Circuit compensation network of non-contact power supply ultrasonic vibration system based on efficiency

A technology of non-contact power supply and ultrasonic vibration, applied in the direction of electromagnetic wave system, etc., can solve the problems of consuming large reactive power, reducing system power factor and transmission efficiency, limiting power transmission capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

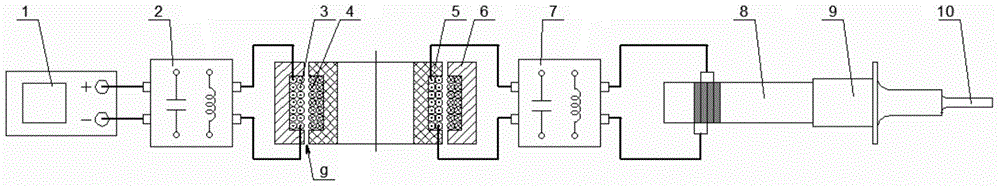

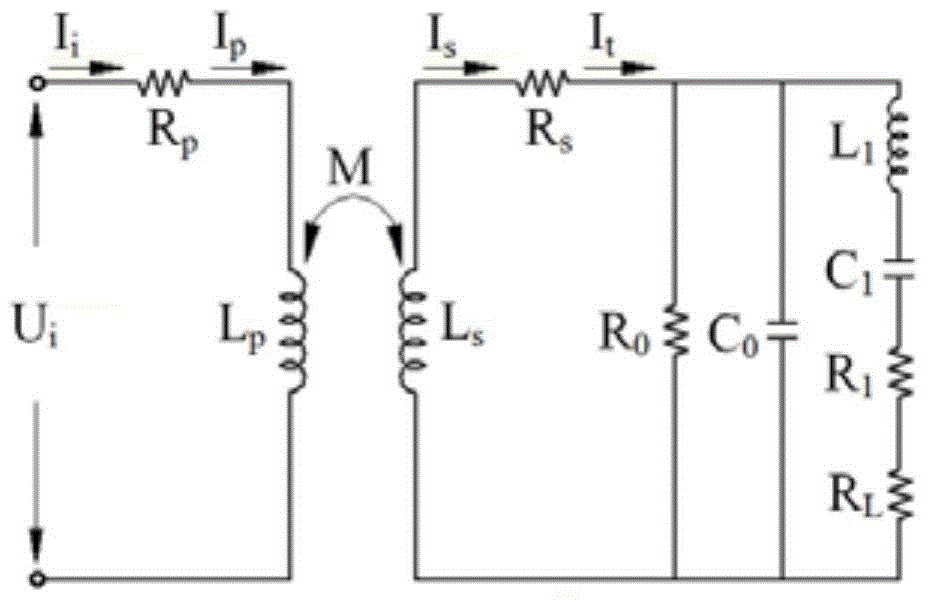

Method used

Image

Examples

Embodiment

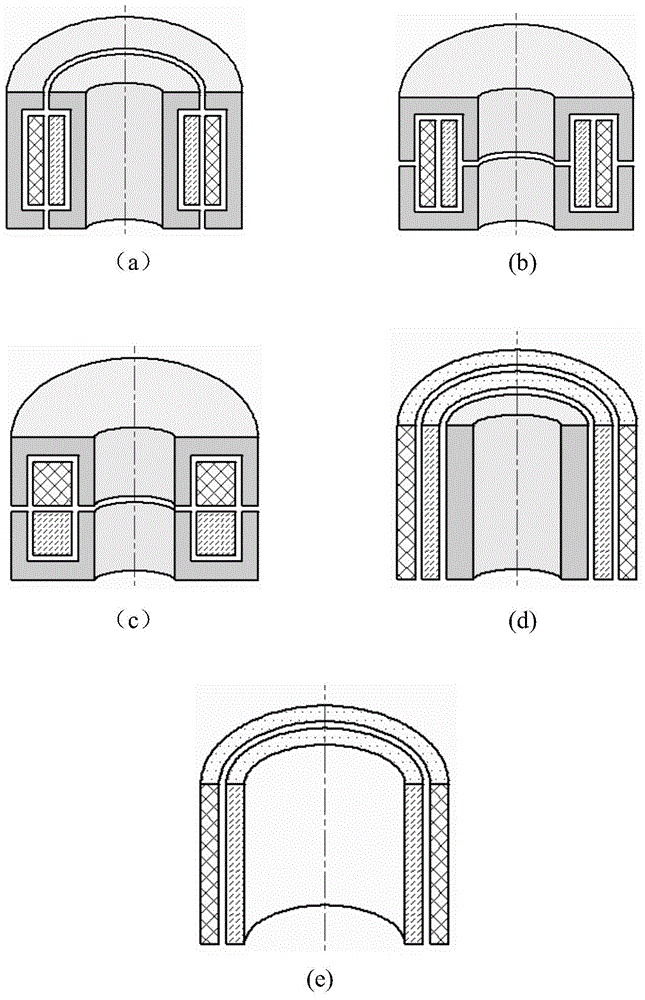

[0097] Below to Figure 7 The U-shaped concentric magnetic core cylindrical induction electromagnetic coupler shown is taken as an example to illustrate the specific method of compensation components and coil optimization. The non-contact electromagnetic coupler is made of manganese-zinc ferrite PC40 material. The size parameters are shown in Table 1. The transducer used The electrical parameters of the device are listed in Table 2. The relationship between the self-inductance of the coupler coil and the AC resistance and the number of turns of the coil measured in the experiment is shown in Figure 8-10 , the coupling coefficient k between the coils is shown in Table 3.

[0098] Table 1 Dimensional parameters of U-type concentric magnetic core cylindrical induction electromagnetic coupler (mm)

[0099] d1

d2

d3

d4

H

a

b

g

65

82

84

101

25

18

4

1

[0100] Table 2 Electrical parameters of ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com