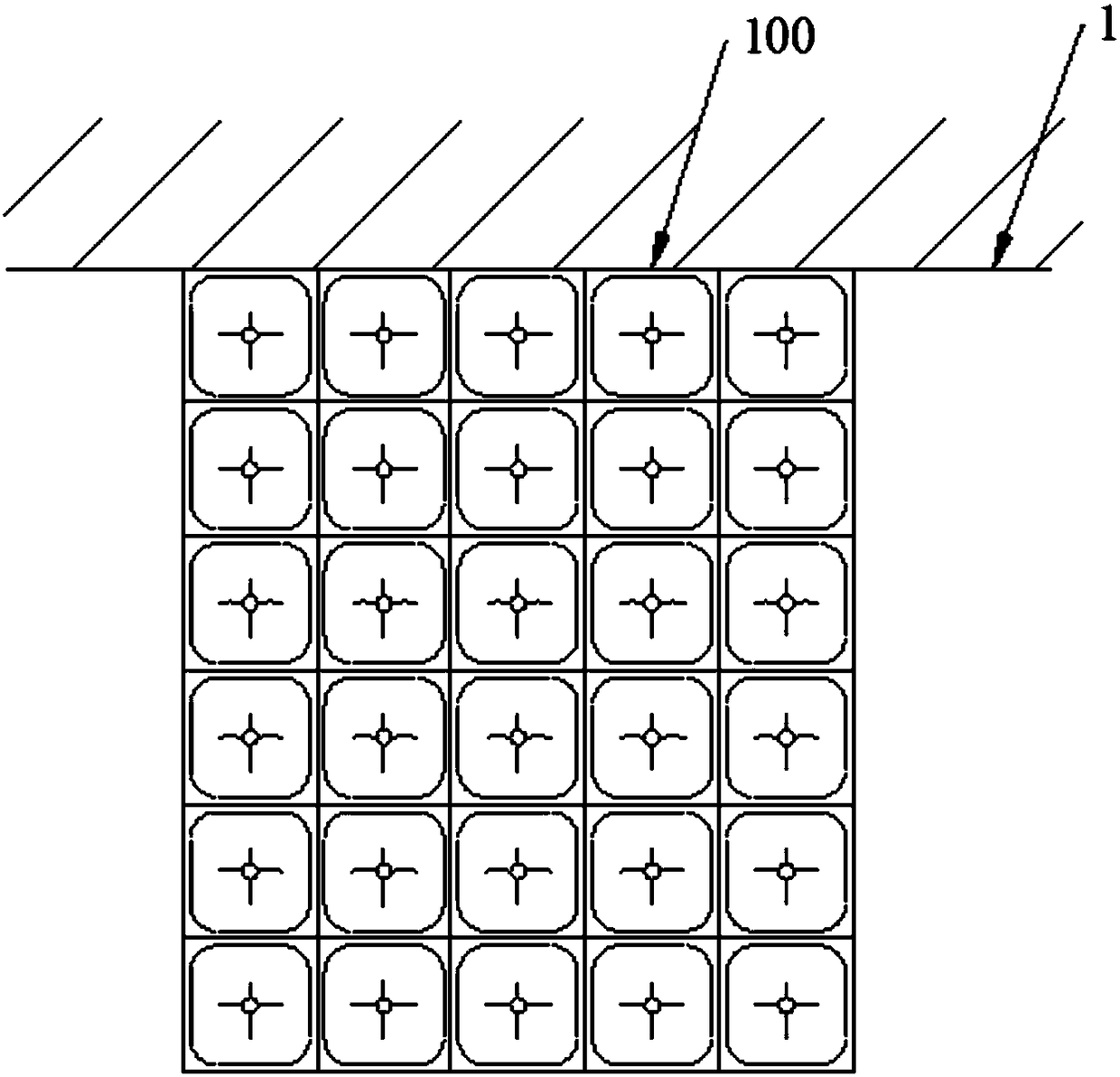

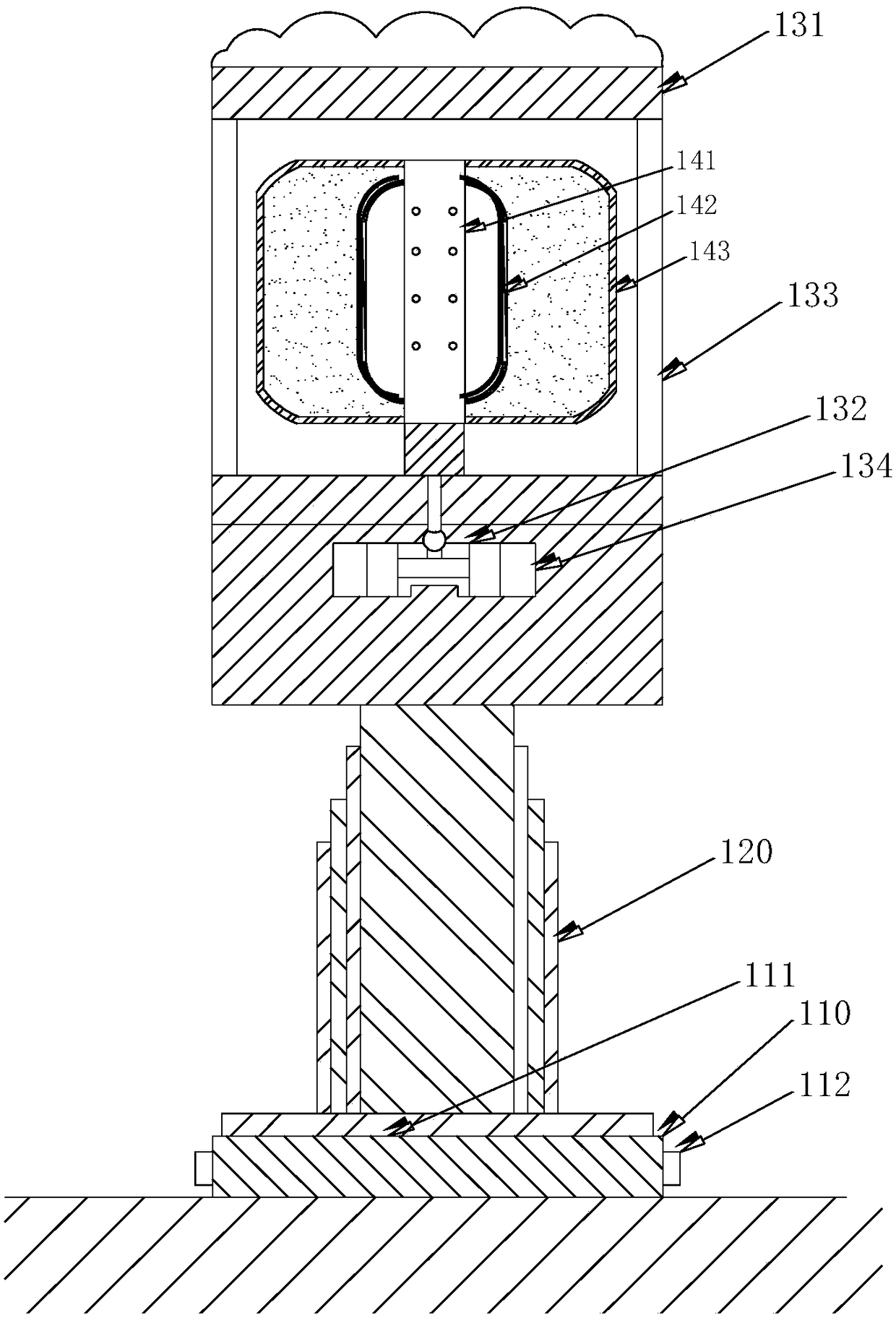

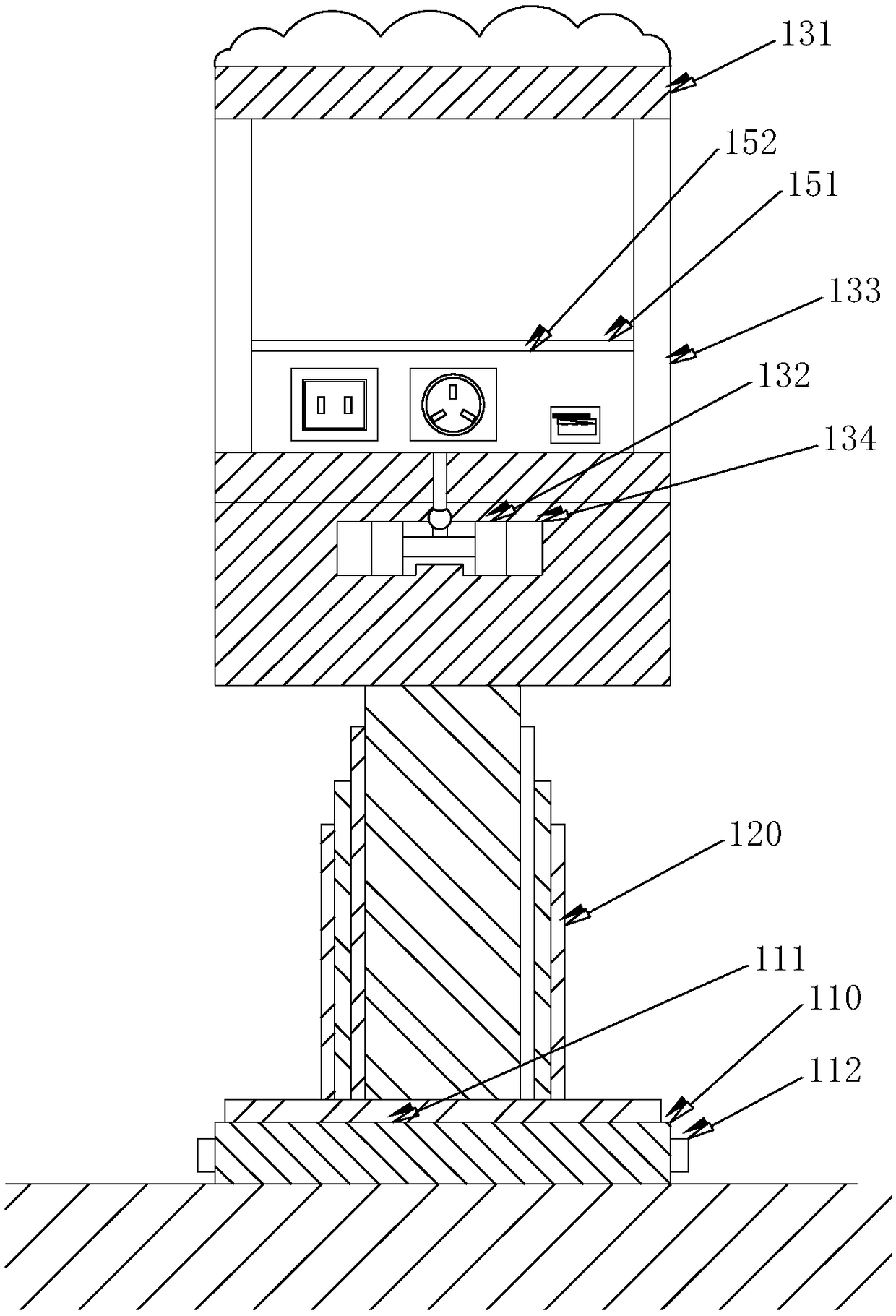

Self-defined modular bed

The invention relates to a self-defined modular bed. For the self-defined modular bed, each bearing bracket is arranged between a bearing soft cushion and a lifting structure for supporting the bearing soft cushion, an adjusting rail section is arranged on the bottom of each bearing bracket, when bed body units are in array arrangement, the adjusting rail sections are connected to form an adjusting rail, the adjusting rail is provided with adjusting parts, the adjusting parts comprise drive structures, the drive structures are used for driving the adjusting parts to move on the adjusting rail,the adjusting parts comprise a leaning part, a power supply part, a placing part, a storage part and an illuminating part according to the type; when the bed needs to be used for sleep, all the bed body units are controlled to be simultaneously positioned at the same horizontal height, then a support plane for lying of people is formed, thus the sleep demand is provided, when a user needs any function application, the drive mechanisms are controlled to act, then the corresponding adjusting parts move to the needed positions, the corresponding adjusting parts are controlled through the liftingstructures to extend out of the support plane, and the effect of the self-defined demand is achieved.

Owner:于文伶

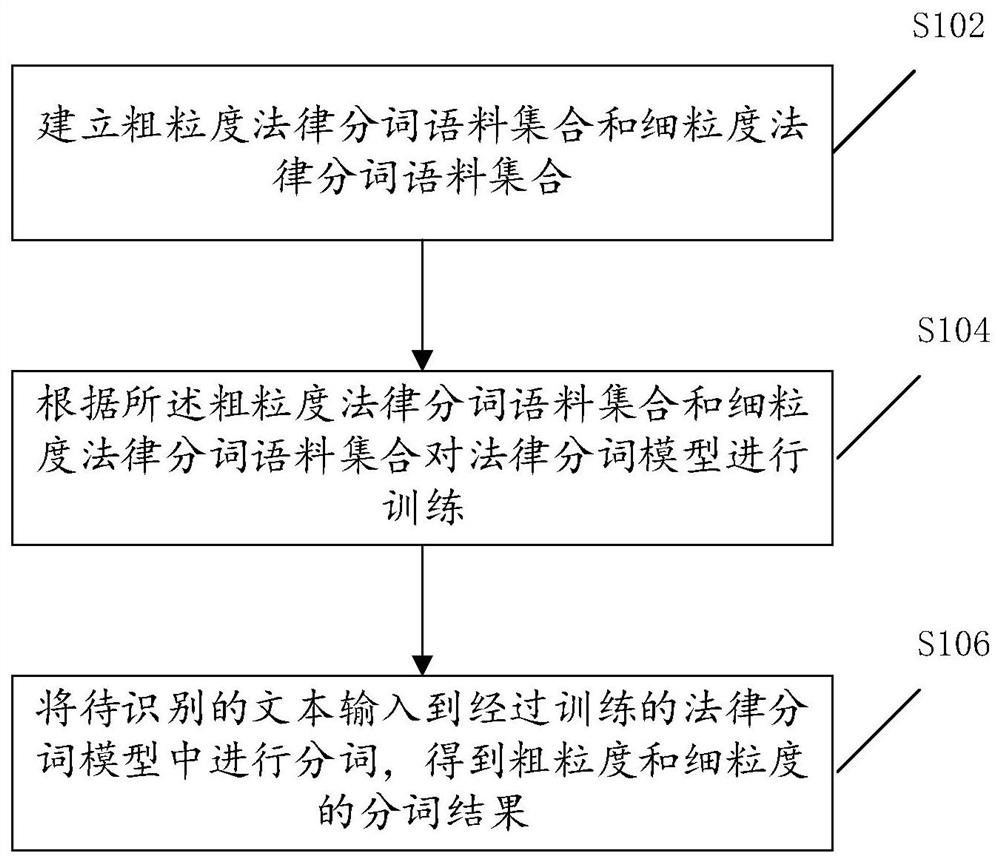

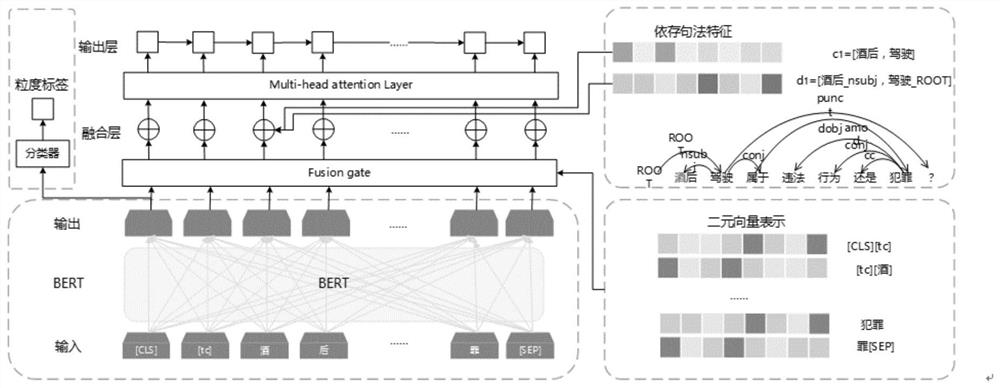

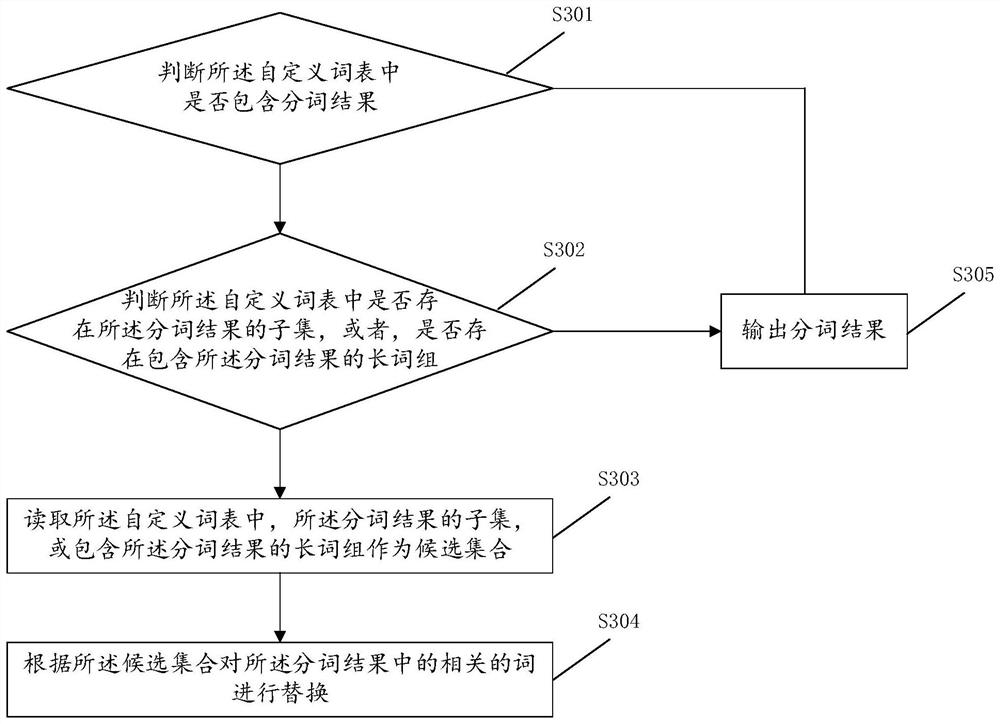

Multi-granularity fusion word segmentation method and device, equipment and storage medium

PendingCN113505592AMeet recallMeet custom needsCharacter and pattern recognitionNatural language data processingPattern recognitionAlgorithm

The invention discloses a multi-granularity fusion word segmentation method and device, equipment and a storage medium. The multi-granularity fusion word segmentation method comprises the following steps: establishing a coarse-granularity legal word segmentation corpus set and a fine-granularity legal word segmentation corpus set; training a legal word segmentation model according to the coarse-grained legal word segmentation word stock set and the fine-grained legal word segmentation word stock set; and inputting a to-be-recognized text into the trained legal word segmentation model for word segmentation to respectively obtain coarse-grained and fine-grained word segmentation results. According to the method, a multi-granularity word segmentation method is adopted, and the word segmentation requirement in a legal scene is met. For understanding and cognition of the text, word segmentation is needed for assistance, the text reading efficiency can be improved, and specific phrases in the legal field can be found.

Owner:上海艾爵斯信息科技有限公司

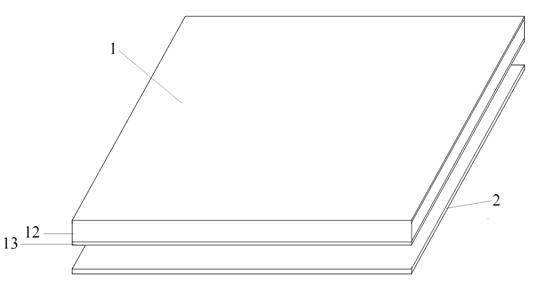

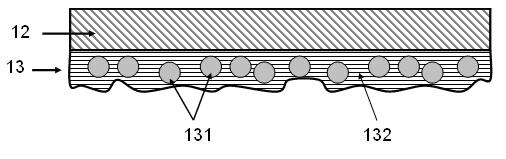

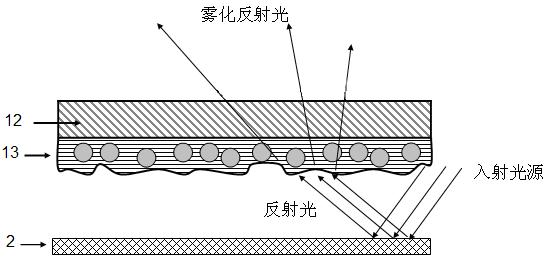

Novel liquid crystal display module device

InactiveCN101893786AGreat tasteMeet custom needsDiffusing elementsLighting device detailsLiquid-crystal displayEngineering

The invention relates to a novel liquid crystal display module device, comprising a reflector plate and a diffusion sheet, wherein the diffusion sheet is arranged above the reflector plate and is used for diffusing and atomizing light sources reflected by the reflector plate. By adopting the invention, the inevitable structural design problem of the traditional module user definition device can be overcome, the module grade is improved and the liquid crystal display is enabled to achieve better picture visual effect.

Owner:TPV DISPLAY TECH (XIAMEN) CO LTD

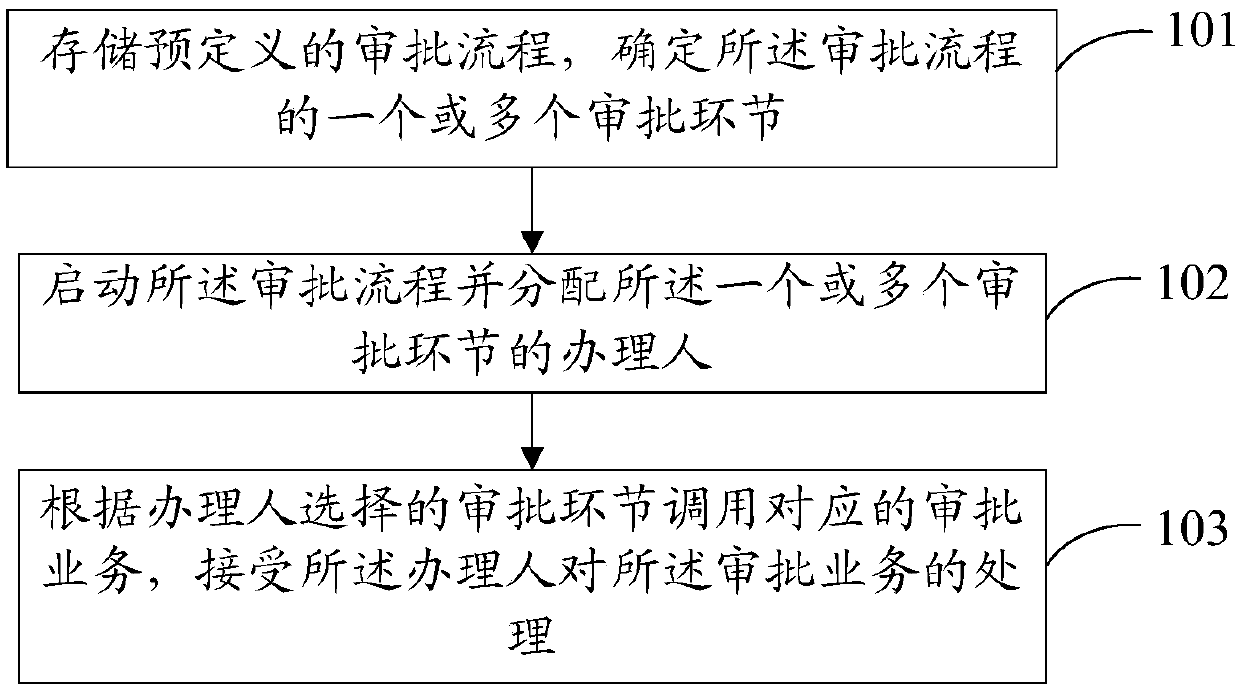

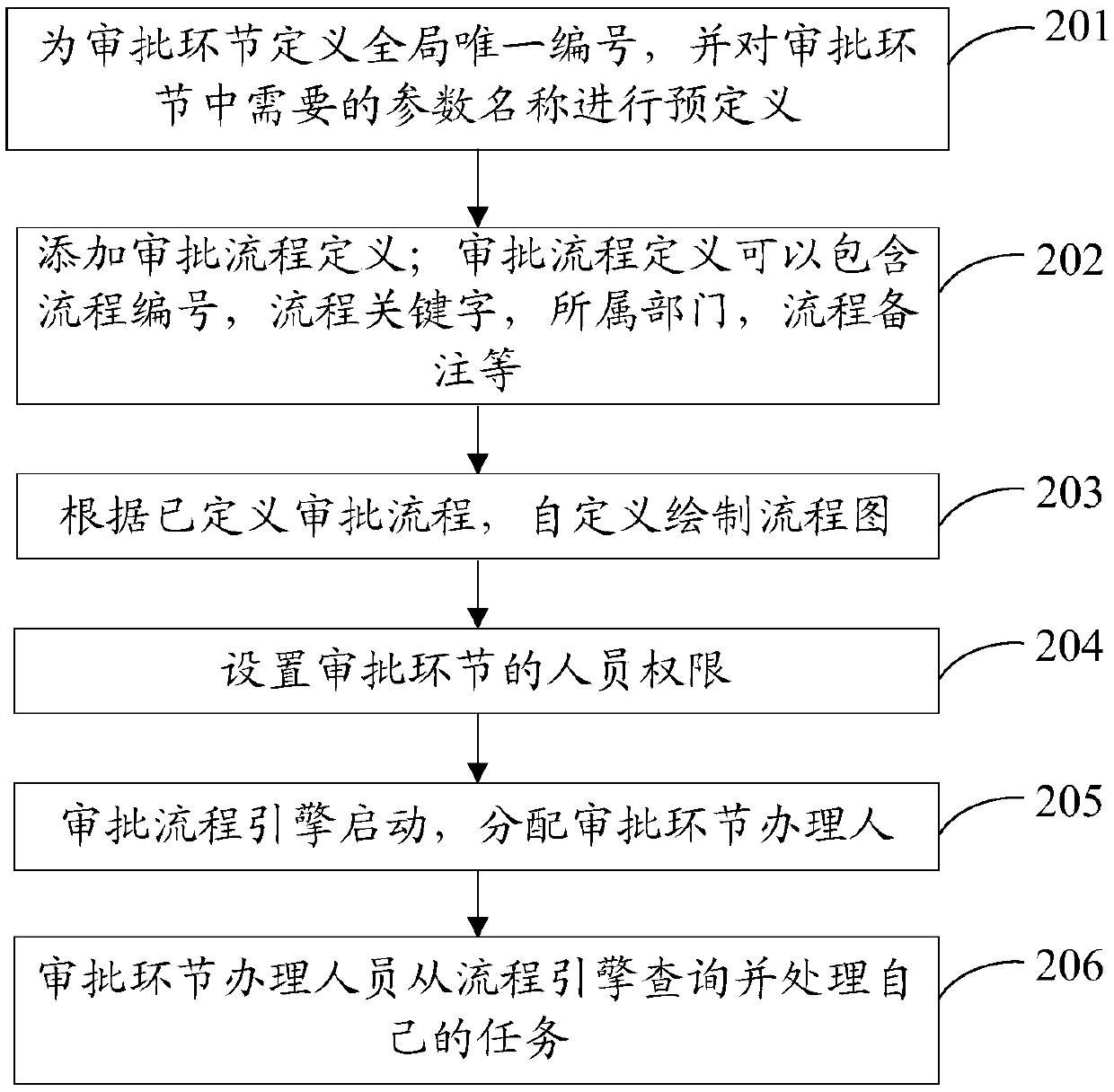

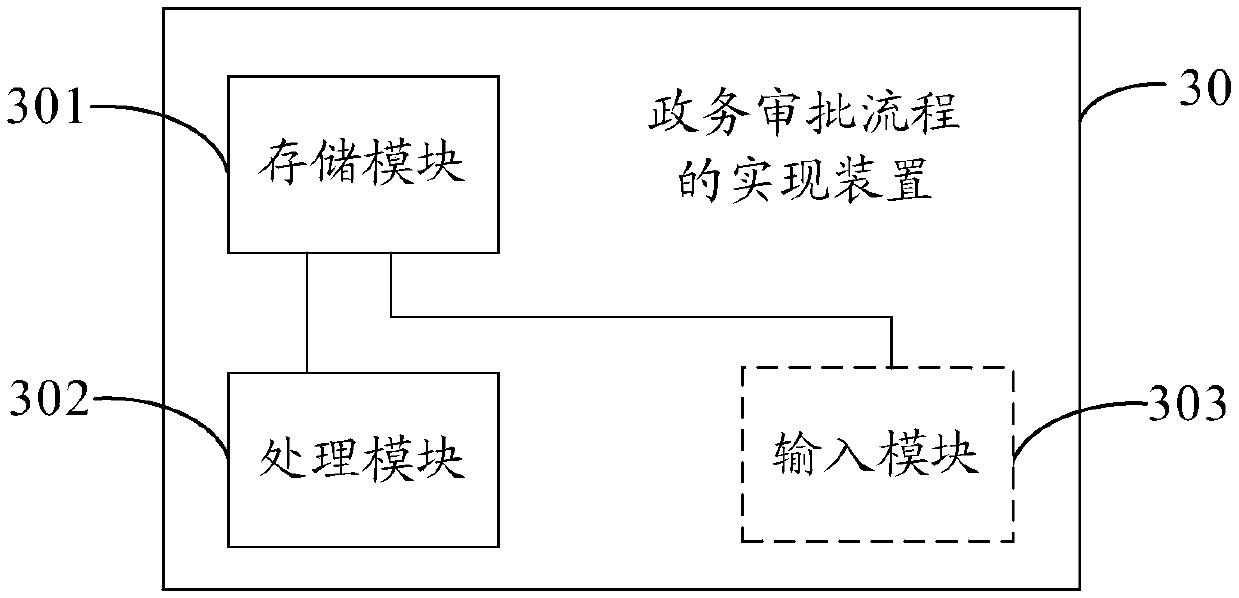

Government affair approval process implementation method and device

PendingCN111062676AMeet custom needsMeet the needs of flexible customizationOffice automationResourcesPersonalizationProcessing

The invention provides a government affair approval process implementation method and a device, relates to the technical field of computers, and can solve the problem that the government affair approval process cannot be flexibly customized. The method specifically comprises the following steps that a predefined approval process is stored, one or more approval links of the approval process are determined, and each approval link has a globally unique number; starting the examination and approval process and allocating transactors of the one or more examination and approval links; and calling the corresponding approval business according to the approval link selected by the transactor, and receiving the processing of the approval business by the transactor. The method is used for process approval of the government affair system, the requirement for personalized, flexible and user-defined approval processes can be met, and approval flexibility and efficiency are improved.

Owner:XIAN ELINK INFORMATION TECH CO LTD

Frames, frame assemblies, and battery modules

ActiveCN109962186BHigh degree of freedom of combinationEfficient use ofCell component detailsBatteriesStructural engineeringMechanical engineering

A frame body, comprising an assembly frame, a first assembly part and a second assembly part; the assembly frame surrounds an accommodating groove; the first assembly part is connected to one side of the assembly frame and extends away from the accommodating groove , so that the thickness of the side with the first assembly part on the frame body is thicker than the opposite side; the second assembly part is located on the other side of the assembly frame adjacent to the first assembly part, and faces the other side away from the accommodating groove The direction extends so that the thickness of the side of the frame body on which the second assembly part is provided is thicker than that of the opposite side. In the present invention, the structural shape of the frames after butt jointing has various changes, and the degree of freedom of combination is high, and multiple frames can be assembled along different axial directions.

Owner:林建廷

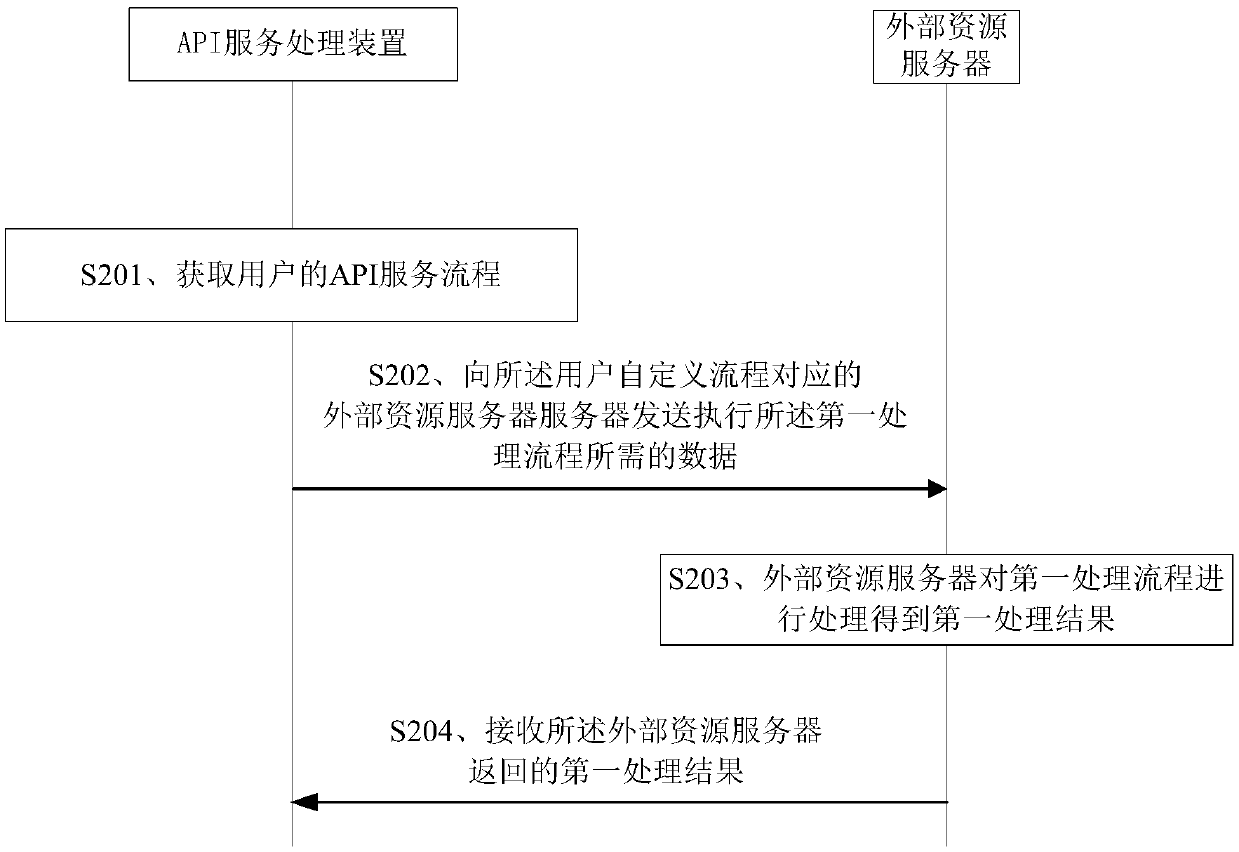

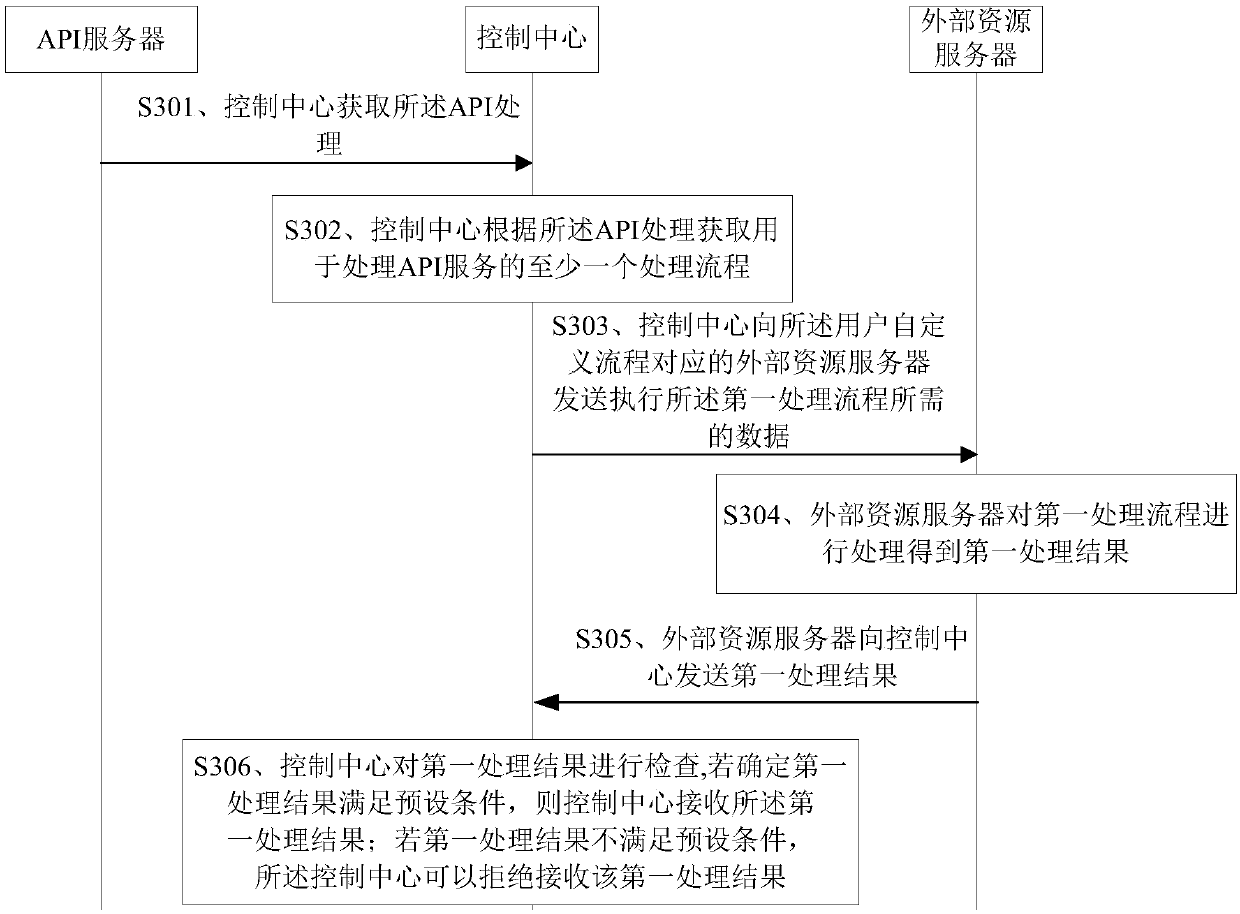

An API service processing method and device

InactiveCN109842654AMeet custom needsImprove user experienceTransmissionDistributed computingUser defined

The embodiment of the invention discloses an API service processing method, an API service processing device obtains an API service process of a user, and the API service process comprises a first processing process corresponding to a user-defined process. When the first processing flow is executed; and the API service processing device sends data required for executing the first processing flow to an external resource server corresponding to the user-defined flow, and processing the first processing flow by an external resource server capable of processing the first processing flow, and obtaining a first processing result obtained by processing the first processing flow by the external resource server from the external resource server. Therefore, even if the API service has a user-definedprocess, the API service can be customized; The API service processing device can still complete the API service under the assistance of the external resource server, so that the user can use the custom content which is hopeful to use when using the API service, the custom requirement of the user is met, and the use experience of the user is improved.

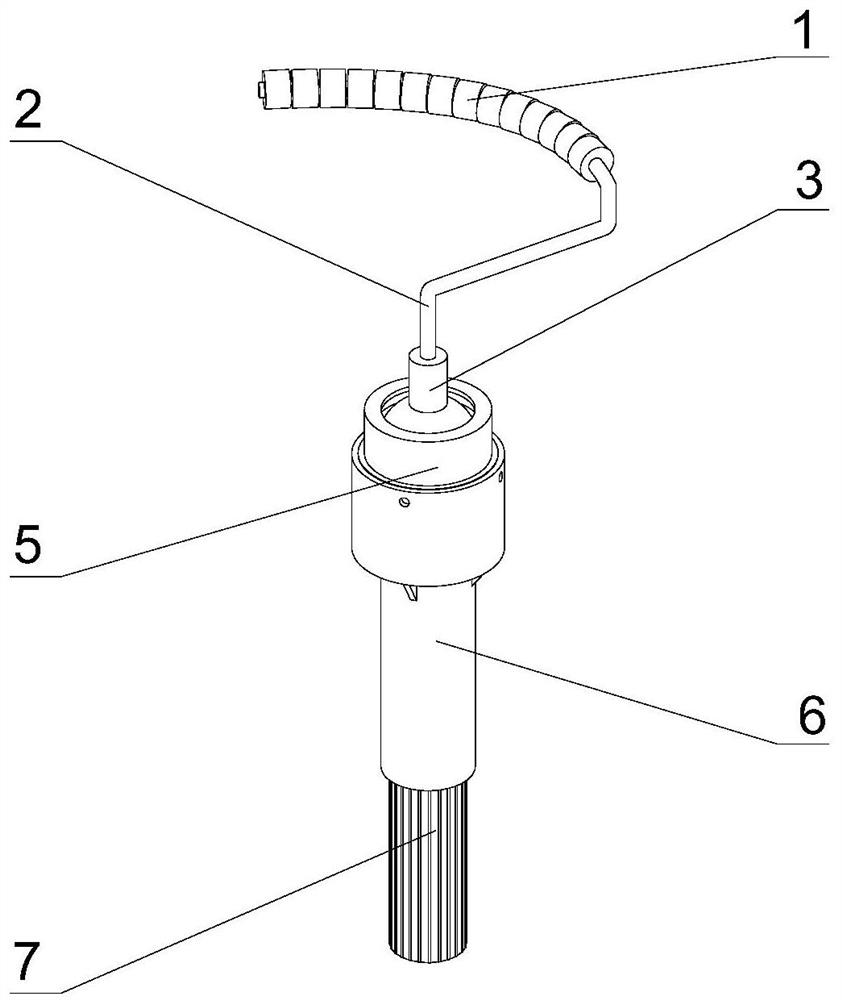

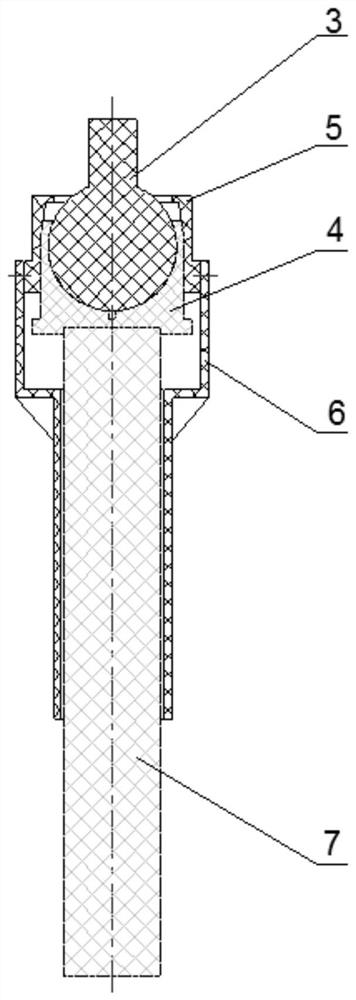

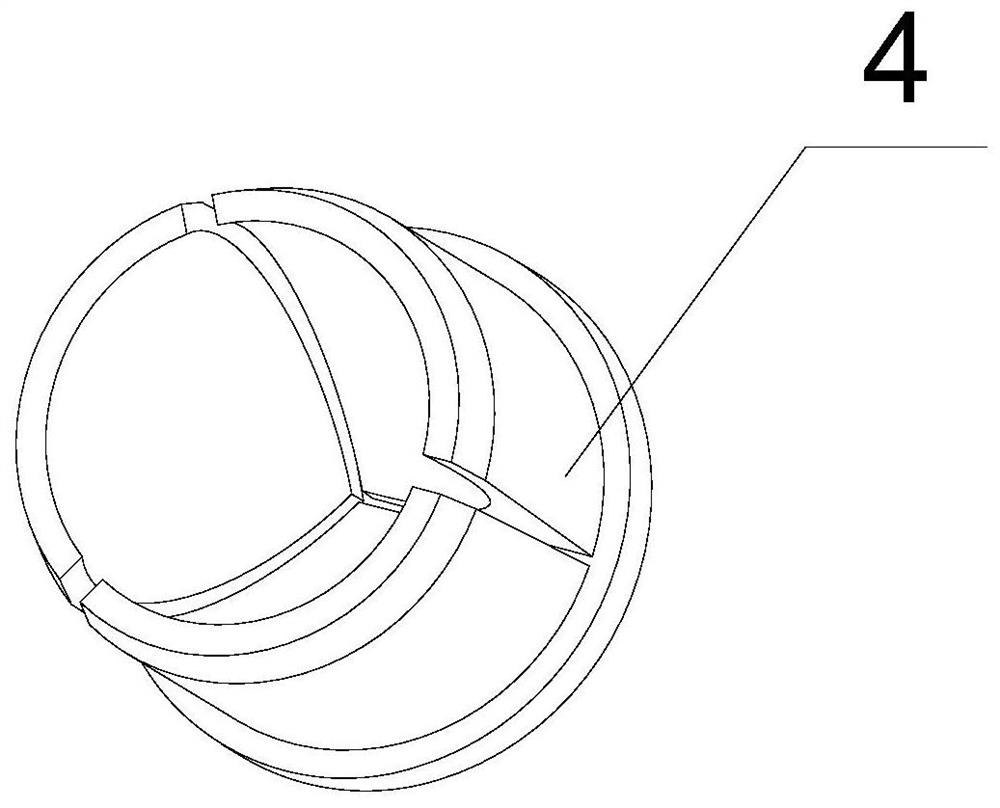

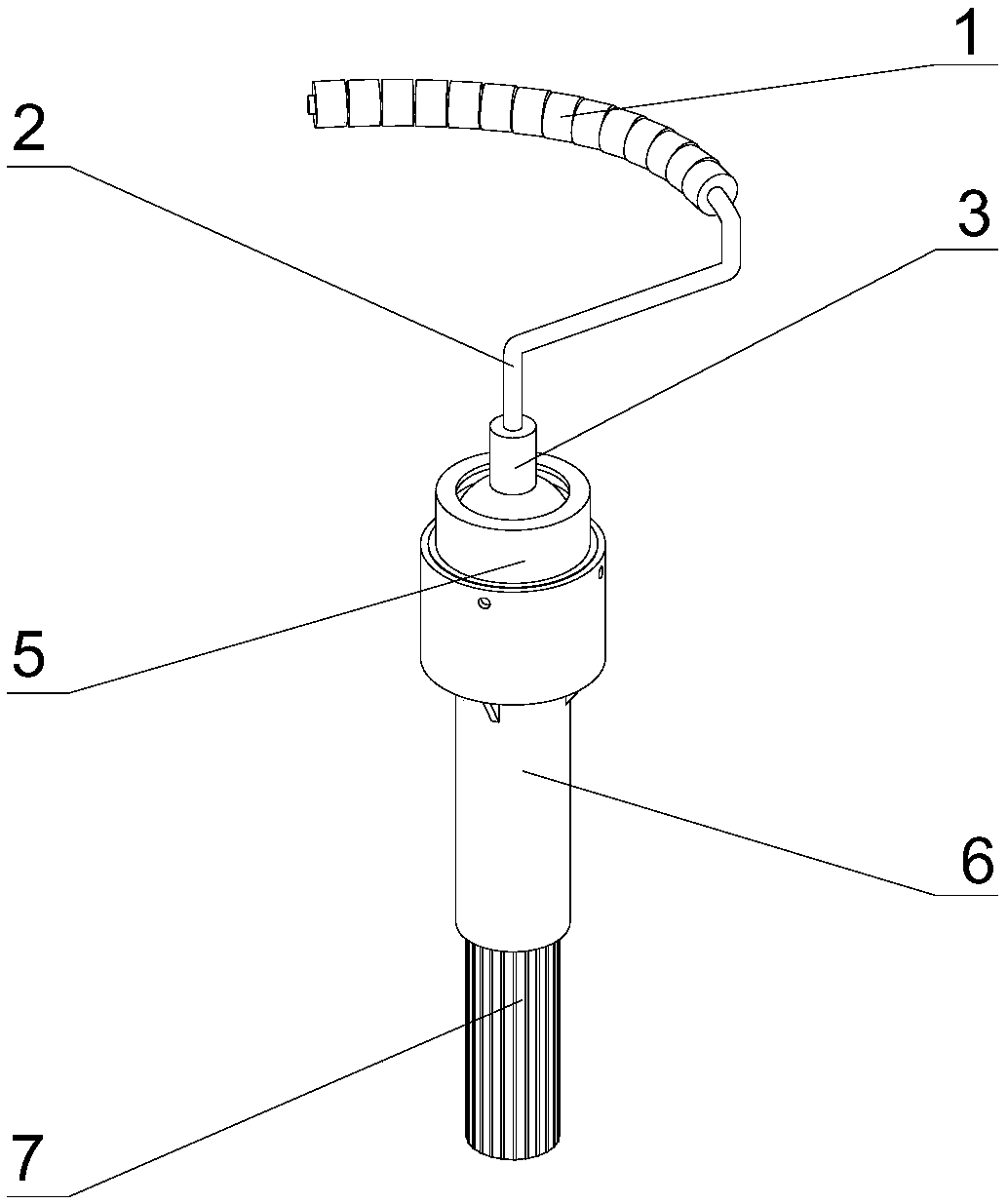

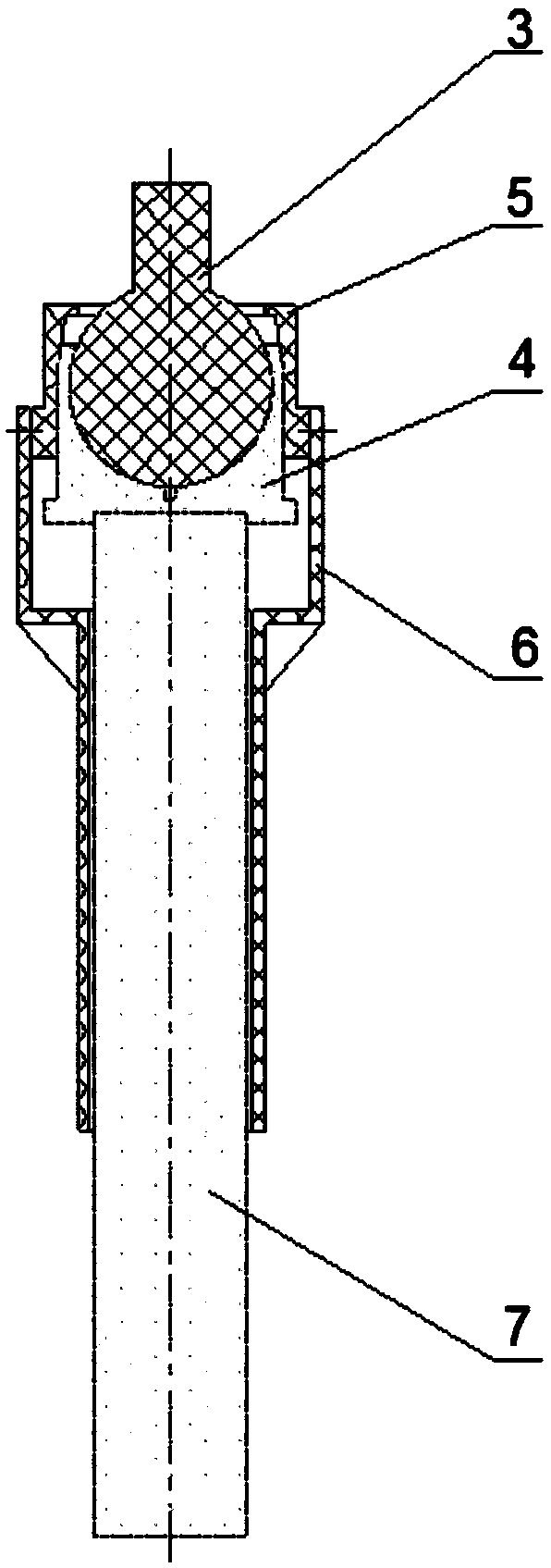

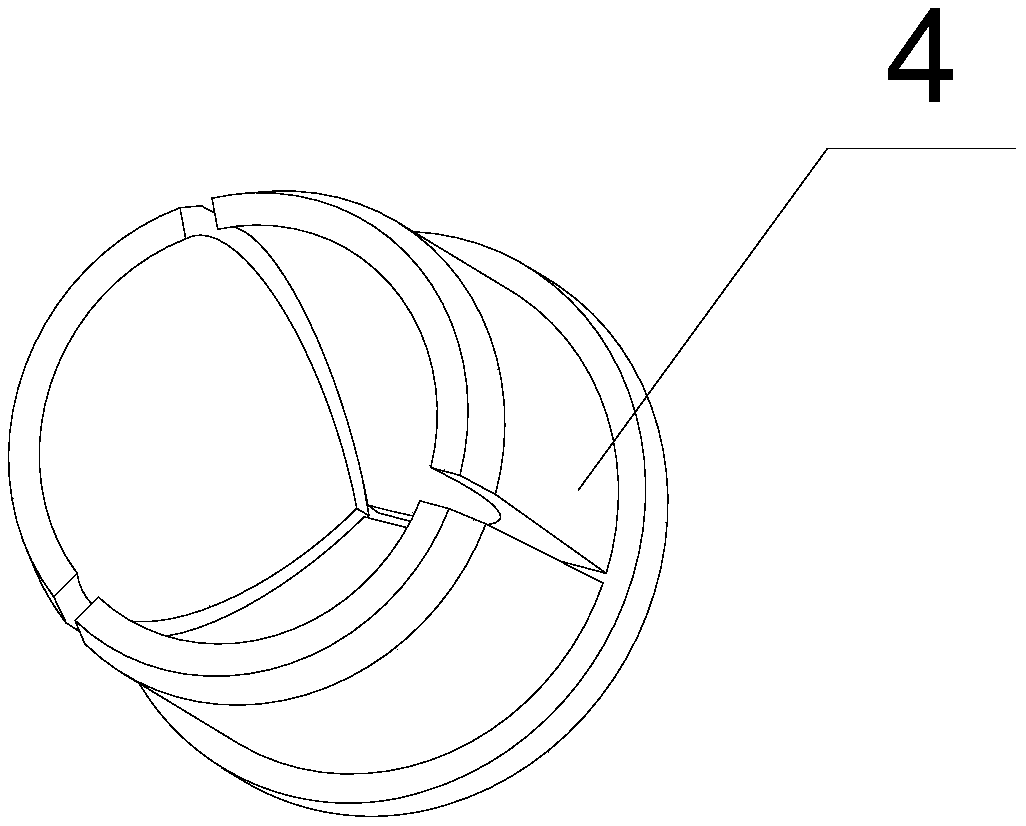

A simple multi-angle adjustable roller brush

ActiveCN109653474BSimple structureFew assembly partsBuilding constructionsClassical mechanicsEngineering

Owner:JIANGSU UNIV OF SCI & TECH

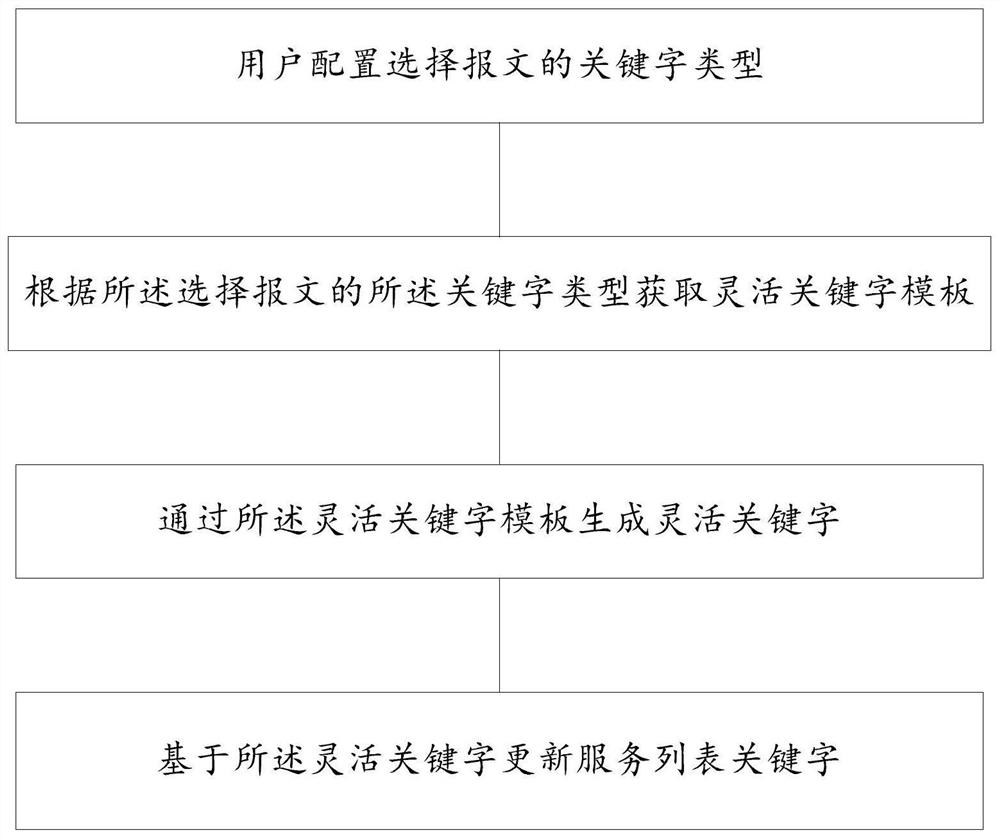

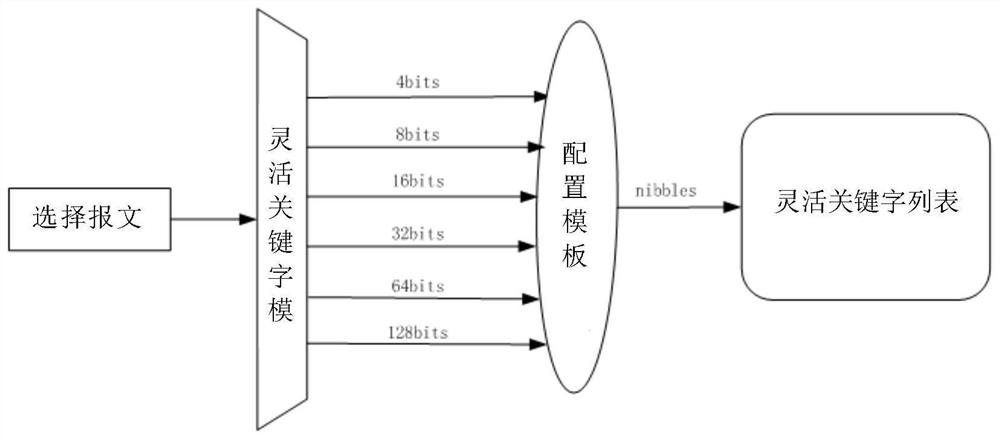

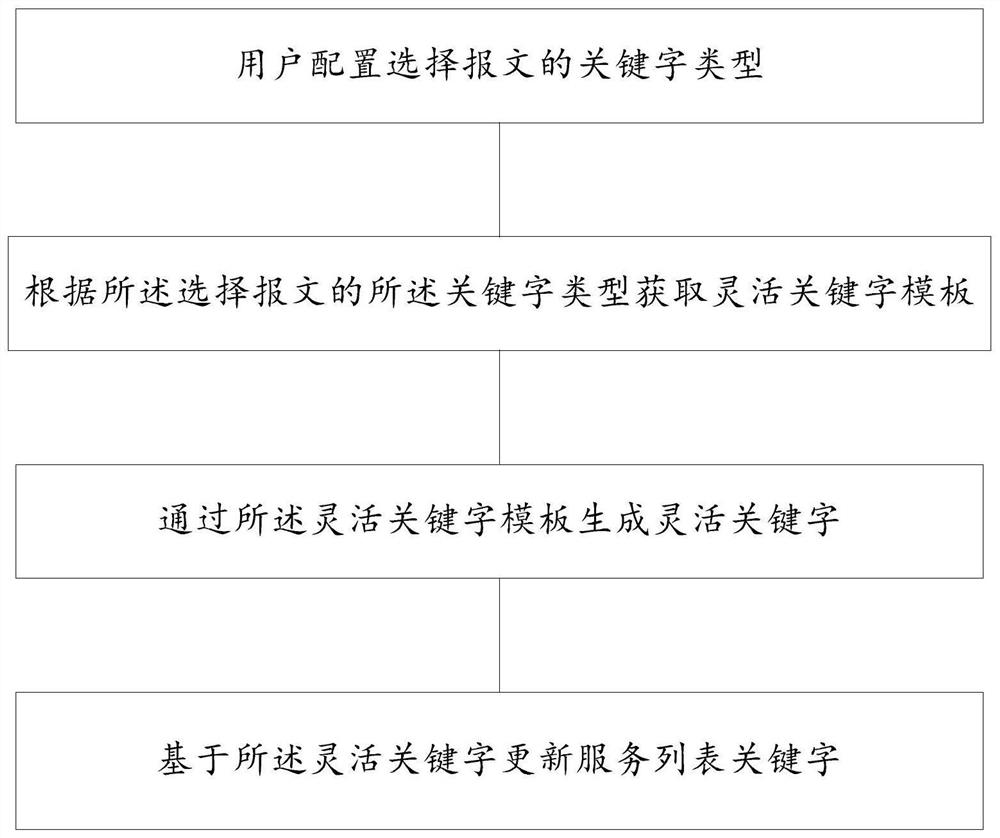

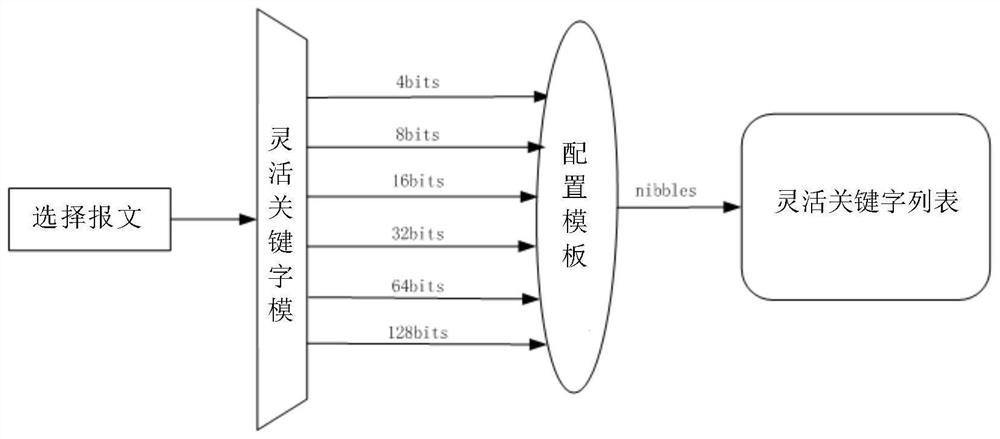

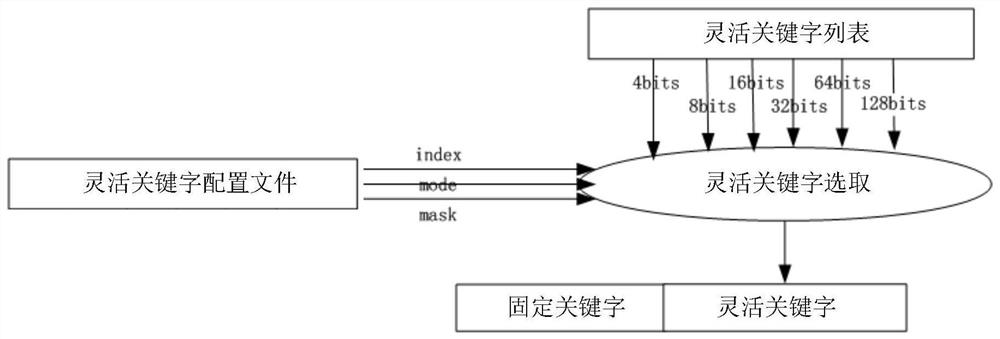

A Programmable Realization Method of Network Chip Scl KEY

ActiveCN112333032BExtended service lifeMeet custom needsTransmissionComputer hardwareSoftware engineering

The present invention relates to a programmable implementation method of SCL KEY. The method comprises the following steps: step 1, the user configures the keyword type of the selection message; step 2, obtains a flexible A keyword template; Step 3, generating a flexible keyword through the flexible keyword template; Step 4, updating the SCL KEY based on the flexible keyword. The present invention selects a field of any position and length in a message through a flexible keyword template to obtain a flexible keyword, and updates the SCL KEY to obtain the SCL KEY, which can realize the flexible programming of the SCL KEY without affecting the logic of the original chip SCL KEY.

Owner:SUZHOU CENTEC COMM CO LTD

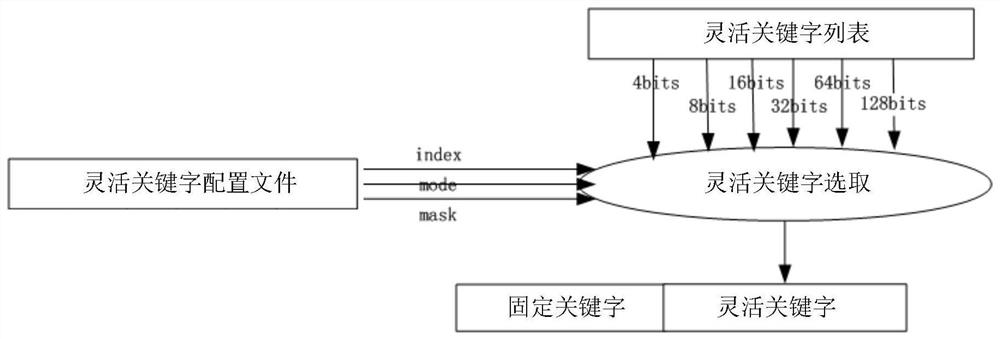

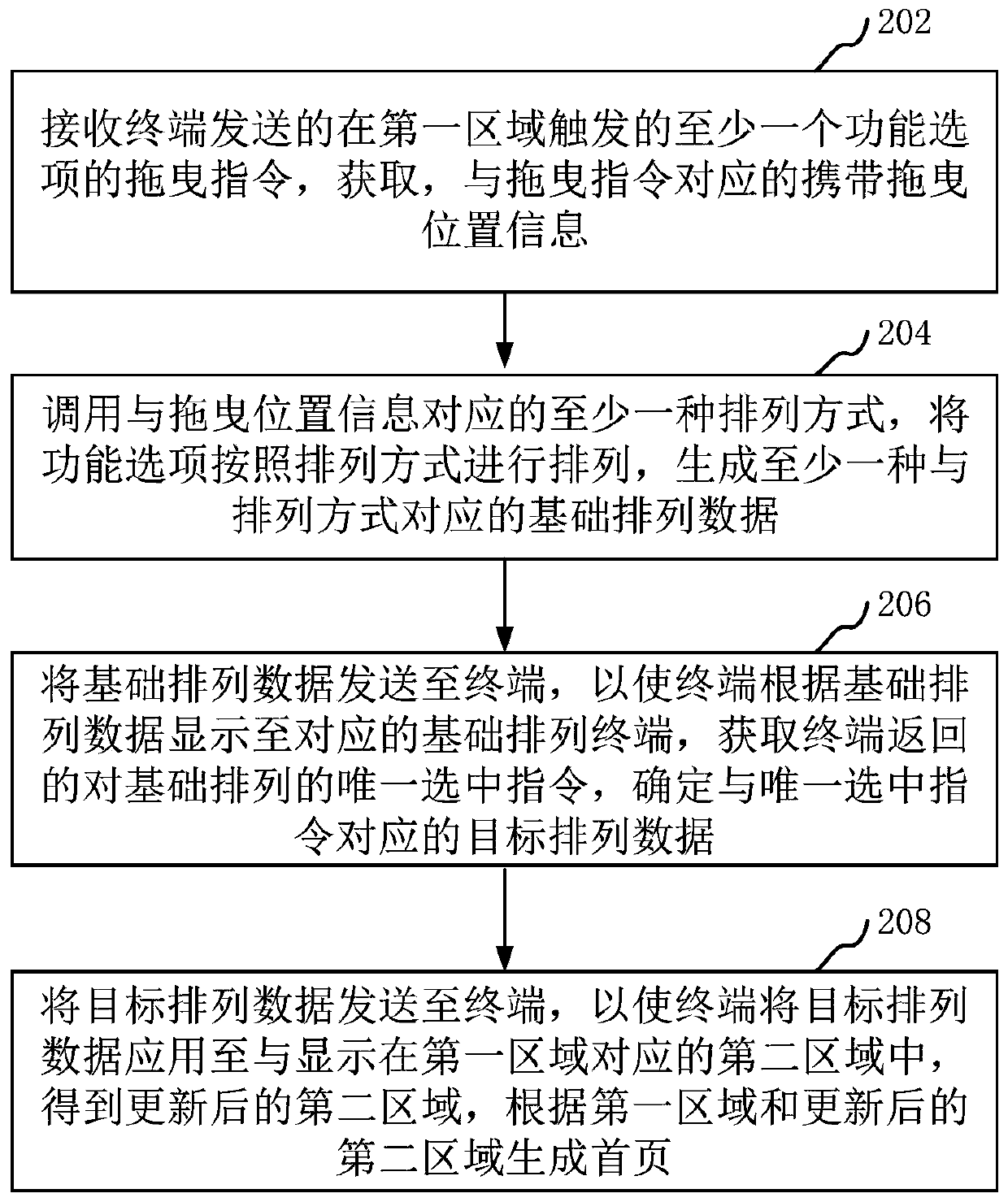

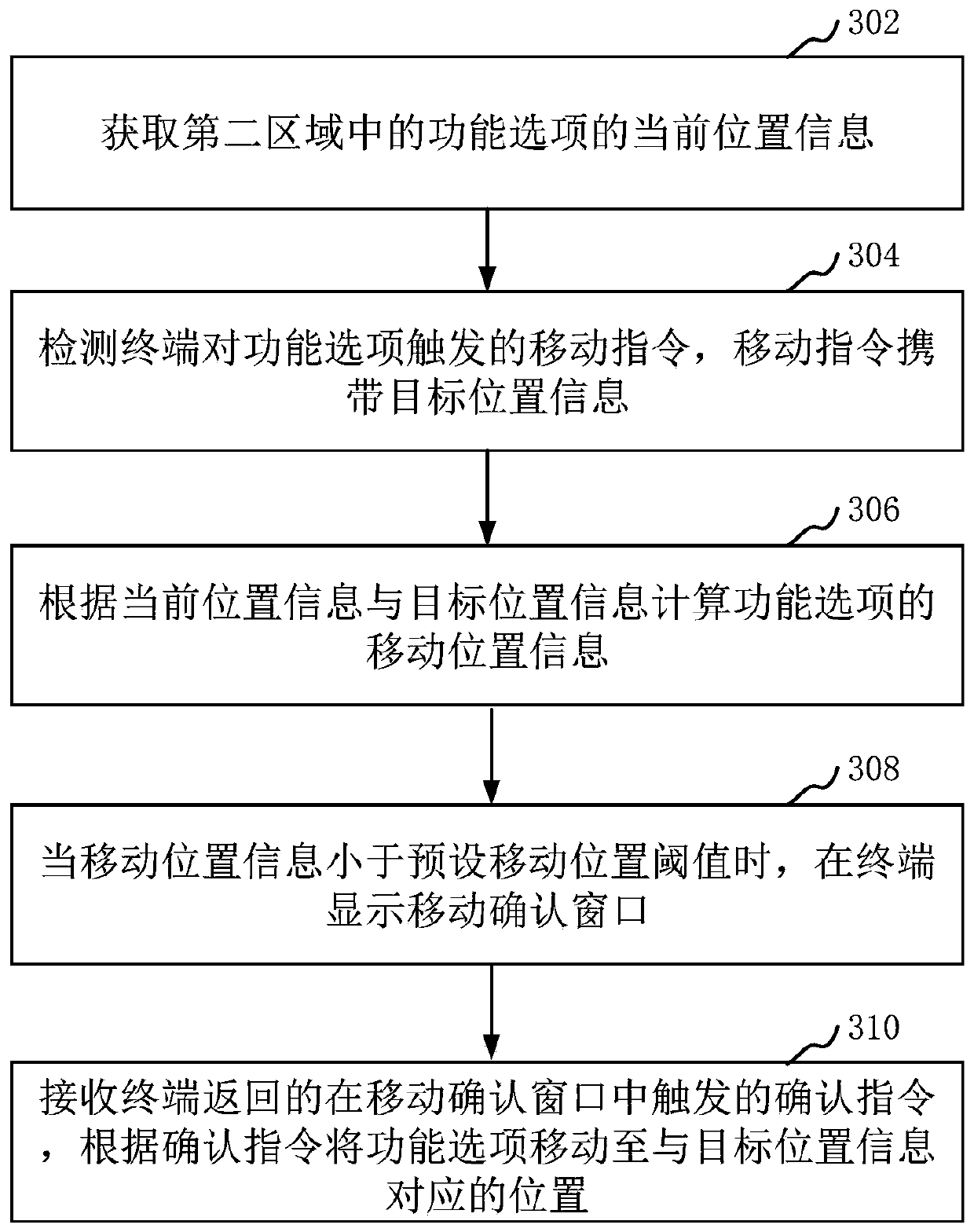

Home page generation method and device, computer equipment and storage medium

ActiveCN110377379AMeet custom needsImprove office response efficiencyExecution for user interfacesInput/output processes for data processingComputer equipmentHome page

The invention relates to research and development management, and provides a home page generation method and a device, computer equipment and a storage medium, and the method comprises the steps: calling at least one arrangement mode corresponding to dragging position information, arranging function options according to the arrangement mode, and generating at least one basic arrangement data corresponding to the arrangement mode; sending the basic arrangement data to the terminal to enable the terminal to display corresponding basic arrangement according to the basic arrangement data, obtaining a unique selection instruction for the basic arrangement returned by the terminal, and determining target arrangement data corresponding to the unique selection instruction; and sending the target arrangement data to the terminal, so that the terminal displays the target arrangement corresponding to the target arrangement data in the second area corresponding to the first area, and a home page meeting the user-defined demand of the user can be generated according to the first area and the second area, thereby improving the office response efficiency.

Owner:PING AN TECH (SHENZHEN) CO LTD

Method and device for frame extraction processing of video code stream

ActiveCN104639951BIncrease playback speedMeet custom needsSelective content distributionVideo bitstreamMultiple use

The present invention discloses a video bitstream frame extraction process and device. The aforementioned process comprises receiving and storing video bitstreams from an IPC; and during playing back the stored video bitstreams, conducting an SVC frame extraction process on the stored video bitstreams, wherein the frame extraction multiple used in the SVC extraction process is dynamically adjusted according to a playback rate selected by a user. According to the technical solution provided in the present invention, the process and device effectively improve the speed for playing video bitstreams during a quick playback process.

Owner:HANGZHOU HIKVISION DIGITAL TECH

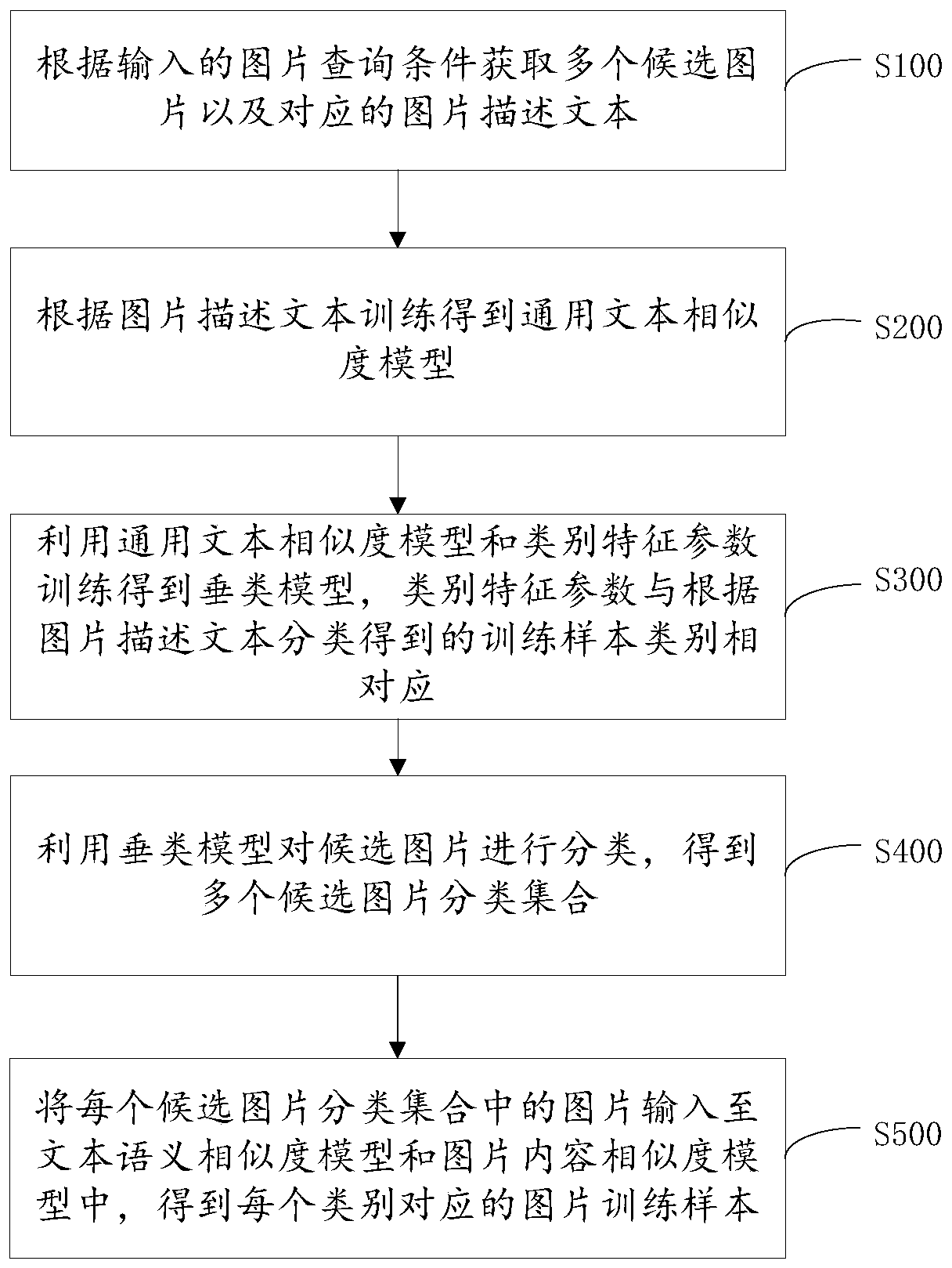

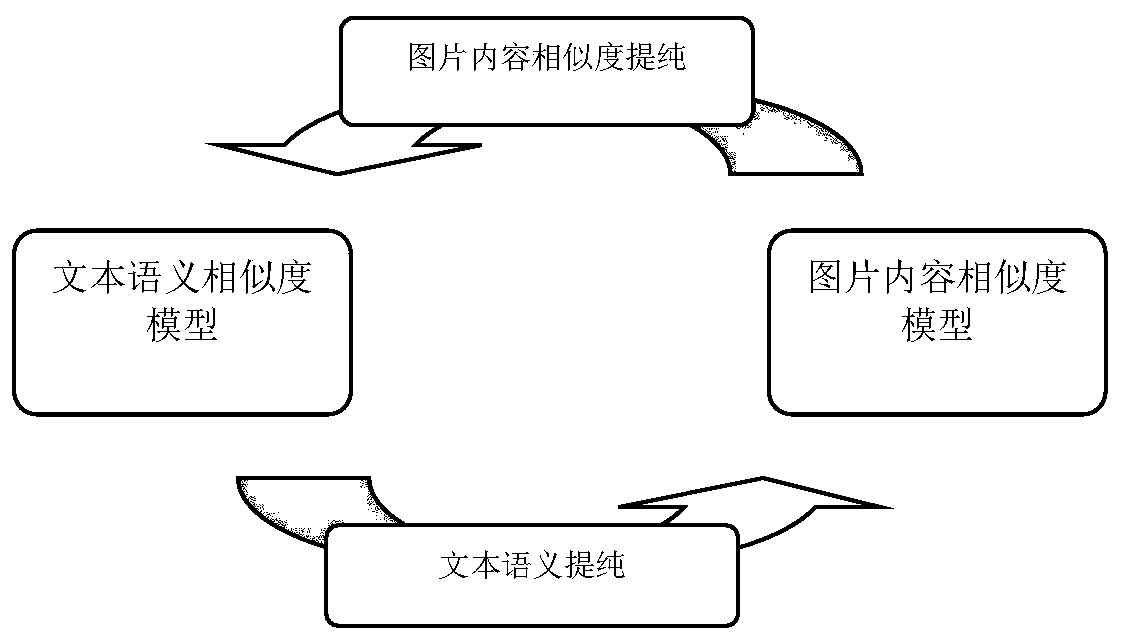

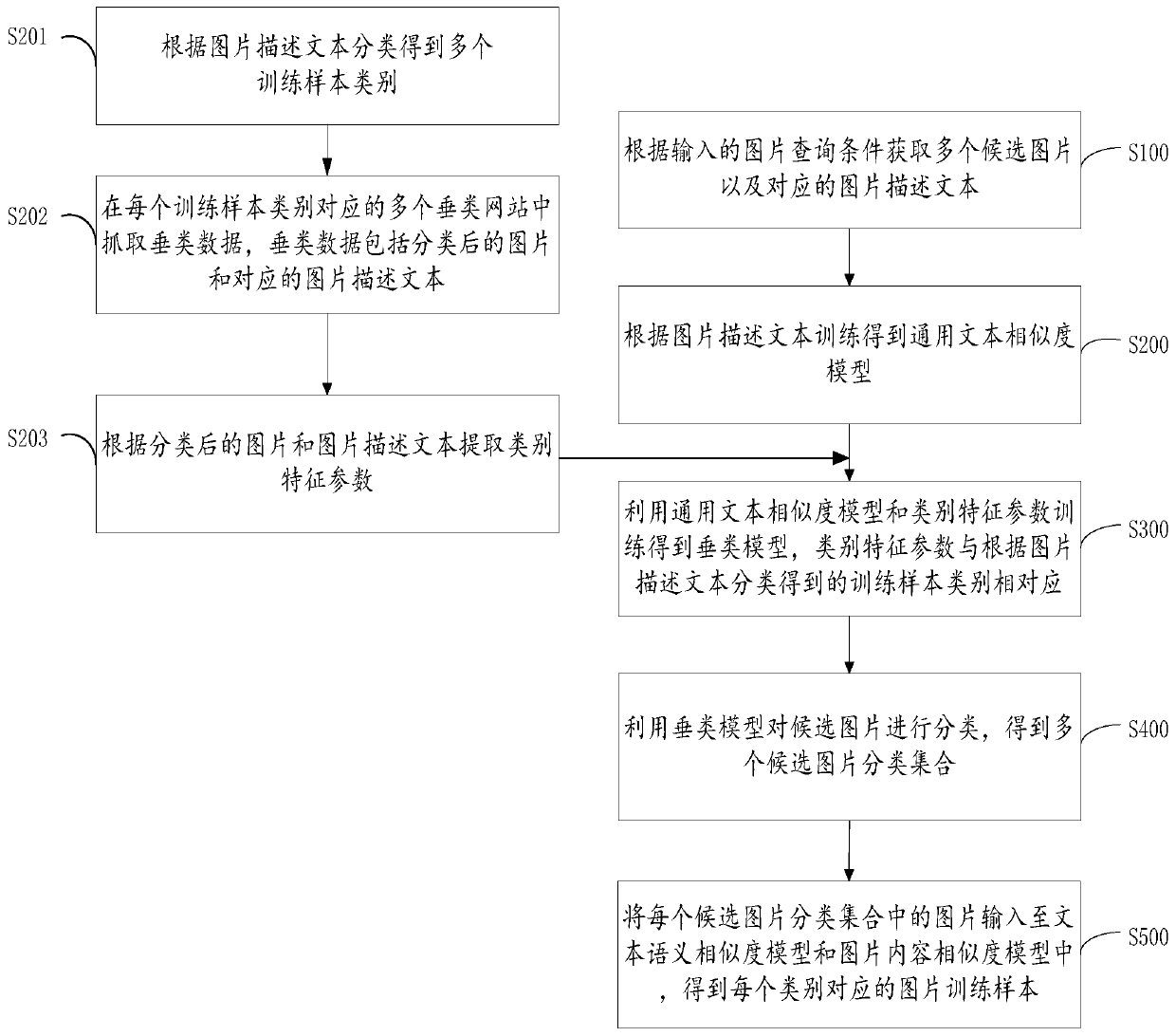

Image training sample mining method, device, terminal and computer-readable storage medium

ActiveCN109242042BEffective automatic miningIncrease productivityCharacter and pattern recognitionClass modelImage query

The present invention proposes a picture training sample mining method, device and terminal, the method comprising: obtaining a plurality of candidate pictures and corresponding picture description texts according to input picture query conditions; training a general text similarity model according to the picture description text; Utilize the general text similarity model and category characteristic parameter training to obtain the vertical class model, the category characteristic parameter corresponds to the training sample category obtained according to the picture description text classification; use the vertical class model to classify the candidate pictures, and obtain a plurality of candidate pictures Classification set: Input the pictures in each candidate picture classification set into the text semantic similarity model and the picture content similarity model to obtain the picture training samples corresponding to each category. When the image query conditions are given, it can effectively and automatically mine image training samples, reduce labor costs, meet the customization needs of different customers, and improve the production efficiency of training samples.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Screen recording method and device

ActiveCN109828715BImplement custom obfuscationFacilitates fuzzingInput/output processes for data processingComputer graphics (images)Human–computer interaction

The present invention provides a screen recording method and device, wherein the method includes: receiving a screen recording command for starting screen recording; detecting a touch fuzzy command executed by a user; identifying whether the interface area corresponding to the touch fuzzy command is A preset fuzzable area; if yes, perform blurring processing on the interface area corresponding to the touch blur instruction. The screen recording method of the present invention can realize custom blurring processing on the preset blurable area of the screen recording video through the touch operation performed by the user on the screen recording interface.

Owner:PING AN TECH (SHENZHEN) CO LTD

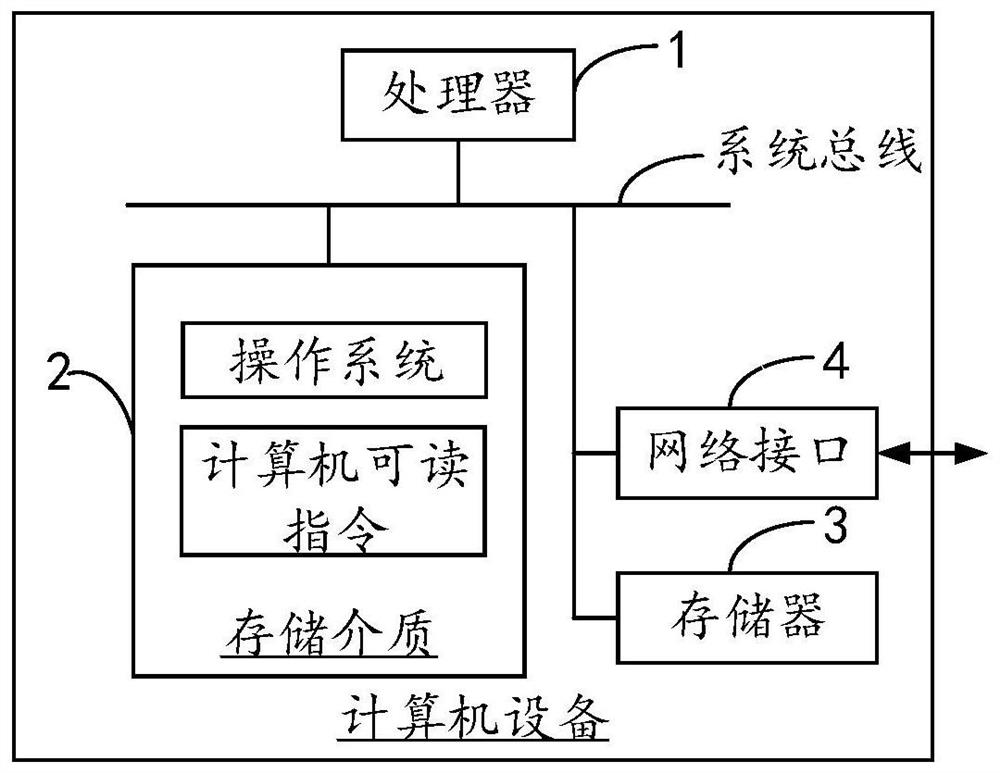

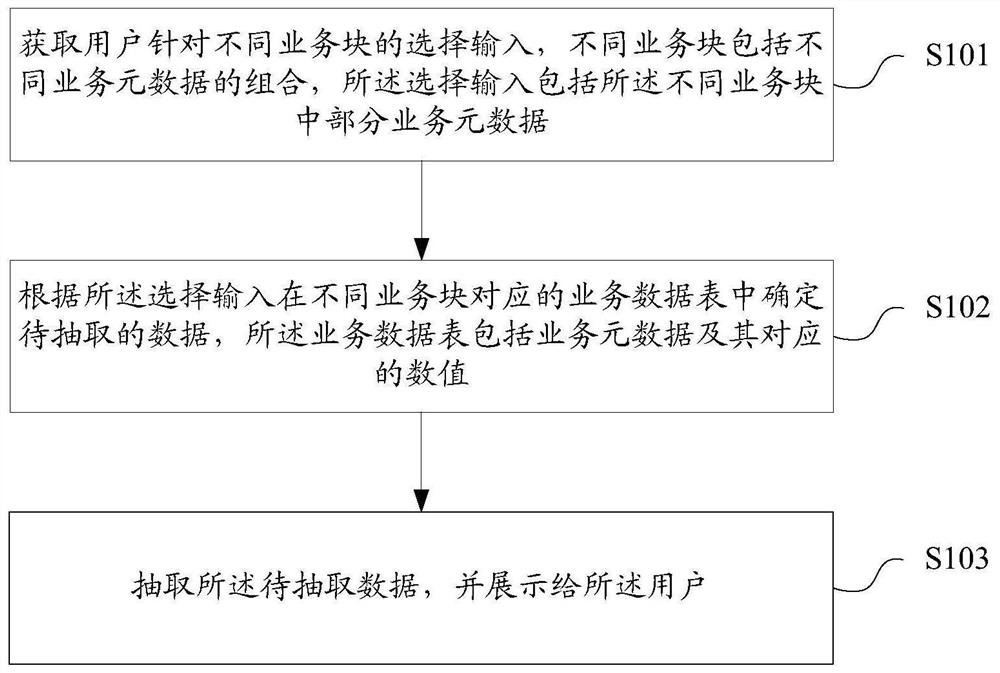

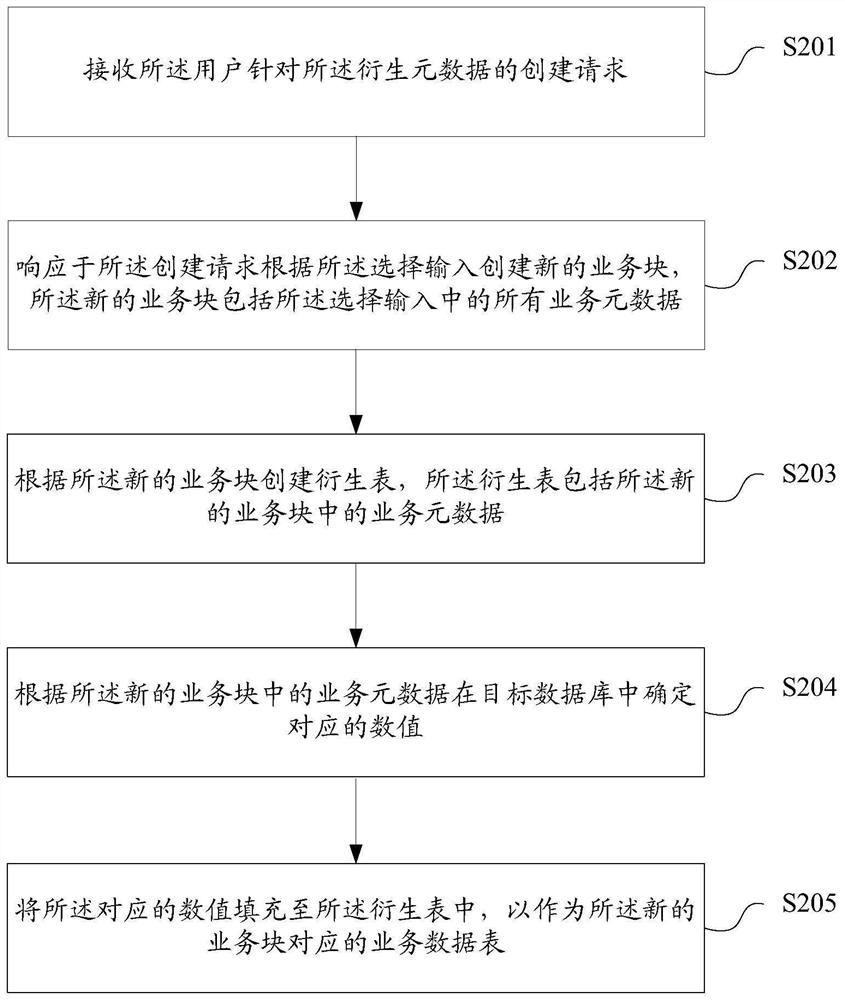

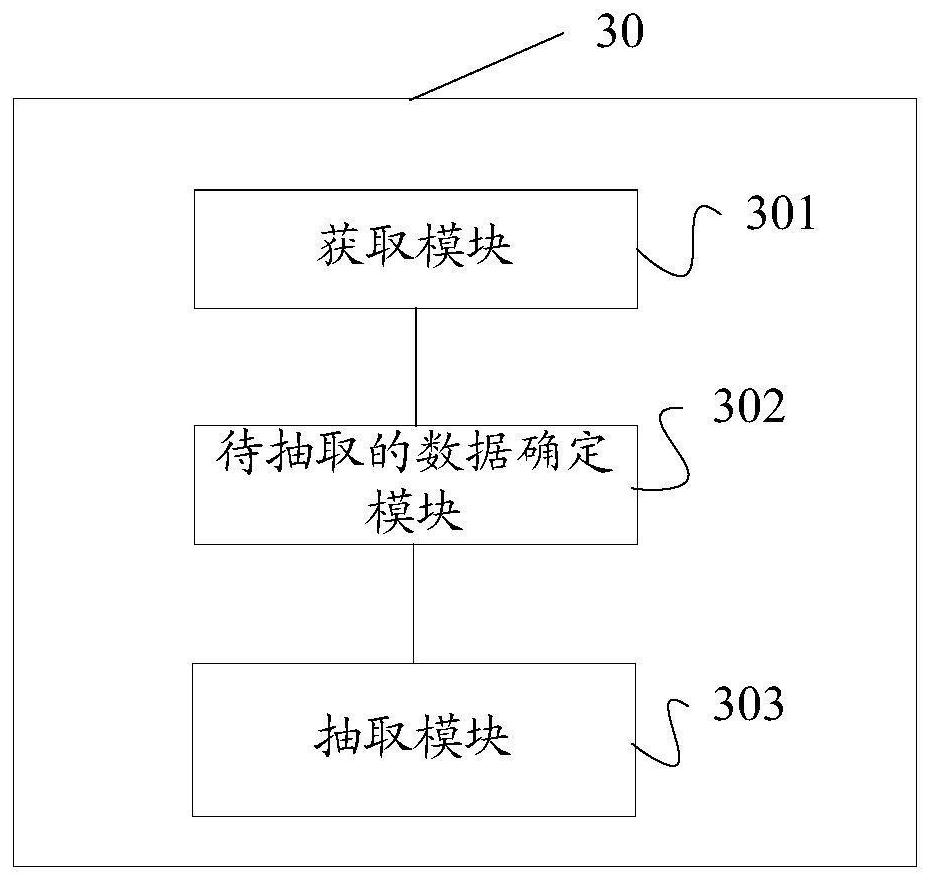

Data asset construction method and device based on metadata

ActiveCN112286879BImprove convenienceMeet custom needsOffice automationFile/folder operationsDatasheetEngineering

A metadata-based data asset construction method and device. The metadata-based data asset construction method includes: obtaining user selection input for different business blocks, where different business blocks include combinations of different business metadata, and the selection input includes all Part of the business metadata in the different business blocks; according to the selection input, determine the data to be extracted in the business data table corresponding to the different business blocks, the business data table includes business metadata and corresponding values; extract the data to be extracted Data is extracted and displayed to the user. The technical solution of the invention can improve the convenience of using metadata.

Owner:上海柯林布瑞信息技术有限公司

Game information display method and device

The invention provides a game information display method and device capable of displaying game information in message boxes. The game information display method comprises the steps that current positions of the message boxes displayed in an interface are acquired; display setting operations performed by users are responded to on the basis of the message boxes, and the message boxes are correspondingly displayed; game information is received, and a channel identifier of the game information is obtained; according to the channel identifier, the game information is displayed in the message boxescorresponding to the channel identifier. By means of the game information display method, the game information viewing efficiency of the users can be improved, and the better game experience is provided for the users.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Simple multi-angle adjustable roller brush

ActiveCN109653474ASimple device structureFew assembly partsBuilding constructionsHinge angleEngineering

The invention discloses a simple multi-angle adjustable roller brush. The simple multi-angle adjustable roller brush comprises a plurality of felt rolling balls, a roller brush foldable handle, a ballhinge, a ball hinge claw seat, a ball hinge seat gland, a roller brush handle sliding sleeve and a roller brush handle, wherein the ball hinge is limited between the ball hinge claw seat and the ballhinge seat gland; the ball hinge claw seat is an elastic plastic part, the front end of the ball hinge claw seat is provided with petal-like patches covering the outer side of the ball hinge, and a gap is reserved between every two patches; by rotating the roller brush handle, the roller brush handle extends forwards to exert an axial force on the ball hinge claw seat, so that the ball hinge seatgland is tightly attached to the ball hinge claw seat, and each patch on the ball hinge claw seat approaches a radial inner side, thereby implementing the seizing and locking for the ball hinge. Thesimple multi-angle adjustable roller brush provided by the invention is simple in structure, fewer in assembly parts, low in development cost and suitable for small and medium-sized roller brushes with low requirements for the operation strength; the customization requirement of a user can be satisfied, and the efficiency of an operator can be increased by virtue of an adjusting brush head; and the roller brush can be fit to a cylindrical surface or a curved surface with a given radian, and has good operation effect.

Owner:JIANGSU UNIV OF SCI & TECH

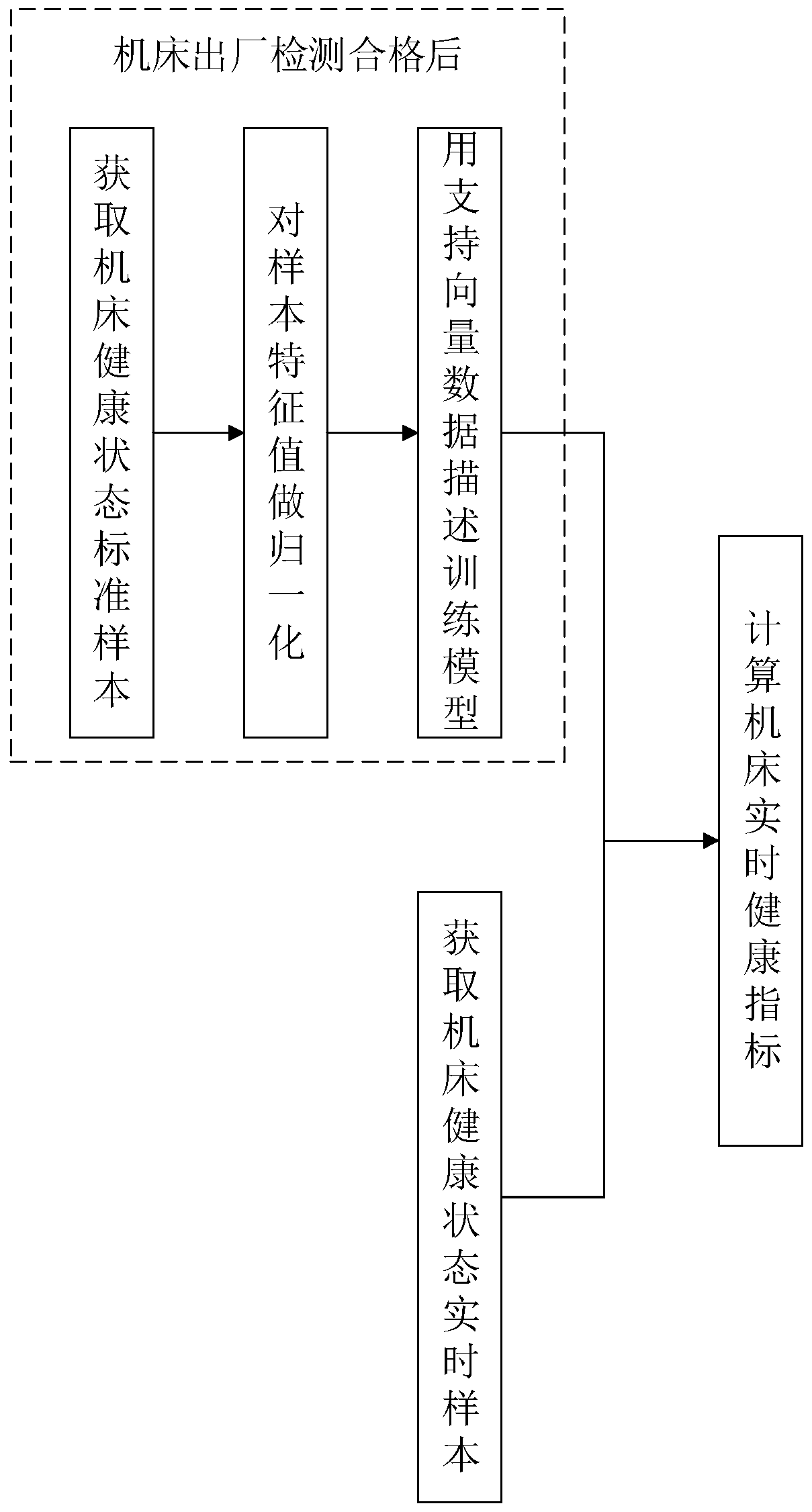

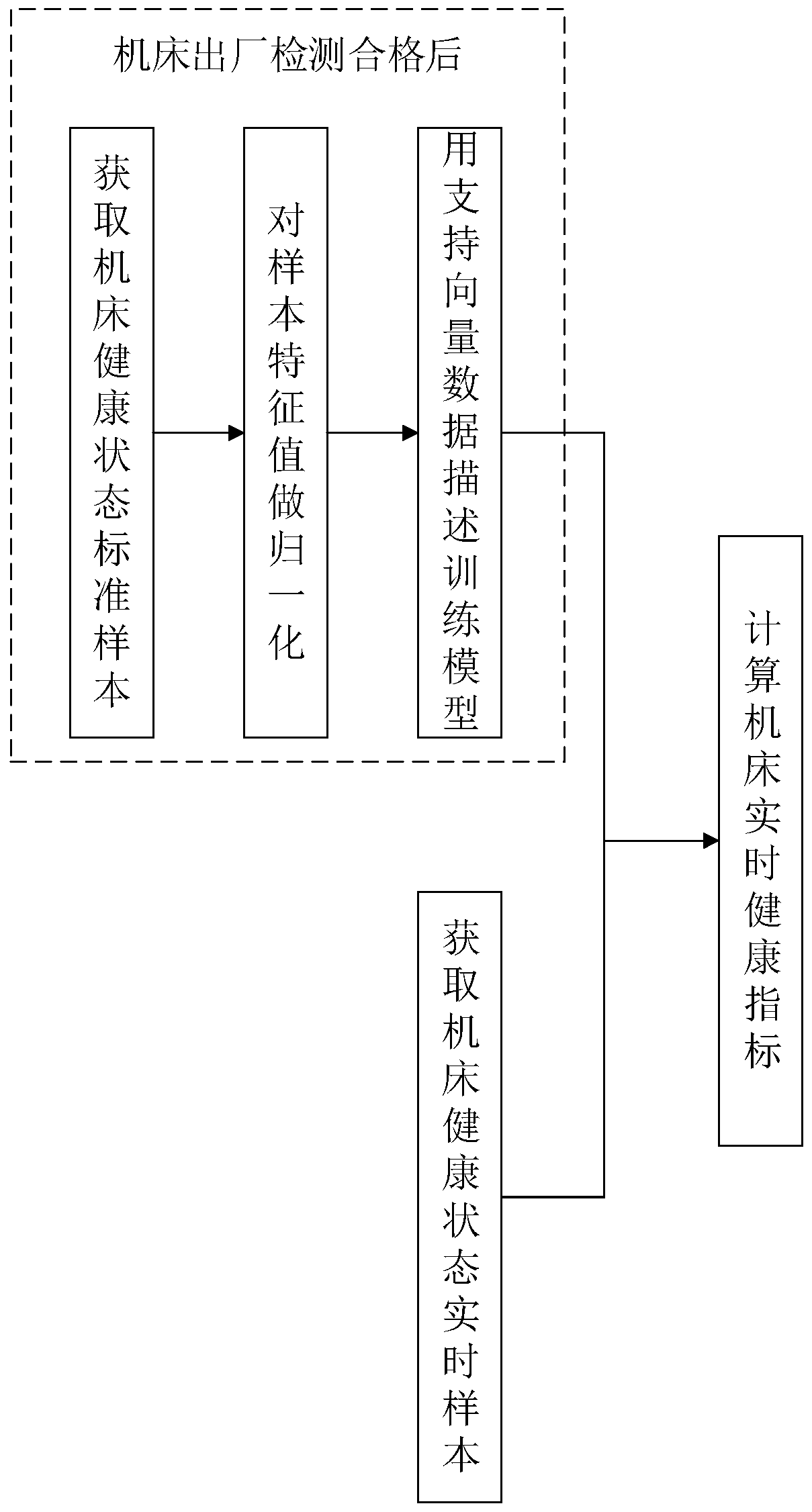

An improved machine tool health status assessment method and CNC machine tool

ActiveCN109623489BThe effect of random fluctuations is smallImprove reliabilityMeasurement/indication equipmentsNumerical controlData description

The invention discloses an improved machine tool health state evaluation method and a numerical control machine tool, and belongs to the field of numerical control machining diagnosis. The improved machine tool health state evaluation method comprises the following steps that (1) operation state information detecting of a target part is conducted on a machine tool which is qualified after being subjected to delivery inspection, and a machine tool health state standard data sample is obtained; (2) a characteristic value of the standard data sample obtained in the step (1) is subjected to normalization processing; (3) normalized data obtained in the step (2) are trained through a support vector data description method, and thus a contrast sample model is obtained; and (4) a machine tool health state data sample is obtained in real time in the machine tool operation process and compared with the contrast sample model obtained in the step (3), and the machine tool real-time health state isobtained. According to the improved machine tool health state evaluation method, the influence of sample random fluctuation during experiment sampling is small, the requirement for the number of experiment times is also greatly reduced, and finally, the obtained contrast sample model has higher reliability and robustness.

Owner:HUAZHONG UNIV OF SCI & TECH

Shooting method and mobile terminal of object motion track

ActiveCN104125407BMeet custom needsTelevision system detailsColor television detailsPattern recognitionObject motion

Owner:NUBIA TECHNOLOGY CO LTD

Programmable implementation method of network chip SCL KEY

ActiveCN112333032AExtended service lifeMeet custom needsData switching networksAlgorithmTheoretical computer science

The invention relates to a programmable implementation method of an SCL KEY. The method comprises the following steps: 1, a user configuring and selecting a keyword type of a message; 2, obtaining a flexible keyword template according to the keyword type of the selection message; 3, generating a flexible keyword through the flexible keyword template; and 4, updating the SCL KEY based on the flexible keyword. According to the invention, the flexible keyword template is used for selecting the field with any length at any position of the message to obtain the flexible keyword, and the SCL KEY isobtained by updating, so that the flexible programming of the SCL KEY can be realized on the basis of not influencing the logic of the original chip SCL KEY.

Owner:SUZHOU CENTEC COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com