Multilayer polymer compound packaging material with with nano layer texture and its processing method

A technology for composite packaging materials and processing methods, which is applied in the field of high molecular polymer composite packaging materials and their processing, can solve the problems that polyolefin packaging materials are difficult to meet high moisture barrier performance, and have limited moisture barrier performance, so as to improve physical and mechanical strength , improved modulus and ductility, and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

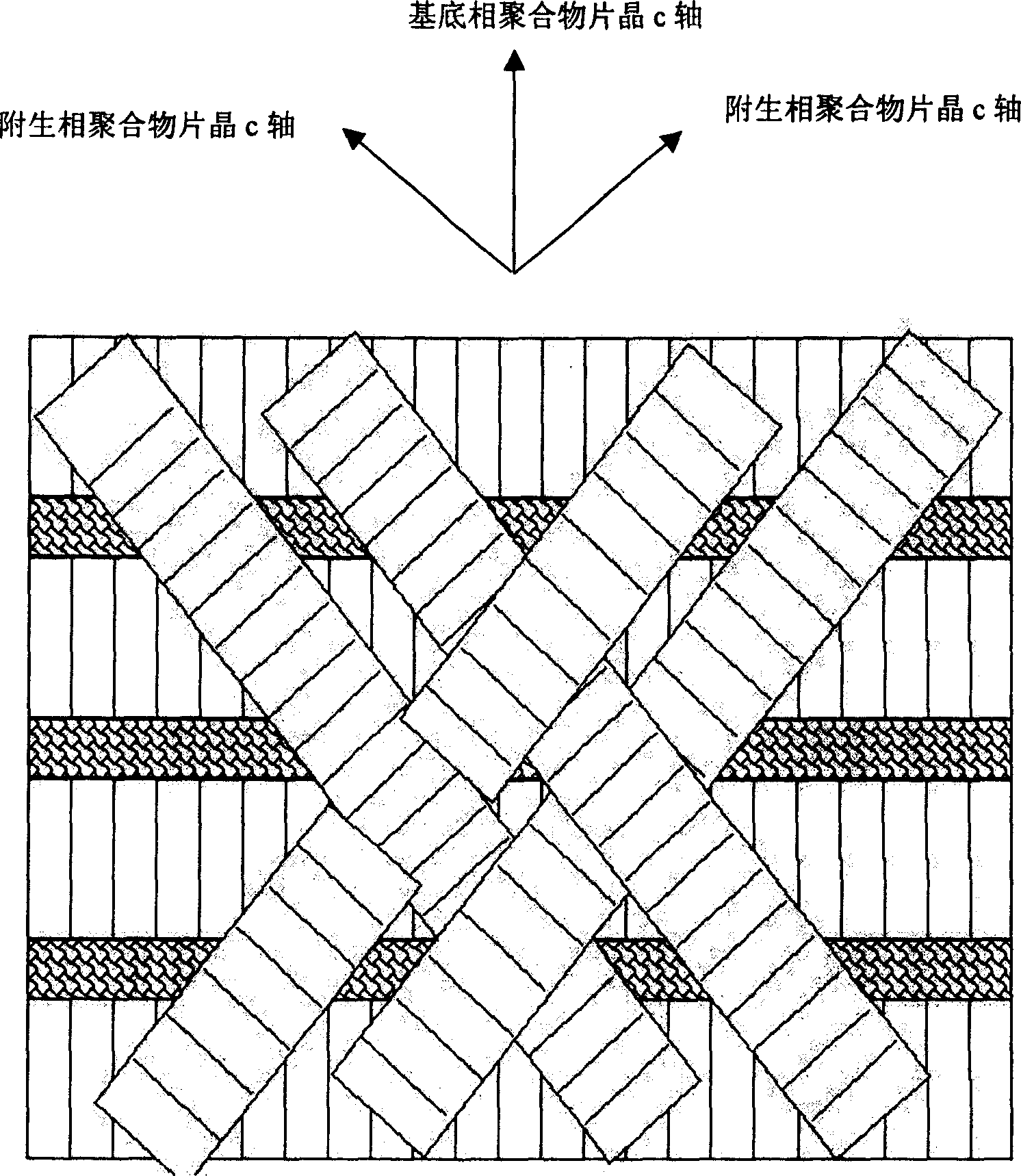

[0032] 1. Polymer material: The polymer combination is high-density polyethylene / isotactic polypropylene (HDPE / iPP);

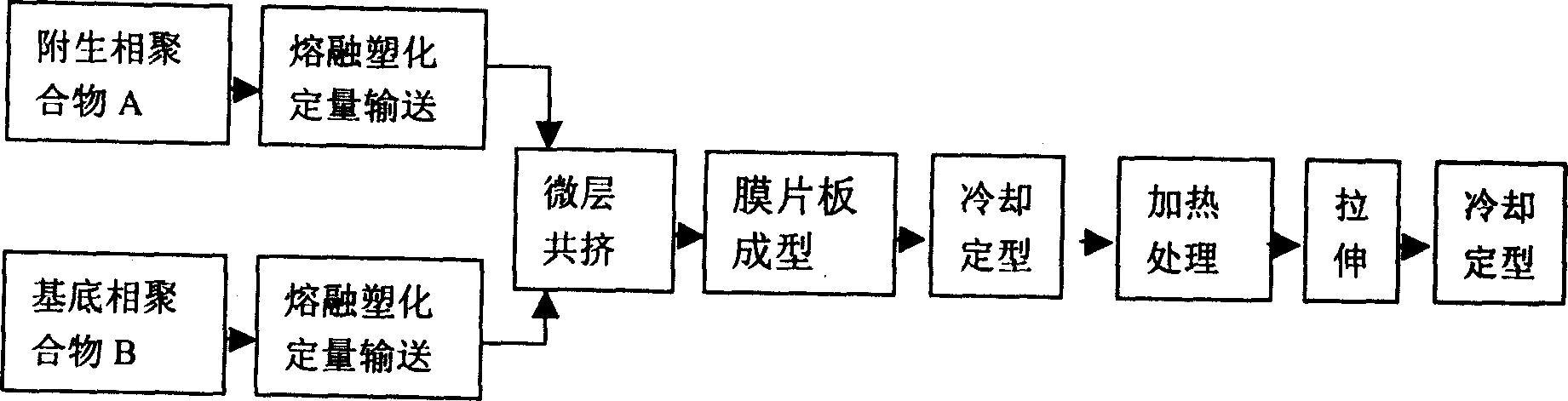

[0033]2. Melt extrusion: The polymer (HDPE) forming the epiphytic phase (A) and the polymer (iPP) forming the base phase (B) are respectively melted and plasticized by two twin-screw extruders, wherein the extrusion of HDPE The temperature is: 190°C, and the extrusion temperature of iPP is 220°C. The extruded melt melted and plasticized by the extruder enters the micro-layer co-extrusion process;

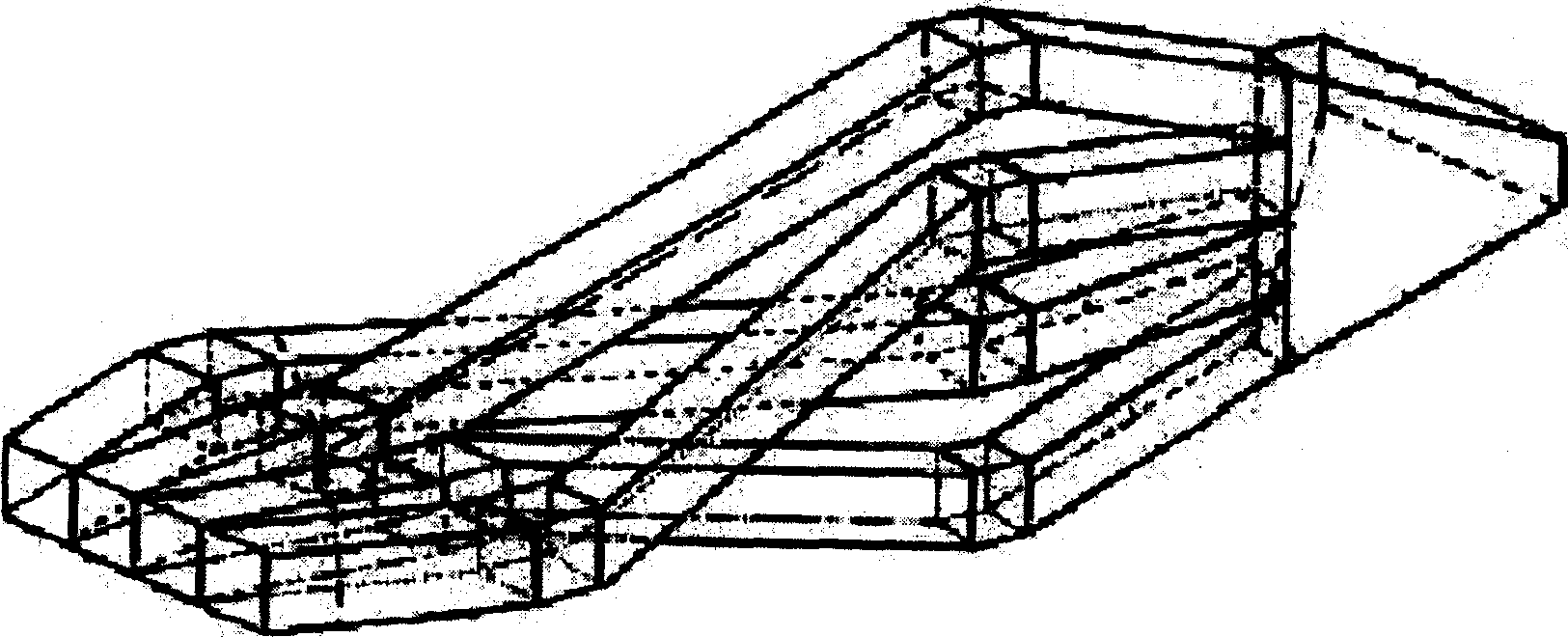

[0034] 3. Micro-layer co-extrusion: The melt of HDPE / iPP is synchronously fed into a design with three-layer co-extrusion mold and 4-channel 5-level multiplier superimposed by two extruders with a flow rate ratio of 10:90. In the micro-layer co-extrusion head, the two melt streams are merged in the co-extrusion die to form a three-layer melt tablet, and the extruded melt tablet enters a 5-level multiplier for 5 divisions-overlap- Convergence increases the number o...

Embodiment 2

[0041] 1. Polymer material: The polymer combination is linear low density polyethylene / isotactic polypropylene (LLDPE / iPP);

[0042] 2. Melt extrusion: The polymer (LLDPE) forming the epiphytic phase (A) and the polymer (iPP) forming the base phase (B) are respectively melted and plasticized by two twin-screw extruders, wherein the extrusion of LLDPE The temperature is: 160°C, and the extrusion temperature of iPP is 200°C. The extruded melt melted and plasticized by the extruder enters the micro-layer co-extrusion process;

[0043] 3. Micro-layer co-extrusion: two extruders synchronously feed the LLDPE / iPP melt into a three-layer co-extrusion mold with a flow rate ratio of 40:60. In the micro-layer co-extrusion head, the two melt streams are merged in the co-extrusion die to form a three-layer melt tablet, and the extruded melt tablet enters a 4-stage multiplier for 4 divisions-overlap- Convergence increases the number of layers of the melt sheet and reduces the thickness of...

Embodiment 3

[0050] 1. Polymer material: The polymer combination is isotactic polypropylene and polyamide 6 (iPP / PA6);

[0051] 2. Melt extrusion: The polymer isotactic polypropylene (iPP) forming the epiphytic phase (A) and the polymer polyamide 6 (PA6) forming the basal phase (B) are respectively melt-molded by two single-screw extruders. Hua, wherein the extrusion temperature of iPP is 220°C, and the extrusion temperature of PA6 is 260°C. The melt extruded by two extruders enters two melt pumps respectively, among which, the melt pump temperature of iPP is 220°C, and the melt pump temperature of PA6 is 260°C;

[0052] 3. Micro-layer co-extrusion: The melt of iPP / PA6 is synchronously sent into a mold designed with three layers of co-extrusion by two melt pumps with a flow rate ratio of 50:50, and then enters 5 stages, 4 channels and finally The first order is in the microlayer co-extrusion head composed of layer multipliers superimposed with 2 channels and 1 order. In the co-extrusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com