Fourdrinier equipped with top former

A technology for a Fourdrinier paper machine and a former, which is applied in the field of papermaking, can solve problems such as poor paper quality, and achieve the effects of improving paper evenness, reducing fiber flocs, and improving paper quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

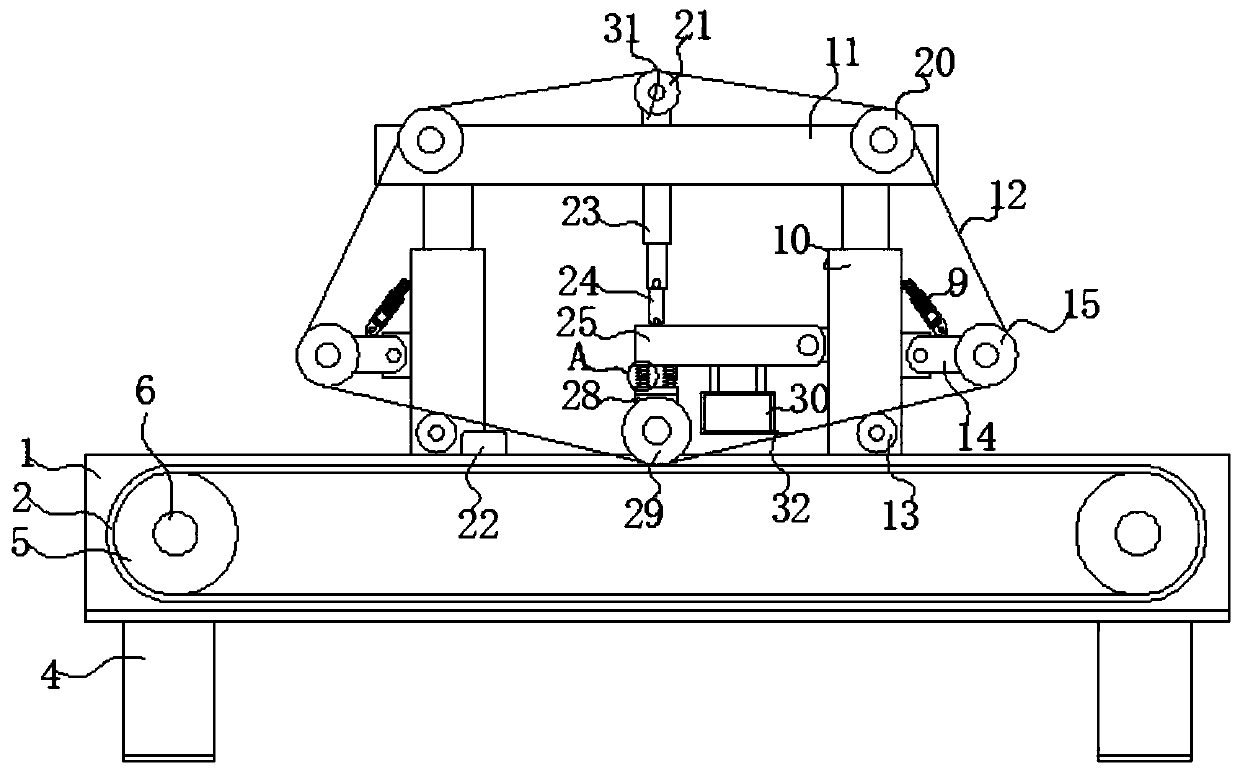

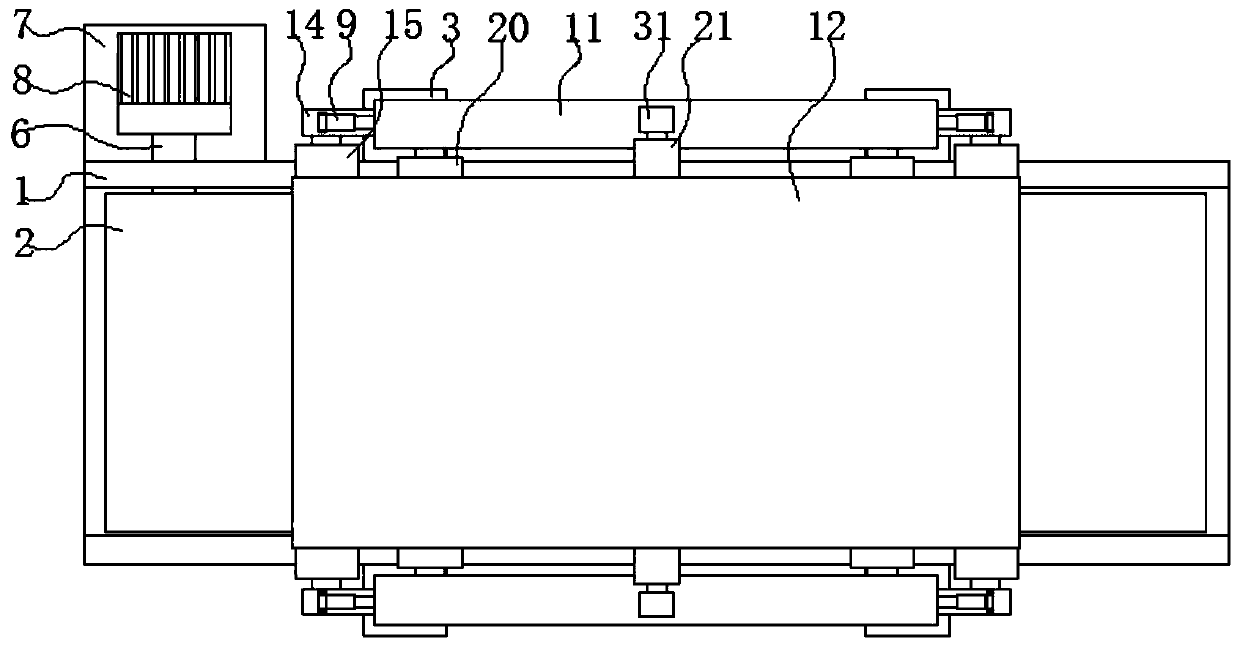

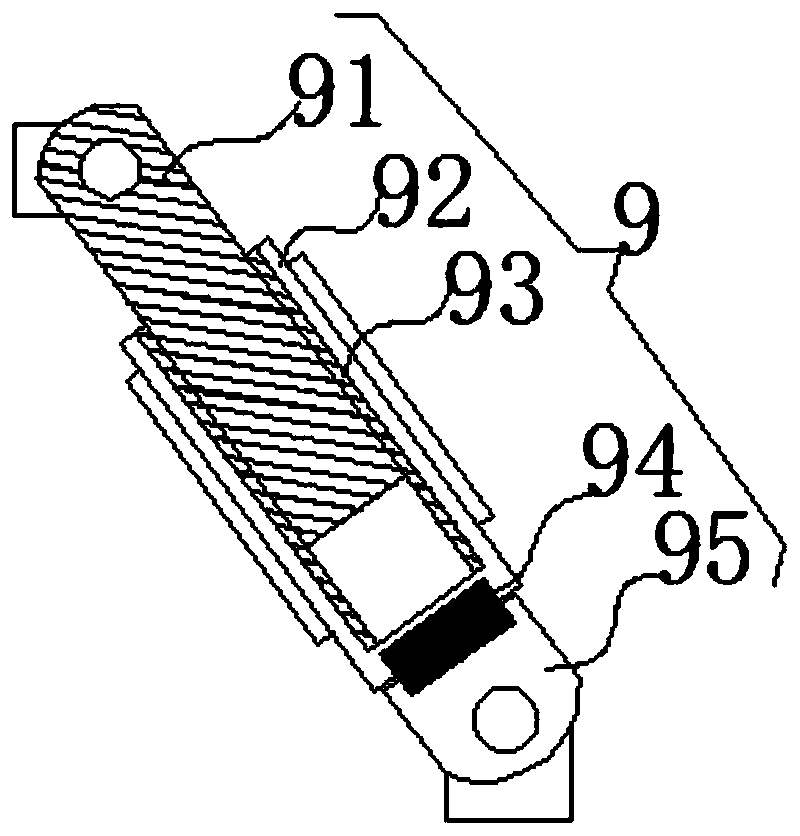

[0022] refer to Figure 1-2 , a fourdrinier paper machine equipped with a top wire former, comprising a transfer bin 1, both sides of the inner wall of the transfer bin 1 are movably connected with transfer shafts 5, one of which is connected by a rotating mechanism, and the transfer shaft 5 is fitted with The lower net 2 is installed, and the bottom plate 3 is fixed around the transfer chamber 1. The hydraulic rod 10 is fixed on the bottom plate 3, and the upper plate 11 is fixed above the hydraulic rods 10 on both sides. Both sides of the two upper plates 11 rotate. There is a return roller 20 connected, and a forming roller 13 is connected to the bottom between the two hydraulic rods 10, and a suction vacuum box 22 is installed on the transfer chamber 1 on one side of one of the forming rollers 13, and the lower side of the hydraulic rod 10 is rotatably connected. There are side plates 14, and a mesh guide roller 15 is rotatably connected between the two side plates 14, and...

Embodiment 2

[0025] refer to Figure 1-2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the rotating mechanism includes a support plate 7, the support plate 7 is fixed on one side of the transfer bin 1, and a motor 8 is installed on the support plate 7, and the motor 8- The side is connected with one end of the rotating shaft 6, and the other end of the rotating shaft 6 passes through the transmission bin 1 and is connected with the transmission rotating shaft 5. The lower net 2 can be driven to move by the rotating mechanism, and the wet paper on the lower net 2 can be driven to move.

Embodiment 3

[0027] refer to Figure 1-2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that an upper connecting plate 31 is fixed in the middle of the top of the upper plate 11, and a school screen roller 21 is rotatably connected between the upper connection plates 31, and the school screen roller The top of 21 is in contact with the top net 12, and the top of the top net 12 can be better supported by the school screen roller 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com