Preparing method for aluminum plastic film for lithium battery packaging

A technology for aluminum-plastic film and packaging, which is applied in the field of preparation of aluminum-plastic film for lithium battery packaging, and can solve problems such as volatile environments, high production costs, and lithium battery leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

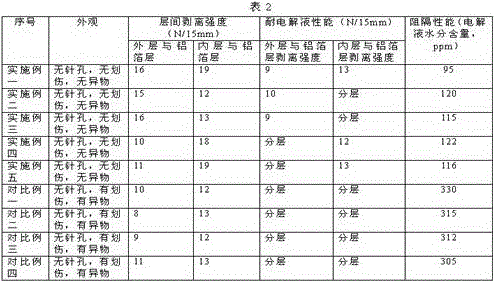

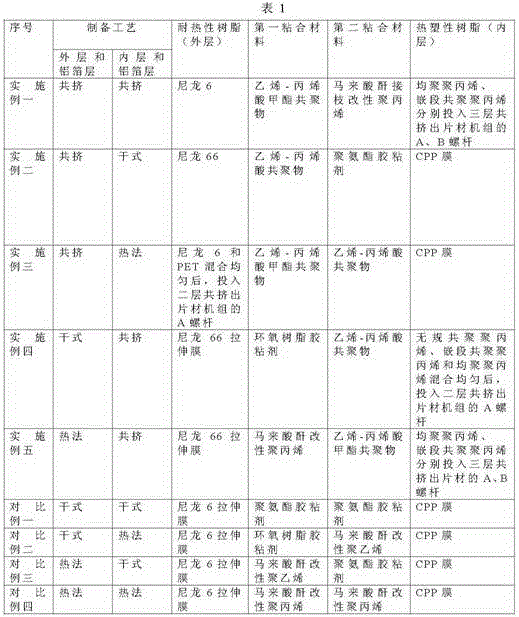

Examples

Embodiment 1

[0071] A preparation method of an aluminum-plastic film for lithium battery packaging, comprising the steps of:

[0072] 1. Select a soft aluminum foil with a thickness of 40 microns. First, perform degreasing and annealing treatment to remove the grease on the surface of the aluminum foil; then use chromium phosphate, chromium nitrate, etc. to perform conversion treatment to improve the corrosion resistance of the aluminum foil; finally use silane coupling The aluminum foil is treated with an agent to improve the bonding performance of the aluminum foil; the treated aluminum foil is passed between a rubber roller and a cooling roller, and the outer layer is cast and co-extruded to form a film;

[0073]2. Put nylon 6 and ethylene-methyl acrylate copolymer into the A screw and B screw of the two-layer co-extrusion sheet unit respectively, and control the temperature at 170-280°C; make the ethylene-methyl acrylate copolymer extruded by the B screw The material faces the side of ...

Embodiment 2

[0078] The treatment process of the aluminum foil layer is the same as in Embodiment 1.

[0079] The aluminum foil layer and the outer layer are composited by a multi-layer co-extrusion casting process, the method is the same as in Example 1, and the set conditions are shown in Table 1.

[0080] The aluminum foil layer and the inner layer are compounded by a dry compounding process. The other side of the aluminum foil that has been co-extruded and cast on the outer layer is sprayed or scraped with a layer of polyurethane adhesive, which is directly laminated and bonded with the cast polypropylene film CPP.

[0081] The above-mentioned aluminum-plastic film is subjected to post-processing, and laminated by two lamination rollers to further bond the layers of the aluminum-plastic film.

[0082] Finished product S2 is obtained by cooling, pulling, and coiling the bonded aluminum-plastic film.

Embodiment 3

[0084] The treatment process of the aluminum foil layer is the same as in Embodiment 1.

[0085] The aluminum foil layer and the outer layer are composited by a multi-layer co-extrusion casting process, the method is the same as in Example 1, and the set conditions are shown in Table 1.

[0086] The aluminum foil layer and the inner layer are compounded by a thermal compounding process. The ethylene-acrylic acid copolymer is added to the single-screw extruder, and the temperature of the screw extruder is controlled at 170-250°C, and the aluminum foil on the opposite side of the outer layer is directly melted and extruded. Between the cast polypropylene film CPP, the inner layer is hot-pressed and laminated.

[0087] The above-mentioned aluminum-plastic film is subjected to post-processing, and laminated by two lamination rollers to further bond the layers of the aluminum-plastic film.

[0088] Finished product S3 is obtained by cooling, pulling, and coiling the bonded aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com