Foamed cement sandwich outer wall thermal insulation board

An external wall thermal insulation and foam cement technology, applied in thermal insulation, building components, fire prevention, etc., can solve the problems affecting the normal use function of buildings, low strength, interlayer shedding, etc., and achieve good interlayer bonding strength and overall strength. Improve and avoid the effect of interlayer peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

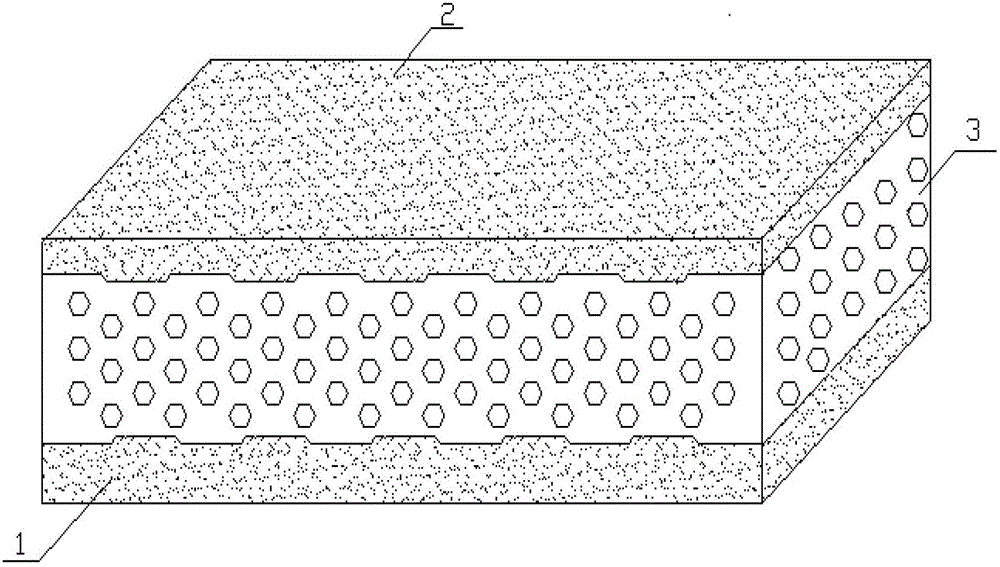

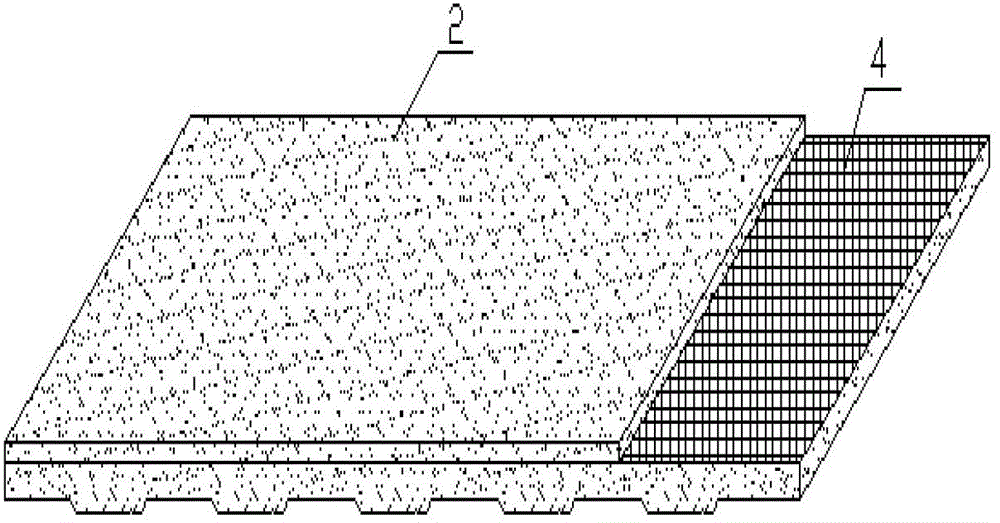

[0021] A kind of foam cement sandwich outer wall insulation board, such as figure 1 As shown, it includes the core body 3 of the external wall thermal insulation board material formed by foaming. On the two sides of the external wall thermal insulation board material core body 3, the outer guard plate of the lightweight cement mortar reinforcement layer, that is, the bottom plate 1 and the panel 2. In the present invention, the structural core foamed concrete is formed first, and after the initial setting, the upper and lower lightweight cement mortar reinforced layer panels are respectively poured on the two surfaces of the foamed concrete to obtain the finished product of the present invention.

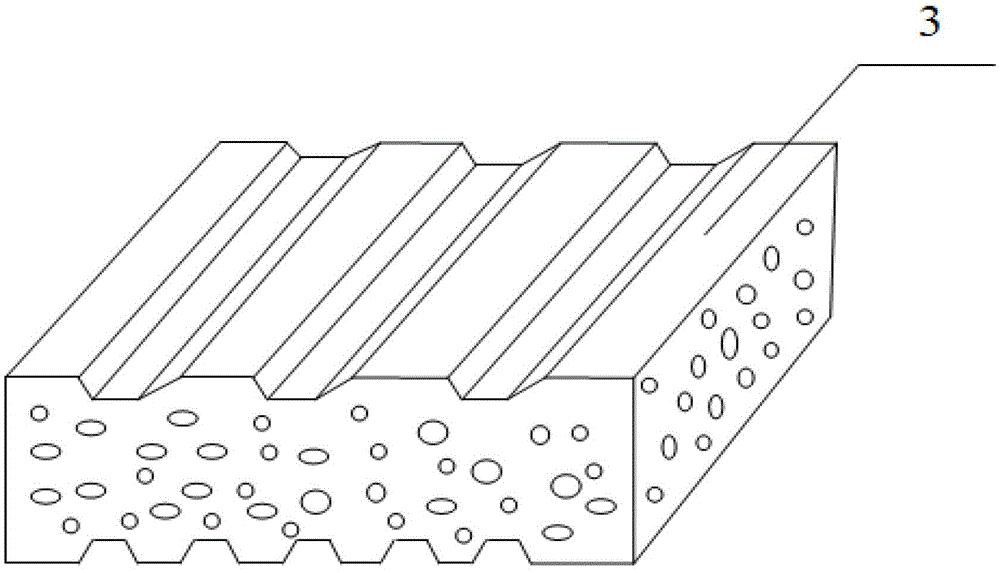

[0022] Such as figure 2 As shown, the inlay structure between the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com