Sealing device suitable for object pressed under ultrahigh pressure and method

A sealing device and ultra-high pressure technology, applied in the direction of packaging and packaging through pressurization/gasification, can solve the problems of non-reusability, compression and strengthening failure, material damage, etc., to achieve fast filling products, simple structure, and realization of The effect of mechanized automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

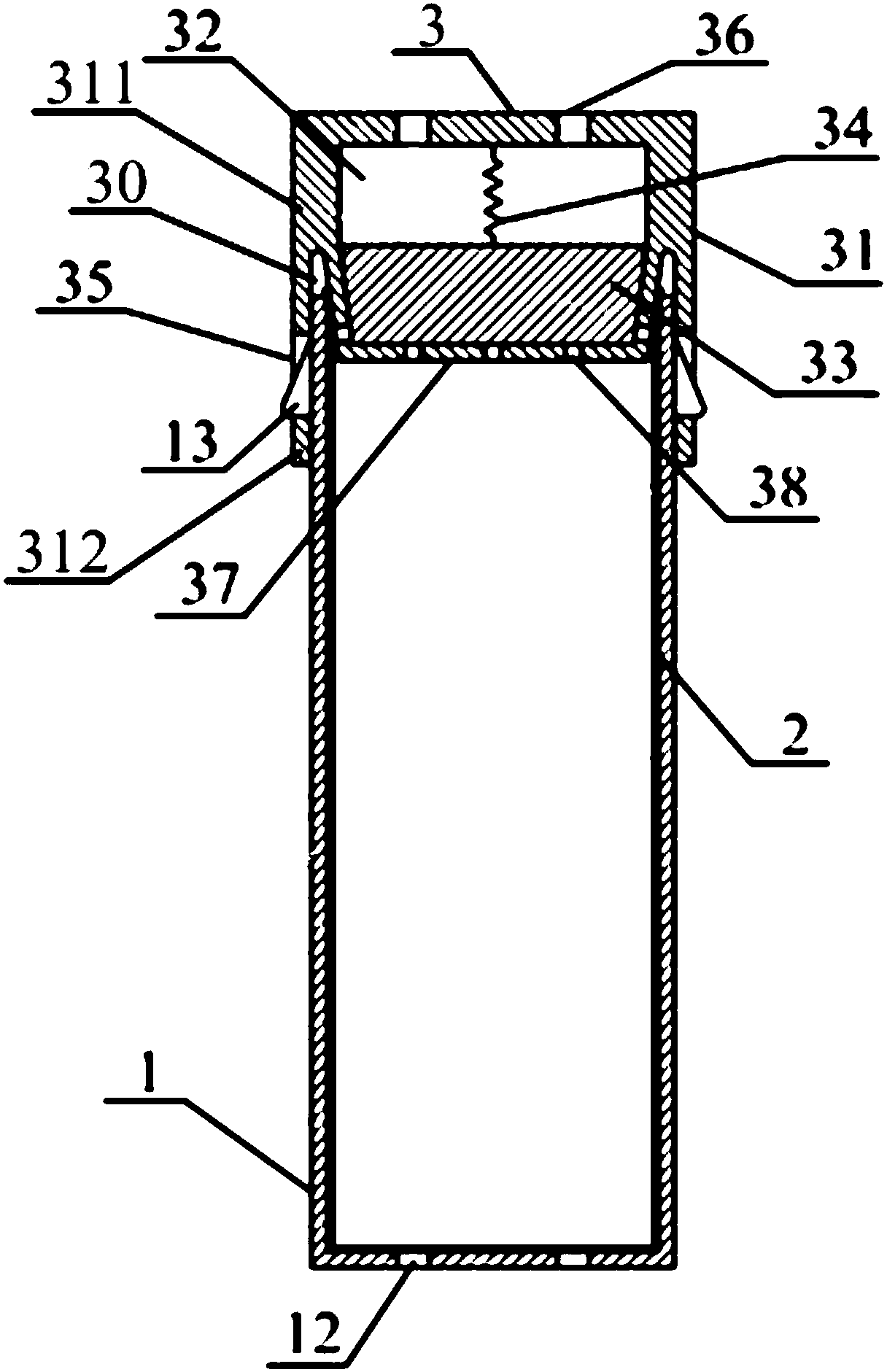

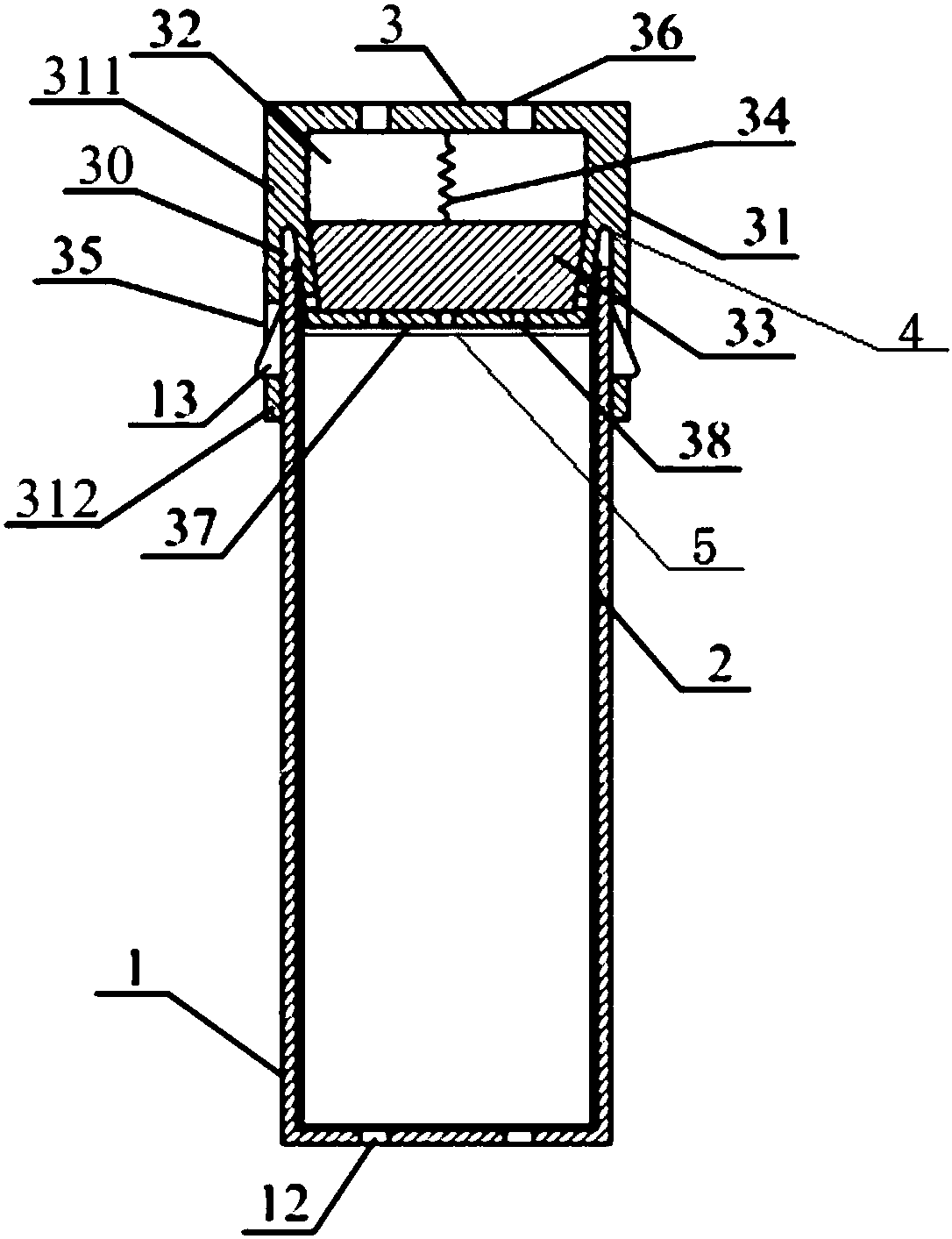

[0051] Such as figure 2 As shown, this embodiment is applicable to the case where the material is in powder form such as ceramic powder.

[0052] In this embodiment, on the basis of the first embodiment, a layer of wire mesh 5 is added under the bottom surface of the end cap protrusion 37, and other structures are not different.

[0053] The method of use of this embodiment is the same except that step 1) is different from step 1) of Embodiment 1. The use step 1) of this embodiment is: withdraw the retaining spring 13 from the retaining spring hole 35, so that the end cover 3 is separated from the outer cylinder 1;

[0054] Load the material into the inner cylinder 2, and tamp the material evenly, and cover the wire mesh 5 at the hole 38 of the end cover

[0055] Cover the end cap 3, and the snap ring 13 is engaged with the snap ring hole 35. At this time, the side wall of the end cap protrusion 37 squeezes the side wall of the inner tube 2, thereby realizing sealing the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com