Multi-layer paper sheet gap former and method

A sandwich forming and paper sheet technology, applied in papermaking, paper machines, textiles and papermaking, etc., can solve the problems of large floor area, poor product quality, high energy consumption, etc., achieve small floor space, low manufacturing cost, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below with reference to the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto.

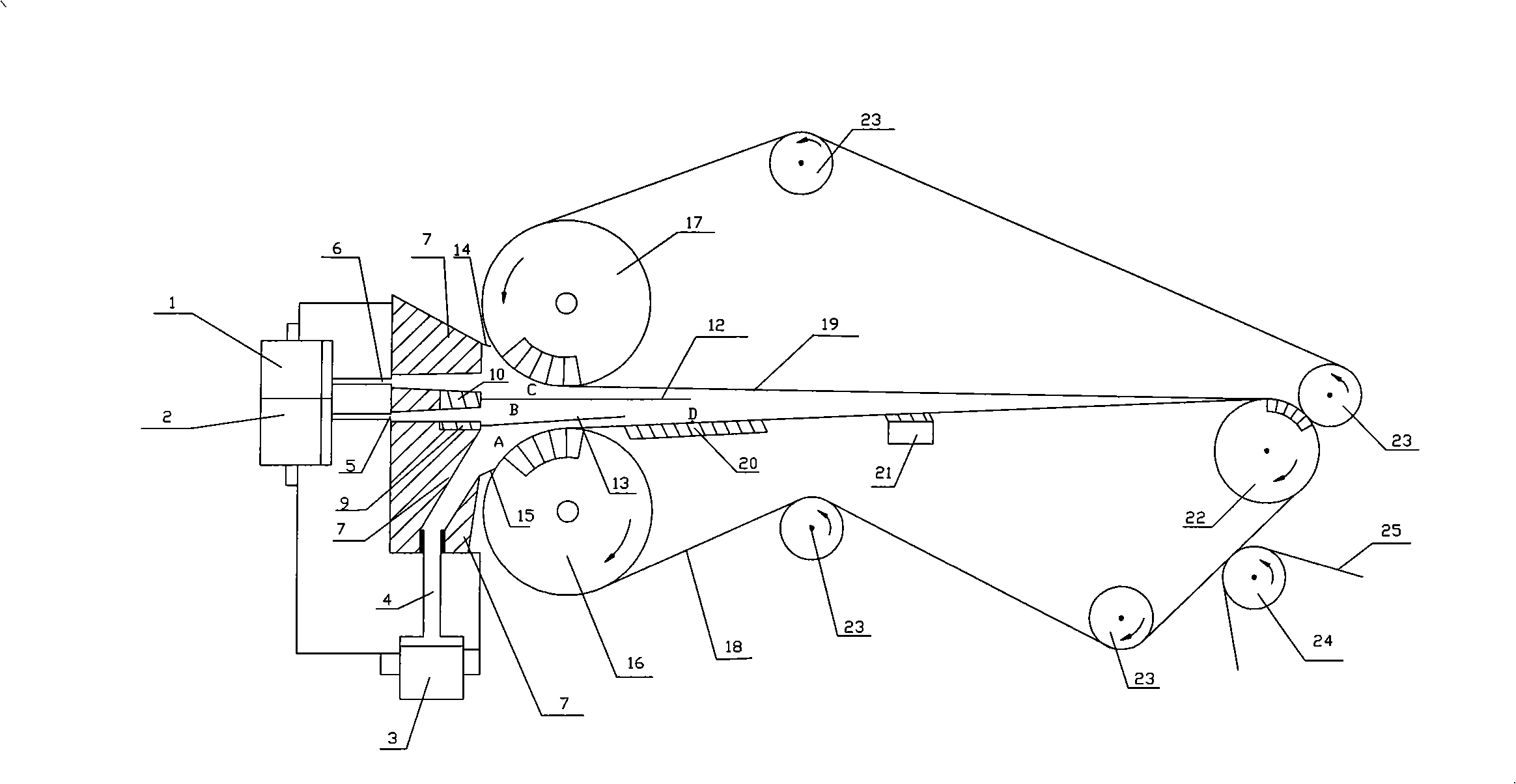

[0025] Such as figure 1 As shown, the multi-layer paper sandwich forming device includes: the upper pulp distribution main pipe 1, the middle pulp distribution main pipe 2, the bottom pulp distribution main pipe 3, the upper pulp distribution branch pipe and the stepped diffusion pipe 6, the lower pulp distribution branch pipe and the stepped diffusion pipe 4 , Medium distribution slurry branch pipe and stepped diffuser pipe 5, multi-layer headbox main body 7, long drifter fixed support 10, short drifter fixed support 9, long drifter 12, short drifter 13, one of the blocking seals 14. The second cover sheet 15, vacuum breast roller 16, vacuum forming roller 17, lower dehydration net 18, upper dehydration net 19, dehydration plate group 20, vacuum dehydration box group 21, vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com