Dish washer with pivot device

A technology of a rotating device and a dishwasher, which is applied to the washing machine/washing machine for tableware, parts of the washing machine/rinsing machine for tableware, cleaning device, etc., can solve problems such as damage to the tableware, and achieve the effect of preventing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

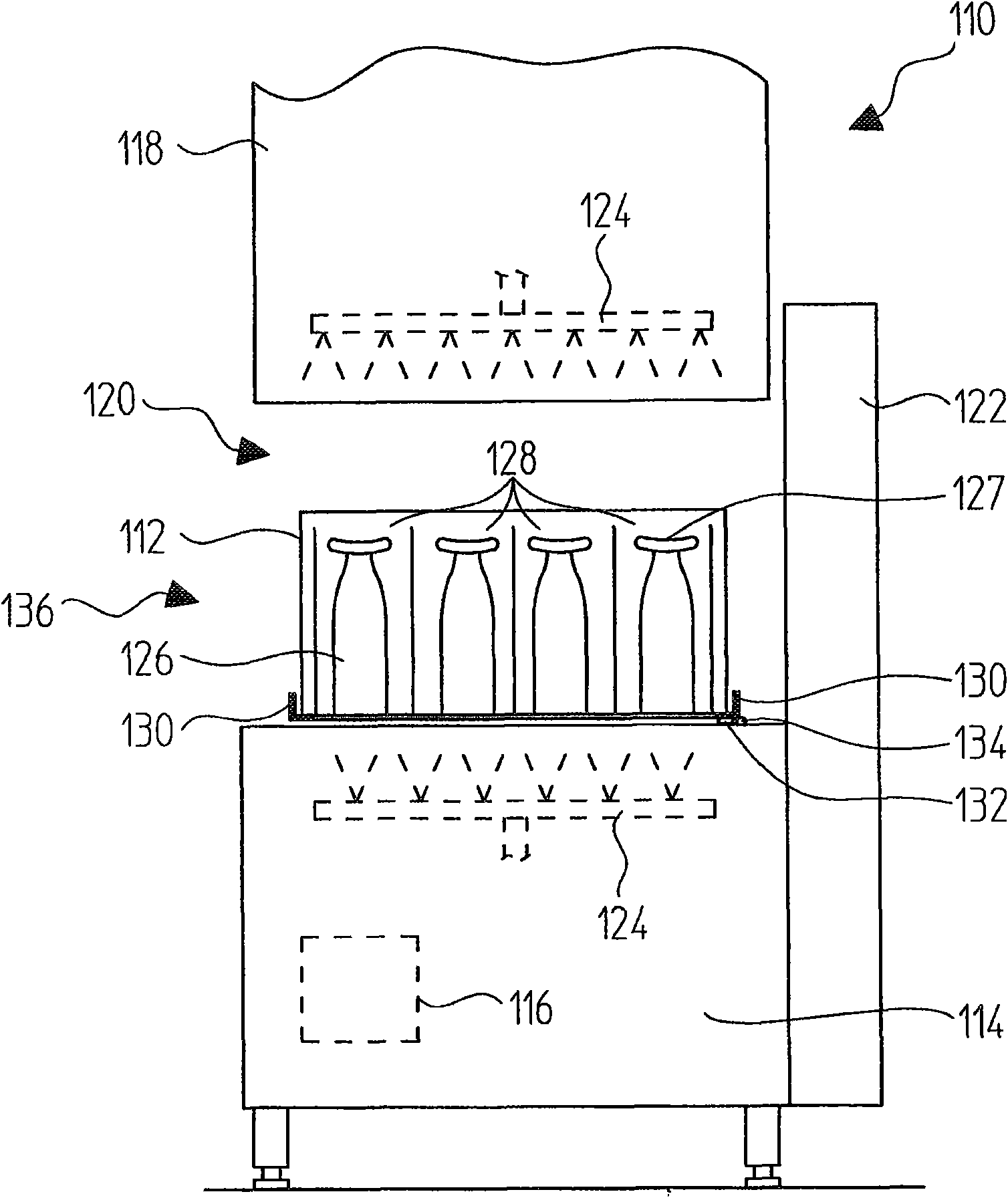

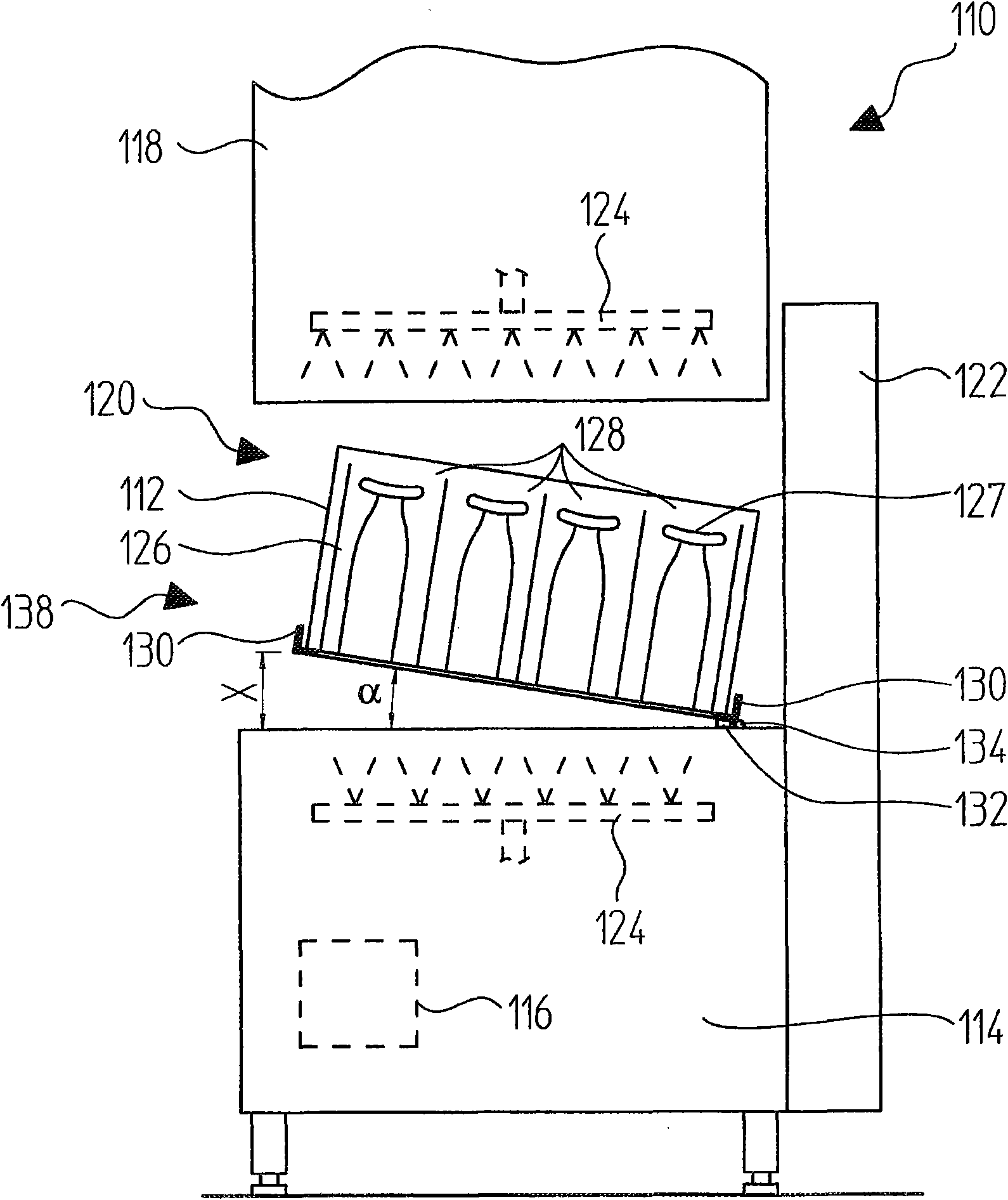

[0048] attached Figure 1A and 1B A possible preferred embodiment of a dishwasher 110 according to the invention is shown in a highly schematic manner. In this case, attach Figure 1A and 1B The difference is that the position of the dish rack 112 is different, which will be described in detail below.

[0049] The dishwasher includes a housing 114 in which a control unit 116 is accommodated (only Figure 1A and 1B shown in ). The dishwasher 110 also includes a cover 118, which is attached Figure 1A and 1B is open, thus allowing access to the cleaning chamber 120. The cover 118 may be disposed along the rear wall 122 in a vertical direction, the cover may be swung or moved upward, and the cover 118 is seated on the housing 114 when the washing chamber 120 is in a closed state. A nozzle system 124 (which is only schematically shown in the drawing) is arranged in the cleaning chamber 120 . The nozzle system 124 includes, for example, nozzles for pre-wash and wash programs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com