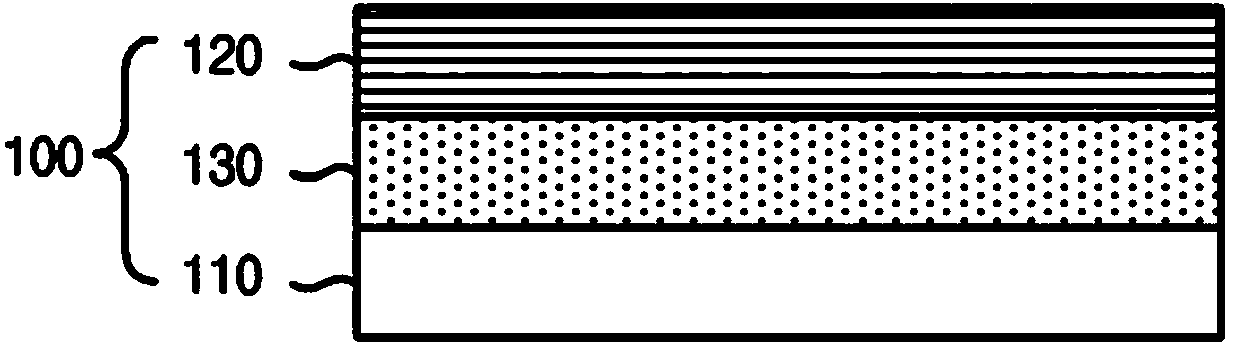

Composition for forming an alignment layer, and alignment layer and phase difference film manufactured using same

A technology of composition and alignment layer, applied in the direction of polarizing element, etc., can solve the problems of interlayer peeling, low bonding strength of retardation film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

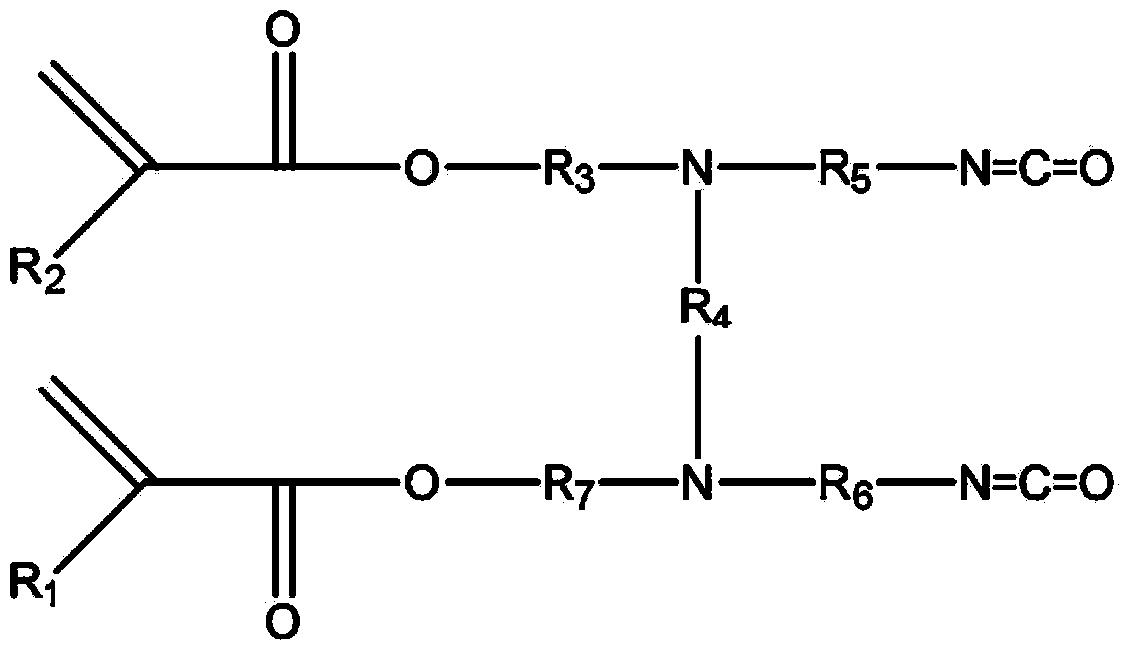

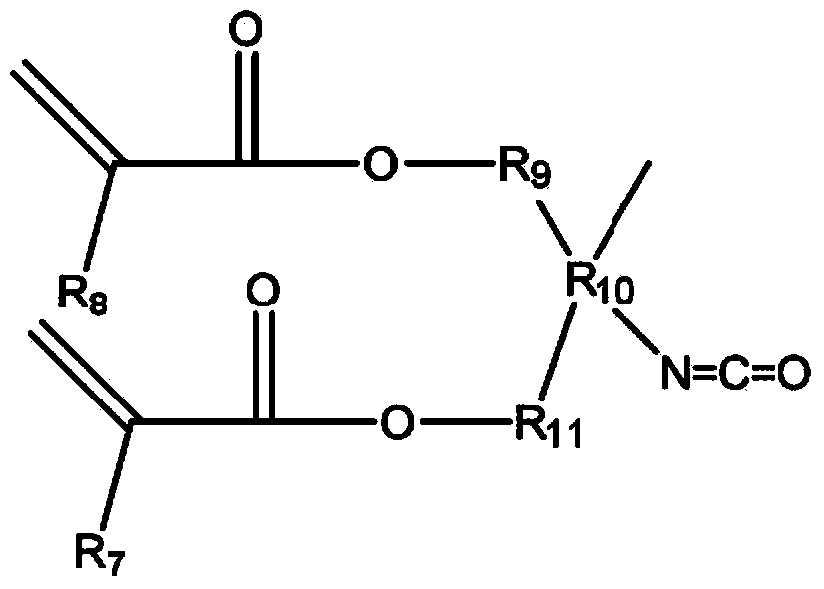

Method used

Image

Examples

Embodiment 1 to 7 and comparative example 1 and 2

[0276] Using the composition shown in the following Table 1, by mixing all the alignment agent, viscosity enhancer, photoinitiator (Irgacure907, manufactured by BASF Co.) and organic solvent (toluene) (unit is g), to prepare each Compositions for the preparation of alignment layers.

[0277] Table 1

[0278]

[0279] sample preparation

[0280] After saponifying each of the compositions prepared in Examples 1 to 7 and Comparative Examples 1 and 2, respectively, the treated compositions were applied to a TAC film (manufactured by Fuji Co.) into which hydroxyl groups had been introduced on the surface, and The coated film was dried at 100° C. for 1 minute, and the dried film was exposed to light to induce a curing reaction, thereby preparing an alignment layer. After coating a photocurable liquid crystal composition (RMS) containing a liquid crystal compound (having a carbon-carbon unsaturated bond at the terminal) to the resulting alignment layer, the coated film was dri...

Embodiment 8 to 14 and comparative example 3 and 4

[0282] With the composition shown in the following Table 2, by mixing all the liquid crystal compound (RMS), viscosity enhancing agent, alignment agent (Irgacure907, manufactured by BASF Co.) and organic solvent (toluene) (unit is g), to Each composition for preparing the liquid crystal layer was prepared.

[0283] Further, with the composition shown in Table 2, by mixing all the alignment agent, adhesion enhancer, photoinitiator (Irgacure907, manufactured by BASF Co.) and organic solvent (toluene) (unit is g), To prepare the composition for preparing the alignment layer.

[0284] Table 2

[0285]

[0286] sample preparation

[0287] After saponifying each of the compositions prepared in Examples 8 to 14 and Comparative Examples 3 and 4, respectively, the treated compositions were applied to a TAC film (manufactured by Fuji Co.) into which hydroxyl groups had been introduced on the surface, and The coated film was dried at 100° C. for 1 minute, and the dried film was e...

experiment example

[0289]

[0290] Of the patterns A and B of the prepared retardation film, the orientation angle of the pattern A was measured using an instrument WPA-100L obtained from Rukeo Co.

[0291] ◎: 45°±3 (for pattern A), 135°±3 (for pattern B)

[0292] ○: 45°±less than 6 ((for pattern A), 135°±less than 6 (for pattern B)

[0293] ×: 45°±6 or more (for pattern A), 135°±6 or more (for pattern B)

[0294]

[0295] Rr: phase retardation of the retardation film prepared in Comparative Example 1 (Table 3) or Comparative Example 3 (Table 4)

[0296] Rs: Phase retardation of the corresponding retardation film

[0297] ◎: 0.97

[0298] ○: 0.95

[0299] △: 0.90

[0300] ×: Rs / Rr is 1.1 or more, or Rs / Rr is 0.90 or less

[0301]

[0302] The formed pattern was observed through an optical microscope, and pattern picking was evaluated according to the following criteria of degrees of pattern picking.

[0303] ◎: Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com